food grade ibc california recycled isn’t just a phrase; it’s a glimpse into the future of food logistics. In a state known for its environmental consciousness and thriving food industry, the demand for sustainable solutions is higher than ever. This guide delves into the world of recycled Intermediate Bulk Containers (IBCs), exploring their role in California’s food supply chain, and revealing how they’re reshaping the way businesses think about packaging and waste reduction.

We’ll dissect the regulations, explore the economic benefits, and uncover the technical aspects that make recycled food grade IBCs a smart choice for businesses looking to reduce their environmental footprint and cut costs. Get ready to dive deep into the processes, the players, and the potential of this innovative approach.

Introduction to Food Grade IBCs in California

Food grade Intermediate Bulk Containers (IBCs) are essential for the safe and efficient transportation and storage of liquid and solid food products within California’s diverse and expansive food industry. These containers are designed to meet stringent regulatory requirements, ensuring product integrity and consumer safety from production to consumption. Their robust construction and specialized features minimize the risk of contamination and spoilage, making them a cornerstone of the state’s food supply chain.

Defining Food Grade IBCs

A “food grade” IBC is specifically designed for the handling and storage of substances intended for human consumption. This designation implies that the IBC meets rigorous standards regarding materials, construction, and cleanliness to prevent the transfer of harmful substances or odors to the food product.The key characteristics of a food grade IBC include:

- Material Compliance: The IBC is constructed from materials approved by the FDA (Food and Drug Administration) and/or other relevant regulatory bodies for direct contact with food. Common materials include high-density polyethylene (HDPE) and stainless steel. These materials are non-reactive, non-toxic, and resistant to chemical degradation.

- Cleanliness Standards: Food grade IBCs are manufactured and maintained under strict cleanliness protocols. This includes thorough cleaning procedures before and after each use, preventing the build-up of bacteria or other contaminants.

- Hygienic Design: The design of a food grade IBC minimizes crevices and hard-to-clean areas where bacteria can thrive. Smooth surfaces and easily accessible components are essential for effective sanitation.

- Traceability: Food grade IBCs often incorporate traceability features, such as serial numbers and batch codes, allowing for easy identification and tracking of the container and its contents throughout the supply chain. This is critical for rapid response in case of contamination or recall.

California Regulations and Standards

California’s food safety regulations, which often align with or exceed federal standards, place a significant emphasis on the integrity of food packaging and storage. While specific regulations pertaining directly to IBCs may be incorporated within broader food safety codes, the following principles are consistently enforced:

- Compliance with Federal Regulations: California generally adheres to federal regulations regarding food contact materials, including those Artikeld by the FDA. This means that food grade IBCs used within the state must meet the standards for materials, construction, and labeling established by the FDA.

- State-Specific Inspections: California’s Department of Public Health (CDPH) and local health departments conduct regular inspections of food processing facilities and storage locations. These inspections assess compliance with food safety regulations, including the proper use and maintenance of food grade IBCs.

- Traceability and Record Keeping: Food businesses are required to maintain detailed records regarding the use and cleaning of food grade IBCs. This includes documentation of cleaning procedures, inspection reports, and any incidents involving contamination or damage to the containers.

- Recycling and Waste Management: California has strict regulations on recycling and waste management. Used food grade IBCs must be disposed of or recycled according to state and local guidelines to minimize environmental impact. Recycled IBCs, if reused, must meet the same rigorous food-grade standards as new containers.

Primary Applications in California’s Food Industry

Food grade IBCs are utilized across a wide spectrum of California’s food industry, playing a vital role in the transportation and storage of various food products. The state’s diverse agricultural landscape and significant food processing sector contribute to the widespread adoption of these containers.The main applications include:

- Transportation of Liquid Food Products: IBCs are frequently used to transport bulk quantities of liquid food products such as fruit juices, vegetable oils, syrups, sauces, and dairy products. The robust construction and sealed design of these containers prevent leaks and maintain product integrity during transit. For example, a large winery in Napa Valley might use food grade IBCs to transport grape must (unfermented grape juice) from the vineyards to the processing facility.

- Storage of Bulk Ingredients: Food grade IBCs are employed for the storage of bulk ingredients, including sugar, flour, grains, and other dry or semi-liquid components. This helps maintain the quality and freshness of these ingredients, preventing contamination and spoilage. A large bakery in Los Angeles might use IBCs to store bulk quantities of flour and sugar, ensuring a consistent supply for production.

- Processing and Mixing: IBCs can be incorporated into food processing lines for mixing, blending, and holding various ingredients. Their ease of cleaning and compatibility with food processing equipment make them ideal for these applications. A manufacturer of sauces and dressings in the Central Valley might use IBCs for blending ingredients and storing finished products before packaging.

- Distribution of Finished Products: Food grade IBCs are also utilized for the distribution of finished food products to retailers and other distribution centers. This allows for efficient and cost-effective transportation of large quantities of products. A major food distributor in Southern California might use IBCs to transport bulk quantities of beverages or packaged foods to supermarkets and other retail outlets.

- Specialty Food Production: California’s thriving specialty food industry, encompassing organic foods, artisanal products, and ethnic cuisines, also relies heavily on food grade IBCs. They are used for handling and storing unique ingredients and products. A producer of organic olive oil in Sonoma County might use food grade IBCs for storing and transporting the oil from the pressing facility to bottling plants.

The Concept of Recycled Food Grade IBCs

The utilization of recycled food grade IBCs represents a significant step towards sustainable practices within the food and beverage industry. This approach minimizes waste, conserves resources, and reduces the environmental impact associated with manufacturing new containers. This section will explore the intricacies of recycling IBCs to meet food grade standards, the materials involved, and the substantial benefits that this practice offers.

Process of Recycling IBCs to Meet Food Grade Standards

Recycling an IBC for food grade applications is a complex process requiring stringent adherence to regulations and thorough cleaning procedures. The process aims to eliminate any residual contaminants and ensure the container meets the hygiene and safety standards mandated for food contact.The general recycling process includes the following key steps:

- Collection and Inspection: Used IBCs are collected from various sources and undergo an initial inspection to assess their condition. This includes checking for structural integrity, identifying the previous contents, and determining the level of contamination.

- Pre-cleaning: Before further processing, the IBC is pre-cleaned to remove bulk residue. This often involves rinsing with water or appropriate solvents, depending on the previous contents.

- Dismantling and Component Separation: The IBC is disassembled, separating the various components, such as the inner bottle, outer cage, and pallet. This facilitates more thorough cleaning and recycling of individual parts.

- Cleaning and Decontamination: This is the most critical step. The inner bottle, typically made of high-density polyethylene (HDPE), undergoes a rigorous cleaning process. This often involves:

- High-pressure washing: Using hot water and specialized detergents to remove residual contaminants.

- Chemical cleaning: Employing specific cleaning agents designed to eliminate any remaining traces of previous contents. The choice of chemicals depends on the type of substances previously stored in the IBC.

- Sterilization: Ensuring the container is free from bacteria and other microorganisms. This can involve heat treatment, chemical sterilization, or a combination of both.

- Inspection and Testing: Following cleaning, the IBC undergoes rigorous inspection and testing to verify that it meets food grade standards. This includes:

- Visual inspection: Checking for any remaining contaminants, damage, or defects.

- Residue testing: Conducting tests to ensure that no traces of the previous contents remain.

- Material testing: Confirming that the HDPE material still meets the required specifications for food contact.

- Reassembly and Certification: The cleaned and tested components are reassembled. The recycled IBC is then certified as food grade, indicating that it meets all necessary safety and hygiene requirements.

Materials Commonly Used in Food Grade IBCs and Their Recyclability

Understanding the materials used in food grade IBCs is crucial for effective recycling. The primary material, high-density polyethylene (HDPE), is highly recyclable.The common materials used in food grade IBCs and their recyclability are:

- High-Density Polyethylene (HDPE) Inner Bottle: This is the primary component in contact with the food product. HDPE is a thermoplastic polymer known for its chemical resistance, durability, and recyclability. The HDPE bottle is typically molded in a single piece, making it easier to clean and recycle. It can be recycled multiple times without significant degradation of its properties.

- Steel or Composite Outer Cage: The outer cage provides structural support to the IBC. Steel cages are also recyclable, though the process may be different from recycling the HDPE bottle. Composite cages, which often include a combination of steel and other materials, can be more complex to recycle.

- Pallet (Plastic or Wood): The pallet at the base of the IBC allows for easy handling and transportation. Plastic pallets, often made from HDPE or polypropylene (PP), are recyclable. Wooden pallets can be recycled, reused, or repurposed, such as for landscaping or biomass fuel.

- Valves and Fittings: Valves and fittings are typically made from plastics or metals. These components can be recycled separately, depending on the material.

Benefits of Using Recycled Food Grade IBCs

The adoption of recycled food grade IBCs offers significant advantages, spanning environmental protection and economic savings. The reduction in waste and conservation of resources make it a sustainable solution for the food and beverage industry.The benefits of using recycled food grade IBCs include:

- Environmental Benefits:

- Reduced Landfill Waste: Recycling IBCs diverts materials from landfills, reducing the strain on these facilities and mitigating the environmental impact of waste disposal.

- Conservation of Resources: Recycling reduces the demand for virgin materials, such as crude oil used to produce new HDPE. This conserves natural resources and minimizes the environmental impact of extraction and processing.

- Lower Greenhouse Gas Emissions: Manufacturing new IBCs requires significant energy, leading to greenhouse gas emissions. Recycling reduces these emissions, contributing to climate change mitigation.

- Economic Benefits:

- Cost Savings: Recycled IBCs are often less expensive than new ones, leading to direct cost savings for businesses.

- Reduced Disposal Costs: Recycling eliminates the need to dispose of used IBCs, reducing waste management expenses.

- Market Opportunities: The growing demand for sustainable products creates new market opportunities for businesses that utilize recycled IBCs.

California’s Role in Recycled Food Grade IBCs

California plays a significant role in promoting the use of recycled food-grade IBCs, driven by stringent environmental regulations and a strong commitment to sustainability. The state’s policies create a favorable environment for businesses that prioritize the circular economy, fostering innovation and driving the adoption of eco-friendly packaging solutions. This section explores California’s environmental regulations, highlights companies involved in recycled food-grade IBCs, and discusses the challenges faced within this industry.

California’s Environmental Regulations Supporting Recycled Materials

California’s environmental regulations are designed to reduce waste, conserve resources, and promote a circular economy. These regulations significantly influence the use of recycled food-grade IBCs by creating incentives and setting standards for material recovery and reuse.

- The California Integrated Waste Management Act (AB 939): This landmark legislation, enacted in 1989, mandates waste reduction, recycling, and composting. It established a framework for local jurisdictions to divert waste from landfills, encouraging the adoption of recycling programs and the use of recycled materials. The act’s goals have driven businesses to seek sustainable packaging solutions, including recycled IBCs, to meet waste reduction targets.

- California’s Plastic Pollution Reduction Act (SB 54): Signed into law in 2022, this act is one of the most ambitious plastic reduction laws in the United States. It requires producers of single-use packaging and food service ware to reduce the amount of plastic they use and ensure that these items are recyclable or compostable. While SB 54 doesn’t specifically mention IBCs, its broad focus on reducing plastic waste creates a favorable environment for recycled alternatives.

- Extended Producer Responsibility (EPR) Regulations: California is increasingly adopting EPR policies, which hold producers responsible for the end-of-life management of their products. These regulations incentivize producers to design products that are easier to recycle and to use recycled materials, as they may be financially responsible for the costs of recycling or disposal. This encourages companies to consider the lifecycle of their packaging, promoting the use of recycled food-grade IBCs to minimize environmental impact.

- State Procurement Policies: The state of California prioritizes the procurement of recycled-content products. Government agencies are required to purchase products containing recycled materials whenever feasible and cost-effective. This creates demand for recycled food-grade IBCs and supports the development of the recycled materials market.

Companies in California Using or Supplying Recycled Food Grade IBCs

Several companies in California are actively involved in the use or supply of recycled food-grade IBCs. These companies are demonstrating the feasibility and benefits of a circular approach to packaging, contributing to a more sustainable supply chain.

- IBC Suppliers: Several companies specialize in supplying recycled food-grade IBCs. These companies collect, clean, and recondition used IBCs to meet food-grade standards. They often work with food and beverage manufacturers to provide cost-effective and environmentally friendly packaging solutions. An example would be a company that focuses on high-quality reconditioning processes, ensuring that the recycled IBCs meet all necessary safety and performance standards.

- Food and Beverage Manufacturers: Many food and beverage companies in California are adopting recycled food-grade IBCs to reduce their environmental footprint and meet sustainability goals. These companies recognize the benefits of using recycled materials, including cost savings, reduced waste, and enhanced brand image. A winery, for example, might choose recycled IBCs for transporting wine, reducing its reliance on virgin plastic and demonstrating its commitment to sustainability to consumers.

- Chemical and Ingredient Suppliers: Companies that supply food-grade chemicals and ingredients also use recycled IBCs. These companies often have stringent requirements for packaging cleanliness and integrity. By using recycled IBCs, they can meet these requirements while minimizing their environmental impact. A company that supplies food additives might use recycled IBCs to transport its products to food manufacturers.

- Logistics and Transportation Companies: Companies involved in the transportation and logistics of food products are also involved in the handling and potential reuse of IBCs. These companies play a key role in the supply chain, ensuring the efficient movement of IBCs and potentially facilitating their return for cleaning and reuse.

Challenges Faced by Companies in California Using or Supplying Recycled Food Grade IBCs

While the use of recycled food-grade IBCs offers significant environmental and economic benefits, companies in California face several challenges. Addressing these challenges is crucial for the continued growth and adoption of recycled packaging solutions.

- Ensuring Food Safety and Compliance: Maintaining food safety standards is paramount. Companies must ensure that recycled IBCs are thoroughly cleaned, inspected, and certified to meet all food-grade requirements. This includes rigorous cleaning processes, material testing, and documentation.

- Availability and Supply Chain Management: The availability of high-quality recycled IBCs can sometimes be limited, depending on the collection and recycling infrastructure. Companies must establish reliable supply chains to ensure a consistent supply of recycled IBCs. This may involve working with multiple suppliers and developing robust logistics systems.

- Perception and Market Acceptance: Overcoming negative perceptions associated with recycled materials can be challenging. Some customers may be hesitant to use recycled packaging due to concerns about contamination or performance. Education and transparency are crucial to build trust and acceptance.

- Cost Considerations: While recycled IBCs can be cost-effective in the long run, the initial investment in cleaning, inspection, and certification processes may be higher. Companies must carefully evaluate the total cost of ownership, considering factors such as transportation, storage, and maintenance.

- Regulation and Certification Complexity: Navigating the regulatory landscape and obtaining the necessary certifications can be complex. Companies must stay informed about evolving regulations and ensure that their processes and products meet all applicable standards.

Food Safety and Recycled IBCs

Ensuring the safety of recycled food-grade IBCs is paramount to protecting public health and maintaining the integrity of the food supply chain. Rigorous procedures, including thorough cleaning, sanitization, testing, inspection, and meticulous documentation, are essential to mitigate any risks associated with reusing these containers. Compliance with stringent food safety standards is not just a regulatory requirement but a fundamental responsibility for all stakeholders involved.

Cleaning and Sanitization Procedures

Effective cleaning and sanitization are the cornerstones of safe recycled food-grade IBCs. The process must eliminate all traces of previous contents and any potential contaminants.To achieve this, a multi-step approach is crucial:

- Initial Inspection and Preparation: Before cleaning, a visual inspection is performed to assess the IBC’s condition. Any IBCs with structural damage, such as cracks or leaks, are rejected. The IBC is then emptied of any residual product.

- Pre-Rinsing: A thorough pre-rinse with potable water removes loose debris and any remaining product residue. The water temperature and pressure are carefully controlled to optimize cleaning effectiveness without damaging the IBC.

- Cleaning with Detergents: The IBC is then cleaned with food-grade detergents. The specific detergent used depends on the nature of the previous contents. The detergent is applied at the recommended concentration and temperature, and the IBC is allowed to soak for a specified period to loosen and remove contaminants.

- Rinsing: After cleaning, the IBC is rinsed thoroughly with potable water to remove all traces of the detergent. Multiple rinsing cycles are often necessary to ensure complete removal.

- Sanitization: Sanitization follows cleaning to eliminate any remaining microorganisms. Common sanitizing agents include chlorine-based solutions, quaternary ammonium compounds, or peracetic acid. The sanitizing agent is applied at the recommended concentration and contact time.

- Final Rinse: A final rinse with potable water removes any residual sanitizing agent.

- Drying: The IBC is dried completely before reuse to prevent microbial growth. Drying can be achieved through air drying or with the use of heated air.

The entire cleaning and sanitization process must be documented, including the date, time, personnel involved, cleaning agents used, concentrations, temperatures, and contact times.

Testing and Inspection Processes

Rigorous testing and inspection processes are vital to verify the effectiveness of the cleaning and sanitization procedures and to ensure the IBC’s structural integrity. These processes involve both visual and analytical assessments.

- Visual Inspection: A comprehensive visual inspection is conducted after cleaning and sanitization. Inspectors look for any signs of residual product, damage, or contamination. This includes checking for odors, discoloration, and any physical defects.

- Swab Testing: Surface swab tests are performed to detect the presence of microorganisms. Swabs are taken from various areas of the IBC, such as the interior surfaces, valves, and fittings. The swabs are then analyzed in a laboratory to determine the level of microbial contamination.

- Rinse Water Testing: Rinse water samples are collected after the final rinse and analyzed for chemical residues and microbial contamination. This testing helps to confirm that the cleaning and sanitization procedures have effectively removed all traces of the previous contents and sanitizing agents.

- Material Testing: Periodic material testing is performed to assess the IBC’s structural integrity and identify any signs of degradation. This testing may include checking for cracks, leaks, and material fatigue. The tests can vary depending on the IBC’s material (e.g., plastic, metal).

- Pressure Testing: IBCs are often subjected to pressure testing to ensure that they can withstand the pressures required for their intended use. This testing helps to identify any potential leaks or weaknesses in the IBC’s structure.

Traceability and Documentation

Traceability and meticulous documentation are essential for ensuring the safety and accountability of recycled food-grade IBCs. This documentation provides a complete history of each IBC, from its initial use to its reuse, enabling rapid identification and response to any potential food safety issues.Key aspects of traceability and documentation include:

- Unique Identification: Each recycled IBC is assigned a unique identification number or code. This code is used to track the IBC throughout its lifecycle.

- Usage History: Detailed records are maintained for each IBC, including its previous contents, cleaning and sanitization procedures, testing results, and inspection reports. This information is essential for assessing the suitability of the IBC for reuse.

- Cleaning and Sanitization Records: Comprehensive records of the cleaning and sanitization procedures are maintained. These records include the date, time, personnel involved, cleaning agents used, concentrations, temperatures, and contact times.

- Testing and Inspection Records: All testing and inspection results are documented, including the date, time, personnel involved, and the specific tests performed. These records provide evidence of the IBC’s safety and suitability for reuse.

- Material Certifications: Documentation, such as certificates of compliance, may be needed to demonstrate that the IBC materials meet the required food-grade standards.

- Supply Chain Tracking: A robust system for tracking the IBC’s movement throughout the supply chain is essential. This allows for rapid identification and isolation of any affected IBCs in the event of a food safety issue.

Complete and accurate documentation is not just a best practice; it’s a legal requirement under many food safety regulations. This documentation is crucial for demonstrating compliance and protecting both consumers and businesses.

Cost Analysis: Recycled vs. New Food Grade IBCs

Understanding the financial implications of choosing between recycled and new food grade IBCs is crucial for businesses in California. This analysis considers both the immediate and long-term costs, providing a comprehensive view to aid in informed decision-making. Evaluating the total cost of ownership allows for a strategic approach, considering initial investment, operational expenses, and potential risks.

Comparing Initial Purchase Costs

The initial purchase price is often the most significant factor influencing the choice between recycled and new IBCs. Recycled IBCs typically offer a substantial cost advantage upfront, while new IBCs come with a higher price tag.The following table provides a comparison of key factors:

| Cost | Lifespan | Environmental Impact | Regulations |

|---|---|---|---|

| Recycled: Significantly lower initial cost. | Recycled: Potentially shorter, dependent on prior use and refurbishment. | Recycled: Lower, due to reduced manufacturing and waste. | Recycled: Must meet stringent cleaning and inspection standards. |

| New: Higher initial cost. | New: Longer, typically 5-7 years under proper care. | New: Higher, due to manufacturing processes. | New: Generally meet all new IBC standards. |

Analyzing Long-Term Costs of Recycled IBCs

While the initial cost of recycled IBCs is lower, businesses must consider long-term expenses that can impact the overall cost of ownership.These long-term costs can include:

- Maintenance: Recycled IBCs may require more frequent inspections and maintenance due to their previous use. This includes potential repairs to valves, frames, and the inner container.

- Cleaning: Thorough cleaning and sanitization are essential to ensure food safety. This process, while critical for all IBCs, can be more intensive and costly for recycled units, potentially involving specialized cleaning services.

- Inspection and Testing: Regular inspections are crucial to identify any damage or contamination. Recycled IBCs might need more frequent and rigorous testing to ensure they meet food safety standards.

- Potential Issues: The history of a recycled IBC is not always fully known, which can lead to unexpected problems. This could include compatibility issues with certain food products or premature failure of the container.

Comparing the Total Cost of Ownership

A total cost of ownership (TCO) analysis provides a holistic view of the financial implications, incorporating both initial and ongoing expenses. This comparison enables businesses to make a more informed decision.For example, consider a scenario where a food processing plant needs 100 IBCs.

- New IBCs: The initial cost per IBC is $800, resulting in a total initial investment of $80,000. The lifespan is estimated at 5 years, with minimal maintenance costs of $50 per IBC per year, totaling $25,000 over the lifespan. The TCO is $105,000.

- Recycled IBCs: The initial cost per IBC is $400, resulting in a total initial investment of $40,000. The lifespan is estimated at 3 years. Maintenance costs are higher, at $150 per IBC per year, totaling $45,000 over the lifespan. The TCO is $85,000.

In this example, although the recycled IBCs offer a lower initial investment, the higher maintenance costs and shorter lifespan result in a TCO that is not significantly lower than that of new IBCs. This highlights the importance of a detailed TCO analysis, considering all relevant factors. The example does not include the potential for early failures or regulatory penalties, which could further increase the cost.

Sourcing and Supply Chain of Recycled IBCs in California

The efficient sourcing and management of the supply chain are critical for the success of recycled food grade IBCs in California. A robust supply chain ensures a consistent flow of containers, maintaining product safety, minimizing costs, and promoting sustainability. This section explores the key players, processes, and models involved in bringing recycled IBCs from suppliers to end-users within the California market.

Major Suppliers of Recycled Food Grade IBCs in California

Identifying reliable suppliers is the first step in establishing a successful recycled IBC program. These suppliers must adhere to stringent food safety standards and possess the infrastructure to handle the cleaning, inspection, and refurbishment of IBCs.

- IBC Refurbishment Companies: Several specialized companies in California focus on the refurbishment of IBCs. These companies typically have the facilities and expertise to clean, inspect, and repair IBCs to meet food grade standards. They often source IBCs from various industries, including chemical and agricultural sectors, after their initial use. An example is a company based in Southern California that boasts a 90% success rate in restoring IBCs to food-grade specifications.

- Industrial Container Suppliers: Some established industrial container suppliers also offer recycled IBC options. These suppliers often have a broader range of container solutions, including new and recycled IBCs, providing customers with diverse choices. They often maintain strong relationships with end-users, facilitating the return and recycling of used IBCs. One such supplier, with locations across California, offers a comprehensive program that includes collection, cleaning, and refurbishment services.

- Logistics and Recycling Companies: Logistics companies with recycling divisions are becoming increasingly involved in the recycled IBC market. They manage the transportation and processing of used IBCs, often partnering with refurbishment companies to complete the recycling process. This integrated approach streamlines the supply chain and reduces transportation costs.

Process of Obtaining and Inspecting Recycled IBCs from Suppliers

Obtaining and inspecting recycled IBCs is a meticulous process that ensures the containers meet the necessary food safety and performance standards. This process typically involves several stages, from initial sourcing to final certification.

- Sourcing and Collection: Suppliers source used IBCs from various industries. This may involve establishing collection programs with end-users, partnering with waste management companies, or purchasing IBCs from secondary markets.

- Initial Inspection: Upon receipt, each IBC undergoes an initial inspection to assess its condition. This inspection includes checking for any structural damage, contamination, or previous use of non-food-grade substances. IBCs deemed unsuitable for refurbishment are rejected and recycled for other purposes.

- Cleaning and Sanitization: The cleaning process is critical for removing any residual contents and contaminants. This typically involves high-pressure washing, using specialized cleaning agents and hot water. The cleaning process must adhere to strict food safety guidelines, ensuring no residues remain that could compromise the safety of food products.

- Repair and Refurbishment: Any damaged IBCs undergo repairs. This may include replacing damaged valves, repairing cracks, or replacing entire components. The goal is to restore the IBC to its original functionality and structural integrity.

- Final Inspection and Testing: After cleaning and repair, each IBC undergoes a final inspection and testing to verify its food-grade suitability. This includes visual inspections, pressure testing, and sometimes laboratory analysis to ensure the absence of contaminants. Suppliers often provide certifications to confirm the IBCs meet food safety standards.

- Certification and Documentation: The supplier provides documentation, including cleaning certificates, inspection reports, and any necessary food safety certifications. This documentation is essential for traceability and regulatory compliance.

Supply Chain Model for Recycled Food Grade IBCs

The supply chain for recycled food grade IBCs is a complex network involving multiple stakeholders and processes. This model illustrates the flow of materials from the source to the end-user, highlighting the key stages and participants.

The supply chain begins with the source, typically industries that use IBCs for transporting and storing various products. These could include food manufacturers, chemical plants, or agricultural businesses. These entities are the originators of the used IBCs.

The next stage involves the collection and transportation of the used IBCs. This may be handled by the original user, a logistics company, or a specialized recycling service. The IBCs are transported to the refurbishment facility.

The refurbishment facility is where the IBCs undergo the cleaning, inspection, repair, and testing processes. This is the central hub of the recycling operation. It’s where the IBCs are restored to food-grade condition. The refurbishment facility is a crucial part of the supply chain.

Once refurbished, the IBCs are ready for distribution. This may involve direct sales to end-users or distribution through industrial container suppliers. The IBCs are transported to the end-user’s location.

Finally, the end-user receives the recycled food grade IBCs. They use the IBCs for their specific needs, such as storing or transporting food products. When the IBCs are no longer needed, the cycle begins again, returning them to the collection stage.

The supply chain model demonstrates a closed-loop system, where used IBCs are continuously recycled and reused. This model minimizes waste, conserves resources, and reduces the environmental impact of IBC usage.

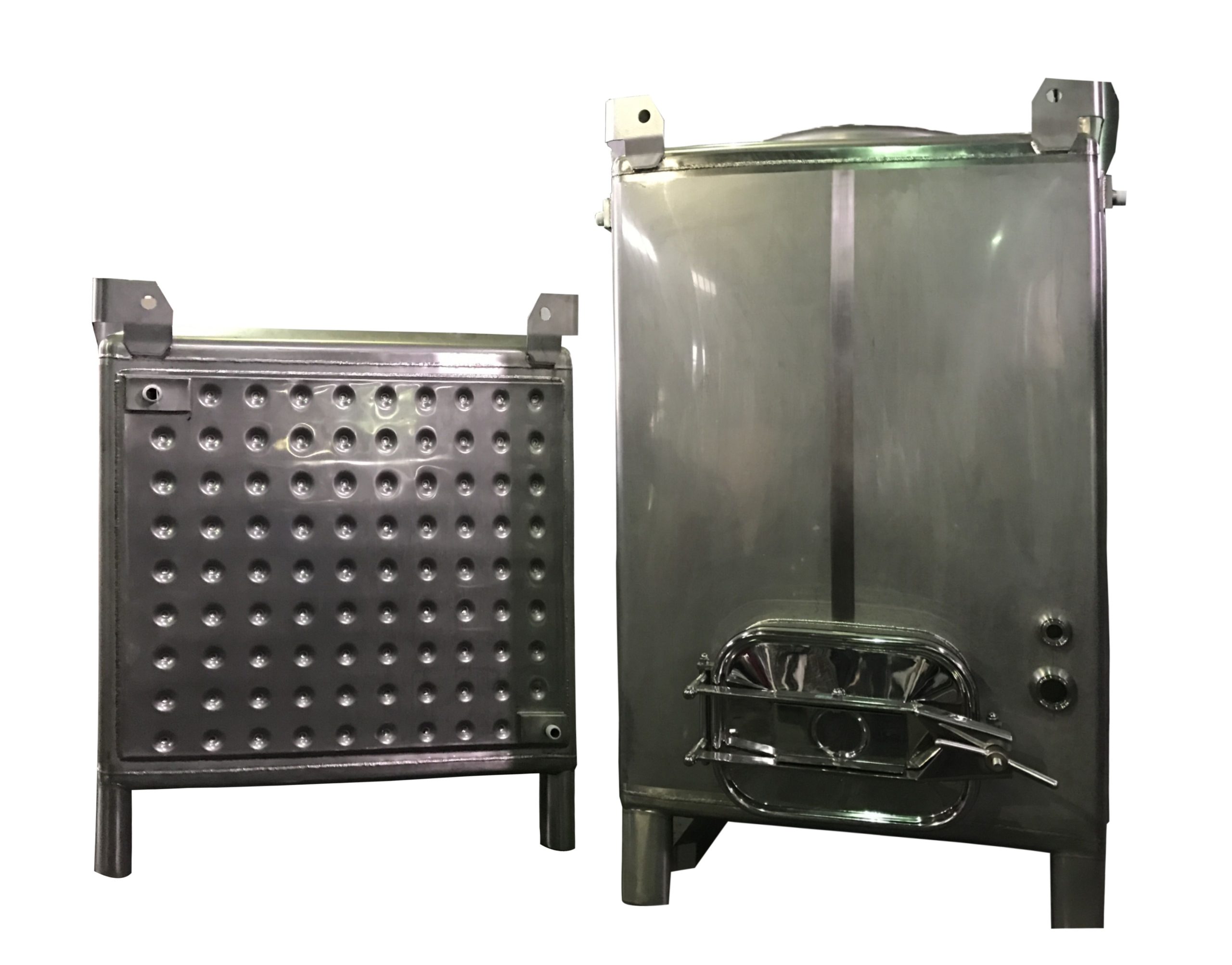

Illustration of the supply chain:

The illustration can be represented as a circular flow diagram. The diagram begins with a graphic depicting a factory or industrial facility, representing the “Source” of used IBCs. Arrows lead from this source to a graphic representing a truck, indicating “Collection and Transportation”. From the truck graphic, arrows lead to a graphic of a refurbishment facility with cleaning equipment, representing the “Refurbishment Facility”.

Another set of arrows lead from this facility to a graphic of a warehouse, representing “Distribution”. Finally, arrows lead from the warehouse to a graphic of a food processing plant, representing the “End-User”. The arrow then returns from the end-user back to the source, completing the circular flow, indicating the continuous recycling process.

Regulations and Certifications for Food Grade IBC Recycling

The recycling of food-grade IBCs in California is subject to stringent regulations and certifications designed to ensure food safety and environmental protection. These requirements are multifaceted, involving both state and federal oversight, and are critical for maintaining the integrity of the food supply chain. Companies involved in this process must adhere to a complex framework to legally and ethically operate.

Specific Certifications Required for Recycling Companies

Recycling food-grade IBCs in California necessitates specific certifications to validate a company’s ability to safely and effectively handle these containers. These certifications demonstrate adherence to industry best practices and regulatory compliance.A critical certification is the Food and Drug Administration (FDA) compliance. This signifies that the recycling processes and materials used meet the FDA’s standards for food contact. Compliance often involves adherence to the Good Manufacturing Practices (GMP), ensuring that the recycling facility maintains a clean and sanitary environment, with appropriate equipment and procedures to prevent contamination.Another significant certification is the ISO 9001 certification, which focuses on quality management systems.

This certification provides assurance that the recycling company has established processes to consistently meet customer and regulatory requirements. The ISO 9001 standard helps companies ensure the quality of their products and services, thereby minimizing the risk of contamination.The Hazard Analysis and Critical Control Points (HACCP) system is another essential component. HACCP is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe.

Recycling companies must implement HACCP plans to identify and control potential hazards in their recycling processes.Additionally, many recycling facilities seek NSF International certification. NSF certifies products and systems, including those used in food processing, to ensure they meet specific standards for public health protection. NSF certification indicates that the recycling company’s processes and materials have been independently assessed and meet stringent safety standards.

Expand your understanding about compare foods fayetteville nc with the sources we offer.

Role of Regulatory Bodies in Overseeing Recycling

Several regulatory bodies play crucial roles in overseeing the recycling of food-grade IBCs in California. Their involvement ensures that recycling practices align with environmental protection and food safety standards.The California Department of Resources Recycling and Recovery (CalRecycle) oversees waste management and recycling efforts within the state. CalRecycle sets standards and regulations for recycling operations, including those involving IBCs, ensuring that they are handled in an environmentally responsible manner.

CalRecycle monitors recycling facilities for compliance with state laws and regulations, and they provide resources and support for businesses engaged in recycling activities.The United States Environmental Protection Agency (EPA) has a broad role in environmental protection, including the regulation of waste management practices. The EPA sets standards for hazardous waste management, which is relevant because IBCs may have contained hazardous materials prior to being recycled.

The EPA’s regulations help to ensure that these containers are properly cleaned and handled to prevent environmental contamination.The California Department of Public Health (CDPH) is responsible for ensuring the safety of the food supply. CDPH works closely with the FDA to enforce food safety regulations and inspect facilities involved in food handling, including those that handle recycled food-grade IBCs. CDPH’s involvement helps to protect consumers from foodborne illnesses and ensure that recycled containers are suitable for food contact.

Key Regulatory Requirements Checklist for Companies, Food grade ibc california recycled

Companies involved in recycling food-grade IBCs must meet a comprehensive set of regulatory requirements. This checklist provides a summary of key areas to address:

- FDA Compliance: Ensure adherence to FDA regulations for food contact materials and processes. This includes compliance with GMP.

- HACCP Implementation: Develop and implement a HACCP plan to identify and control potential hazards.

- ISO 9001 Certification: Obtain and maintain ISO 9001 certification to demonstrate a commitment to quality management.

- NSF Certification: Consider NSF certification for processes and materials to ensure they meet stringent safety standards.

- CalRecycle Compliance: Adhere to all regulations set by CalRecycle for waste management and recycling operations.

- EPA Compliance: Comply with EPA regulations for hazardous waste management, particularly concerning the handling and disposal of any hazardous materials that may have been contained in the IBCs.

- CDPH Collaboration: Cooperate with the CDPH to ensure compliance with food safety regulations and to facilitate inspections.

- Material Traceability: Maintain detailed records of all materials used in the recycling process, including the origin and history of the IBCs. This traceability helps to ensure the integrity of the recycled containers.

- Sanitation and Cleaning Protocols: Establish and strictly follow comprehensive cleaning and sanitation protocols to prevent contamination of the recycled IBCs. These protocols should be documented and regularly reviewed.

- Employee Training: Provide thorough training to all employees involved in the recycling process on proper handling procedures, safety protocols, and regulatory requirements. Regular training updates are crucial.

Technical Aspects of Recycling Food Grade IBCs

Recycling food-grade intermediate bulk containers (IBCs) is a complex process that demands rigorous attention to detail to ensure safety and maintain the integrity of the container for reuse. This involves sophisticated cleaning procedures, comprehensive structural assessments, and stringent quality control measures. Successfully recycling these containers minimizes environmental impact and offers cost-effective solutions, but it hinges on a thorough understanding of the technical aspects involved.

Cleaning and Preparation Processes

The cleaning and preparation of food-grade IBCs are critical steps, removing all traces of previous contents to prevent cross-contamination. This involves multiple stages and utilizes specialized equipment.

- Initial Inspection and Emptying: The process begins with a thorough visual inspection of the IBC for any visible damage, residue, or contamination. Residual product is completely drained.

- Rinsing and Pre-Cleaning: A high-pressure rinse with hot water is typically the first step to remove bulk contaminants. This is often followed by a pre-cleaning step using detergents or solvents, depending on the nature of the previous contents.

- Chemical Cleaning: This is a critical step where specialized cleaning agents are used to remove remaining residues. The choice of cleaning agent depends on the previous contents and must be food-grade compatible. This process might involve caustic solutions, acids, or enzymatic cleaners. The IBC is often submerged or subjected to a circulating cleaning solution.

- Disinfection and Sterilization: After chemical cleaning, the IBC undergoes disinfection to eliminate any microorganisms. This could involve heat sterilization, using steam or hot water, or chemical sterilization with food-grade sanitizers like peracetic acid or chlorine dioxide.

- Final Rinse and Drying: The IBC is rinsed thoroughly with potable water to remove any remaining cleaning agents or sanitizers. Then, the IBC is dried completely, typically using heated air, to prevent mold or bacterial growth.

- Testing and Validation: The final step involves testing the IBC for cleanliness and ensuring that it meets the required food-grade standards. This may include swab tests, residue analysis, and sensory evaluation.

Structural Integrity Assessment Techniques

Assessing the structural integrity of recycled IBCs is paramount to ensure their safe and reliable performance. Various non-destructive testing (NDT) methods are employed to detect potential weaknesses without damaging the container.

- Visual Inspection: This remains a fundamental assessment tool. Inspectors meticulously examine the IBC for cracks, bulges, dents, or other signs of physical damage. The presence of any such defect may automatically disqualify the container.

- Hydrostatic Testing: This involves filling the IBC with water and applying pressure to simulate the stresses it will experience during use. The container is monitored for leaks, deformations, or any signs of structural failure. The pressure applied is typically higher than the maximum working pressure.

- Ultrasonic Testing: This technique uses high-frequency sound waves to detect internal flaws or weaknesses in the IBC’s walls. The sound waves are transmitted through the material, and any changes in their reflection indicate potential problems.

- Thickness Measurement: Using ultrasonic thickness gauges, inspectors measure the wall thickness of the IBC at multiple points to ensure it meets the minimum required thickness specified by the manufacturer.

- Leak Testing: This is often performed after cleaning and before any structural assessments. It involves pressurizing the IBC with air or inert gas and monitoring for any pressure drop, which would indicate a leak.

- Drop Testing: This simulates the impact an IBC might experience during handling and transportation. A fully or partially filled IBC is dropped from a specified height onto a hard surface to assess its ability to withstand impact forces.

Disqualification Criteria for Recycling Food Grade IBCs

Several types of damage or contamination would automatically disqualify a food-grade IBC from being recycled. These criteria are in place to protect consumer safety and ensure the integrity of the recycled container.

- Severe Physical Damage: This includes any significant cracks, punctures, or deformations that compromise the structural integrity of the IBC. Bulges, dents, or areas of thinning material also fall into this category.

- Unremovable Contamination: If the IBC contains residues of non-food-grade substances that cannot be completely removed through cleaning, it is disqualified. This includes hazardous chemicals, paints, or other materials that could contaminate food products.

- Evidence of Chemical Degradation: Exposure to certain chemicals can degrade the plastic material of an IBC, making it brittle or susceptible to failure. Signs of chemical degradation, such as discoloration, swelling, or softening, are disqualifying.

- History of Non-Food Use: IBCs previously used to store non-food-grade substances are generally not suitable for recycling for food use, even if thoroughly cleaned. This is because it is difficult to guarantee that all traces of the previous contents have been removed.

- Unidentified or Unapproved Repairs: Any repairs made to the IBC must be documented and approved by the manufacturer or a qualified specialist. Unauthorized or poorly executed repairs can compromise the container’s safety and performance.

- Non-Compliance with Regulations: If the IBC does not meet the required regulations and certifications for food-grade containers, it cannot be recycled for food use.

Case Studies: Success Stories in California: Food Grade Ibc California Recycled

California’s diverse food processing industry provides a rich landscape for observing the practical benefits of utilizing recycled food-grade IBCs. Numerous companies across the state have embraced these containers, realizing both economic and environmental advantages. The following case studies highlight the positive impacts of integrating recycled IBCs into their operations.

Successful Implementation in Tomato Processing

A prominent tomato processing company, based in the Central Valley of California, transitioned to using recycled food-grade IBCs for storing and transporting tomato concentrate. This shift offered substantial improvements to their supply chain.

- Cost Reduction: The company significantly reduced its packaging expenses by choosing recycled IBCs. The initial investment in recycled IBCs was considerably lower than purchasing new ones, and ongoing maintenance costs were also competitive.

- Environmental Benefits: By utilizing recycled containers, the company decreased its carbon footprint. This aligns with the growing consumer demand for sustainable practices and helped the company meet its environmental goals.

- Operational Efficiency: The IBCs were designed to fit seamlessly into the existing logistics system. The IBCs’ standardized dimensions simplified handling and storage, resulting in faster turnaround times and reduced labor costs.

Dairy Product Manufacturer’s Experience

A California-based dairy product manufacturer incorporated recycled food-grade IBCs for the storage and transportation of milk and cream. This case demonstrates the versatility and suitability of recycled IBCs in a sensitive food processing environment.

- Food Safety Compliance: The company rigorously followed all regulatory requirements, including thorough cleaning and sanitization procedures. The use of recycled IBCs was compliant with all California Department of Public Health regulations.

- Durability and Reliability: The recycled IBCs demonstrated robustness, withstanding the rigors of daily use. Proper inspection and maintenance ensured the containers’ longevity and prevented leaks or contamination.

- Positive Brand Image: The company’s commitment to sustainability enhanced its brand reputation. This commitment resonated positively with consumers, who increasingly favor companies with environmentally responsible practices.

Impact on Sustainability Efforts in the Wine Industry

A winery in Napa Valley embraced recycled IBCs for the bulk storage of wine during the aging process. The winery’s actions illustrate the integration of sustainable practices within the wine industry.

- Waste Reduction: The winery significantly decreased its waste generation by using recycled IBCs, reducing the need for single-use containers.

- Resource Conservation: Choosing recycled IBCs conserved resources compared to using new containers, reducing the demand for raw materials and energy-intensive manufacturing processes.

- Contribution to a Circular Economy: The winery’s adoption of recycled IBCs supported a circular economy model, promoting the reuse of materials and minimizing waste sent to landfills. This is a critical component of sustainable business practices.

Future Trends and Innovations

The food grade IBC recycling landscape is poised for significant transformation, driven by increasing environmental awareness, stricter regulations, and technological advancements. These changes are not only reshaping the industry but also presenting new opportunities for businesses to optimize their operations and contribute to a more sustainable future. The following sections delve into the key trends, innovative technologies, and emerging materials that are shaping the future of food grade IBC recycling.

Potential Future Trends in Recycling Food Grade IBCs

The recycling of food grade IBCs is expected to evolve significantly in the coming years, adapting to both market demands and environmental pressures. Several key trends are anticipated to influence this evolution.

- Increased Demand for Recycled Content: Consumer preference for sustainable products is driving demand for IBCs made with recycled materials. Food and beverage companies are increasingly setting targets for recycled content in their packaging, including IBCs, to reduce their environmental footprint and enhance their brand image. For example, Unilever has committed to using 100% reusable, recyclable or compostable plastic packaging by 2025, influencing their suppliers to adopt similar practices.

- Circular Economy Models: The shift towards a circular economy, where materials are kept in use for as long as possible, is gaining momentum. This model encourages the design of IBCs that are easier to disassemble, recycle, and reuse. Companies are exploring closed-loop systems where IBCs are collected, cleaned, recycled, and then used to manufacture new IBCs, minimizing waste and resource consumption.

- Greater Emphasis on Data and Traceability: Technologies like blockchain and RFID tags are enabling improved tracking of IBCs throughout their lifecycle. This data provides valuable insights into IBC usage, recycling rates, and potential contamination risks. Real-time data allows for more efficient management of IBC fleets, optimized recycling processes, and enhanced transparency in the supply chain.

- Expansion of Chemical Recycling: While mechanical recycling remains the primary method, chemical recycling techniques are emerging as a complementary approach. Chemical recycling can break down plastic polymers into their basic building blocks, allowing for the production of high-quality recycled materials suitable for food grade applications. This technology can address the challenge of recycling mixed plastics and contaminated IBCs that are difficult to process using traditional methods.

- Policy and Regulatory Support: Governments worldwide are implementing policies to promote recycling and reduce plastic waste. Extended Producer Responsibility (EPR) schemes, which hold manufacturers responsible for the end-of-life management of their products, are becoming more common. These policies incentivize the use of recycled materials and investment in recycling infrastructure, driving innovation in the food grade IBC recycling sector.

Innovative Technologies for Improving the Recycling Process

Advancements in technology are essential for optimizing the efficiency and effectiveness of food grade IBC recycling. Several innovative technologies are showing promise in this area.

- Advanced Sorting and Separation Systems: Automated sorting systems equipped with advanced sensors, such as near-infrared (NIR) spectroscopy and machine vision, can identify and separate different types of plastics with high accuracy and speed. These systems can handle complex mixtures of plastics, improving the quality of recycled materials and reducing contamination. For example, TOMRA Sorting GmbH’s systems are widely used in recycling facilities to sort plastics based on polymer type.

- Enhanced Cleaning and Decontamination Techniques: Ensuring that IBCs are thoroughly cleaned and decontaminated is crucial for food safety. Innovative cleaning technologies, such as ultrasonic cleaning and supercritical CO2 cleaning, are being developed to remove residues and contaminants more effectively than traditional methods. These technologies can also reduce water and energy consumption, making the recycling process more sustainable.

- Improved Material Processing Technologies: Technologies like advanced extrusion and injection molding are being refined to process recycled plastics into high-quality IBCs. These technologies can overcome challenges associated with recycled materials, such as reduced mechanical properties, by optimizing the processing parameters and using additives to enhance performance.

- Robotics and Automation: Robotics and automation are being integrated into various stages of the recycling process, from sorting and cleaning to disassembly and reassembly. Robots can perform repetitive and hazardous tasks more efficiently and safely than human workers, increasing throughput and reducing labor costs. For example, automated systems are used to handle and process large volumes of IBCs in recycling facilities.

- Digital Twins: Digital twins, which are virtual representations of physical assets, are being used to simulate and optimize recycling processes. By creating a digital twin of a recycling facility, operators can analyze performance, identify bottlenecks, and test different scenarios to improve efficiency and reduce waste. This technology can also be used to monitor the condition of equipment and predict maintenance needs.

Emerging Materials for Food Grade IBCs

The development of new materials is critical for improving the sustainability and performance of food grade IBCs. Several emerging materials are attracting attention in the industry.

- Bio-based Plastics: Plastics derived from renewable resources, such as cornstarch, sugarcane, and algae, are gaining popularity as an alternative to traditional petroleum-based plastics. Bio-based plastics can reduce the carbon footprint of IBCs and contribute to a circular economy. However, challenges remain in terms of cost, performance, and compatibility with existing recycling infrastructure. Polylactic acid (PLA) and bio-polyethylene (bio-PE) are examples of bio-based plastics being explored for IBC applications.

- Compostable Plastics: Compostable plastics are designed to break down into natural substances in a composting environment. While not yet widely used in food grade IBCs due to regulatory hurdles and potential contamination risks, they offer a potential solution for end-of-life management. Research and development are focused on creating compostable materials that meet the stringent requirements of food safety.

- Advanced Recycled Plastics: Innovations in recycling technology are enabling the production of high-quality recycled plastics that can meet the performance requirements of food grade IBCs. Advanced recycling processes, such as chemical recycling, can break down mixed plastics into their building blocks, allowing for the creation of recycled materials with properties similar to virgin plastics.

- Composite Materials: Composite materials, which combine different materials to enhance their properties, are being explored for IBC applications. These materials can offer improved strength, durability, and barrier properties, extending the lifespan of IBCs and reducing the need for virgin materials. For example, composites made with recycled plastics and natural fibers can reduce the environmental impact of IBCs.

- Nanomaterials: Nanomaterials, such as nanoparticles and nanocomposites, are being investigated to enhance the performance of IBCs. These materials can improve barrier properties, mechanical strength, and resistance to degradation, extending the lifespan of IBCs and improving food safety. However, the use of nanomaterials in food contact applications is subject to strict regulatory scrutiny.

Last Word

From stringent regulations to innovative recycling processes, food grade ibc california recycled represents a significant step towards a more sustainable future for the state’s food industry. Embracing recycled IBCs not only helps companies meet environmental goals but also offers a compelling cost-effective solution. As technology advances and consumer demand for eco-friendly practices increases, the adoption of recycled IBCs will only continue to grow.

By understanding the benefits and challenges, businesses can make informed decisions, contributing to a circular economy and a healthier planet.