In the realm of food processing and handling, food grade hoses play a crucial role in ensuring the safety and integrity of our edible goods. These specialized hoses are designed to meet stringent regulations and standards, guaranteeing the absence of harmful substances that could contaminate food products.

As we delve into the intricacies of food grade hoses, we will explore their construction, materials, applications, and the essential considerations for selecting, installing, and maintaining them. Our aim is to provide a comprehensive guide that empowers you with the knowledge to make informed decisions and ensure the highest levels of food safety.

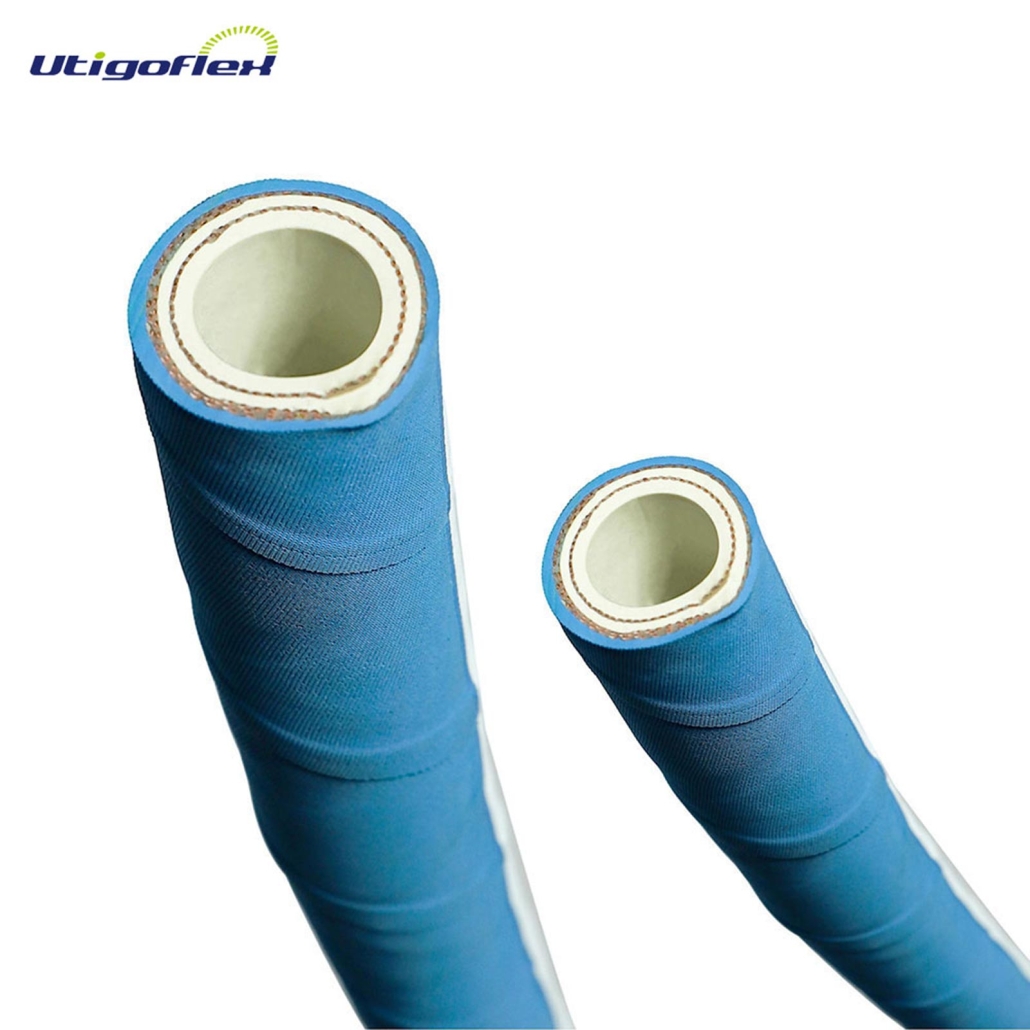

Food Grade Hoses

Food grade hoses are specifically designed to transport food and beverage products, ensuring the safety and quality of the contents. They are constructed using materials that meet strict regulations and standards to prevent contamination and maintain the integrity of the food.

Applications of Food Grade Hoses

- Transferring food products in processing plants

- Dispensing beverages in commercial establishments

- Conveying ingredients in food manufacturing facilities

- Transporting liquids in dairy, beverage, and confectionery industries

Regulations and Standards, Food grade hose

Food grade hoses are subject to stringent regulations and standards to ensure they meet the highest levels of safety and hygiene. These regulations vary by country and region, but some common standards include:

- FDA (US Food and Drug Administration):Regulates food contact materials in the United States, including food grade hoses.

- EC (European Commission):Establishes food safety standards for the European Union, including requirements for food grade hoses.

- 3-A Sanitary Standards:A voluntary set of standards developed by the International Association for Food Protection (IAFP), which provides guidelines for the design, construction, and use of food grade hoses.

Materials and Construction

Food grade hoses are designed to transport food products safely and hygienically. The materials and construction methods used in their production play a critical role in ensuring the integrity and quality of the food being transported.

Food grade hoses are typically constructed using materials that are FDA-approved for food contact. These materials include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyurethane (PU)

- Ethylene propylene diene monomer (EPDM)

- Silicone

The choice of material depends on the specific application and the type of food being transported. For example, PE is a lightweight and flexible material that is often used for transporting liquids, while PP is a more rigid material that is suitable for transporting solids.

Construction Methods

Food grade hoses are constructed using a variety of methods, including:

- Extrusion:In this method, the hose is formed by extruding the molten material through a die.

- Mandrel winding:In this method, the hose is formed by winding a strip of material around a mandrel.

- Braiding:In this method, the hose is formed by braiding multiple strands of material together.

The construction method used affects the strength, flexibility, and durability of the hose. For example, extruded hoses are typically more flexible than mandrel-wound hoses, while braided hoses are more durable.

Types of Food Grade Hoses

Food grade hoses are available in various types, each with distinct characteristics and applications. The choice of hose depends on the specific requirements of the food processing or handling operation.

The following table provides an overview of different types of food grade hoses, their characteristics, and applications:

| Type of Hose | Characteristics | Applications |

|---|---|---|

| Rubber Hoses | Flexible, durable, and resistant to abrasion and chemicals | Transferring liquids, gases, and solids in food processing plants |

| Thermoplastic Hoses | Lightweight, flexible, and resistant to corrosion and temperature extremes | Transferring liquids, gases, and solids in food and beverage processing |

| Silicone Hoses | Flexible, heat-resistant, and non-toxic | Transferring liquids, gases, and solids in food and beverage processing, pharmaceutical manufacturing |

| Stainless Steel Hoses | Durable, corrosion-resistant, and easy to clean | Transferring liquids, gases, and solids in food and beverage processing, pharmaceutical manufacturing |

| Braided Hoses | Flexible, durable, and resistant to high pressure | Transferring liquids, gases, and solids in food and beverage processing, pharmaceutical manufacturing |

Examples of Food Grade Hoses

Examples of food grade hoses include:

- Rubber hoses:Nitrile rubber hoses are commonly used in food processing plants for transferring liquids, gases, and solids.

- Thermoplastic hoses:Polyethylene hoses are often used in food and beverage processing for transferring liquids, gases, and solids.

- Silicone hoses:Silicone hoses are used in food and beverage processing, pharmaceutical manufacturing, and other applications where high purity and non-toxicity are required.

- Stainless steel hoses:Stainless steel hoses are used in food and beverage processing, pharmaceutical manufacturing, and other applications where durability and corrosion resistance are required.

- Braided hoses:Braided hoses are used in food and beverage processing, pharmaceutical manufacturing, and other applications where flexibility and high pressure resistance are required.

Food Grade Hose Selection

Selecting the right food grade hose is crucial to ensure the safety and quality of your food products. Consider these factors when making your choice:

- Material:Food grade hoses are made from materials that are safe for food contact, such as rubber, silicone, or thermoplastic elastomers (TPE).

- Size:Choose a hose with an appropriate diameter and length for your application.

- Pressure:Consider the maximum pressure that the hose will be subjected to.

- Temperature:Select a hose that can withstand the temperatures of the fluids it will be conveying.

- Flexibility:Choose a hose that is flexible enough to handle bends and curves.

- Chemical resistance:Consider the chemicals that the hose will be exposed to and choose a material that is resistant to those chemicals.

- Sanitation:Select a hose that can be easily cleaned and sanitized.

Step-by-Step Guide to Selecting the Right Hose

- Determine the purpose of the hose:What type of food or beverage will it be used for?

- Consider the factors listed above:Material, size, pressure, temperature, flexibility, chemical resistance, and sanitation.

- Research different hose options:Consult with manufacturers or distributors to find hoses that meet your requirements.

- Request samples:Get samples of the hoses you are considering to test their performance and suitability.

- Make your selection:Choose the hose that best meets your needs and specifications.

Installation and Maintenance

Proper installation and regular maintenance are crucial for ensuring optimal performance and longevity of food grade hoses. By following the recommended guidelines, you can minimize the risk of contamination, extend hose life, and maintain compliance with food safety regulations.

Installation Procedures

- Inspect the hose thoroughly before installation, checking for any damage or defects.

- Cut the hose to the desired length using a sharp knife or hose cutter.

- Remove any burrs or sharp edges from the cut ends.

- Install the hose fittings securely, ensuring they are compatible with the hose material and the intended application.

- Tighten the fittings according to the manufacturer’s specifications, using a torque wrench if necessary.

- Route the hose properly, avoiding sharp bends or kinks that could restrict flow or damage the hose.

- Secure the hose using clamps or supports to prevent excessive movement or vibration.

Maintenance Schedule

Regular maintenance is essential to detect and address any potential issues early on. Establish a comprehensive maintenance schedule that includes the following tasks:

- Daily:Visually inspect the hose for any leaks, damage, or wear.

- Weekly:Clean the hose thoroughly using a mild detergent and water.

- Monthly:Inspect the hose fittings for tightness and corrosion.

- Quarterly:Pressure test the hose to check for leaks or weak spots.

- Annually:Replace the hose if it shows signs of significant wear or damage.

By following these guidelines, you can ensure that your food grade hoses are installed and maintained properly, minimizing the risk of contamination and maximizing their performance.

Troubleshooting and Repair: Food Grade Hose

Ensuring the optimal performance and longevity of food grade hoses is crucial to maintain the integrity of food products and the safety of consumers. By identifying common problems and implementing appropriate troubleshooting measures, you can minimize downtime, prevent costly repairs, and extend the service life of your food grade hoses.

Troubleshooting involves recognizing the symptoms of a problem, determining the underlying cause, and implementing appropriate corrective actions. Repair procedures may vary depending on the type of hose, the severity of the damage, and the availability of resources.

Common Problems and Troubleshooting

Some common problems associated with food grade hoses include:

- Leaks:Leaks can occur due to cracks, punctures, or loose connections. Inspect the hose thoroughly for any visible damage. Check the fittings and clamps to ensure they are properly tightened.

- Kinks:Kinks can restrict the flow of liquid and damage the hose. Avoid bending the hose excessively or storing it in a way that creates kinks.

- Blockages:Blockages can occur due to the accumulation of food particles or debris. Flush the hose thoroughly with water or a suitable cleaning solution.

- Wear and tear:Over time, food grade hoses can deteriorate due to exposure to chemicals, temperature fluctuations, or mechanical stress. Regularly inspect the hose for signs of wear and replace it if necessary.

Repair Procedures

Depending on the nature of the problem, different repair procedures may be necessary:

- Leaks:For minor leaks, a hose repair kit can be used to patch the damaged area. For more severe leaks, the affected section of the hose may need to be replaced.

- Kinks:If a kink is not too severe, it may be possible to straighten the hose by gently manipulating it. Avoid applying excessive force as this could further damage the hose.

- Blockages:To remove blockages, flush the hose with water or a suitable cleaning solution. Use a high-pressure water jet if necessary.

- Wear and tear:If the hose is significantly worn or damaged, it should be replaced to ensure the safety and integrity of the food products.

Safety Considerations

When using food grade hoses, it is essential to prioritize safety to prevent potential hazards and ensure the well-being of individuals and the integrity of the food products being handled.

Understanding and adhering to safety guidelines is paramount to mitigate risks and maintain a safe working environment.

Potential Hazards and Mitigation

- Contamination:Food grade hoses must be meticulously cleaned and sanitized to prevent the introduction of contaminants into food products. Regular inspections and proper storage practices are crucial to maintain hose integrity and prevent contamination.

- Leaks and Bursts:Inspecting hoses for cracks, tears, or loose connections is vital to prevent leaks or bursts. Damaged hoses can lead to spillage or contamination, compromising food safety and potentially causing injuries.

- Pressure Overload:Using hoses beyond their specified pressure rating can result in hose failure, leading to injuries or damage to equipment. It is essential to adhere to the manufacturer’s guidelines and use hoses designed for the intended pressure range.

- Chemical Compatibility:Food grade hoses must be compatible with the substances being transported. Incompatible materials can leach into food products, posing health risks. Proper selection of hoses based on their chemical resistance is crucial.

- Temperature Considerations:Hoses must withstand the temperature range of the fluids being handled. Using hoses outside their specified temperature range can compromise hose integrity and potentially lead to accidents.

Summary

In conclusion, food grade hoses are indispensable tools in the food industry, ensuring the safe and hygienic transfer of food products. By adhering to industry standards, selecting the appropriate hose for specific applications, and implementing proper installation and maintenance practices, we can effectively mitigate risks and safeguard the quality of our food supply.