Salt meter for food opens a doorway to mindful eating, a practice that resonates with the spiritual principle of honoring the body as a temple. This exploration goes beyond mere measurement; it’s about cultivating awareness of what we consume, understanding the subtle energies of food, and aligning our choices with our highest good. Just as a yogi seeks balance in the physical form, we can seek balance in our diet, ensuring that the fuel we provide nourishes both body and soul.

We’ll journey through the history and function of salt meters, revealing their power to guide us toward healthier choices. Imagine early methods of measurement, each step a testament to the human desire to understand and improve. We will examine the different types of salt meters, from those that work by conductivity, ion-selective electrodes, and others. We will explore the advantages and disadvantages of each, equipping you with the knowledge to make informed choices about your well-being and the culinary art.

Introduction to Salt Meters for Food

A salt meter, also known as a salinity meter or salt analyzer, is a device used to measure the salt content in food and other solutions. Its primary function is to provide an accurate and objective assessment of sodium chloride (NaCl) concentration, which is crucial for both health and culinary purposes. Understanding and controlling salt levels is essential for anyone concerned about their dietary intake, food safety, and the overall quality of their meals.

Purpose of a Salt Meter in Food Preparation and Consumption

The core purpose of a salt meter is to quantify the amount of salt present in a substance. This quantification serves several key functions.

- Health Management: Salt meters help individuals, particularly those with hypertension or other health conditions sensitive to sodium intake, to monitor and control their dietary salt consumption. This is vital for managing blood pressure and reducing the risk of cardiovascular diseases.

- Food Quality Control: In food production, salt meters ensure consistency in taste and adherence to recipe specifications. They are essential for maintaining the desired flavor profile of food products.

- Culinary Precision: Home cooks and professional chefs can use salt meters to precisely season their dishes, enhancing flavor and avoiding over-salting. This leads to more balanced and palatable meals.

- Food Safety: In certain food preservation methods, like pickling, salt concentration is critical for inhibiting the growth of harmful bacteria. Salt meters help ensure that the correct salt levels are achieved, promoting food safety.

Brief History of Salt Meters

Early methods of measuring salt content were rudimentary and lacked precision. The evolution of salt measurement techniques reflects advancements in scientific understanding and technological innovation.

- Early Methods: Historically, salt content was estimated using taste, which is highly subjective and inaccurate. Other early methods included using hydrometers to measure the density of brine solutions, a method limited by its lack of specificity for salt concentration.

- Titration Methods: As chemistry advanced, titration methods became more prevalent. These involved reacting a sample with a known reagent, like silver nitrate, and calculating the salt concentration based on the amount of reagent used. While more accurate than taste or density measurements, titration was time-consuming and required specialized equipment and expertise.

- Modern Salt Meters: Modern salt meters typically utilize electrochemical principles, such as conductivity or ion-selective electrodes. Conductivity meters measure the ability of a solution to conduct electricity, which increases with the concentration of dissolved ions, including salt. Ion-selective electrodes directly measure the concentration of specific ions, such as sodium. These devices are faster, more accurate, and easier to use than older methods.

Benefits of Using a Salt Meter

The adoption of salt meters offers several advantages across various applications.

- Health Benefits: The primary health benefit is the ability to monitor and control sodium intake. By accurately measuring salt levels, individuals can adhere to dietary guidelines and reduce their risk of hypertension, heart disease, and stroke.

- Culinary Advantages: Salt meters allow for greater precision in seasoning, resulting in more flavorful and consistently delicious dishes. Chefs can fine-tune recipes and ensure that each serving has the desired taste profile.

- Improved Food Quality: In food production, salt meters help maintain consistent product quality and meet regulatory requirements. They enable manufacturers to standardize recipes and avoid variations in salt content that could affect taste or safety.

- Enhanced Food Safety: In food preservation, accurate salt measurement is critical for preventing the growth of harmful microorganisms. Salt meters ensure that salt concentrations are sufficient to inhibit bacterial growth and maintain food safety.

- Cost Savings: By avoiding over-salting, salt meters can potentially reduce the amount of salt used in food preparation, leading to cost savings, especially in large-scale food production.

Types of Salt Meters

The market offers a variety of salt meters, each employing different technologies to measure salt concentration in food and other solutions. Understanding the operating principles, accuracy, and limitations of each type is crucial for selecting the appropriate meter for a specific application. This section delves into the diverse categories of salt meters available.

Conductivity Meters

Conductivity meters, also known as electrolytic conductivity meters, are a common type of salt meter. They operate based on the principle that the conductivity of a solution is directly proportional to the concentration of ions present. Since salt (like sodium chloride) dissociates into ions (Na+ and Cl-) when dissolved in water, its presence increases the solution’s conductivity.These meters typically consist of two electrodes immersed in the solution.

An alternating current is passed between the electrodes, and the meter measures the resulting current flow. The greater the current, the higher the conductivity and, consequently, the higher the salt concentration.

- Operating Principle: Measures the ability of a solution to conduct electricity. Salt, when dissolved, increases conductivity due to the presence of ions.

- Accuracy and Precision: Generally, conductivity meters offer good accuracy and precision for salt measurement, especially in solutions with relatively high salt concentrations. However, accuracy can be affected by temperature variations, as conductivity is temperature-dependent.

- Advantages:

- Relatively inexpensive.

- Simple to operate.

- Provide rapid measurements.

- Disadvantages:

- Can be affected by the presence of other ions in the solution, potentially leading to inaccurate readings.

- Temperature compensation is often required to maintain accuracy.

- Not ideal for very low salt concentrations.

Ion-Selective Electrode (ISE) Meters

Ion-selective electrode (ISE) meters are a more specialized type of salt meter, designed to measure the concentration of specific ions, such as sodium (Na+) or chloride (Cl-). They use an electrode that is selectively sensitive to the target ion.The electrode generates a voltage that is proportional to the activity (effective concentration) of the target ion in the solution. This voltage is measured by the meter, and the concentration is calculated using a calibration curve.

- Operating Principle: Measures the electrical potential difference generated by a specific ion interacting with a selective membrane.

- Accuracy and Precision: ISE meters can provide high accuracy and precision, especially for measuring specific ions. However, accuracy depends on proper calibration and the absence of interfering ions.

- Advantages:

- Highly specific to certain ions (e.g., sodium or chloride).

- Can be used in complex matrices.

- Offer a wide measurement range.

- Disadvantages:

- More expensive than conductivity meters.

- Electrodes require regular maintenance and calibration.

- May be affected by interfering ions.

Refractometers

Refractometers measure salt concentration indirectly by measuring the refractive index of a solution. The refractive index is a measure of how much light bends when passing through a substance. The presence of dissolved salt increases the refractive index of the solution.These meters shine a light beam through the solution and measure the angle at which the light bends. This angle is directly related to the salt concentration.

- Operating Principle: Measures the refractive index of a solution, which is proportional to the salt concentration.

- Accuracy and Precision: Refractometers are generally less accurate than conductivity or ISE meters for salt measurement. Accuracy can be affected by temperature and the presence of other dissolved substances.

- Advantages:

- Simple to use.

- Require only a small sample volume.

- Relatively inexpensive.

- Disadvantages:

- Less accurate than other methods.

- Sensitive to temperature variations.

- Can be affected by the presence of other dissolved substances.

Titration-Based Salt Meters

Titration-based salt meters use a chemical reaction to determine the salt concentration. These meters involve adding a reagent to the sample that reacts with the salt. The amount of reagent required to complete the reaction is measured, and the salt concentration is calculated based on the stoichiometry of the reaction.One common method is argentometric titration, where silver nitrate (AgNO3) is used to titrate chloride ions (Cl-).

The endpoint of the titration is usually determined by an indicator that changes color when all the chloride ions have reacted with the silver ions.

- Operating Principle: Determines salt concentration by reacting the sample with a reagent, measuring the amount of reagent used in the reaction.

- Accuracy and Precision: Titration methods can provide very accurate and precise measurements, especially when performed carefully. However, the accuracy depends on the correct preparation of reagents and careful execution of the titration.

- Advantages:

- High accuracy and precision.

- Can be used for a wide range of salt concentrations.

- Disadvantages:

- Requires some expertise and laboratory skills.

- Can be time-consuming.

- Requires the use of chemicals.

How Salt Meters Work

Salt meters, also known as salinity meters or conductivity meters, are essential tools for measuring the salt content in food. They utilize scientific principles to provide accurate and reliable readings, crucial for quality control and ensuring consumer safety. Understanding how these meters operate, from the underlying scientific concepts to the practical application, is vital for effective use.

Scientific Principles of Operation

Salt meters function primarily based on the principle of conductivity measurement. This measurement relies on the ability of salt, when dissolved in water, to conduct electricity. The more salt present in the solution, the higher the conductivity.The fundamental concept is based on the following:

Ions in Solution

You also can investigate more thoroughly about chicken canned cat food to enhance your awareness in the field of chicken canned cat food.

Salt (NaCl) dissociates into sodium (Na+) and chloride (Cl-) ions when dissolved in water. These ions are charged particles.

Electrical Conductivity

The presence of these free-moving ions allows the solution to conduct electricity. The greater the concentration of ions, the better the conductivity.

Conductivity Measurement

A salt meter typically has two electrodes (usually made of stainless steel or platinum) immersed in the food sample.

Applying Voltage

The meter applies a small alternating current (AC) voltage across these electrodes.

Measuring Current

The meter measures the resulting current flow between the electrodes. The current flow is directly proportional to the conductivity of the solution.

Calculating Salt Concentration

The meter’s internal circuitry then uses a pre-programmed algorithm and calibration data to convert the measured conductivity into a salt concentration value, usually expressed in parts per million (ppm), percentage (%), or grams per liter (g/L).The relationship between conductivity and salt concentration is often approximated by the following formula:

Salt Concentration ∝ Conductivity

This proportionality is not perfectly linear, and the meter’s calibration accounts for the non-linearity.

Calibration of Salt Meters

Calibration is a crucial step to ensure the accuracy of salt meter readings. It involves adjusting the meter to a known standard to correct for any inherent errors in the device. Calibration should be performed regularly, as recommended by the manufacturer, or when the meter is suspected of providing inaccurate readings.The calibration process generally involves these steps:

- Prepare Calibration Solutions: Prepare or obtain calibration solutions of known salt concentrations. These solutions are typically made using high-purity sodium chloride (NaCl) and distilled or deionized water. The manufacturer usually specifies the appropriate calibration solutions (e.g., 0% NaCl, 0.5% NaCl, and 1% NaCl).

- Rinse the Probe: Thoroughly rinse the salt meter’s probe with distilled or deionized water. This removes any residual salt from previous measurements and prevents contamination.

- Calibrate to Standards:

- Immerse the probe in the first calibration solution (e.g., 0% NaCl).

- Follow the meter’s instructions to calibrate to this standard. This usually involves pressing a calibration button and allowing the meter to stabilize.

- Repeat the process for the other calibration solutions (e.g., 0.5% NaCl and 1% NaCl).

- Verify Calibration: After calibration, measure the salt concentration of each calibration solution again to verify that the meter is providing accurate readings.

- Record Calibration Data: Record the date and results of the calibration process for future reference.

Failure to calibrate a salt meter properly can lead to significant errors in measurements, potentially affecting food quality and safety.

Measuring Salt Content in Food Samples

Measuring salt content in various food samples requires a systematic approach to ensure accurate and reliable results. The specific steps may vary slightly depending on the type of food and the salt meter used, but the general principles remain the same.Here’s a step-by-step guide:

- Sample Preparation:

- Liquid Samples: For liquid samples (e.g., sauces, soups, brines), the sample is usually ready to be measured directly. Ensure the sample is at a stable temperature (usually room temperature) to avoid temperature-related errors.

- Solid Samples: For solid samples (e.g., cheese, cured meats, bread), the sample needs to be prepared for measurement. This often involves the following steps:

- Homogenization: Grind or blend the solid sample into a homogenous mixture. This ensures that the salt is evenly distributed throughout the sample.

- Extraction: Extract the salt from the sample by dissolving it in distilled or deionized water. Use a known weight of the sample and a known volume of water.

- Filtration: Filter the solution to remove any solid particles that might interfere with the measurement.

- Rinse the Probe: Before each measurement, rinse the salt meter’s probe with distilled or deionized water to remove any residue from the previous sample.

- Immerse the Probe: Immerse the probe of the salt meter into the prepared sample. Ensure that the probe is fully submerged in the liquid and that the electrodes are in contact with the sample.

- Allow Stabilization: Allow the reading on the meter to stabilize. This may take a few seconds or minutes, depending on the meter and the sample. The meter will typically display a stable reading once the measurement is complete.

- Record the Reading: Record the salt concentration reading displayed on the meter. Note the units of measurement (e.g., ppm, %, g/L).

- Clean the Probe: After each measurement, thoroughly clean the probe with distilled or deionized water to remove any remaining sample residue. This is crucial to prevent cross-contamination between samples and to maintain the accuracy of the meter.

- Repeat for Multiple Samples: If measuring multiple samples, repeat the process for each sample, ensuring that the probe is rinsed and cleaned between measurements.

- Document Results: Document all measurements, including the sample type, preparation method, date, time, and the salt concentration reading. This documentation is essential for quality control and record-keeping.

Food Applications of Salt Meters

Salt meters are indispensable tools in the food industry, ensuring product quality, consistency, and adherence to health regulations. Their versatility allows for applications across various stages of food production and preparation, from the initial ingredient assessment to the final product evaluation. Understanding these applications is crucial for both food professionals and consumers.

Food Categories Utilizing Salt Meters

Salt meters are employed across a broad spectrum of food categories to control and monitor sodium levels. This helps in maintaining product quality and complying with dietary guidelines.

- Processed Foods: Salt meters are crucial for monitoring salt content in processed foods, including ready-to-eat meals, canned goods, and frozen products. They help manufacturers maintain consistent flavor profiles and meet consumer expectations for sodium content. For example, in the production of canned soups, a salt meter is used to ensure that the sodium level remains within the specified range, preventing excessive saltiness or blandness.

- Sauces and Condiments: The production of sauces, dressings, and condiments heavily relies on salt meters. These meters ensure the correct salt balance, which significantly impacts the taste and preservation qualities of the product. Soy sauce, ketchup, and salad dressings are common examples where salt content is closely monitored.

- Soups: Both commercially produced and restaurant-prepared soups benefit from salt meter usage. These meters help maintain the desired saltiness and ensure consistency across batches. In commercial soup production, salt meters are integrated into the production line to provide real-time sodium level readings, allowing for immediate adjustments to the recipe if necessary.

- Baked Goods: Salt plays a crucial role in baking, affecting both flavor and texture. Salt meters help bakers maintain the correct salt levels in bread, pastries, and other baked goods, ensuring the desired taste and shelf life.

- Meat and Poultry Products: Salt meters are frequently used in meat processing to control the salt content in sausages, hams, and other cured meats. Proper salt levels are essential for preservation, flavor enhancement, and meeting regulatory requirements.

Salt Meter Usage in Restaurant Kitchens

Restaurants utilize salt meters to maintain consistent flavor profiles, control sodium intake for customers, and manage ingredient quality. This technology supports efficient kitchen operations and enhances customer satisfaction.

- Recipe Standardization: Salt meters help chefs standardize recipes, ensuring that dishes taste the same every time, regardless of who is preparing them. This consistency is critical for building a loyal customer base.

- Ingredient Quality Control: Checking the salt content of ingredients like stocks, broths, and sauces before they are used in dishes helps ensure that the final product meets quality standards.

- Menu Labeling: As consumers become more aware of sodium intake, restaurants can use salt meters to accurately label the sodium content of their menu items, aiding customers in making informed dietary choices.

- Waste Reduction: By accurately measuring salt levels, chefs can avoid over-salting dishes, which reduces food waste and minimizes ingredient costs.

- Staff Training: Salt meters provide a practical tool for training kitchen staff on the importance of precise seasoning and the impact of salt on food quality.

Salt Meter Applications in Food Manufacturing

Food manufacturers integrate salt meters into their production processes for quality control, process optimization, and regulatory compliance. These applications improve efficiency, consistency, and product safety.

- Inline Monitoring: Salt meters are often integrated into production lines to continuously monitor the salt content of food products during manufacturing. This real-time monitoring allows for immediate adjustments to the process, ensuring that the final product meets quality specifications. For example, in a sauce production line, a salt meter can automatically adjust the salt addition based on the measured salt concentration, maintaining the desired flavor profile.

- Batch Testing: Before releasing a batch of food products, manufacturers often use salt meters to test samples and verify that the salt content is within acceptable limits. This testing helps prevent products with incorrect salt levels from reaching consumers.

- Ingredient Analysis: Salt meters can be used to analyze the salt content of incoming ingredients, such as salt itself, flavorings, and other components. This helps manufacturers ensure that the ingredients meet quality standards and do not introduce unexpected variations in the final product.

- Process Optimization: By analyzing salt meter data, manufacturers can optimize their production processes to improve efficiency and reduce waste. This can involve adjusting the timing or amount of salt addition, as well as refining other aspects of the production process.

- Regulatory Compliance: Salt meters assist food manufacturers in meeting regulatory requirements for sodium content labeling and product safety. Accurate measurement of salt levels is essential for providing consumers with accurate nutritional information and complying with health guidelines.

Using a Salt Meter: Methods and Procedures

Accurate salt measurement using a salt meter hinges on a combination of proper technique and understanding the instrument’s functionality. This section provides a detailed guide on using a salt meter effectively, covering sample preparation, measurement procedures, and interpreting the results. It emphasizes the critical steps necessary for reliable and consistent salt content analysis in food.

Step-by-Step Guide to Measuring Salt Content

Measuring salt content with a salt meter involves several key steps. Following these procedures ensures accurate and repeatable results.

- Prepare the Sample: Sample preparation is crucial for accurate readings. For solid foods, such as cheese or processed meats, the sample needs to be homogenized. This typically involves grinding or blending the food to create a uniform mixture. For liquids, like sauces or soups, ensure the sample is well-mixed.

- Calibrate the Salt Meter: Before each use, calibrate the salt meter using a standard solution with a known salt concentration. This ensures the meter is reading accurately. Follow the manufacturer’s instructions for calibration, which usually involves immersing the sensor in the calibration solution and adjusting the meter until it displays the correct value.

- Prepare the Meter: Ensure the salt meter’s sensor is clean. Rinse the sensor with distilled water and dry it thoroughly with a soft, lint-free cloth.

- Measure the Sample: Immerse the sensor of the salt meter into the prepared food sample. Make sure the sensor is fully submerged and that no air bubbles are trapped around it.

- Wait for the Reading: Allow the reading on the salt meter to stabilize. This usually takes a few seconds, but it’s important to wait until the reading is consistent before recording the value. The stabilization time can vary depending on the food sample and the specific salt meter model.

- Record the Reading: Note the salt concentration displayed on the meter. The units of measurement may vary depending on the meter, such as parts per thousand (ppt), percentage (%), or parts per million (ppm). Be sure to record the units along with the numerical value.

- Clean the Sensor: After each measurement, thoroughly clean the sensor with distilled water to remove any food residue. Dry the sensor with a soft cloth before storing the meter.

Interpreting Salt Meter Readings

Understanding how to interpret the readings on a salt meter is essential for determining the salt content of food samples. The readings provide quantitative data that can be used to assess the salinity.

Salt meters display readings in various units, including percentage (%), parts per thousand (ppt), and parts per million (ppm). The specific unit used depends on the meter’s design and the manufacturer’s specifications. It’s important to understand the units to interpret the results correctly.

For example, if a salt meter displays a reading of 0.5%, this means that 0.5% of the sample’s weight is salt. A reading of 5 ppt (parts per thousand) is equivalent to 0.5% (since 5/1000 = 0.005, which is 0.5%). A reading of 5000 ppm (parts per million) is also equivalent to 0.5% (since 5000/1000000 = 0.005, which is 0.5%).

Different foods have different acceptable salt content ranges. These ranges are often determined by regulatory standards or consumer preferences. For example, some processed meats might have a target salt content of 2-3%, while bread may have a lower target, around 1-2%. It’s important to be aware of these ranges when interpreting the salt meter readings.

Importance of Sample Preparation for Accurate Measurements

Proper sample preparation is paramount for achieving accurate and reliable salt measurements. Inconsistent or poorly prepared samples can lead to inaccurate readings and misleading conclusions.

The goal of sample preparation is to create a homogeneous and representative sample that accurately reflects the salt content of the entire food product. For solid foods, this usually involves processes like grinding, blending, or homogenization to ensure the salt is evenly distributed throughout the sample.

- Homogenization: Grinding or blending a solid food sample into a uniform mixture ensures that the salt is evenly distributed throughout the sample. Without homogenization, the salt content can vary significantly between different parts of the sample, leading to inconsistent readings.

- Dilution: In some cases, particularly with highly concentrated or viscous samples, it may be necessary to dilute the sample with distilled water. This can help the salt meter’s sensor to function properly and provide more accurate readings. The dilution factor must be taken into account when interpreting the results.

- Temperature Control: The temperature of the sample can affect the salt meter’s readings. It is crucial to ensure that the sample temperature is within the meter’s operating range. Allow the sample to reach room temperature before measurement.

For example, consider measuring the salt content of a block of cheddar cheese. If a chunk is taken without proper preparation, the salt content may vary depending on where the chunk was cut. However, if the cheese is grated and thoroughly mixed, the resulting sample will be much more representative of the overall salt content of the cheese. Another example is a soup, where the salt concentration can vary throughout the pot if not mixed before taking a sample.

Factors Affecting Salt Meter Readings

Salt meter readings, while offering a convenient way to assess salinity, are not immune to external influences. Several factors can subtly or significantly alter the accuracy of the measurements, potentially leading to misinterpretations of the salt content in food. Understanding these factors and implementing strategies to mitigate their impact is crucial for obtaining reliable and consistent results.

Temperature Influence on Readings

Temperature plays a significant role in salt meter readings. The electrical conductivity of a solution, which salt meters measure, is directly affected by temperature. As temperature increases, the mobility of ions in the solution increases, leading to a higher conductivity reading, and vice versa. This means that a food sample at a higher temperature might register a higher salt content compared to the same sample at a lower temperature, even if the actual salt concentration is the same.To address this, most modern salt meters incorporate automatic temperature compensation (ATC).

This feature uses a built-in temperature sensor to measure the sample’s temperature and automatically adjust the conductivity reading to a standard temperature, typically 25°C (77°F). However, the effectiveness of ATC can vary, and it’s important to be aware of its limitations.For example, consider two identical samples of soup, one at 20°C and the other at 30°C. Without ATC, the soup at 30°C would likely register a higher salt content.

With ATC, the meter would compensate for the temperature difference, ideally providing similar salt content readings for both samples. However, the accuracy of this compensation relies on the meter’s calibration and the specific characteristics of the food being tested.

Impact of Food Composition on Measurements

The composition of the food being tested can also influence salt meter readings. While salt meters are designed to measure the conductivity primarily due to sodium chloride (table salt), other dissolved substances present in the food can also contribute to the overall conductivity. These substances include other salts, acids, and bases, which can interfere with the accuracy of the salt measurement.Different food matrices have varying compositions.

For instance, a sample of soy sauce, which contains a complex mixture of compounds, might yield different readings compared to a simple saline solution with the same salt concentration. The presence of sugars, proteins, and other organic molecules can also affect the conductivity of the solution.To minimize the impact of food composition, it is crucial to:

- Calibrate the meter: Calibrate the salt meter using a standard solution that closely resembles the food matrix being tested. This helps to account for the influence of other ions and substances.

- Consider the food type: Be aware that the readings may not be directly comparable across different food types. For example, the meter might show a different reading for a given salt concentration in a meat marinade compared to a vegetable broth.

- Dilute the sample: Diluting the food sample with distilled water can sometimes reduce the influence of interfering substances, though this also reduces the concentration of the salt itself, potentially affecting accuracy.

Electrode Condition and its Effect

The condition of the salt meter’s electrodes is critical for accurate measurements. Electrodes are the sensors that come into contact with the food sample and measure its conductivity. Over time, these electrodes can become contaminated with food particles, oils, or other residues, which can affect their performance. Corrosion or damage to the electrodes can also impact the readings.Regular maintenance and cleaning of the electrodes are essential to ensure accurate and reliable readings.

Here are some tips for maintaining and cleaning the electrodes:

- Rinse thoroughly: After each use, rinse the electrodes with distilled or deionized water to remove any food residue.

- Gentle cleaning: Use a soft, non-abrasive cloth or brush to gently clean the electrodes. Avoid using harsh chemicals or abrasive materials that could damage the electrodes.

- Calibration checks: Regularly check the meter’s calibration using a standard solution to verify its accuracy. If the readings are consistently off, the electrodes may need to be cleaned or replaced.

- Storage: Store the salt meter and its electrodes properly, following the manufacturer’s instructions. This may involve storing the electrodes in a specific solution to prevent drying or corrosion.

Other Influencing Factors

Besides the factors mentioned above, several other elements can impact the accuracy of salt meter readings.

- Sample Preparation: Inconsistent sample preparation can introduce errors. Ensure the food sample is properly homogenized (blended or mixed) to distribute the salt evenly.

- Meter Calibration: Regular calibration is crucial. Use standard solutions of known salt concentrations to calibrate the meter.

- Meter Quality: The quality and design of the salt meter itself can affect accuracy. Choose a reputable brand and model.

Salt Meter Specifications and Features

Selecting the right salt meter is crucial for accurate and reliable measurements in food applications. Understanding the specifications and features of these instruments allows users to choose a model that best suits their specific needs and ensures the quality and safety of their products. This section details the key considerations when choosing a salt meter.

Key Specifications to Consider

Several specifications are critical when evaluating salt meters. These specifications directly impact the accuracy, precision, and usability of the instrument. Careful consideration of these factors ensures that the chosen meter meets the required performance standards.

- Measurement Range: The measurement range defines the lowest and highest salt concentrations the meter can accurately detect. This range should encompass the expected salt levels in the food being tested. For example, a meter used for measuring salt in soy sauce might require a higher range than one used for measuring salt in cheese.

- Resolution: Resolution refers to the smallest change in salt concentration the meter can detect and display. A higher resolution provides more precise readings. For instance, a meter with a resolution of 0.01% would provide more detailed information than one with a resolution of 0.1%.

- Accuracy: Accuracy indicates how close the meter’s readings are to the true salt concentration. Accuracy is usually expressed as a percentage of the reading or a specific value (e.g., ±0.1%). Higher accuracy is essential for critical applications where precise salt content control is necessary.

- Response Time: Response time is the duration it takes for the meter to provide a stable and accurate reading. A faster response time is beneficial for quick measurements, especially in a production environment.

- Temperature Compensation: Temperature significantly affects the conductivity of salt solutions. Temperature compensation automatically adjusts the readings to account for temperature variations, ensuring accurate results regardless of the sample’s temperature.

- Calibration: Calibration is the process of adjusting the meter to ensure its readings are accurate. The calibration process should be simple and straightforward, with clear instructions provided by the manufacturer.

Salt Meter Features

Salt meters come with various features designed to enhance their usability and functionality. These features can significantly improve the efficiency and effectiveness of salt measurement in food applications.

- Data Logging: Data logging allows the meter to record and store measurement data over time. This feature is invaluable for monitoring salt content trends, tracking quality control, and creating reports. The data can often be transferred to a computer for further analysis.

- Waterproof Design: A waterproof or water-resistant design is essential for meters used in food processing environments, where they may be exposed to moisture and spills. This feature protects the meter from damage and ensures its longevity.

- Portability: Portable salt meters are battery-operated and compact, allowing for easy use in various locations. This feature is particularly useful for field testing, quality control checks, and on-site measurements.

- Display: The display should be clear and easy to read, even in low-light conditions. Some meters feature backlit displays for improved visibility.

- Electrode Type: The type of electrode used by the meter influences its performance and suitability for different food types. Some electrodes are designed for general use, while others are specifically designed for viscous or solid samples.

- User Interface: A user-friendly interface simplifies the operation of the meter. Intuitive menus and controls minimize the learning curve and reduce the potential for errors.

Salt Meter Model Comparison

The following table compares the features of three different salt meter models, providing a quick overview of their specifications and capabilities.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Measurement Range | 0.00 to 10.00% NaCl | 0.00 to 5.00% NaCl | 0.00 to 20.00% NaCl |

| Resolution | 0.01% NaCl | 0.01% NaCl | 0.01% NaCl |

| Accuracy | ±0.1% NaCl | ±0.05% NaCl | ±0.2% NaCl |

| Data Logging | Yes (100 readings) | Yes (500 readings) | No |

| Waterproof | IP67 | IP65 | IP54 |

| Portability | Yes (Battery Operated) | Yes (Battery Operated) | Yes (AC Power) |

| Temperature Compensation | Automatic | Automatic | Automatic |

| Electrode Type | General Purpose | Specialty for Liquids | General Purpose |

Salt Content Standards and Regulations

Maintaining appropriate sodium levels in food is crucial for public health. Governments and health organizations worldwide have established guidelines and regulations to help consumers make informed choices and reduce their sodium intake. These standards aim to mitigate the risks associated with excessive sodium consumption, such as hypertension and cardiovascular diseases. Salt meters play a vital role in ensuring food manufacturers adhere to these regulations, ultimately contributing to a healthier food supply.

Recommended Daily Sodium Intake and Dietary Guidelines

Understanding the recommended daily sodium intake is fundamental to adopting a healthy diet. Various health organizations have developed dietary guidelines to assist individuals in managing their sodium consumption.The World Health Organization (WHO) recommends that adults consume less than 2,000 milligrams of sodium per day (equivalent to 5 grams of salt). The American Heart Association (AHA) suggests a similar target, advising most adults to limit their sodium intake to no more than 2,300 milligrams per day and aiming for an ideal limit of no more than 1,500 milligrams per day for those with high blood pressure or at risk.Adhering to these guidelines can significantly reduce the risk of sodium-related health problems.

Dietary guidelines often emphasize reducing the consumption of processed foods, which are typically high in sodium, and increasing the intake of fresh, unprocessed foods.

Compliance with Salt Content Regulations through Salt Meters

Food manufacturers must adhere to stringent salt content regulations to ensure consumer safety and compliance with health guidelines. Salt meters are indispensable tools in this process, offering accurate and efficient methods for monitoring sodium levels.Salt meters allow food producers to:

- Accurately Measure Sodium Levels: Salt meters provide precise measurements of sodium content in food products, enabling manufacturers to verify that their products meet regulatory requirements.

- Monitor Production Processes: By regularly using salt meters during production, manufacturers can monitor and control sodium levels throughout the manufacturing process, identifying and correcting any deviations from target values.

- Conduct Quality Control: Salt meters facilitate quality control checks, ensuring that the sodium content of finished products falls within acceptable limits before they are released to the market.

- Maintain Documentation: Salt meter readings can be recorded and used as evidence of compliance with regulations, providing valuable documentation for audits and inspections.

By integrating salt meters into their quality control procedures, food manufacturers can proactively manage sodium content, reduce the risk of regulatory violations, and demonstrate their commitment to consumer health.

Role of Salt Meters in Food Labeling and Consumer Information

Accurate food labeling is essential for empowering consumers to make informed dietary choices. Salt meters contribute significantly to the accuracy and reliability of food labeling information, enabling consumers to monitor their sodium intake effectively.Salt meters support the following:

- Accurate Nutrition Facts Panels: Salt meters enable manufacturers to provide precise data for the “sodium” content on nutrition facts panels, allowing consumers to easily assess the sodium content of a product.

- Ingredient Labeling: Salt meters assist in identifying the sodium content of various ingredients used in food products, ensuring that the total sodium content is accurately reflected on the ingredient list.

- Consumer Education: Accurate labeling, supported by salt meter data, helps educate consumers about the sodium content of different foods, empowering them to make healthier choices.

- Transparency and Trust: The use of salt meters and accurate labeling promotes transparency in the food industry, fostering trust between manufacturers and consumers.

By providing reliable data for food labeling, salt meters play a critical role in supporting consumer health and enabling informed dietary choices.

Troubleshooting Common Issues: Salt Meter For Food

Using a salt meter can significantly improve the accuracy and consistency of salt content measurement in food. However, like any scientific instrument, salt meters are susceptible to various issues that can affect their performance. This section addresses common problems users may encounter and provides practical solutions to ensure accurate and reliable readings. Proper troubleshooting is essential for maintaining the meter’s functionality and achieving desired results.

Calibration Problems and Solutions, Salt meter for food

Calibration is crucial for the accuracy of a salt meter. Inaccurate calibration is a frequent cause of erroneous readings.To resolve calibration issues:

- Calibration Solutions: Use fresh, properly prepared calibration solutions of known salt concentrations (e.g., 0.0%, 0.5%, 1.0%, and 2.0% NaCl) as specified by the meter’s manufacturer. Always verify the expiry dates of calibration solutions.

- Calibration Procedure: Carefully follow the manufacturer’s calibration instructions. This typically involves immersing the sensor in each calibration solution and adjusting the meter’s settings until it displays the correct salt concentration for each solution.

- Sensor Condition: Check the sensor for any damage or contamination before calibrating. Clean the sensor gently with distilled water and a soft cloth. Replace the sensor if it is damaged.

- Temperature Compensation: Ensure that the meter’s temperature compensation function is working correctly. The temperature of the calibration solutions should be within the specified range.

- Regular Calibration: Calibrate the meter regularly, as recommended by the manufacturer or more frequently if the meter is used heavily.

Inaccurate Readings and Potential Causes

Inaccurate readings can stem from various factors, impacting the reliability of the salt meter.Common causes of inaccurate readings include:

- Sensor Contamination: Food particles or residues on the sensor can interfere with readings.

- Air Bubbles: Air bubbles trapped around the sensor can disrupt the measurement.

- Incorrect Sample Preparation: Improper sample preparation, such as inadequate homogenization, can lead to inconsistent results.

- Temperature Variations: Significant temperature differences between the sample and the calibration solutions can affect accuracy.

- Electrode Aging: The sensor electrode degrades over time, leading to less accurate readings.

- Battery Issues: Low battery power can impact the meter’s performance.

Resolving Technical Difficulties

Addressing technical issues promptly is important for maintaining the salt meter’s functionality.Here are solutions for common technical difficulties:

- Cleaning the Sensor: Gently clean the sensor with distilled water and a soft cloth after each use and before calibration. For stubborn residues, use a mild detergent solution.

- Removing Air Bubbles: Tap the sensor gently to dislodge air bubbles. Ensure the sensor is fully immersed in the sample.

- Sample Preparation: Follow the recommended sample preparation procedures, including proper homogenization and dilution. Use a calibrated scale for accurate weighing.

- Temperature Control: Allow the sample and calibration solutions to reach a stable temperature. Some meters have automatic temperature compensation (ATC) to correct for temperature variations.

- Sensor Replacement: Replace the sensor when it becomes worn or damaged. The lifespan of a sensor varies depending on usage and care.

- Battery Check: Replace the batteries when the meter displays a low battery indicator. Ensure the correct battery type is used.

- Meter Malfunctions: If the meter continues to give inaccurate readings or shows error messages, consult the manufacturer’s troubleshooting guide or contact technical support.

Tips for Troubleshooting and Resolving Technical Difficulties

Employing systematic troubleshooting techniques can efficiently identify and resolve problems.Effective troubleshooting strategies:

- Consult the Manual: Refer to the manufacturer’s manual for specific troubleshooting steps and error codes.

- Check Connections: Ensure all connections, such as the sensor cable, are secure.

- Isolate the Problem: Test the meter with known solutions to determine if the issue lies with the meter or the sample.

- Documentation: Keep a log of readings, calibration dates, and any issues encountered. This helps in tracking performance and identifying patterns.

- Seek Expert Assistance: If the problem persists, contact the manufacturer’s technical support for assistance.

Alternatives to Salt Meters

While salt meters offer a precise and convenient way to measure salt content, several alternative methods exist for estimating the salt levels in food. These methods range in accuracy, complexity, and cost, making them suitable for different applications and users. Understanding these alternatives is crucial for food professionals and home cooks who need to manage sodium intake but may not have access to or require the precision of a salt meter.

Sensory Evaluation

Sensory evaluation, relying on taste, smell, and sometimes visual cues, is a common and readily available method for estimating saltiness. This approach leverages human perception to gauge the salt content in food.The primary advantage of sensory evaluation is its simplicity and accessibility. No specialized equipment is needed, making it a convenient option for anyone. However, the significant disadvantage lies in its subjectivity.

Taste perception varies greatly among individuals due to factors like age, genetics, and prior exposure to salt.The limitations of sensory evaluation are substantial compared to a salt meter.

- Subjectivity: Taste perception is highly individual, leading to inconsistent results. What one person perceives as adequately salted, another may find bland or overly salty.

- Inaccuracy: Sensory evaluation provides only a rough estimate of salt content. It cannot provide precise measurements like a salt meter.

- Inability to Detect Hidden Salt: Sensory evaluation is ineffective in detecting salt that is masked by other flavors or present in processed foods where the salt may not be immediately apparent.

- Fatigue: Repeated tasting can lead to taste fatigue, diminishing the accuracy of subsequent evaluations.

Use of Recipes and Ingredient Lists

Analyzing recipes and ingredient lists provides an indirect method for estimating salt content. By knowing the amount of salt added during food preparation, one can infer the approximate salt level in the final product.The advantage of this method is its relative ease, especially when dealing with recipes one has created or meticulously followed. It provides a reasonable starting point for understanding the salt content of a dish.

However, the accuracy hinges on precise measurements during cooking and the consistency of the recipe.The limitations of using recipes and ingredient lists are considerable when compared to salt meters.

- Incomplete Information: Recipes may not always specify the exact amount of salt added, using terms like “to taste,” leading to significant variations in salt content.

- Ingredient Variations: Salt content in ingredients can vary. For instance, the salt content in commercially available broths or sauces can differ significantly between brands.

- Unaccounted for Salt: This method does not account for salt naturally present in ingredients.

- Complexity with Prepared Foods: It is challenging to estimate salt content in commercially prepared foods using this method, as recipes are often proprietary information.

Estimation Based on Nutritional Information

Examining the nutritional information panel on packaged foods offers another way to estimate salt content, particularly for processed foods. The “sodium” content listed on the label directly indicates the amount of sodium present.The advantage is that this method is readily available for packaged foods and provides a relatively precise sodium measurement. However, it’s crucial to consider that the label may refer to a serving size, and the total salt content depends on how much of the product is consumed.The limitations compared to a salt meter are as follows:

- Limited Applicability: This method is only applicable to packaged foods with nutritional labels. It cannot be used for fresh foods, homemade meals, or food served in restaurants.

- Conversion Required: While sodium is directly provided, the salt content (sodium chloride) needs to be calculated. The conversion formula is:

- Incomplete Information: The nutritional information may not always specify the exact salt added during processing, especially if other ingredients containing sodium are used.

- Serving Size Variability: The salt content is per serving, and individuals may consume different serving sizes, leading to inaccurate estimations.

Salt (g) = Sodium (g)

– 2.54

Chemical Titration

Chemical titration, a more scientific method, involves a chemical reaction to determine the salt content. This usually involves reacting a food sample with a solution of known concentration.The primary advantage of chemical titration is its accuracy. It can provide relatively precise measurements of salt content. However, the method is complex and requires specialized equipment and trained personnel.The limitations of chemical titration compared to a salt meter are significant.

- Complexity and Cost: Chemical titration requires laboratory equipment, chemicals, and trained personnel, making it expensive and time-consuming.

- Time-Consuming: The process of chemical titration is generally more time-consuming than using a salt meter.

- Destructive Testing: Chemical titration typically involves destroying the food sample, which means the food cannot be consumed after the analysis.

- Limited Accessibility: Chemical titration is not practical for routine use in home kitchens or many food service settings due to its complexity and equipment requirements.

Future Trends in Salt Meter Technology

The landscape of salt meter technology is constantly evolving, driven by demands for greater precision, user-friendliness, and integration with broader analytical systems. These advancements promise to reshape how we monitor and manage salt content in food, enhancing both food safety and the consumer experience.

Miniaturization and Improved Accuracy

Significant progress is expected in miniaturizing salt meter devices while simultaneously enhancing their accuracy. This trend is crucial for several reasons, from enabling more convenient point-of-use testing to allowing for more detailed analysis at the cellular level.

- Smaller, More Portable Devices: The reduction in size allows for more compact and portable salt meters, suitable for use in various settings, including home kitchens, restaurants, and field testing scenarios. This aligns with the growing demand for on-the-go food safety checks.

- Enhanced Sensitivity and Precision: Improved sensor technology, including advancements in electrochemical and optical sensing methods, will contribute to higher levels of accuracy. This allows for detecting even trace amounts of salt, providing more comprehensive analysis.

- Integration of Advanced Materials: The utilization of advanced materials, such as nanomaterials and biocompatible polymers, will enhance sensor sensitivity and stability. These materials can improve the interaction between the sensor and the food sample, leading to more accurate readings.

Potential Advancements in Salt Meter Design and Functionality

Future salt meters are likely to incorporate a range of innovative features, significantly improving their usability and expanding their application.

- Wireless Connectivity and Data Logging: Future salt meters will feature wireless connectivity (e.g., Bluetooth, Wi-Fi) to transmit data directly to smartphones, tablets, or cloud-based platforms. This enables real-time monitoring, data logging, and integration with other analytical tools.

- Multi-Parameter Analysis: Advanced salt meters may go beyond simple salt concentration measurements, incorporating the ability to measure other relevant parameters, such as pH, temperature, and other ionic concentrations. This provides a more comprehensive understanding of food composition.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms can be used to analyze data, predict salt content in different food types, and provide customized recommendations. This could include suggestions for salt reduction strategies based on the user’s preferences and dietary needs.

- User-Friendly Interfaces and Touchscreen Displays: Enhanced user interfaces, featuring touchscreen displays and intuitive software, will simplify the operation and interpretation of results. The design will prioritize ease of use, making the devices accessible to a wider range of users.

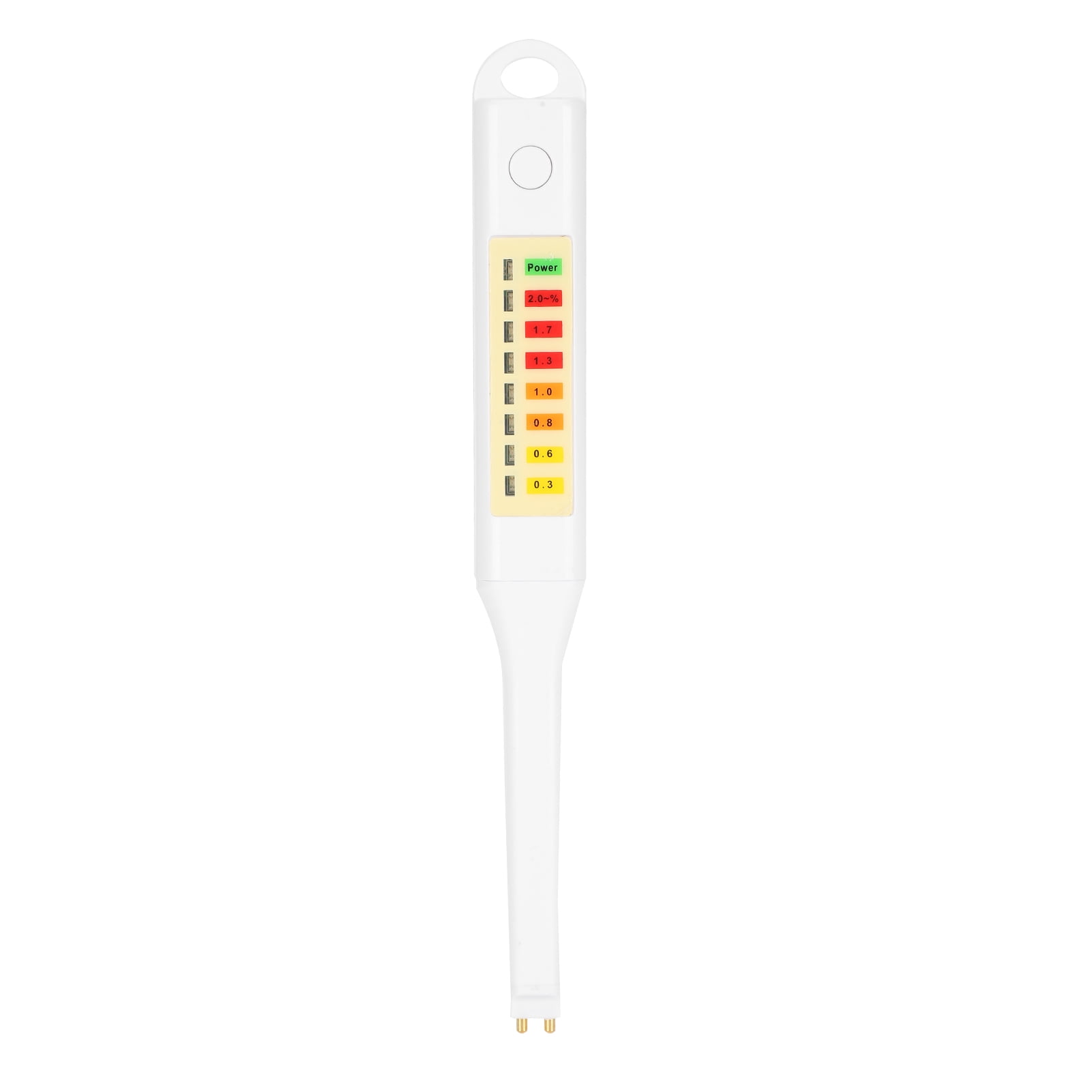

Futuristic Salt Meter Illustration

Imagine a futuristic salt meter: a sleek, handheld device shaped like a pen, approximately 6 inches in length and 0.75 inches in diameter. The body is constructed from a durable, matte-black composite material, resistant to both water and impact. A small, high-resolution touchscreen display is embedded near the top of the device, providing a clear view of measurement readings, data trends, and user interface controls.The device features a retractable probe, extending from the bottom.

This probe is made of biocompatible material and houses advanced sensor technology. The probe’s tip is designed to be easily cleaned and sanitized. A single, multi-function button is located on the device’s side, controlling power, measurement initiation, and menu navigation.The user interface is intuitive and graphically rich. The main screen displays a real-time salt concentration reading, presented numerically and graphically.

Data is displayed in a color-coded format, with green indicating a low salt level, yellow representing a moderate level, and red signifying a high level. The display also shows historical data, allowing the user to track salt content trends over time. The device connects wirelessly to a companion smartphone app via Bluetooth. The app offers detailed data analysis, allows users to set salt intake goals, and provides personalized recommendations for healthier eating habits.

Closure

In essence, the salt meter for food is a tool for empowerment, a guide on the path to conscious living. By understanding salt content, we embrace the opportunity to align our dietary choices with our deepest values. Let the knowledge of the salt meter illuminate your path toward a balanced, vibrant life. May your journey be filled with awareness, gratitude, and the joy of nourishing your body and spirit.