Indiana Food Handler Certification isn’t just about rules; it’s a journey of self-awareness, a mindful practice in the art of serving. Imagine your hands as vessels of intention, your actions a dance of care, protecting not just the food but the well-being of every soul you serve. This certification, therefore, is a call to elevate your practice into a sacred duty.

Embarking on this path begins with understanding the essence of food safety regulations in Indiana. It’s a commitment to upholding standards that resonate with the very fabric of health and wellness. From the initial overview to the nuances of specialized training, this exploration unveils the essential steps to obtaining your certificate. It covers the importance of personal hygiene, the prevention of cross-contamination, and the recognition of foodborne illnesses.

Through approved training providers, a clear certification process, and a deep dive into food safety practices, you’ll discover the key to maintaining your certification and reaping its numerous benefits.

Overview of Indiana Food Handler Certification

Food handler certification in Indiana is a crucial element in maintaining public health and safety. It ensures that individuals working with food possess the fundamental knowledge and skills necessary to prevent foodborne illnesses. This certification is mandated across the state, reflecting a commitment to protecting consumers and upholding industry standards.

Purpose of Food Handler Certification in Indiana

The primary purpose of Indiana food handler certification is to educate food service workers about safe food handling practices. This education aims to minimize the risk of foodborne illnesses, which can result from improper food handling, preparation, and storage. The certification program covers various critical areas, including food contamination, personal hygiene, proper cooking temperatures, and cross-contamination prevention. These measures are essential to safeguard the health of the public.

Brief History of Food Safety Regulations in Indiana

Indiana’s food safety regulations have evolved over time, mirroring the increasing understanding of foodborne illnesses and the best practices for prevention. The Indiana State Department of Health (ISDH) plays a central role in overseeing these regulations. Early regulations focused on basic sanitation, gradually expanding to encompass more detailed requirements related to food handling procedures, employee training, and facility inspections. The evolution of these regulations reflects a commitment to adopting the latest scientific findings and best practices in food safety.

The adoption of the FDA Food Code as a basis for Indiana’s food safety regulations is a significant example of this evolution, providing a nationally recognized standard for food safety practices.

Who is Required to Obtain an Indiana Food Handler Certificate

Indiana law requires food handlers to obtain a food handler certificate. This requirement generally applies to anyone who handles unpackaged food, food equipment or utensils, or food-contact surfaces. Specific categories of workers are mandated to obtain this certificate.

The following list Artikels who is typically required to obtain certification:

- Food Service Workers: This includes individuals working in restaurants, cafes, bars, and other establishments that prepare and serve food.

- Food Handlers in Retail Settings: Employees working in grocery stores, convenience stores, and other retail locations that sell unpackaged food.

- Temporary Food Service Workers: Individuals involved in food handling at temporary events, such as festivals and fairs, also require certification.

- School Food Service Staff: Employees who handle food in school cafeterias and other educational settings.

- Healthcare Facilities: Food handlers working in hospitals, nursing homes, and other healthcare facilities.

Failure to obtain the necessary certification can result in penalties for both the food handler and the establishment.

Food handler certification is typically valid for a specific period, often two to three years, and requires renewal to maintain compliance.

Requirements for Certification

The Indiana food handler certification is a crucial step for anyone involved in preparing, serving, or handling food in the state. This certification ensures that food handlers possess the necessary knowledge to prevent foodborne illnesses and maintain safe food handling practices. Understanding the specific requirements is essential to successfully obtaining and maintaining this important credential.

Eligibility Criteria

To be eligible for an Indiana food handler certificate, individuals generally need to meet specific requirements. These criteria ensure that candidates have the basic understanding and capabilities necessary to complete the training and perform their duties safely.The primary eligibility requirement is a willingness to learn and a commitment to following safe food handling practices. There are no specific age requirements mandated by the state of Indiana to obtain a food handler certificate.

However, employers may have their own age restrictions based on the nature of the job and state labor laws concerning minors.

Acceptable Training Methods

Indiana allows for various methods to complete the required food handler training course. These methods provide flexibility and accessibility for individuals to obtain their certification.Approved training courses are typically offered through online platforms and in-person classes. Online courses provide the convenience of self-paced learning, allowing individuals to study at their own schedule. In-person classes offer the benefit of direct interaction with an instructor and the opportunity to ask questions and engage in discussions.

The specific format and content of the courses are designed to align with the state’s food safety guidelines.

Topics Covered in Training Programs

Approved Indiana food handler training programs cover a comprehensive range of topics essential for ensuring food safety. These topics are designed to equip food handlers with the knowledge and skills to prevent foodborne illnesses and maintain a safe and sanitary work environment.

- Foodborne Illness: This section provides information about common foodborne illnesses, their causes, and how they spread. Understanding the sources of contamination is crucial in preventing outbreaks. For instance, the training would likely cover the Norovirus, a highly contagious virus often linked to food service settings, and the importance of handwashing and proper hygiene to prevent its spread.

- Personal Hygiene: Emphasis is placed on the importance of personal hygiene practices, including proper handwashing techniques, the use of gloves, and the appropriate attire for food handling. Proper handwashing, for example, involves washing hands with soap and water for at least 20 seconds, especially after touching raw food, using the restroom, or handling garbage.

- Cross-Contamination: This section focuses on how to prevent cross-contamination, which occurs when harmful bacteria or other microorganisms are transferred from one food item or surface to another. The training will include strategies such as using separate cutting boards for raw meat and vegetables, and proper storage of food items.

- Time and Temperature Control: Food handlers learn about the critical importance of controlling time and temperature to prevent bacterial growth. This includes understanding the temperature danger zone (between 40°F and 140°F or 4°C and 60°C), where bacteria multiply rapidly, and how to properly cook, cool, and store food. For example, cooked foods should be cooled from 135°F (57°C) to 70°F (21°C) within two hours, and then to 41°F (5°C) or below within an additional four hours.

- Cleaning and Sanitizing: The training covers the proper procedures for cleaning and sanitizing food contact surfaces, equipment, and utensils. This involves using the correct cleaning agents and sanitizing solutions and following the manufacturer’s instructions.

- Safe Food Handling Practices: Food handlers learn about various safe food handling practices, including proper receiving, storage, preparation, and serving techniques. This also includes recognizing and reporting potential food safety hazards.

Approved Training Providers

In Indiana, obtaining a food handler certification is crucial for anyone working in the food service industry. This certification ensures that individuals possess the necessary knowledge and skills to handle food safely, preventing foodborne illnesses. The state does not directly provide training; instead, it approves various training providers. These providers offer a range of courses designed to meet the requirements set forth by the Indiana Department of Health.

List of Indiana-Approved Food Handler Training Providers

Indiana relies on a network of approved training providers to deliver food handler certification courses. These providers offer a variety of training formats, including online courses, in-person classes, and blended learning options. The courses cover essential topics such as food safety principles, proper food handling techniques, personal hygiene, and preventing cross-contamination.

- 360training.com: Offers comprehensive online food handler training.

- StateFoodSafety.com: Provides online food handler training courses, available in multiple languages.

- ServSafe: A well-known provider offering online and in-person food safety training and certification, often utilized by restaurants and food establishments.

- Learn2Serve by 360training: Another option from 360training, offering online food handler courses.

- FoodHandlerSolutions.com: Provides online food handler training, designed to meet Indiana’s requirements.

Comparison of Training Options

The approved providers offer various training methods and cost structures. Choosing the right provider depends on individual preferences, learning styles, and budget. The following table provides a comparison of some of the most popular providers. Note that costs are subject to change, and it’s recommended to check the provider’s website for the most up-to-date pricing.

| Provider Name | Training Method | Cost (Approximate) |

|---|---|---|

| 360training.com | Online | $10 – $20 |

| StateFoodSafety.com | Online | $10 – $20 |

| ServSafe | Online & In-Person | $15 – $35 (Online) / Varies (In-Person) |

| Learn2Serve by 360training | Online | $10 – $20 |

| FoodHandlerSolutions.com | Online | $10 – $20 |

Verification of Accreditation

Verifying the accreditation of a training provider is essential to ensure that the certification is valid and recognized in Indiana. The Indiana Department of Health (IDOH) maintains a list of approved training providers. This list is the most reliable source for confirming a provider’s accreditation status.To verify accreditation:

- Check the IDOH Website: The primary method is to visit the official website of the Indiana Department of Health. Look for a section dedicated to food handler certification and approved training providers. This list is regularly updated to reflect any changes in accreditation status.

- Confirm with the Provider: If you are unsure, you can always directly contact the training provider and inquire about their accreditation. Ask for their approval number, which can then be cross-referenced with the IDOH’s list.

- Look for the IDOH Seal: While not always present, some providers may display the IDOH seal or a statement confirming their approval. This can serve as an additional confirmation, but always verify the information through the official IDOH resources.

It’s crucial to confirm that the training provider is listed on the IDOH’s approved list. This ensures that the certificate will be recognized by employers and health inspectors throughout Indiana. Failure to obtain certification from an approved provider may result in the certificate being invalid.

The Certification Process

Obtaining an Indiana food handler certificate involves a structured process designed to ensure food handlers possess the necessary knowledge to handle food safely. This process typically involves completing an approved training program and passing an examination. The certificate is essential for individuals working in food service establishments to demonstrate their commitment to food safety practices, which is vital for public health.

Steps for Obtaining an Indiana Food Handler Certificate

The process for obtaining certification can be broken down into several key steps. These steps are designed to guide individuals through the training and examination requirements efficiently.

- Select an Approved Training Provider: The first step involves choosing a training provider that is approved by the Indiana Department of Health. A list of approved providers is available on the state’s official website. This ensures the training meets the state’s required standards.

- Complete the Training Course: Once a provider is selected, the next step is to complete the food handler training course. This course typically covers topics such as foodborne illnesses, proper food handling techniques, personal hygiene, and cleaning and sanitizing procedures. The course can be completed online or in person, depending on the provider.

- Pass the Examination: After completing the training, individuals must pass an examination to demonstrate their understanding of the material. The examination is usually administered online or in person by the training provider. A passing score is required to receive certification.

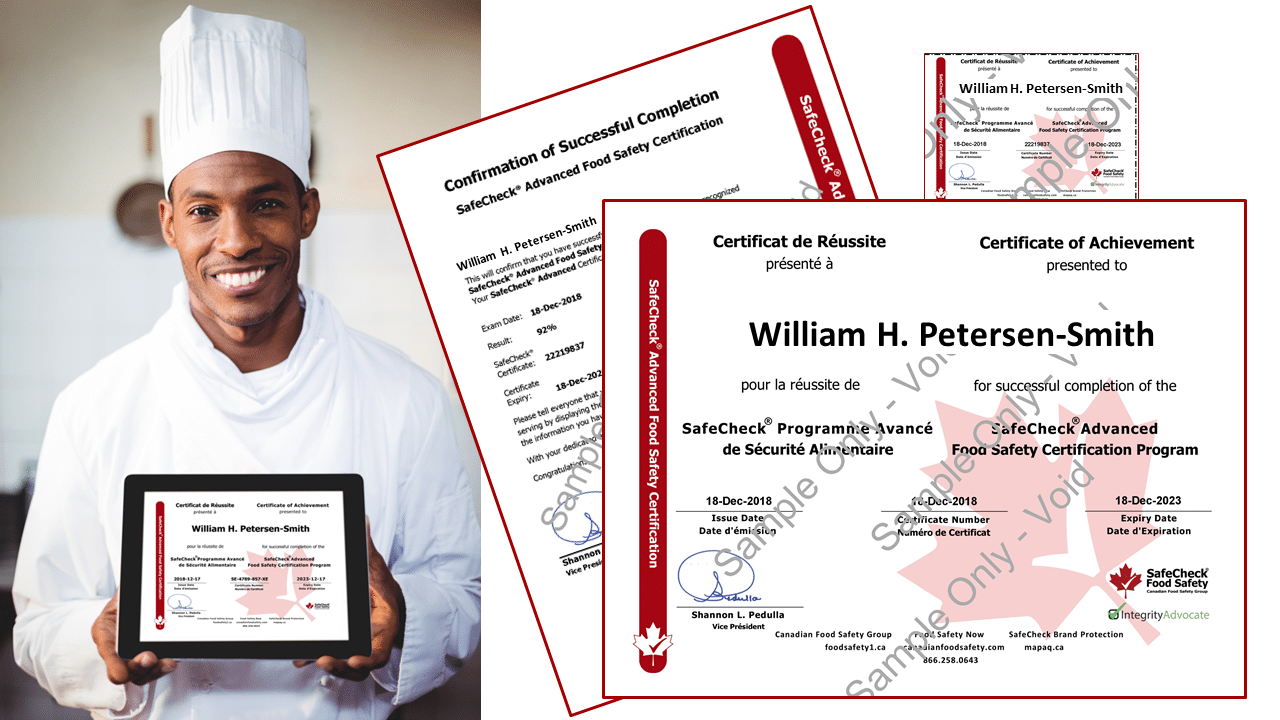

- Receive the Certificate: Upon successfully passing the examination, the training provider will issue a food handler certificate. This certificate typically includes the individual’s name, the date of completion, and the expiration date.

- Maintain the Certificate: Food handler certificates are valid for a specific period, usually three years. It’s important to renew the certification before it expires to remain compliant with Indiana regulations. Renewal typically involves retaking the training and examination.

Online Training and Examination Process

The online training and examination process offers a convenient and accessible way for individuals to obtain their food handler certification. This process typically involves a series of modules, followed by an examination.

The online training usually consists of several modules, each focusing on a specific aspect of food safety. These modules may include videos, interactive quizzes, and downloadable resources. Participants can usually work at their own pace, making it easier to fit the training into their schedules. After completing all the modules, individuals proceed to the examination.

The examination is typically administered online and consists of multiple-choice questions. The questions assess the individual’s understanding of the material covered in the training. The examination is usually timed, and a passing score is required to receive certification. The training provider will notify the participant of their score immediately after completing the exam.

Procedures for Retaking the Exam

In the event of failing the examination, individuals are typically given the opportunity to retake it. The procedures for retaking the exam are designed to help individuals understand their areas of weakness and improve their knowledge.

The specific procedures for retaking the exam vary depending on the training provider. However, some general guidelines are typically followed.

- Review the Training Material: After failing the exam, individuals are encouraged to review the training material again. This helps reinforce their understanding of the key concepts and identify areas where they need improvement.

- Retake the Exam: Most training providers allow individuals to retake the exam after a waiting period, which can be a few hours or days. There may be a limit to the number of retakes allowed.

- Pay a Retake Fee (if applicable): Some training providers may charge a fee for retaking the exam. This fee covers the administrative costs associated with administering the exam.

- Receive a New Certificate (upon passing): Upon successfully passing the retake examination, the individual will receive their food handler certificate.

Content Covered in Training

The Indiana Food Handler Certification training comprehensively covers critical aspects of food safety, ensuring that food handlers possess the necessary knowledge to protect public health. The training modules delve into several key areas, equipping individuals with the skills to handle food safely and prevent foodborne illnesses. This section focuses on the core topics included in the training curriculum.

Personal Hygiene Practices

Maintaining impeccable personal hygiene is paramount in preventing food contamination. Food handlers play a crucial role in safeguarding the food supply from potential hazards. Adherence to stringent hygiene practices minimizes the risk of transferring harmful bacteria or viruses to food, thereby ensuring consumer safety.

- Handwashing: Proper handwashing is the cornerstone of food safety. Hands must be washed frequently and thoroughly.

- Wash hands with warm, soapy water for at least 20 seconds.

- Scrub all surfaces of the hands, including between fingers and under fingernails.

- Rinse hands thoroughly under running water.

- Dry hands with a single-use paper towel or a hand dryer.

- Handwashing should occur before starting work, after touching raw food, after using the restroom, after coughing or sneezing, and after handling garbage.

- Grooming: Food handlers must maintain good grooming habits.

- Keep hair restrained, using hairnets or caps to prevent hair from falling into food.

- Keep beards and mustaches trimmed and covered.

- Avoid wearing excessive jewelry, as it can harbor bacteria and potentially fall into food. Remove rings, except for a plain wedding band.

- Keep fingernails trimmed, clean, and unpolished.

- Clothing and Uniforms: Proper attire is essential for maintaining hygiene standards.

- Wear clean uniforms or aprons.

- Change aprons frequently, especially if they become soiled.

- Avoid wearing street clothes in food preparation areas.

- Illness: Food handlers must stay home if they are sick.

- Report any symptoms of illness, such as vomiting, diarrhea, fever, or jaundice, to a supervisor.

- Do not handle food if experiencing these symptoms.

Preventing Cross-Contamination

Cross-contamination is a significant threat to food safety, and preventing it is critical. It occurs when harmful microorganisms are transferred from one surface or food item to another. The training emphasizes strategies to eliminate or minimize cross-contamination risks, protecting food from potentially dangerous bacteria and viruses.

- Separate Raw and Ready-to-Eat Foods: Keep raw animal products (meat, poultry, seafood, and eggs) separate from ready-to-eat foods.

- Store raw foods below ready-to-eat foods in refrigerators to prevent dripping.

- Use separate cutting boards, utensils, and equipment for raw and ready-to-eat foods.

- Proper Cleaning and Sanitizing: Regular cleaning and sanitizing of surfaces and equipment are crucial.

- Wash, rinse, and sanitize all food contact surfaces, such as cutting boards, utensils, and countertops.

- Use approved sanitizers and follow the manufacturer’s instructions for proper dilution and contact time.

- Preventing Cross-Contamination from Hands: Food handlers’ hands can easily transfer pathogens.

- Wash hands thoroughly after any activity that could contaminate them, such as touching raw food, using the restroom, or handling garbage.

- Use single-use gloves when handling ready-to-eat foods.

- Change gloves frequently, and whenever they become torn or contaminated.

- Preventing Cross-Contamination from Equipment: Equipment can also be a source of cross-contamination.

- Use separate equipment for raw and ready-to-eat foods.

- Clean and sanitize equipment thoroughly after each use.

- Regularly inspect equipment for cleanliness and repair any damage promptly.

Identifying and Controlling Foodborne Illnesses

Understanding foodborne illnesses, their causes, and how to prevent them is vital for food handlers. The training provides information on the common types of foodborne illnesses, the pathogens that cause them, and the steps to take to minimize the risk of outbreaks.

- Common Foodborne Pathogens: Several pathogens commonly cause foodborne illnesses.

- Bacteria: Salmonella, E. coli, Listeria monocytogenes, and Staphylococcus aureus are examples of bacteria that can cause foodborne illness.

- Viruses: Norovirus and hepatitis A are common viruses transmitted through food.

- Parasites: Parasites such as Giardia and Cryptosporidium can contaminate food and cause illness.

- Symptoms of Foodborne Illness: Recognizing the symptoms of foodborne illness is essential.

- Symptoms can vary but commonly include nausea, vomiting, diarrhea, abdominal cramps, and fever.

- Symptoms can appear within hours or days of consuming contaminated food.

- Time and Temperature Control: Controlling time and temperature is critical for preventing bacterial growth.

- Keep potentially hazardous foods (PHFs) at safe temperatures to prevent bacterial growth.

- Danger Zone: Avoid keeping PHFs in the “danger zone” (between 41°F and 135°F) for more than four hours.

- Cook food to the required internal temperatures.

- Use a food thermometer to check internal temperatures.

- Proper Food Storage: Storing food correctly is crucial for maintaining its safety.

- Store food at the correct temperatures.

- Use the “first-in, first-out” (FIFO) method to rotate stock.

- Store food in a clean, dry environment.

- Protect food from contamination by covering it and storing it away from chemicals and other potential hazards.

- Employee Training and Awareness: Educating employees about food safety is essential.

- Provide regular food safety training.

- Encourage employees to report any potential food safety concerns.

- Implement food safety policies and procedures.

Food Safety Practices

Ensuring food safety is paramount in the Indiana food service industry. This section Artikels critical practices to prevent foodborne illnesses, protect public health, and maintain operational integrity. Adhering to these guidelines is a legal requirement and a fundamental aspect of responsible food handling.

Safe Food Storage Guidelines in Indiana

Proper food storage is essential for maintaining food safety and preventing the growth of harmful bacteria. The Indiana State Department of Health (ISDH) provides specific guidelines that must be followed to ensure food is stored correctly.Food must be stored to prevent cross-contamination. This means:

- Raw meats, poultry, and seafood must be stored below ready-to-eat foods to prevent dripping.

- Foods must be stored in designated storage areas, away from chemicals and cleaning supplies.

- Containers must be properly labeled with the food name and the date it was prepared or opened.

- Dry goods must be stored in a cool, dry place, off the floor, and away from walls.

Temperature control is crucial for food safety. The following temperature guidelines must be observed:

- Refrigerated foods must be stored at 41°F (5°C) or below.

- Frozen foods must be stored at 0°F (-18°C) or below.

- Regularly monitor and record temperatures to ensure compliance.

Rotation of stock, also known as the “first in, first out” (FIFO) method, is a vital practice.

The FIFO method involves using the oldest products first, which minimizes waste and ensures that food is consumed before it spoils.

This is achieved by:

- Placing new deliveries behind existing stock.

- Checking expiration dates regularly.

- Discarding expired or spoiled food promptly.

Correct Methods for Cooking and Cooling Food

Proper cooking and cooling methods are essential for eliminating harmful bacteria and preventing their growth. The ISDH mandates specific procedures to ensure food is cooked to safe internal temperatures and cooled quickly.Cooking Food to Safe Internal Temperatures:The following are minimum internal cooking temperatures for various types of food:

- Poultry: 165°F (74°C)

- Ground meat (including beef, pork, and lamb): 155°F (68°C)

- Seafood: 145°F (63°C)

- Eggs (for immediate service): 145°F (63°C)

- Reheated foods: 165°F (74°C)

It is crucial to use a food thermometer to verify the internal temperature of food.

The thermometer must be inserted into the thickest part of the food, away from bones, to ensure an accurate reading.

Understand how the union of lombard food pantry can improve efficiency and productivity.

Cooling Food Safely:Food must be cooled rapidly to prevent bacterial growth. The following guidelines must be followed:

- Cool food from 135°F (57°C) to 70°F (21°C) within two hours.

- Cool food from 70°F (21°C) to 41°F (5°C) or below within an additional four hours.

- Use methods like shallow pans, ice baths, or blast chillers to speed up the cooling process.

- Stir food frequently during cooling to ensure even cooling.

Importance of Proper Handwashing Techniques

Handwashing is one of the most critical practices in preventing the spread of foodborne illnesses. Proper handwashing removes bacteria and viruses that can contaminate food and cause illness.The Handwashing Procedure:The following steps must be followed when washing hands:

- Wet hands with warm water.

- Apply soap and lather thoroughly for at least 20 seconds, including between fingers and under fingernails.

- Rinse hands thoroughly under running water.

- Dry hands with a single-use paper towel or a hand dryer.

When to Wash Hands:Handwashing must be performed at specific times to maintain food safety:

- Before starting work.

- After touching raw meat, poultry, or seafood.

- After using the restroom.

- After touching the face, hair, or body.

- After sneezing, coughing, or blowing the nose.

- After handling garbage.

- After changing tasks.

Proper Handwashing Facilities:Handwashing stations must be properly equipped and maintained:

- Handwashing stations must have hot and cold running water.

- Soap and single-use paper towels or hand dryers must be available.

- Handwashing stations must be located near food preparation areas and restrooms.

Maintaining Certification

Maintaining your Indiana Food Handler Certification is crucial for ensuring food safety and compliance with state regulations. This involves understanding the validity period of the certificate and adhering to the renewal process to avoid any lapses in your certification status. Consistent certification demonstrates a commitment to food safety best practices and protects both the food handler and the public.

Validity Period of an Indiana Food Handler Certificate, Indiana food handler certification

The Indiana Food Handler Certificate is valid for a specific duration, after which it must be renewed. Understanding this timeframe is vital for food handlers to remain compliant.The Indiana Food Handler Certificate is generally valid for three years from the date of issue. This means that a food handler must complete a new training course and pass the associated exam every three years to maintain their certification.

The expiration date is clearly indicated on the certificate itself, providing a visual reminder for the food handler.

Benefits of Certification

Obtaining an Indiana food handler certificate provides numerous advantages for both employees and employers within the food service industry. Certification demonstrates a commitment to food safety, leading to a safer environment for both workers and consumers. This commitment is crucial for building trust and ensuring the long-term success of food service establishments.

Employee Advantages

Having an Indiana food handler certificate offers several benefits for employees, enhancing their career prospects and providing them with valuable skills.

- Enhanced Employability: Certification significantly increases an individual’s marketability within the food service industry. Employers often prioritize hiring certified food handlers, as it demonstrates a pre-existing knowledge of food safety principles. This advantage makes certified individuals more competitive in the job market, providing more opportunities for employment and career advancement.

- Increased Knowledge and Skills: The training required for certification equips food handlers with essential knowledge and skills related to food safety. This includes understanding proper food handling techniques, preventing cross-contamination, and recognizing and responding to potential foodborne illnesses. This knowledge empowers employees to make informed decisions and perform their duties effectively.

- Improved Workplace Safety: Certified food handlers are better equipped to identify and mitigate food safety hazards, contributing to a safer working environment. By adhering to established food safety protocols, they reduce the risk of foodborne illnesses, protecting themselves and their colleagues. This promotes a culture of safety within the workplace.

- Career Advancement Opportunities: Certification often serves as a stepping stone for career progression within the food service industry. Employees with a food handler certificate are often considered for promotions to positions with greater responsibilities, such as supervisory roles or management positions. This can lead to increased earning potential and professional growth.

- Increased Confidence and Professionalism: The knowledge and skills gained through certification boost employees’ confidence in their ability to handle food safely. This increased confidence translates into a more professional approach to their work, enhancing their interactions with colleagues, customers, and supervisors.

Employer Advantages

Employers also benefit significantly from having certified food handlers, leading to improved operational efficiency and a stronger reputation.

- Reduced Risk of Foodborne Illness Outbreaks: Certified employees are trained in proper food handling practices, significantly reducing the risk of foodborne illnesses. This, in turn, protects customers and the business from potential legal liabilities and reputational damage.

- Improved Compliance with Regulations: Certification demonstrates a commitment to food safety regulations, making it easier for businesses to comply with state and local health codes. This can help avoid costly fines and penalties.

- Enhanced Reputation and Customer Trust: Having a workforce of certified food handlers signals a dedication to food safety, building trust with customers and enhancing the establishment’s reputation. This can lead to increased customer loyalty and positive word-of-mouth referrals.

- Reduced Employee Turnover: Providing training and certification demonstrates a commitment to employee development, which can increase employee satisfaction and reduce turnover rates. Lower turnover can lead to reduced training costs and improved operational efficiency.

- Improved Operational Efficiency: Certified employees are more knowledgeable and skilled in food safety practices, leading to fewer mistakes and greater efficiency in the kitchen. This can result in reduced food waste, lower costs, and improved overall productivity.

Examples of Improved Food Safety Standards

Certification directly contributes to the implementation of improved food safety standards, leading to measurable positive outcomes.

- Proper Handwashing: Certified food handlers are trained in the correct techniques for handwashing, including the use of soap and water for at least 20 seconds. This simple practice is critical in preventing the spread of bacteria and viruses, such as

-Salmonella* and Norovirus, which can cause foodborne illnesses. - Preventing Cross-Contamination: Certification emphasizes the importance of preventing cross-contamination, which occurs when harmful bacteria or viruses are transferred from one food item to another, or from surfaces to food. This includes using separate cutting boards for raw meat and vegetables, proper storage of food items, and the use of sanitizing solutions.

- Temperature Control: Certified food handlers understand the importance of maintaining proper temperatures for food storage, cooking, and holding. This knowledge helps prevent the growth of bacteria that thrive in the “danger zone” (temperatures between 40°F and 140°F). For example, cooked foods should be held at 135°F or higher, and cold foods should be kept at 41°F or below.

- Safe Food Preparation Practices: Certification covers safe food preparation practices, such as washing fruits and vegetables thoroughly, cooking food to the correct internal temperatures, and avoiding cross-contamination during food preparation. These practices are essential to minimize the risk of foodborne illnesses. For instance, poultry should be cooked to an internal temperature of 165°F to kill harmful bacteria.

- Pest Control: Certified food handlers are educated on pest control measures to prevent pests from contaminating food and food preparation areas. This includes proper storage of food, regular cleaning, and the use of appropriate pest control methods.

Common Challenges and Solutions

Obtaining Indiana Food Handler Certification, while a crucial step for food service professionals, can present several hurdles. Understanding these challenges and having access to practical solutions can significantly improve the certification process, leading to greater success. This section will explore the typical difficulties individuals face and offer strategies to overcome them, along with resources to support learners.

Language Barriers

Language proficiency can pose a significant obstacle for some individuals. Food safety concepts and training materials may not always be readily accessible in their native language, creating difficulties in understanding and retaining information.

- Challenge: Difficulty understanding training materials and exam questions due to language barriers.

- Solution: Utilize training providers that offer materials and exams in multiple languages, including Spanish, which is common in Indiana. Seek out bilingual instructors or translation assistance when available. Consider using online translation tools cautiously, focusing on key terms and concepts.

- Resources: The Indiana Department of Health website might provide links to translated materials or a list of providers offering multilingual support. Community organizations and local libraries may also offer language assistance services.

Scheduling Conflicts and Time Constraints

Balancing work, family responsibilities, and other commitments can make it difficult to find time to complete the required training. The time commitment required, even for online courses, can be a significant hurdle.

- Challenge: Inability to dedicate sufficient time to complete the training course and take the exam due to conflicting schedules.

- Solution: Opt for online courses that offer flexibility and allow learners to progress at their own pace. Look for courses that provide options for pausing and resuming training. Consider scheduling specific blocks of time for studying and taking the exam, treating it as a priority.

- Resources: Many online training providers offer mobile-friendly platforms, enabling learning on-the-go. Explore employer-sponsored training programs or ask for time off to complete the certification.

Financial Constraints

The cost of the food handler certification course can be a barrier for some individuals, particularly those working in entry-level positions or experiencing financial hardship.

- Challenge: Inability to afford the cost of the certification course.

- Solution: Research free or low-cost training options. Some employers may cover the cost of certification for their employees. Explore scholarship programs or financial assistance offered by community organizations or workforce development programs.

- Resources: Check with local health departments and community colleges for potential financial aid or discounted training opportunities. Consider looking for training programs that are part of job training initiatives.

Learning Disabilities and Different Learning Styles

Individuals with learning disabilities or those who prefer different learning methods may find the standard training format challenging. Traditional lectures and exams might not suit everyone.

- Challenge: Difficulty understanding and retaining information due to learning disabilities or a preference for alternative learning styles.

- Solution: Choose training providers that offer a variety of learning methods, such as visual aids, interactive exercises, and hands-on activities. Consider online courses with closed captioning and transcripts. Request accommodations if needed.

- Resources: The Americans with Disabilities Act (ADA) ensures reasonable accommodations for individuals with disabilities. Consult with the training provider to understand available accommodations. Explore resources from disability advocacy groups for additional support.

Exam Anxiety and Test-Taking Strategies

The prospect of taking an exam can create anxiety for some individuals, potentially hindering their performance. Lack of familiarity with test-taking strategies can further exacerbate this issue.

- Challenge: Experiencing anxiety or difficulty with test-taking, which can negatively affect exam results.

- Solution: Practice with sample questions and practice exams to familiarize yourself with the format and content. Develop effective test-taking strategies, such as time management and process of elimination. Identify and address any test-related anxieties through relaxation techniques or other coping mechanisms.

- Resources: Many training providers offer practice exams and study guides. The Indiana Department of Health may provide access to sample questions. Consider utilizing online resources dedicated to test-taking strategies and anxiety management.

State Regulations and Guidelines: Indiana Food Handler Certification

Food safety in Indiana is a shared responsibility, with the state’s health department playing a pivotal role in safeguarding public health. Understanding and adhering to these regulations are crucial for food handlers to ensure the safety of the food they prepare and serve. This section delves into the specific regulations and guidelines established by the Indiana Department of Health (IDOH).

Role of the Indiana Department of Health in Food Safety

The Indiana Department of Health (IDOH) is the primary agency responsible for overseeing food safety in the state. Its role encompasses a wide range of activities designed to protect Hoosiers from foodborne illnesses.

- Inspection and Enforcement: The IDOH conducts regular inspections of food establishments, including restaurants, grocery stores, and food processing facilities, to ensure compliance with food safety regulations. These inspections help identify and correct potential hazards.

- Regulation and Rulemaking: The IDOH develops and enforces food safety regulations, setting standards for food handling, preparation, storage, and sanitation. These regulations are regularly updated to reflect the latest scientific knowledge and best practices.

- Education and Training: The IDOH provides resources and guidance to food handlers and establishments to promote food safety. This includes providing information about foodborne illnesses, proper food handling techniques, and best practices.

- Outbreak Investigation: The IDOH investigates reports of foodborne illnesses, working to identify the source of the outbreak and prevent further spread. This may involve collecting samples, interviewing individuals, and working with local health departments.

- Collaboration: The IDOH collaborates with local health departments, federal agencies (such as the FDA), and industry stakeholders to ensure a comprehensive approach to food safety.

Relevant Indiana Food Safety Regulations and Guidelines

The IDOH provides various resources to guide food handlers and establishments in adhering to food safety standards. These resources are typically available on the IDOH website.

- Indiana Food Code: This is the primary set of regulations governing food safety in Indiana. It Artikels specific requirements for food handling, preparation, storage, and sanitation. The Indiana Food Code is based on the FDA Food Code, with some state-specific modifications.

- Local Health Department Regulations: While the IDOH sets statewide standards, local health departments may have additional regulations or guidelines specific to their jurisdictions. Food handlers should be aware of and comply with any local requirements.

- Guidance Documents and Fact Sheets: The IDOH provides various guidance documents and fact sheets to clarify specific aspects of the Indiana Food Code and offer best practices. These documents may cover topics such as proper handwashing, preventing cross-contamination, and safe food storage.

- Training Materials: The IDOH often provides or recommends training materials to help food handlers understand and comply with food safety regulations. This can include information on topics such as foodborne illnesses, proper food handling techniques, and sanitation procedures.

- Website and Online Resources: The IDOH website is a valuable resource for food handlers, offering access to the Indiana Food Code, guidance documents, training materials, and contact information for local health departments. The website also often provides updates on new regulations or changes to existing ones.

Importance of Staying Updated on Food Safety Regulations

Food safety regulations are not static; they evolve over time to reflect advancements in scientific knowledge and to address emerging food safety challenges. Staying informed about these changes is crucial for food handlers to maintain food safety practices and protect public health.

- Preventing Foodborne Illnesses: Staying updated on regulations helps food handlers implement the most effective food safety practices, minimizing the risk of foodborne illnesses. This protects both the food handler’s customers and the reputation of the establishment.

- Ensuring Compliance: Regular updates on regulations ensure that food handlers remain compliant with state and local laws, avoiding potential penalties such as fines or even temporary closure of the establishment.

- Maintaining Consumer Trust: Demonstrating a commitment to food safety by staying updated on regulations builds trust with customers, who are more likely to patronize establishments that prioritize their health and safety.

- Adapting to New Technologies and Practices: Food safety regulations often evolve to incorporate new technologies and best practices. Staying updated allows food handlers to adopt these advancements, improving efficiency and food safety standards. For example, the rise of mobile food vendors and food delivery services has led to updates in regulations to address unique challenges associated with these business models.

- Protecting Public Health: The primary goal of food safety regulations is to protect public health. By staying informed and adhering to these regulations, food handlers contribute to a safer food supply and a healthier community.

Enforcement and Inspections

In Indiana, maintaining food safety is a shared responsibility, with the Indiana Department of Health (IDOH) playing a critical role in ensuring the safety of the food supply. This involves regular inspections of food establishments to verify compliance with established regulations and guidelines. These inspections are a crucial part of protecting public health and preventing foodborne illnesses.

Food Safety Inspections in Indiana

Food safety inspections in Indiana are conducted by the IDOH and local health departments. These inspections are designed to evaluate a food establishment’s adherence to the Indiana Food Code. The frequency of inspections depends on the type of establishment and its history of compliance. High-risk establishments, such as restaurants and hospitals, are typically inspected more frequently than lower-risk establishments, such as convenience stores.Inspections generally follow a standardized format, covering various aspects of food handling and facility operations.

The inspector will examine the following areas:

- Food Handling Practices: This includes proper food storage, cooking temperatures, cooling methods, and preventing cross-contamination. Inspectors check for the correct use of thermometers, the maintenance of food at safe temperatures, and the prevention of contamination from raw to ready-to-eat foods. For example, the inspector will look for a calibrated thermometer used to verify that cooked chicken reaches an internal temperature of 165°F (74°C) to kill harmful bacteria.

- Employee Hygiene: Inspectors will assess employee practices, such as handwashing, proper attire, and the prevention of bare-hand contact with ready-to-eat foods. For instance, the inspector will observe if employees wash their hands thoroughly with soap and water for at least 20 seconds before handling food.

- Facility Sanitation: This includes cleanliness of the facility, including food contact surfaces, equipment, and restrooms. The inspector will check for pest control measures, proper waste disposal, and general sanitation of the premises.

- Equipment Maintenance: Proper maintenance of equipment, such as refrigerators, freezers, and dishwashers, is crucial. Inspectors will ensure that equipment is functioning correctly and maintained in a sanitary condition.

- Documentation and Record Keeping: Food establishments are required to maintain records of food temperatures, cooling logs, and employee training. Inspectors will review these records to verify compliance.

The inspector will document any violations observed during the inspection and provide a written report to the establishment. The report will Artikel the specific violations and any corrective actions that must be taken. The establishment is typically given a specific timeframe to correct the violations.

Potential Penalties for Violating Food Safety Regulations

Violating food safety regulations in Indiana can result in a range of penalties, depending on the severity and frequency of the violations. These penalties are designed to deter non-compliance and protect public health.The potential penalties may include:

- Written Warnings: For minor violations, the inspector may issue a written warning, providing the establishment with an opportunity to correct the issue.

- Fines: Establishments may be subject to fines for violations, with the amount of the fine depending on the severity of the violation and the establishment’s history of compliance. Fines can range from a few hundred dollars to several thousand dollars, depending on the violation.

- Suspension of Permit: For more serious or repeated violations, the health department may suspend the establishment’s permit to operate. This would require the establishment to cease operations until the violations are corrected and the permit is reinstated.

- Closure of Establishment: In extreme cases, where violations pose an immediate threat to public health, the health department may order the closure of the establishment. This is usually reserved for situations involving severe food contamination, widespread pest infestations, or other serious issues.

- Legal Action: In cases of severe or repeated violations, the health department may pursue legal action against the establishment and/or responsible individuals. This could result in additional fines, legal fees, and other penalties.

The specific penalties imposed will depend on the specific circumstances of the violation, including its severity, the potential risk to public health, and the establishment’s history of compliance. The health department has the authority to determine the appropriate penalties.

Preparing for a Food Safety Inspection

Food handlers play a crucial role in ensuring their establishment is prepared for a food safety inspection. Thorough preparation can help to ensure a smooth inspection process and demonstrate a commitment to food safety.Here are some key steps food handlers can take to prepare for an inspection:

- Review and Understand the Indiana Food Code: Food handlers should be familiar with the requirements of the Indiana Food Code. This includes understanding the specific regulations related to food handling, employee hygiene, facility sanitation, and other aspects of food safety.

- Maintain Proper Food Handling Practices: Food handlers should consistently follow proper food handling practices, including proper handwashing, cooking food to the correct temperatures, preventing cross-contamination, and storing food safely. This is a continuous process, not just something done for an inspection.

- Ensure Employee Training: All food handlers should receive proper training on food safety principles and practices. This training should be documented and readily available for review during the inspection.

- Maintain a Clean and Sanitary Facility: Regularly clean and sanitize all food contact surfaces, equipment, and the entire facility. Implement and follow a comprehensive cleaning schedule.

- Monitor Food Temperatures: Use calibrated thermometers to monitor food temperatures throughout the entire process. Keep records of food temperatures, including cooking, cooling, and holding temperatures.

- Maintain Accurate Records: Keep accurate records of food temperatures, cooling logs, employee training, and other relevant information. These records should be readily available for review during the inspection.

- Address Any Previous Violations: If the establishment has received any previous violations, ensure that all corrective actions have been taken and that the issues have been resolved. Review any past inspection reports to ensure that all required changes have been made.

- Be Prepared to Answer Questions: Food handlers should be prepared to answer questions from the inspector about food safety practices, employee hygiene, and other aspects of food handling.

- Cooperate with the Inspector: Be courteous and cooperative with the inspector. Provide any requested documentation and answer questions honestly and accurately.

Specialized Training Considerations

Indiana food handler certification provides a foundational understanding of food safety. However, certain food establishments and handling practices necessitate more specialized training to ensure the highest standards of food safety are met. This section explores the specific training requirements and certifications that may be required based on the type of establishment, the handling of allergens, and other specific food safety management needs.

Specific Training Requirements for Different Food Establishments

Different types of food establishments present unique food safety challenges. These establishments may require specialized training to address their specific operational needs.* Restaurants and Cafeterias: These establishments often require training focused on preventing cross-contamination, proper cooking temperatures for various menu items, and safe food handling practices for high-volume food preparation. Training should cover topics such as:

Proper handwashing techniques.

Safe food storage procedures.

Safe food preparation practices.

Temperature control for potentially hazardous foods (PHFs).

Mobile Food Units (Food Trucks)

Mobile food units face unique challenges due to limited space and resources. Training should emphasize:

Proper food storage and transportation.

Waste disposal.

Maintaining proper temperatures during transport.

Preventing contamination in a confined space.

Schools and Childcare Facilities

These settings require extra emphasis on preventing foodborne illnesses in vulnerable populations. Training should include:

Proper food handling practices for children.

Allergen awareness and management.

Safe food preparation for large groups.

Adherence to specific regulations regarding food safety in schools.

Healthcare Facilities (Hospitals, Nursing Homes)

Food safety in healthcare settings is critical due to the susceptibility of patients to foodborne illnesses. Training should focus on:

Food safety practices to prevent cross-contamination.

Special dietary needs of patients.

Proper food handling procedures for patients with compromised immune systems.

Safe food storage and preparation practices.

Training Needs for Handling Allergens

Food allergies are a serious public health concern, and food handlers must be trained to prevent allergic reactions.* Allergen Awareness: Food handlers must be trained to recognize common food allergens and understand the importance of preventing cross-contact.

Ingredient Labeling

Training should cover how to read food labels and identify potential allergens in food products.

Preventing Cross-Contact

Food handlers must be trained on how to prevent cross-contact, which occurs when allergens are transferred from one food to another.

This includes using separate cutting boards, utensils, and cooking equipment for allergen-free foods.

Thorough cleaning and sanitizing of all equipment and surfaces after handling allergens.

Proper handwashing techniques.

Communicating with Customers

Food handlers must be trained to communicate effectively with customers about their food allergies.

Emergency Procedures

Food handlers should be trained on how to respond to an allergic reaction, including recognizing symptoms and administering epinephrine if trained and authorized to do so.

Knowing the location of epinephrine auto-injectors and how to use them.

Necessity of Specific Certifications for Managing Food Safety

Certain settings or roles may require specific certifications to manage food safety effectively.* Certified Food Safety Manager (CFSM): Many establishments are required to have at least one CFSM on staff. The CFSM certification demonstrates a comprehensive understanding of food safety principles and practices.

The CFSM is responsible for overseeing food safety operations, training employees, and ensuring compliance with food safety regulations.

The CFSM certification often involves passing an exam and completing a food safety training program.

ServSafe Certification

ServSafe is a widely recognized food safety training and certification program. It provides comprehensive training on food safety topics, including foodborne illness, food handling, and sanitation.

Other Specialized Certifications

Depending on the specific type of food establishment or handling practices, additional certifications may be required or recommended.

For example, establishments that handle seafood may require specialized training on seafood safety.

Establishments that prepare and serve potentially hazardous foods, such as raw oysters, may require additional certifications.

Example

Seafood Safety Certification: A restaurant specializing in seafood might require its staff to obtain a specialized certification in seafood safety. This certification would cover topics such as:

Proper seafood handling and storage.

Identifying and preventing seafood toxins.

Safe cooking temperatures for seafood.

Compliance with specific regulations for seafood safety.

Final Review

In essence, Indiana Food Handler Certification transcends mere compliance; it becomes a testament to your dedication to safeguarding health. As you master the art of safe food handling, remember that each action carries the weight of responsibility. Embrace the journey, knowing that you are not just preparing meals, but nurturing the well-being of others. Let this certification be a beacon of your commitment, a reflection of your inner light, illuminating the path towards a safer and more conscious food service experience.