Alright, buckle up, because we’re diving headfirst into the world of food safe acrylic sealer! This stuff is the unsung hero of your kitchen, the silent guardian of your grub. We’re talking about the stuff that keeps your countertops, cutting boards, and even your food storage containers safe from nasty stuff while looking totally awesome. Think of it as a shield, a force field, but for your food!

We’ll break down what makes these sealers tick, from their superpowers (chemical resistance, durability – you name it!) to how they’re made. We’ll cover the ins and outs of application, curing, and keeping things sparkling clean. Plus, we’ll dish on the latest trends and what the future holds for keeping your food safe and stylish.

Introduction to Food Safe Acrylic Sealers

Imagine a world where the art of culinary creation and the safety of what we consume intertwine seamlessly. Food-safe acrylic sealers are the unsung heroes in this narrative, acting as a protective barrier that safeguards both the aesthetic appeal and the hygienic integrity of food-related surfaces. These specialized coatings are designed to create a non-toxic, durable, and often glossy finish, ensuring that food contact surfaces remain safe and beautiful.

Definition and Primary Function

Food-safe acrylic sealers are essentially clear coatings formulated with specific resins and additives that are certified as safe for contact with food. Their primary function is to provide a protective layer that prevents the migration of potentially harmful substances from the underlying material into the food. This protective barrier also serves to enhance the durability, water resistance, and aesthetic qualities of the surface it’s applied to.

They’re typically applied to wooden surfaces, concrete, and other materials commonly used in food preparation and serving.

Common Applications

The versatility of food-safe acrylic sealers makes them indispensable in a variety of settings. Their use is widespread, particularly in areas where direct or indirect contact with food is prevalent.

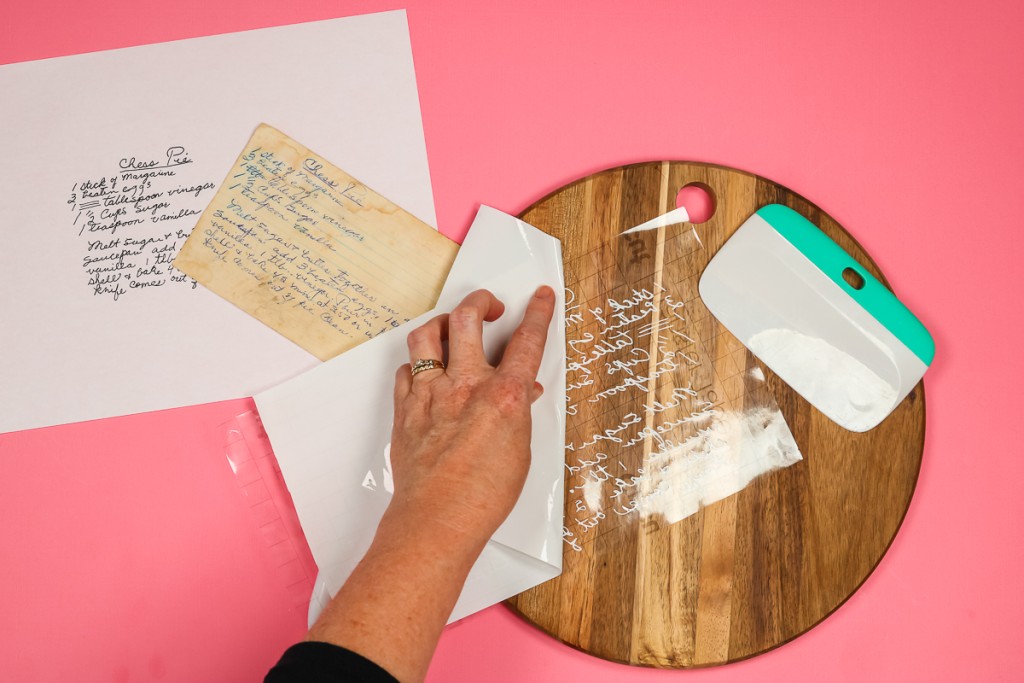

- Wooden Cutting Boards: Sealing cutting boards with food-safe acrylic helps prevent bacteria from penetrating the wood, making them easier to clean and more sanitary. A well-sealed board also resists staining and warping.

- Serving Trays and Platters: These sealers create a non-porous surface on serving pieces, preventing food from seeping into the material and making cleanup effortless. This is particularly crucial for items like cheese boards or charcuterie platters.

- Countertops and Table Tops: In restaurants and home kitchens, food-safe sealers protect countertops and tables from spills, stains, and wear and tear, ensuring longevity and ease of maintenance. The sealer’s glossy finish also enhances the overall aesthetic appeal.

- Decorative Food Displays: For decorative elements in food displays, such as cake stands or pedestals, food-safe sealers ensure that the aesthetics of the display don’t compromise the safety of the food. This is vital for bakeries and other food establishments.

- Food-Grade Epoxy Coatings: In some instances, food-safe acrylic sealers are used as a topcoat over food-grade epoxy resin. This combination provides exceptional durability and water resistance, ideal for surfaces subjected to heavy use.

Importance of Food-Safe Materials

The significance of utilizing food-safe materials cannot be overstated. The health and well-being of consumers are paramount, and the materials used in food preparation and service play a crucial role in maintaining safety standards.

“Food safety is a scientific discipline describing handling, preparation, and storage of food in ways that prevent foodborne illness.”

Choosing food-safe sealers is an essential step in preventing the contamination of food with harmful chemicals or bacteria. This is not only a matter of compliance with regulations but also a commitment to consumer health and a responsible approach to food handling practices. Contamination can occur through the migration of chemicals from the surface material into the food. Using a food-safe sealer acts as a barrier, preventing such contamination and upholding the integrity of the food supply.

The Food and Drug Administration (FDA) provides guidelines and regulations regarding the use of food-safe materials, reinforcing the importance of adhering to these standards.

Properties and Characteristics

The essence of a food-safe acrylic sealer lies in its inherent qualities, transforming a mere protective layer into a guardian of both the food and the surface it coats. These characteristics are not merely desirable; they are essential for maintaining the integrity, safety, and longevity of the treated items. Understanding these properties allows for informed choices, ensuring that the sealer performs its intended function without compromising health or performance.

Key Properties of Food-Safe Acrylic Sealers

Food-safe acrylic sealers are defined by a specific set of properties that set them apart from their non-food-safe counterparts. These properties are meticulously engineered to meet stringent requirements, ensuring that the sealer interacts safely with food and its surrounding environment.

- Chemical Resistance: The ability to withstand exposure to a wide range of substances, including acids, bases, solvents, and cleaning agents, is paramount. This resistance prevents the sealer from degrading or dissolving when it comes into contact with food or cleaning products. The chemical resistance also ensures that the sealer does not leach harmful chemicals into the food. For instance, a food-safe acrylic sealer used on a wooden cutting board must resist the acids in citrus fruits and the harsh chemicals in dish soap.

- Durability: Food-safe sealers must be robust enough to withstand the wear and tear of daily use, including abrasion, scratching, and impact. This durability ensures that the protective layer remains intact, preventing food from coming into direct contact with the underlying surface. A sealer applied to a countertop, for example, needs to resist scratches from utensils and the impact of dropped objects.

- Non-Toxicity: The most critical property is the absence of harmful substances. Food-safe sealers are formulated without ingredients that could leach into food and pose a health risk. This includes the absence of volatile organic compounds (VOCs), heavy metals, and other potentially toxic chemicals. The formulation must adhere to strict regulations, such as those set by the FDA in the United States, which specifies the types of materials and the maximum allowable levels of any potentially migrating substances.

- Water Resistance: The sealer must effectively repel water and moisture to prevent the growth of mold, mildew, and bacteria. This property is crucial in environments where food and moisture are frequently present. For example, a sealer applied to a wooden serving platter must prevent water absorption from spilled liquids.

- Adhesion: The sealer must adhere strongly to the substrate it is applied to, whether it is wood, metal, or another material. This adhesion ensures that the sealer remains in place and provides continuous protection. Poor adhesion can lead to peeling, cracking, and ultimately, a compromised protective layer.

- Flexibility: The ability to withstand minor movements and temperature changes without cracking or peeling is vital. This flexibility prevents the sealer from becoming brittle and failing prematurely. A sealer applied to a wooden surface, for example, must be able to accommodate the natural expansion and contraction of the wood.

Differences Between Food-Safe and Non-Food-Safe Acrylic Sealers

The fundamental difference between food-safe and non-food-safe acrylic sealers lies in their composition and intended use. While both types of sealers share some common characteristics, their formulations are distinct, reflecting their specific applications and the regulatory requirements they must meet.

The table below highlights the key distinctions:

| Feature | Food-Safe Acrylic Sealer | Non-Food-Safe Acrylic Sealer |

|---|---|---|

| Chemical Composition | Formulated with ingredients approved for food contact, typically compliant with FDA regulations. | May contain ingredients not suitable for food contact, such as certain solvents, pigments, and additives. |

| Toxicity | Non-toxic and free from harmful substances that could leach into food. | May contain toxic substances that could pose a health risk if they come into contact with food. |

| Regulations | Subject to stringent regulations and testing to ensure safety for food contact. | May not be subject to the same level of regulatory scrutiny. |

| Applications | Specifically designed for use on surfaces that come into contact with food, such as countertops, cutting boards, and serving dishes. | Intended for non-food contact applications, such as furniture, decorative items, and industrial coatings. |

| Cost | Often more expensive due to the use of specialized, food-grade ingredients and rigorous testing. | Generally less expensive due to the use of less expensive materials and less stringent manufacturing processes. |

Factors Affecting Performance and Longevity

The performance and longevity of food-safe acrylic sealers are influenced by several factors, ranging from the application process to the environmental conditions they are exposed to. Understanding these factors is crucial for ensuring the sealer performs as intended and maintains its protective properties over time.

- Surface Preparation: Proper surface preparation is critical for optimal adhesion. The surface must be clean, dry, and free of any contaminants, such as dust, grease, or old coatings. Sanding the surface to create a slightly rough texture can improve adhesion.

- Application Technique: Following the manufacturer’s instructions for application is essential. This includes using the correct application method (e.g., brushing, spraying), applying the sealer in the recommended number of coats, and allowing sufficient drying time between coats.

- Environmental Conditions: Temperature and humidity can affect the drying and curing of the sealer. Applying the sealer within the recommended temperature and humidity range is important for optimal performance. High humidity can slow down the drying process and may affect the final appearance of the coating.

- Exposure to Harsh Chemicals: While food-safe sealers are designed to resist chemicals, prolonged exposure to strong solvents or abrasive cleaners can damage the coating. It is important to use appropriate cleaning agents and avoid harsh chemicals.

- UV Exposure: Prolonged exposure to ultraviolet (UV) light can cause the sealer to degrade and yellow over time. For outdoor applications, using a sealer with UV resistance is recommended.

- Maintenance: Regular cleaning and maintenance can help extend the life of the sealer. Cleaning the surface with mild soap and water and avoiding abrasive cleaners can prevent damage and maintain its protective properties.

Materials and Composition

The heart of any food-safe acrylic sealer lies in its carefully chosen ingredients, each playing a crucial role in achieving the desired properties. Understanding these components is key to appreciating the sealer’s performance and its suitability for contact with food. The formulations are complex, but generally adhere to a principle of using safe, non-toxic materials that meet stringent regulatory requirements, such as those set by the FDA in the United States or similar bodies in other countries.

Typical Ingredients and Components

The foundation of a food-safe acrylic sealer is a combination of acrylic resins, solvents, additives, and pigments. The selection and proportion of these components directly influence the sealer’s performance characteristics, including its adhesion, durability, flexibility, and resistance to moisture and chemicals.* Acrylic Resins: These are the film-forming components, providing the base for the protective coating. Different types of acrylic resins offer varying properties, impacting the sealer’s flexibility, hardness, and resistance to environmental factors.

Solvents

These are used to dissolve the acrylic resins and other components, allowing for easy application and film formation. The solvents evaporate as the sealer dries, leaving behind the protective acrylic film. Food-safe sealers typically use low-VOC (volatile organic compound) solvents to minimize environmental impact and health risks.

Additives

A wide range of additives can be included to enhance specific properties. These can include:

Plasticizers

Increase flexibility and reduce brittleness.

UV Stabilizers

Obtain access to pro 89 dog food to private resources that are additional.

Protect against degradation from sunlight.

Wetting Agents

Improve the flow and leveling of the sealer during application.

Defoamers

Prevent the formation of bubbles during application.

Thickeners

Adjust the viscosity for optimal application properties.

Pigments

Used to add color to the sealer. Food-safe pigments must be carefully selected to ensure they are non-toxic and do not leach into food. They can also provide UV protection.

Crosslinking Agents (in some formulations)

These can be included to increase the durability and chemical resistance of the cured film by creating a more interconnected polymer network.

Different Types of Acrylic Resins

The type of acrylic resin used significantly impacts the performance of the sealer. Several types of acrylic resins are employed in food-safe formulations, each bringing its own strengths and weaknesses.* Thermoplastic Acrylic Resins: These resins are typically used in solvent-based sealers. They form films through the evaporation of the solvent. They offer good adhesion and flexibility, but can be more susceptible to solvents and chemicals than some other types.

Thermosetting Acrylic Resins

These resins often involve a curing process, such as through the addition of a hardener or through heat. This creates a more cross-linked and durable film. They are often used in high-performance sealers that need to withstand harsh conditions.

Acrylic Emulsions (Water-Based)

These are acrylic resins dispersed in water. They are environmentally friendly and have low VOC content. They are generally less resistant to solvents than solvent-based acrylics, but have seen improvements in recent years.

Modified Acrylic Resins

These are acrylic resins that have been chemically altered to enhance specific properties, such as improved adhesion, flexibility, or resistance to certain chemicals. They are often tailored to meet the specific requirements of the application.

Comparison of Acrylic Sealer Formulations

The advantages and disadvantages of different acrylic sealer formulations can be summarized in the following table. It’s important to note that the best choice depends on the specific application and the desired performance characteristics.

| Formulation Type | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Solvent-Based, Thermoplastic Acrylic | Excellent adhesion; good flexibility; relatively easy application. | Higher VOC content; can be sensitive to solvents; potentially slower drying time. | Sealing wooden countertops; protecting artwork on food-contact surfaces; general-purpose sealing. |

| Water-Based, Acrylic Emulsion | Low VOC; environmentally friendly; easy cleanup; typically good flexibility. | Can be less resistant to solvents; potentially lower durability compared to some solvent-based options; drying time may be longer in humid conditions. | Sealing wooden cutting boards; protecting painted surfaces on food-contact items; applications where low odor is critical. |

| Solvent-Based, Thermosetting Acrylic | High durability; excellent chemical resistance; can withstand high temperatures. | May require a catalyst or hardener; often more complex application process; higher cost. | Sealing industrial food processing equipment; high-wear surfaces; applications requiring extreme durability. |

| Modified Acrylic (e.g., with Polyurethane) | Enhanced scratch resistance; improved impact resistance; often good flexibility and adhesion. | May be more expensive; the formulation complexity could be increased. | Sealing floors and countertops that need to resist abrasion and impacts; applications that require enhanced durability. |

Safety and Regulations

The realm of food-safe acrylic sealers, while offering protective and aesthetic benefits, demands meticulous attention to safety and adherence to stringent regulations. Ensuring the health and well-being of consumers is paramount, necessitating a thorough understanding of the standards that govern these materials and the potential hazards associated with their misuse. This section delves into the crucial aspects of safety regulations, potential risks, and methods for verifying the food-safe status of acrylic sealers.

Relevant Safety Standards and Regulations

The production and application of food-safe acrylic sealers are heavily regulated to protect public health. These regulations vary by region but generally aim to ensure that the materials used do not leach harmful substances into food. Compliance with these standards is crucial for manufacturers and applicators alike.

- United States: The Food and Drug Administration (FDA) is the primary regulatory body. The FDA’s regulations are Artikeld in the Code of Federal Regulations (CFR), specifically 21 CFR Part 177. This part details the requirements for polymeric materials, including acrylics, that come into contact with food. Compliance often involves demonstrating that the sealer meets the FDA’s migration limits, meaning that the amount of any substance that can migrate from the sealer into the food is below a specified safe level.

“Materials used in the manufacture of food-contact articles must be safe for their intended use, meaning they must not transfer any substances to food that could be harmful.”

-21 CFR Part 177 (paraphrased). - European Union: The European Food Safety Authority (EFSA) and the European Commission oversee food contact materials. Regulations are established under the framework Regulation (EC) No 1935/2004, which sets out general requirements for all food contact materials, including acrylic sealers. Specific regulations, such as those related to plastic materials (Regulation (EU) No 10/2011), provide detailed requirements for the composition, migration limits, and testing of these materials.

The EU system often employs a positive list approach, where only substances specifically authorized for use in food contact materials are permitted.

- Other Regions: Other countries and regions, such as Canada, Australia, and Japan, have their own regulatory bodies and standards, which often align with or reference those of the FDA and EU. Manufacturers intending to sell their products in these markets must research and comply with the relevant local regulations.

Potential Hazards Associated with Improper Sealer Use

Improper use of acrylic sealers can pose several health risks. These hazards often arise from the migration of chemicals from the sealer into food.

- Chemical Migration: Unapproved or improperly formulated sealers may contain chemicals that can leach into food. This can lead to chemical contamination, potentially causing acute or chronic health problems. The specific health risks depend on the chemicals involved.

For instance, if a sealer contains residual solvents or unreacted monomers, these substances can migrate into food and pose a risk.

An example would be a sealer containing high levels of a specific monomer that is not fully polymerized; this monomer could then migrate into food and potentially cause allergic reactions or other adverse health effects.

- Allergic Reactions: Some individuals may be allergic to components in acrylic sealers. Contact with sealed food or the sealer itself can trigger allergic reactions, ranging from mild skin irritation to severe anaphylaxis.

- Toxicity: Certain chemicals used in sealers can be toxic if ingested. This can lead to a range of symptoms, from nausea and vomiting to more serious organ damage, depending on the substance and the level of exposure.

- Cross-Contamination: If the sealer is not applied correctly or if it is damaged, it may create crevices that can harbor bacteria or other microorganisms. These microorganisms can then contaminate the food.

Methods for Verifying the Food-Safe Status of an Acrylic Sealer

Verifying the food-safe status of an acrylic sealer is essential to ensure its safe use. Several methods and indicators can provide assurance.

- Reviewing Product Documentation: The most straightforward step is to review the manufacturer’s documentation. This should include a declaration of compliance with relevant regulations, such as the FDA or EU standards. Look for statements confirming the sealer’s suitability for food contact.

For example, a manufacturer might provide a certificate of compliance stating that their sealer meets the requirements of 21 CFR Part 177 or Regulation (EU) No 10/2011.

- Checking for Third-Party Certifications: Reputable manufacturers often obtain certifications from independent testing laboratories. These certifications, such as those from NSF International or similar organizations, verify that the product has been tested and meets specific food-safety standards.

A product certified by NSF would have undergone rigorous testing to confirm that it meets specific food-contact safety requirements.

- Requesting Migration Testing Data: Manufacturers should be able to provide data from migration testing, which shows the levels of substances that migrate from the sealer into food under specific conditions. This data provides direct evidence of the sealer’s compliance with migration limits.

Migration testing involves exposing the sealer to a food simulant (e.g., water, olive oil) under controlled conditions and then analyzing the simulant for the presence of migrating substances.

- Examining the Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS): The MSDS or SDS provides information about the sealer’s composition, potential hazards, and safe handling practices. It can help identify any components that may raise concerns about food safety.

- Consulting with Experts: If there is any doubt about the food-safe status of a sealer, consulting with a food safety expert or a regulatory specialist can provide valuable guidance.

Application Methods and Techniques

The journey of a food-safe acrylic sealer, from its liquid form to a protective, enduring layer, is a delicate dance between preparation and execution. It demands precision and a keen understanding of the materials involved, transforming a simple surface into a canvas of culinary resilience. The following details provide a guide to ensure the sealer performs its crucial role, safeguarding both the integrity of the material and the health of those who will come into contact with it.

Proper Surface Preparation Techniques

Before the embrace of the sealer, the surface must be prepared to receive it. This preparatory stage is not merely a formality but a critical foundation for the sealer’s longevity and effectiveness. Neglecting this step is akin to building a house upon sand; the structure will inevitably falter.The initial step involves meticulous cleaning. Remove any existing debris, dust, grease, or previous coatings that could hinder adhesion.

A gentle scrubbing with a mild detergent and warm water, followed by a thorough rinsing, often suffices. For more stubborn contaminants, a solvent appropriate for the substrate material may be required. Always consult the sealer manufacturer’s guidelines for compatibility.Next, address any imperfections on the surface. Fill any cracks, chips, or holes with a compatible filler, allowing it to dry completely and then sanding it smooth.

This creates a uniform surface, ensuring the sealer applies evenly and prevents the trapping of air bubbles.Sanding, if necessary, is crucial. Lightly sanding the surface creates microscopic “teeth,” enhancing the sealer’s mechanical bond. The grit of the sandpaper should be appropriate for the substrate material. Finer grits are generally used for smoother surfaces, while coarser grits are used for rougher surfaces.

After sanding, remove any sanding dust with a tack cloth or vacuum cleaner.Finally, allow the surface to completely dry. Moisture is the enemy of adhesion, so ensure the surface is entirely dry before proceeding. The time required for drying depends on the material and environmental conditions.

Steps Involved in Applying a Food-Safe Acrylic Sealer

The application process is where the science of surface preparation meets the art of execution. Whether applied by brush or spray, the technique must be precise to achieve a uniform and durable finish. Brushing:Brushing is a classic method, suitable for smaller projects or detailed work.

1. Preparation

Ensure the sealer is thoroughly mixed according to the manufacturer’s instructions. Pour a small amount into a clean container.

2. Application

Dip the brush into the sealer, removing excess by gently tapping it against the edge of the container. Apply the sealer in smooth, even strokes, overlapping each stroke slightly. Avoid excessive brushing, which can introduce air bubbles.

3. Multiple Coats

Allow each coat to dry completely before applying the next, as per the manufacturer’s recommendations. Multiple thin coats are generally preferred over a single thick coat. Spraying:Spraying offers a faster and more uniform application, ideal for larger surfaces.

1. Preparation

Prepare the sealer according to the manufacturer’s instructions. Ensure proper ventilation and wear appropriate respiratory protection.

2. Equipment Setup

Adjust the spray gun’s settings to achieve a consistent spray pattern. The specific settings will vary depending on the gun type and the sealer’s viscosity.

3. Application

Hold the spray gun at a consistent distance from the surface, moving it in a smooth, even motion. Overlap each pass slightly to ensure complete coverage.

4. Multiple Coats

Allow each coat to dry completely before applying the next, following the manufacturer’s instructions.

Best Practices for Achieving a Smooth and Even Finish

Achieving a flawless finish is the ultimate goal. The following practices will help to ensure the sealer performs at its best, creating a surface that is both beautiful and functional.

- Temperature and Humidity: Apply the sealer within the recommended temperature and humidity range specified by the manufacturer. Extreme conditions can affect drying time and the final finish.

- Thin Coats: Apply multiple thin coats rather than a single thick coat. This minimizes the risk of runs, drips, and uneven coverage.

- Proper Ventilation: Ensure adequate ventilation to allow the sealer to dry properly and to dissipate fumes.

- Dust Control: Minimize dust exposure during application and drying. Dust particles can contaminate the finish, creating imperfections.

- Consistent Technique: Maintain a consistent brushing or spraying technique throughout the application process. Varying the technique can lead to an uneven finish.

- Drying Time: Allow each coat to dry completely before applying the next, as specified by the manufacturer. Premature application can lead to adhesion problems and an uneven finish.

- Storage: Store the sealer properly to maintain its quality. Keep it in a tightly sealed container, away from extreme temperatures and direct sunlight.

Curing and Drying Process

The transformation of a food-safe acrylic sealer from a liquid or semi-liquid state to a solid, protective film is a delicate dance of chemical reactions and environmental influences. Understanding this process, known as curing and drying, is paramount to achieving the desired performance and ensuring the safety of the treated surface. It is a crucial step that determines the sealer’s durability, resistance to various elements, and, most importantly, its suitability for contact with food.

The Curing Process Explained

Curing, in the context of acrylic sealers, is a process where the sealer undergoes a chemical reaction, typically involving the cross-linking of polymer chains. This cross-linking creates a three-dimensional network that solidifies the sealer and gives it its desired properties. The curing process isn’t merely a matter of drying; it’s a transformation driven by chemical reactions. These reactions can be triggered by various factors, including the evaporation of solvents (in solvent-based sealers), the reaction with atmospheric moisture (in water-based sealers), or the presence of catalysts.

This complex interplay ultimately results in a robust, protective barrier.

Factors Influencing Curing Time

Several environmental factors can significantly impact the curing time of food-safe acrylic sealers. Understanding these factors is critical for proper application and achieving optimal results.

- Temperature: Warmer temperatures generally accelerate the curing process, while colder temperatures slow it down. Most sealers have a recommended temperature range for optimal curing. Applying the sealer outside of this range can lead to incomplete curing or other problems. For instance, a sealer might cure in 24 hours at 25°C (77°F), but take 48 hours or longer at 10°C (50°F).

- Humidity: Humidity plays a vital role, especially for water-based sealers. High humidity can slow down the evaporation of water, thus extending the curing time. Conversely, extremely low humidity can cause the sealer to dry too quickly, potentially leading to surface imperfections.

- Airflow: Adequate airflow facilitates the evaporation of solvents and moisture, accelerating the curing process. Poor ventilation can trap solvents and moisture, prolonging the curing time and potentially affecting the sealer’s final properties.

- Sealer Type: Different types of acrylic sealers have different curing mechanisms and, therefore, varying curing times. Solvent-based sealers might cure faster than water-based ones due to the faster evaporation of solvents.

- Film Thickness: The thickness of the applied sealer film also influences the curing time. Thicker coats will naturally take longer to cure than thinner ones, as the solvents or moisture have further to travel to escape.

Tips for Ensuring Proper Curing

To ensure the food-safe acrylic sealer cures correctly and achieves its intended protective qualities, follow these guidelines:

- Follow Manufacturer’s Instructions: The manufacturer’s instructions provide specific guidelines for the product, including recommended temperature, humidity, and application techniques. Adhering to these instructions is paramount.

- Maintain Optimal Temperature and Humidity: Ensure the application area is within the recommended temperature and humidity range. If necessary, use climate control systems like heaters, dehumidifiers, or air conditioners.

- Ensure Adequate Ventilation: Provide adequate airflow to facilitate solvent or moisture evaporation. This can be achieved through natural ventilation (opening windows and doors) or mechanical ventilation (using fans).

- Apply Thin, Even Coats: Applying thin, even coats is crucial. Thick coats can lead to uneven curing, surface imperfections, and prolonged curing times. Multiple thin coats, with appropriate drying time between each, are generally preferred.

- Allow Sufficient Drying Time: Allow the sealer to cure completely before exposing the surface to food or other elements. The manufacturer’s instructions will provide the recommended curing time. Rushing this process can compromise the sealer’s performance and potentially pose safety risks.

- Avoid Contamination: Protect the freshly applied sealer from dust, dirt, and other contaminants during the curing process. These contaminants can become trapped in the film and affect its appearance and performance.

- Inspect the Cured Surface: Once the sealer has cured, inspect the surface for any imperfections, such as pinholes, bubbles, or unevenness. If any issues are found, address them according to the manufacturer’s recommendations.

Maintenance and Cleaning

The gentle caress of a food-safe acrylic sealer on your surfaces is a promise of enduring beauty and hygiene. Yet, like all things crafted with care, it requires mindful attention to retain its luster and ensure its longevity. Proper maintenance and cleaning are not merely tasks; they are acts of preservation, safeguarding the integrity of the sealed surface and the well-being of those who come into contact with it.

Neglecting these practices can lead to diminished performance, aesthetic degradation, and even potential health hazards.

Recommended Cleaning Procedures

The essence of maintaining a food-safe acrylic sealed surface lies in gentle yet effective cleaning. Harsh abrasives and aggressive chemicals can erode the protective layer, leaving the surface vulnerable. The following procedures, practiced with regularity, will ensure its enduring beauty and functionality:A soft cloth, dampened with warm water, is your primary ally. Begin by gently wiping the surface to remove loose debris.

For more stubborn stains or residues, the addition of a mild soap solution is permissible.* Gentle Wiping: Employ a soft, non-abrasive cloth, such as microfiber, to wipe the surface. Avoid excessive pressure, which can scratch the acrylic sealer. Wipe in a consistent direction to prevent streaks.* Mild Soap Solution: Prepare a solution of mild, pH-neutral soap and warm water.

Dilution is key; follow the soap manufacturer’s instructions. Apply the solution to the cloth and gently wipe the affected area.* Rinsing: After cleaning, rinse the surface thoroughly with clean, warm water to remove any soap residue. Ensure all traces of soap are eliminated to prevent dulling or stickiness.* Drying: Dry the surface immediately with a clean, soft cloth.

This prevents water spots and ensures a streak-free finish.* Frequency: The frequency of cleaning depends on usage and exposure. Surfaces used daily, such as countertops, should be cleaned after each use. Less frequently used surfaces may require cleaning weekly or as needed.

Safe Cleaning Agents

Choosing the right cleaning agents is paramount to preserving the integrity of the food-safe acrylic sealer. The following options are safe and effective:* Mild Soap: pH-neutral soaps are gentle and effective at removing grease and grime without damaging the sealant.

Warm Water

Warm water is a universal solvent that aids in cleaning and rinsing.

Vinegar Solution

A diluted solution of white vinegar (e.g., one part vinegar to one part water) can be used for disinfecting and removing hard water stains. Be sure to rinse thoroughly afterward.

Specific Acrylic Cleaners

Commercially available acrylic cleaners are specifically formulated for these surfaces. They are designed to be gentle and effective. Always follow the manufacturer’s instructions.Avoid using abrasive cleaners, harsh chemicals, or solvents, as these can damage the acrylic sealer.

Potential Issues and Resolutions

Even with diligent care, issues can arise. Understanding these potential problems and their solutions is crucial for maintaining the surface’s beauty and functionality:* Staining: Food spills, especially those containing dyes, can stain the surface. Address stains promptly.

Resolution

Blot the stain immediately with a clean, damp cloth. Avoid rubbing, which can spread the stain. For stubborn stains, use a mild soap solution or a specialized acrylic cleaner.* Scratching: Abrasive cleaning tools or objects can scratch the surface.

Resolution

Avoid using abrasive cleaners, scrub brushes, or scouring pads. Use only soft cloths and gentle cleaning techniques. If scratches occur, minor scratches can sometimes be buffed out with a plastic polish specifically designed for acrylics.* Clouding/Dulling: The use of harsh chemicals or the buildup of soap residue can cause clouding or dulling.

Resolution

Rinse the surface thoroughly after cleaning to remove soap residue. Avoid harsh chemicals. If clouding occurs, try using a specialized acrylic cleaner or polish to restore the shine.* Water Spots: Hard water can leave mineral deposits that create water spots.

Resolution

Dry the surface immediately after cleaning to prevent water spots. Use a vinegar solution to remove existing water spots, and rinse thoroughly.* Chemical Damage: Exposure to harsh chemicals can degrade the sealer.

Resolution

Immediately wipe up any spills of harsh chemicals. Avoid using harsh cleaning agents. If damage occurs, the surface may require professional repair or reapplication of the sealer.

Common Uses and Applications: Food Safe Acrylic Sealer

Food-safe acrylic sealers, with their unique properties, have become indispensable in various applications where direct contact with food is a concern. Their ability to provide a protective, non-toxic barrier makes them ideal for surfaces and containers that come into contact with consumables. This section explores the practical uses of these sealers, highlighting their versatility and importance in maintaining food safety and hygiene.

Kitchen Countertops

Kitchen countertops are frequently exposed to moisture, spills, and the wear and tear of daily food preparation. Food-safe acrylic sealers offer a robust solution for protecting these surfaces.Countertops sealed with food-safe acrylic provide a non-porous surface. This means liquids and food particles cannot penetrate the material, which is essential in preventing bacterial growth and contamination. This characteristic is especially crucial in kitchens, where hygiene is paramount.

- Enhanced Durability: The sealer forms a protective layer that resists scratches, stains, and abrasion, extending the lifespan of the countertop.

- Easy Cleaning: The smooth, non-porous surface is easy to wipe clean, simplifying the process of maintaining a hygienic kitchen environment. Regular cleaning with mild soap and water is usually sufficient.

- Versatile Application: Food-safe acrylic sealers can be applied to various countertop materials, including concrete, wood, and certain types of stone, allowing for a wide range of design choices.

- Aesthetic Appeal: Sealers can be clear or tinted, allowing the natural beauty of the countertop material to shine through or enhancing the color with a desired hue.

Food Storage Containers

Food storage containers benefit significantly from the application of food-safe acrylic sealers, especially those made from materials that are prone to degradation or leaching.Sealed containers offer a safe and effective way to store a variety of food items, from leftovers to dry goods. The sealer acts as a barrier between the food and the container material, preventing the migration of potentially harmful substances.

- Preventing Leaching: For containers made from materials like certain plastics, the sealer prevents the leaching of chemicals into the food, ensuring its safety.

- Airtight Seal: The sealer can help create a more airtight seal, especially when used in conjunction with lids, extending the shelf life of food by reducing exposure to air and moisture.

- Odor Resistance: The sealer helps prevent odors from being absorbed into the container material, keeping the containers fresh and easy to clean.

- Durability: Sealed containers are more resistant to damage from impacts, scratches, and other wear and tear, making them more long-lasting.

Food Preparation Surfaces and Cutting Boards

Food preparation surfaces, including cutting boards, are direct contact points for food. Food-safe acrylic sealers provide a safe and hygienic solution for these essential kitchen tools.Cutting boards, in particular, are susceptible to cuts and scratches that can harbor bacteria. A food-safe acrylic sealer provides a protective layer that helps mitigate this risk.

- Sealing Wood Cutting Boards: Wooden cutting boards are popular but porous, making them prone to absorbing moisture and harboring bacteria. Sealing them with a food-safe acrylic sealer creates a non-porous surface, preventing bacterial growth and making cleaning easier. The sealer should be reapplied periodically as needed.

- Protecting Food Preparation Surfaces: Applying a food-safe acrylic sealer to other food preparation surfaces, such as butcher block countertops or work tables, enhances their durability and hygiene. This is especially beneficial in commercial kitchens where surfaces are subject to heavy use.

- Enhancing Hygiene: The sealer’s non-porous nature prevents the absorption of food particles and liquids, reducing the risk of cross-contamination and making cleaning and sanitizing more effective.

- Durability and Longevity: The sealer protects the surface from scratches, stains, and moisture damage, extending the life of the cutting board or preparation surface.

Choosing the Right Sealer

The selection of a food-safe acrylic sealer is a crucial step in ensuring the safety and longevity of any project involving food contact. The market offers a diverse range of products, each with unique properties and applications. Understanding the factors influencing this choice, alongside a comparative analysis of available brands, will empower you to make an informed decision that aligns with your specific needs.

Factors to Consider for Selection

Several key factors influence the choice of a food-safe acrylic sealer. Prioritizing these aspects ensures that the sealer not only protects the substrate but also maintains the integrity of the food it comes into contact with.

- Food Contact Regulations Compliance: Confirm that the sealer complies with relevant food contact regulations, such as those established by the FDA in the United States or similar bodies in other regions. The product label should clearly indicate its compliance.

- Application Method Suitability: Consider the application method. Some sealers are suitable for brushing, spraying, or dipping. The chosen method should align with the project’s size, shape, and material.

- Durability and Abrasion Resistance: Assess the sealer’s durability and resistance to abrasion, particularly for surfaces that will experience frequent use or cleaning. High durability extends the lifespan of the sealed item.

- Chemical Resistance: Evaluate the sealer’s resistance to common food acids, oils, and cleaning agents. This is critical to prevent degradation and ensure food safety.

- Appearance and Aesthetics: Consider the desired aesthetic outcome. Sealers are available in various finishes, including clear, matte, satin, and gloss. Choose the finish that complements the project’s design.

- Ease of Application and Drying Time: Opt for a sealer that is relatively easy to apply and has a reasonable drying time. This simplifies the application process and minimizes downtime.

- Substrate Compatibility: Ensure that the sealer is compatible with the substrate material. Some sealers are designed for specific materials, such as wood, metal, or plastic.

Comparative Analysis of Food-Safe Acrylic Sealers

The market offers various brands of food-safe acrylic sealers. A comparative analysis of these products helps in identifying the most suitable option based on specific requirements. The following table provides a comparison of several popular brands, highlighting their key properties and features.

| Brand | Key Features | Application Methods | Compliance | Typical Uses |

|---|---|---|---|---|

| Brand A | Excellent clarity, high gloss finish, good abrasion resistance. | Brush, spray | FDA compliant | Wooden cutting boards, serving trays, countertops |

| Brand B | Matte finish, good chemical resistance, easy to clean. | Brush, dip | FDA compliant | Food storage containers, bowls, decorative items |

| Brand C | Fast drying, good adhesion to various substrates, versatile. | Spray | FDA compliant | Platters, utensils, custom projects |

| Brand D | Low VOC, eco-friendly, satin finish, good scratch resistance. | Brush, spray | FDA compliant | Food-grade packaging, decorative elements |

Troubleshooting and Problem Solving

Even the most carefully applied food-safe acrylic sealer can encounter issues. These problems can range from minor aesthetic imperfections to more significant functional failures. Understanding common issues and how to address them is crucial for ensuring the longevity and safety of your sealed surfaces. This section offers guidance on identifying and resolving these challenges, along with methods for repairing minor damage.

Common Application Problems

Several issues can arise during the application of food-safe acrylic sealers, often stemming from environmental factors, improper surface preparation, or incorrect application techniques. Recognizing these problems early on allows for timely intervention and prevents more serious damage.

- Bubbling: Bubbles trapped within the sealer during application are a frequent issue. This can result in an uneven surface and compromise the sealer’s protective properties.

- Causes: Trapped air due to rapid application, applying the sealer in excessively thick coats, or applying over a porous surface without proper priming.

- Solutions: Apply the sealer in thinner, more even coats, allowing each coat to dry sufficiently before applying the next. Use a high-quality brush or applicator designed to minimize air entrapment. For porous surfaces, apply a primer specifically designed for acrylic sealers before applying the sealer itself.

- Peeling: The sealer detaching from the substrate, often along edges or in larger sheets. This can expose the underlying surface to potential contamination.

- Causes: Inadequate surface preparation (e.g., not cleaning the surface properly), applying the sealer to a surface that is not completely dry, or using incompatible materials.

- Solutions: Thoroughly clean and prepare the surface according to the manufacturer’s instructions. Ensure the surface is completely dry before application. If the surface has been previously sealed, consider lightly sanding it to improve adhesion. Test the sealer’s compatibility with the substrate in an inconspicuous area before full application.

- Cracking: The formation of hairline fractures in the cured sealer, compromising its integrity and potentially allowing moisture and contaminants to penetrate.

- Causes: Applying the sealer in excessively thick coats, temperature fluctuations during curing, or using a sealer that is not flexible enough for the substrate’s movements.

- Solutions: Apply the sealer in multiple thin coats rather than one thick coat. Control the environmental conditions during curing, avoiding extreme temperatures or rapid temperature changes. Choose a sealer with the appropriate flexibility for the specific application.

- Cloudiness or Whitening: The sealer appearing opaque or milky instead of clear. This can affect the aesthetic appearance of the sealed surface.

- Causes: Moisture trapped during the curing process, applying the sealer in high humidity, or using a sealer that is not fully compatible with the substrate.

- Solutions: Apply the sealer in a dry environment. Ensure the surface is completely dry before application. Allow the sealer to cure fully in a well-ventilated area. Consider the specific environmental conditions when selecting a sealer, choosing one designed for high-humidity environments if necessary.

Addressing Cured Sealer Issues

Even after the sealer has fully cured, problems can still arise. These issues may be due to wear and tear, accidental damage, or exposure to harsh chemicals. Knowing how to address these problems can extend the life of the sealed surface.

- Minor Scratches: Superficial marks that don’t penetrate deeply into the sealer but can detract from its appearance.

- Solutions: Lightly buff the scratched area with a fine-grit abrasive pad or polishing compound specifically designed for acrylic surfaces. Always follow the manufacturer’s instructions for the polishing compound. For deeper scratches, consider a professional repair.

- Stains: Discoloration caused by food spills or other substances that penetrate the sealer.

- Solutions: Immediately clean spills with a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, which can damage the sealer. For stubborn stains, try a specialized acrylic cleaner, but test it in an inconspicuous area first.

- Chips or Small Cracks: Small areas where the sealer has broken away, potentially exposing the underlying surface.

- Solutions: Clean the damaged area thoroughly. Fill the chip or crack with a food-safe acrylic filler or a compatible sealant, ensuring it is flush with the surrounding surface. Allow the filler to cure completely, then sand smooth and polish if necessary.

Repairing Minor Damage

Small imperfections can often be repaired, restoring the functionality and aesthetics of the sealed surface. The following steps provide a general guideline.

- Preparation: Clean the damaged area thoroughly, removing any loose debris or contaminants. Lightly sand the area around the damage to create a better surface for adhesion.

- Application: Apply a food-safe acrylic filler or compatible sealant to the damaged area, ensuring it is slightly overfilled.

- Curing: Allow the filler or sealant to cure completely, following the manufacturer’s instructions.

- Finishing: Once cured, sand the repaired area smooth, feathering the edges to blend with the surrounding surface. Polish the area to restore its original shine.

Alternatives to Acrylic Sealers

The quest for food-safe surfaces extends beyond acrylic sealers, encompassing a diverse array of materials and techniques. These alternatives offer distinct advantages and disadvantages, often catering to specific needs or preferences. Understanding these options allows for a more informed decision when choosing the best method to protect and preserve food-contact surfaces.

Other Food-Safe Sealing Options

Beyond acrylics, several other materials can be used to create food-safe seals. These options often stem from natural sources or are engineered for specific purposes. They each possess unique properties affecting their application and suitability for various scenarios.

- Mineral Oil: A simple and readily available option, mineral oil is derived from petroleum. It’s commonly used on wooden cutting boards and utensils.

- Beeswax: Beeswax, a natural product of honeybees, provides a water-resistant barrier. It’s often combined with other oils to create a food-safe sealant.

- Linseed Oil (Food-Grade): Derived from flax seeds, food-grade linseed oil is a penetrating oil that hardens over time, creating a durable, protective finish.

- Epoxy Resin (Food-Safe): Certain epoxy resins, specifically formulated for food contact, offer a robust and chemically resistant seal.

- Shellac (Food-Grade): Shellac, derived from the lac insect, is a natural resin that can be dissolved in alcohol to create a hard, glossy finish.

Comparison of Sealing Methods, Food safe acrylic sealer

Each sealing method possesses a unique set of characteristics. This comparison considers factors such as durability, ease of application, cost, and specific application suitability.

Acrylic Sealers vs. Alternatives: A Comparative Overview

Property Acrylic Sealers Mineral Oil Beeswax Linseed Oil (Food-Grade) Food-Safe Epoxy Resin Food-Grade Shellac Durability Good, resistant to scratches and chemicals. Low, requires frequent reapplication. Moderate, depends on the beeswax mixture. High, forms a hard, durable finish. Very High, highly resistant to chemicals and abrasion. Moderate, susceptible to heat and moisture. Ease of Application Relatively easy, spray or brush application. Very easy, wipe-on application. Easy, often applied with a cloth. Moderate, requires careful application and ventilation. Moderate, requires precise mixing and application. Easy, brush or spray application. Cost Moderate, varies based on the specific formulation. Low, readily available and inexpensive. Moderate, depending on the source and additives. Moderate, generally more expensive than mineral oil. High, due to specialized formulations. Moderate, varies with the grade and source. Food Safety Generally food-safe when properly formulated and cured. Food-safe, but provides limited protection. Food-safe, provides a water-resistant barrier. Food-safe when fully cured. Food-safe when specifically designed for food contact. Food-safe, but not suitable for all applications. Best Use Cases Cutting boards, countertops, and other food-contact surfaces. Wooden cutting boards and utensils. Wooden cutting boards and food storage containers. Wooden surfaces that require a durable finish. Countertops, tables, and surfaces requiring high chemical resistance. Fruits and vegetables for preserving.

Future Trends and Innovations

The horizon of food-safe acrylic sealers shimmers with potential, driven by the relentless pursuit of enhanced safety, sustainability, and performance. Innovation in this field is no longer merely about preserving food; it’s about revolutionizing the entire ecosystem of food production, processing, and consumption, touching everything from farm to table. We are on the cusp of witnessing a paradigm shift, where technology and environmental consciousness converge to create a future where food safety is paramount and the impact on our planet is minimized.

Advancements in Food-Safe Acrylic Sealer Technology

The future of food-safe acrylic sealers promises a landscape of unprecedented innovation, focusing on several key areas. These advancements are not just incremental improvements; they represent a fundamental reimagining of the material’s capabilities and its role in the food industry.

- Self-Healing Properties: Imagine a sealer that can mend minor scratches and imperfections on its own. Research is actively exploring the incorporation of microcapsules containing healing agents. When damage occurs, these capsules rupture, releasing the agent to fill the gaps and restore the protective barrier. This self-healing capability would dramatically extend the lifespan of sealed surfaces, reducing waste and enhancing food safety.

For example, researchers are investigating the use of polymers with embedded microcapsules filled with a reactive monomer. When a scratch occurs, the monomer is released and polymerizes, effectively repairing the damage.

- Smart Sealers with Sensors: The integration of nanotechnology is leading to the development of “smart” sealers equipped with embedded sensors. These sensors could detect the presence of bacteria, changes in temperature or humidity, or the breakdown of the sealer itself. The information could be relayed wirelessly to a monitoring system, providing real-time alerts and enabling proactive interventions to prevent food spoilage or contamination.

An example would be a sealer containing nanoparticles that change color in response to the presence of specific pathogens, acting as an early warning system.

- Bio-Based and Biodegradable Formulations: Sustainability is no longer a trend; it’s a necessity. The future demands sealers derived from renewable resources, such as plant-based polymers. Research is focused on creating acrylic sealers from materials like cornstarch, cellulose, and algae. Furthermore, these formulations are being engineered to be biodegradable, breaking down naturally in the environment at the end of their life cycle. This approach minimizes the environmental impact and contributes to a circular economy.

- Enhanced Barrier Properties: Scientists are continually striving to improve the barrier properties of acrylic sealers. This includes creating sealers that are even more resistant to water, oxygen, and other gases that can compromise food quality. This can be achieved by modifying the polymer structure, incorporating nanoparticles, or using multilayered coatings. The goal is to create sealers that provide an even longer shelf life for food products.

Emerging Trends in the Food Safety Industry Related to Sealing Materials

The food safety industry is undergoing a period of rapid transformation, driven by evolving consumer demands, stricter regulations, and technological advancements. Sealing materials are at the forefront of these changes, playing a crucial role in safeguarding food products.

- Traceability and Transparency: Consumers are increasingly demanding to know where their food comes from and how it is processed. This trend is driving the adoption of sealing materials that can be integrated with traceability systems. Sealers may incorporate unique identifiers, such as QR codes or microchips, that allow for tracking the product’s journey from farm to table.

- Personalized Food Packaging: The rise of personalized nutrition is influencing the packaging industry. Sealers will play a vital role in creating packaging that caters to individual dietary needs and preferences. This could involve sealers that can be customized with specific ingredients or that change color to indicate freshness based on the food’s characteristics.

- Active Packaging: Active packaging is designed to interact with the food product to extend shelf life and enhance safety. Sealers are being developed that can release antimicrobial agents, absorb oxygen, or control moisture levels within the packaging. For instance, sealers containing natural preservatives like essential oils are being explored to inhibit microbial growth.

- Regulatory Compliance: Food safety regulations are becoming increasingly stringent worldwide. This trend necessitates the development of sealers that meet the highest standards of safety and compliance. Manufacturers are investing in research and development to ensure their products meet all relevant requirements and are regularly tested to verify their performance.

Hypothetical Future Application of Food-Safe Acrylic Sealers

Envision a future where food packaging is not just a container but a dynamic, intelligent system. Consider a farmer’s market where fresh produce is sealed using an innovative food-safe acrylic sealer.

- Scenario: Imagine a vibrant display of organically grown strawberries. Each punnet of strawberries is sealed with a clear, flexible acrylic sealer. This sealer is not just a barrier; it’s a “smart” package. Embedded within the sealer are microscopic sensors that constantly monitor the strawberries’ condition. These sensors detect any changes in temperature, humidity, or the presence of spoilage-causing microorganisms.

The sealer also contains micro-reservoirs filled with natural, antimicrobial agents derived from plant extracts.

- Functionality: As the strawberries are placed in the punnet, the sealer begins its work. The sensors immediately begin monitoring the berries. If any signs of spoilage are detected, the sealer releases the antimicrobial agents, slowing down the process. The sealer also includes a small, embedded display that provides real-time information to the consumer. This display shows the freshness of the strawberries, their origin, and the farmer’s information.

The sealer is also designed to be fully biodegradable, breaking down naturally in a compost pile after use.

- Impact: This hypothetical application demonstrates how food-safe acrylic sealers can transform the food industry. It provides:

- Enhanced food safety by proactively preventing spoilage and contamination.

- Extended shelf life, reducing food waste and allowing for longer distribution.

- Increased consumer transparency, building trust and providing valuable information.

- A more sustainable approach to packaging, minimizing environmental impact.

Final Review

So, there you have it: food safe acrylic sealer – the key to a safe, stylish, and totally awesome kitchen. From choosing the right stuff to keeping it clean and looking fresh, you’re now armed with the knowledge to make the best choices. Remember, it’s all about keeping your food safe, your surfaces looking fly, and your kitchen the coolest place in the house.

Now go forth and seal!