Manual food slicer, a time-honored tool in kitchens worldwide, offers a unique blend of precision and practicality. From the humble beginnings of hand-cranked models to the sophisticated lever-operated designs, these tools have evolved alongside culinary techniques. Understanding the mechanics, types, and maintenance of manual food slicers reveals a world of culinary possibilities.

This manual explores the diverse world of manual food slicers, delving into their history, features, and applications. We’ll cover everything from comparing different types to understanding the intricate workings of their blades, ensuring you’re well-equipped to choose the right slicer for your needs. Prepare to be amazed by the versatility and precision these tools offer!

Introduction to Manual Food Slicers

Manual food slicers, a cornerstone of kitchen efficiency, have a rich history deeply intertwined with culinary practices. From simple hand-cranked devices to more sophisticated lever-operated models, these tools have evolved alongside the changing needs and demands of home cooks and professional chefs. Their enduring appeal lies in their ability to produce uniform slices with precision, a key aspect of many culinary tasks.A fundamental understanding of manual food slicers involves recognizing the mechanical principles that underpin their operation.

The design and construction of these tools have progressed from simple, hand-cranked mechanisms to more refined lever-operated models, enabling greater control over slice thickness and overall efficiency.

History of Manual Food Slicers

The earliest forms of manual food slicers were likely simple, hand-cranked devices. These rudimentary tools, often crafted from wood, provided a basic means of slicing fruits, vegetables, and cheeses. Over time, these designs evolved, incorporating improvements in materials and mechanisms to enhance performance and durability. The advent of metal components marked a significant advancement, providing greater strength and precision.

This evolution culminated in lever-operated models that offered adjustable thickness settings, further enhancing versatility and user control.

Types of Manual Food Slicers

Manual food slicers are categorized by their operation mechanism. Hand-crank models, often constructed from wood or metal, are characterized by their straightforward design and compact size. Lever-operated models, typically made of metal, boast adjustable thickness settings and increased capacity. These distinctions highlight the tailored approach to different culinary needs.

Comparison of Manual Food Slicer Types

| Type | Material | Capacity | Features |

|---|---|---|---|

| Hand-crank | Wood/Metal | Small (typically for smaller batches of produce) | Simple design, straightforward operation, generally lighter weight. |

| Lever-operated | Metal (often stainless steel) | Medium (can handle larger volumes of food) | Adjustable thickness settings, allowing for consistent slicing, more powerful for larger quantities, and greater control over thickness. |

Basic Mechanics and Working Principles

The core mechanism of a manual food slicer involves a sharp blade that is driven by either a hand crank or a lever. The blade, housed within a frame, is positioned to contact the food item. Application of force, either through cranking or leverage, rotates or moves the blade across the food, producing the desired slices. The quality of the blade and the precision of the blade’s positioning directly affect the final result, ensuring even and consistent cuts.

The blade’s sharpness and the evenness of the slicing action are essential for efficient and safe use.

Types and Variations of Manual Food Slicers

Manual food slicers offer a diverse range of options, catering to various culinary needs and preferences. From effortlessly slicing delicate fruits to achieving precise julienne cuts for vegetables, these tools are versatile workhorses in the kitchen. Their design variations are tailored to specific food types and desired cut thicknesses.Understanding the differences between blade types and their suitability for different foods is crucial for maximizing the slicer’s performance and achieving the desired culinary results.

The available blade thicknesses, from thin slices for delicate vegetables to thicker cuts for robust produce, contribute to the tool’s adaptability.

Blade Types and Their Suitability

Various blade types are designed for specific food types and desired cut qualities. This section explores the different blade types and their applications, highlighting the key distinctions.

- Slicing blades are the most common type, optimized for creating thin or thick slices. These blades are often adjustable, allowing for a range of thicknesses, making them suitable for fruits, vegetables, and even cheeses. A fine-tuned slicing blade can effortlessly produce perfectly even slices for garnishing, sandwiches, or preparing appetizers.

- Julienne blades, characterized by their precise, narrow grooves, are designed for creating matchstick-like cuts. These are ideal for vegetables like carrots, zucchini, and celery, enabling uniform julienne cuts, commonly used in salads or stir-fries.

- Mandoline blades are an advanced type, providing precise and intricate cuts. They are capable of producing very thin slices, consistent cuts, and various shapes. These blades are excellent for creating uniform cuts, decorative garnishes, and precise presentations. Their adjustable blade positions and varied configurations allow for various cut styles.

Blade Thicknesses

The thickness of the blade directly influences the final cut. Different foods require different thicknesses for optimal presentation and culinary use. For instance, thin slices of cucumber are ideal for salads, while thicker slices of potatoes might be preferred for frying.

- Adjustable blade thickness allows for a wide range of cuts. This feature caters to diverse culinary preferences and recipes. From delicate slices to robust cuts, the flexibility of the adjustable blade offers versatility.

- Specific blade thicknesses are tailored for specific foods. For example, thin blades are ideal for slicing delicate fruits, while thicker blades are suitable for vegetables or cheeses. The choice of blade thickness is directly related to the food type and the intended culinary application.

Specialized Manual Food Slicers

Beyond basic slicing, specialized manual food slicers offer intricate cutting options, such as julienning, and other decorative cuts. These variations allow for more complex culinary presentations.

- Julienne slicers are designed for creating matchstick-like cuts, facilitating consistent and precise julienne cuts for vegetables. These specialized slicers are essential for achieving uniformity and aesthetics in culinary preparations.

- Mandoline slicers, with their adjustable blades, offer a wide range of cutting options, including intricate shapes and decorative slices. They are excellent for creating visually appealing and uniform cuts, enhancing the presentation of dishes.

Table of Blade Types and Uses

This table summarizes the different blade types, their corresponding food types, the types of cuts they produce, and the associated blade thicknesses.

Get the entire information you require about beef liver dog food on this page.

| Blade Type | Food Type | Cut Type | Blade Thickness |

|---|---|---|---|

| Slicing | Fruits/Vegetables/Cheese | Thin/Thick | Adjustable |

| Julienne | Vegetables | Matchstick | Small |

| Mandoline | Fruits/Vegetables/Cheese | Thin, Thick, Decorative | Adjustable |

Features and Benefits of Manual Food Slicers

Manual food slicers, despite their simplicity, offer a compelling alternative to electric models. Their unique features and benefits lie in their precise control, tactile engagement, and inherent durability. These attributes translate into a superior user experience and a more rewarding culinary process.Manual slicers are designed for focused, deliberate slicing, encouraging a deeper connection with the food being prepared.

The controlled nature of manual slicing allows for a high degree of precision and control, resulting in consistently even cuts and a superior food presentation.

Blade Sharpness and Precision

The sharpness of the blade is paramount in a manual food slicer. A razor-sharp blade ensures clean, even slices with minimal effort and prevents the food from tearing or becoming unevenly cut. A dull blade can lead to uneven cuts, bruised food, and increased effort during the slicing process. High-quality manual slicers often feature replaceable or easily sharpened blades, allowing for prolonged use and optimal performance.

Safety Mechanisms and Ease of Use

Manual food slicers are often designed with safety in mind. Features like blade guards, secure handles, and ergonomic designs ensure a comfortable and safe slicing experience. These safety features, combined with the intuitive operation of many models, make them easy to use for both novice and experienced cooks. The straightforward operation, without complex controls, contributes to the ease of use, enabling quick and efficient slicing.

Durability and Longevity

Well-made manual food slicers are renowned for their durability. High-quality materials, such as robust metal construction and reinforced components, ensure that the slicer will withstand repeated use over extended periods. Their simple design, with fewer moving parts compared to electric models, contributes to their long lifespan and reliability. Proper maintenance, such as regular cleaning and blade sharpening, will further enhance the longevity of the manual slicer.

Improved Food Presentation

The precision of manual food slicers significantly enhances food presentation. Even slices, precise cuts, and the ability to control the thickness of the slices create visually appealing dishes. This control allows for intricate and aesthetically pleasing presentations, elevating the overall dining experience. For example, perfectly sliced fruits or vegetables for salads or garnishes create a more inviting and visually appealing dish.

Comparison: Manual vs. Electric Slicers, Manual food slicer

| Feature | Manual Slicers | Electric Slicers |

|---|---|---|

| Ease of Use | Simple, intuitive operation; less complex controls. | Can have more complex controls, requiring more learning. |

| Effort Required | Requires physical effort; some models can be heavy. | Requires less physical effort, but potentially more initial investment. |

| Cost | Generally more affordable than electric models. | Generally more expensive than manual models. |

| Precision | High precision possible with sharp blades and proper technique. | Precision depends on the model and user skill. |

| Durability | Often built to last with high-quality materials. | Durability varies based on model and usage. |

Maintenance and Safety Precautions

Proper maintenance and adherence to safety precautions are crucial for the longevity and safe operation of a manual food slicer. Neglecting these aspects can lead to blade damage, decreased efficiency, and potentially serious injuries. This section details essential steps to ensure your slicer remains in optimal condition and use.

Maintaining Optimal Performance

Regular maintenance is key to preventing malfunctions and extending the lifespan of your manual food slicer. A well-maintained slicer ensures consistent performance and reduces the risk of accidents. A clean, sharp blade guarantees precise cuts and reduces the risk of food sticking or tearing.

- Cleaning the Slicer After Each Use: Immediately after each use, thoroughly clean the slicer with warm, soapy water. Remove any food particles from the blade, the cutting surface, and the housing. Use a soft brush or sponge to avoid scratching the blade. Allow the slicer to air dry completely before storing. This prevents the growth of bacteria and mold, ensuring the safety and hygiene of your food prep area.

- Sharpening the Blades Periodically: Blade sharpness is paramount for safe and efficient slicing. Over time, blades can dull, leading to uneven cuts, increased risk of food tearing, and potentially more effort in the slicing process. Regular sharpening, ideally every few uses or as needed, is vital for maintaining precision and preventing injury. Consult the manufacturer’s guidelines for the recommended sharpening method.

Use appropriate sharpening tools and techniques to maintain the blade’s edge.

- Inspecting for Damage: Regularly inspect the slicer for any signs of damage. Check for cracks, chips, or any other damage to the blade, housing, or handles. Damaged parts should be replaced immediately to prevent further damage and potential injuries. Observe the slicer’s overall condition to ensure it remains intact and suitable for use.

- Storing in a Safe Location: Store the slicer in a dry, cool place, away from direct sunlight and extreme temperatures. Keep it out of reach of children and ensure the blade is protected from accidental damage. Storing it in a dedicated area and safely securing it helps prevent injuries.

Safety Precautions for Injury Prevention

Safe operation of a manual food slicer necessitates the implementation of preventive measures. Understanding these precautions will minimize the risk of accidents and ensure a safe and efficient food preparation process.

- Always Use Protective Gloves: Using protective gloves during the slicing process is essential. This will shield your hands from accidental cuts or nicks, minimizing the risk of injury.

- Ensure a Stable Surface: Place the slicer on a stable and level surface to prevent slippage or tilting during operation. A stable surface prevents accidents and injuries. A wobbly or uneven surface can lead to the slicer moving unexpectedly.

- Never Place Hands Near the Blade: Avoid placing your hands near the blade while the slicer is in operation. Maintain a safe distance from the blade to prevent accidental cuts or injuries. Keep your hands and fingers well away from the blade area during use.

- Check for Obstructions: Before operating the slicer, ensure that no foreign objects or food debris are lodged in the blade or cutting area. Remove any obstruction to avoid jamming and potential injuries. Clear the blade area to avoid unintended accidents and maintain smooth slicing.

- Understand the Slicer’s Design: Familiarize yourself with the slicer’s design and operation before use. Understand the controls and mechanisms to operate the slicer safely and efficiently. Thorough knowledge of the slicer’s design helps prevent mistakes and injuries.

Importance of Blade Sharpness

Sharp blades ensure clean and precise cuts, reducing the risk of food tearing and minimizing the effort required for slicing.

Dull blades can cause food to stick or tear, increasing the risk of injury. A sharp blade slices cleanly, reducing the force needed to slice through food, thus lowering the risk of accidents. A sharp blade also cuts more efficiently, minimizing the time spent on slicing tasks.

Applications and Uses in Culinary Practices

Manual food slicers, with their precision and control, are indispensable tools in a variety of culinary settings. From bustling restaurant kitchens to home cooks preparing a special meal, these versatile machines offer unparalleled efficiency and consistent results. Their ability to create uniform slices, whether for elegant presentations or efficient food preparation, makes them a staple in professional and domestic kitchens alike.A skilled chef, or home cook, will quickly recognize the importance of consistent cuts in achieving a desired culinary outcome.

A perfectly sliced tomato for a salad, or a uniformly thick cut of meat for a gourmet dish, significantly enhances the overall presentation and flavor profile of the food. The manual slicer’s ease of use and adaptability to diverse culinary applications make it a cornerstone in modern food preparation.

Manual Slicers in Restaurants

Manual food slicers are frequently employed in restaurants to efficiently prepare large quantities of sliced produce, meats, and cheeses. Their consistent slicing capability ensures a uniform presentation, crucial for maintaining quality control and customer satisfaction. In high-volume operations, manual slicers are particularly useful for prepping ingredients for salads, appetizers, and sandwiches. For instance, a restaurant serving a daily special featuring thinly sliced roast beef on a baguette would rely on the precise cuts achievable with a manual slicer.

Manual Slicers in Home Kitchens

In home kitchens, manual slicers offer a satisfying level of control for preparing gourmet meals. Home cooks can create beautiful presentations for dinner parties or simply enjoy the precision of slicing ingredients like cucumbers, tomatoes, and hard cheeses. The consistent thickness of slices is essential for maintaining the visual appeal and balance of a dish. For instance, a home cook preparing a layered vegetable platter for a gathering will find a manual slicer invaluable for creating uniformly sliced vegetables.

Examples of Dishes Using Manual Food Slicers

- Thinly sliced roast beef for sandwiches or gourmet platters.

- Uniformly sliced vegetables for salads, stir-fries, or as part of elaborate side dishes.

- Precisely sliced cheeses for decorative purposes on charcuterie boards or as toppings for various dishes.

- Thinly sliced fruits for garnishing desserts or creating elegant fruit platters.

The consistent slices achieved by manual slicers ensure an aesthetically pleasing presentation of these foods.

Importance of Precise Cuts

Precise cuts are paramount in culinary practices. Uniform slices not only enhance the visual appeal of a dish but also impact the overall texture and flavor experience. Precise slicing can lead to better flavor distribution, improved presentation, and a more balanced dish. In some cases, precise slicing is crucial for maintaining the integrity of a recipe, like ensuring uniform thickness of sliced meat in a marinade.

Recipes Benefitting from Manual Food Slicers

- Carpaccio: The delicate slices of raw meat require precise and thin cuts for optimal flavor and texture.

- Sushi: While often associated with specialized tools, a manual slicer can provide the necessary precision for slicing vegetables and certain types of fish.

- Fruit salads: Manual slicers allow for uniform slices of fruits, enhancing visual appeal and texture.

- Sandwiches: A variety of sandwiches, especially those with thinly sliced meats, cheeses, or vegetables, benefit greatly from the consistent slicing.

- Platters and appetizers: Manual slicers are ideal for creating elegant and uniform slices for a wide array of platters and appetizers.

The uniformity and precision offered by manual slicers contribute to the overall visual appeal and the balanced flavor profile of these dishes.

Food Presentations Enhanced by Manual Slicers

Manual slicers are instrumental in creating visually appealing presentations. The uniform slices create a sense of order and elegance. This is especially evident in elaborate charcuterie boards, elegant fruit platters, and dishes that feature layered components. For example, a meticulously sliced cheese platter, or a beautifully arranged platter of fruit, showcases the ability of manual slicers to elevate the presentation of food.

Comparison with Electric Alternatives

Manual food slicers offer a distinct approach to food preparation compared to their electric counterparts. Understanding the nuances of each type—from speed and cost to space requirements—allows chefs and home cooks to select the tool best suited to their needs and preferences. Manual slicers often embody a certain charm and tactile engagement, while electric options excel in efficiency.Electric slicers provide a significant speed advantage, perfect for large-scale food preparation or when speed is a critical factor.

Manual slicers, on the other hand, offer a more intimate and often preferred method for precise slicing and dicing, potentially enhancing the sensory experience.

Speed and Efficiency

Manual slicers, relying on human power, operate at a slower pace compared to their electric counterparts. This slower operation, however, can be advantageous. It allows for greater control over the slicing process, enabling chefs to achieve precise cuts and maintain product integrity. The deliberate pace of manual slicing, for instance, is particularly beneficial for delicate vegetables or fruits.

Electric slicers, conversely, rapidly execute slicing tasks, ideal for high-volume production. They are significantly faster and more efficient in tasks such as slicing large quantities of prepped ingredients, like potatoes or tomatoes, for commercial use.

Cost-Effectiveness

Manual food slicers typically present a more budget-friendly option than electric models. The lower initial investment can be a significant factor for individuals or small businesses. However, the long-term cost-effectiveness of manual versus electric depends on the volume of usage. For occasional home use, the lower initial cost of a manual slicer might outweigh the long-term benefits of an electric slicer.

For restaurants or large-scale catering, the electric slicer’s speed and efficiency may result in cost savings in the long run by reducing labor time.

Space Requirements and Portability

Manual slicers, generally smaller and more compact, are easier to store and transport than electric models. This portability makes them a convenient choice for home kitchens or smaller food service operations. Electric slicers, with their motors and components, often require more space and are less portable, making them better suited for fixed locations. A large commercial kitchen might readily accommodate an electric slicer, while a home cook might prefer the portability of a manual option.

Comparison Table

| Feature | Manual Slicer | Electric Slicer |

|---|---|---|

| Speed | Slow, allowing for precise control | Fast, ideal for high-volume tasks |

| Cost | Lower initial investment | Higher initial investment |

| Space Requirements | Compact and space-saving | Larger footprint |

| Portability | Highly portable | Less portable |

| Control | Greater user control over slicing | Less user control, more automated |

| Maintenance | Simple, often requiring minimal upkeep | Potentially more complex maintenance, depending on the model |

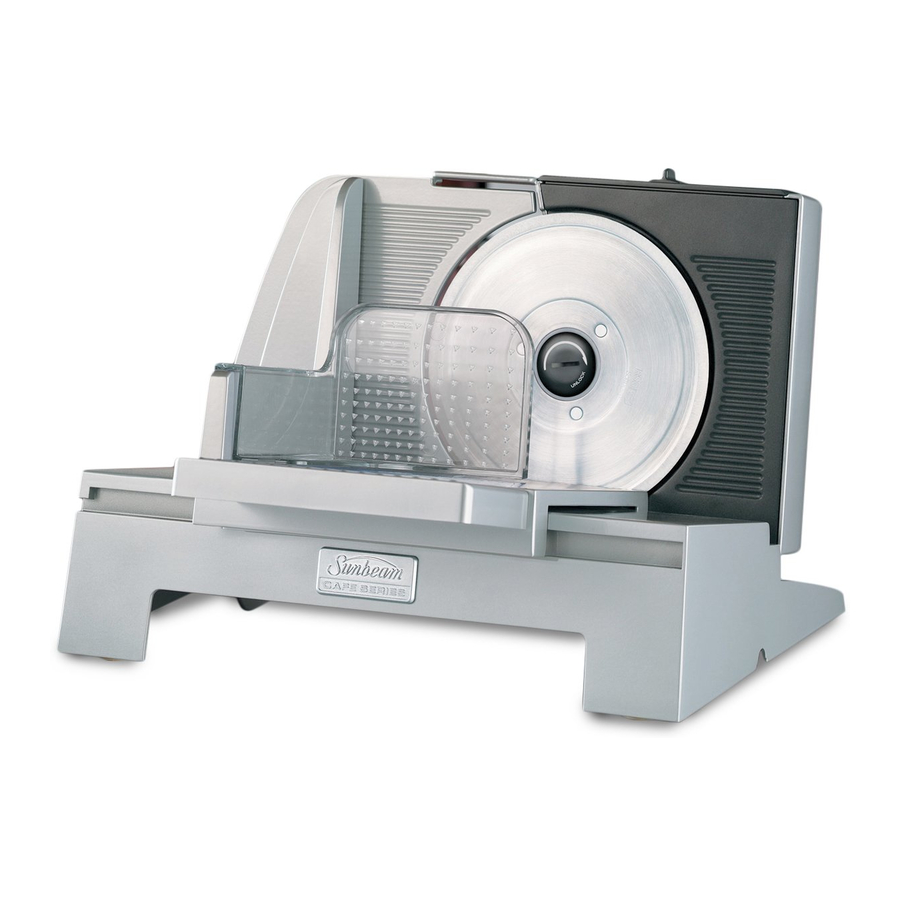

Illustrative Examples of Manual Food Slicers

Manual food slicers offer a diverse range of models, each tailored for specific culinary needs. From simple, hand-cranked models to more sophisticated, adjustable designs, these tools provide a precise and controlled slicing experience. Understanding the variations in blade types and functionalities is key to choosing the right slicer for your tasks.These manual slicers provide a practical alternative to electric models, especially in situations where portability, ease of storage, or lower cost are priorities.

Their effectiveness in achieving consistent slices, often exceeding the capabilities of some electric counterparts for certain food types, makes them a valuable tool in any kitchen.

Types of Manual Food Slicers

Manual food slicers vary in their construction, blade types, and functionalities. This variety allows for a suitable slicer for nearly any food preparation task. These tools cater to a range of needs and culinary preferences.

- The Basic Hand-Crank Slicer: This model typically features a simple hand crank mechanism to rotate the blade. The design is straightforward and easy to operate, ideal for beginners. The hand crank, positioned for comfortable grip, rotates the blade through the food. The simplicity and ease of use make this model suitable for tasks requiring consistent but not complex cuts.

These are generally compact and lightweight, making them portable and ideal for smaller kitchens or for use in the field. The blade design is generally a single, fixed blade for a relatively flat cut. Best suited for slicing softer vegetables and fruits.

- The Adjustable Slicer: This model typically includes an adjustable blade height or a variety of interchangeable blades, allowing for different slicing thicknesses. This allows for precision cuts, ensuring consistent thickness for different dishes. The blade is positioned on a sliding mechanism, permitting adjustment of the slicing depth. This feature makes it suitable for a wide range of food types, including vegetables, fruits, and cheeses.

This model offers greater versatility and control in achieving consistent cuts across different food items.

- The Rocking Slicer: This type features a rocking or reciprocating blade motion. The back and forth movement of the blade creates a slicing action. This mechanism is generally more efficient for slicing thicker pieces of food. The rocking action of the blade facilitates a clean cut, especially for tougher foods. It is particularly suited for slicing larger vegetables or meats.

Blade Designs and Their Functions

The blade design significantly impacts the slicer’s performance and the quality of the cut.

- Straight Blades: These blades provide consistent, flat cuts, ideal for slicing soft produce like tomatoes, cucumbers, and fruits. The simple, straight edge ensures a consistent slicing thickness. The predictable nature of the cut makes this a useful tool for consistent presentation of food items. Ideal for basic slicing and dicing operations.

- Serrated Blades: These blades feature a serrated edge, designed to grip and slice through tougher foods like bread, cakes, and certain cheeses. The serrated design helps to prevent the food from slipping during the slicing process. The serrated edge allows for a more controlled slicing action on these foods.

- Knife-like Blades: These blades are designed with a sharpened edge, creating a fine slicing effect. The sharp edges of the blade allow for thin and even slices, ideal for delicate foods and creating precise decorative cuts. These blades are commonly used for slicing meats and creating decorative garnishes.

Food Suitability for Different Manual Slicers

The choice of slicer often depends on the type of food being sliced.

| Slicer Type | Best Suited Foods |

|---|---|

| Basic Hand-Crank Slicer | Soft vegetables (tomatoes, cucumbers, zucchini), fruits (apples, pears), cheese |

| Adjustable Slicer | Wide range of vegetables and fruits, cheeses, bread (with appropriate blade), meats |

| Rocking Slicer | Vegetables (potatoes, carrots), meats (certain cuts), tougher fruits |

Wrap-Up

In conclusion, manual food slicers remain a vital tool for both home cooks and professional chefs. Their enduring appeal lies in their precision, durability, and the ability to add a touch of artistry to culinary creations. While electric slicers offer speed, the tactile experience and unique charm of manual slicers make them a valuable asset for any kitchen.