Alright, so, let’s talk about the univex food slicer. No, it’s not a fancy new dating app (though, imagine the possibilities!). It’s actually a workhorse in the food world, the unsung hero that makes your deli sandwiches look like they came from a Michelin-starred restaurant. We’re talking about slicing things, and slicing them well. And hey, if you’re like me and your kitchen skills peak at “making instant noodles,” this thing might just be the secret to impressing your friends (and yourself).

This isn’t just some random kitchen gadget; Univex has been around the block, a veteran in the food service industry. We’ll dive into the different models, from the manual ones (for those of us who like a good arm workout) to the automatic ones (for the lazy, like me). We’ll uncover how these slicers are used, their features, and how they can save you time, money, and maybe even a finger or two (safety first, people!).

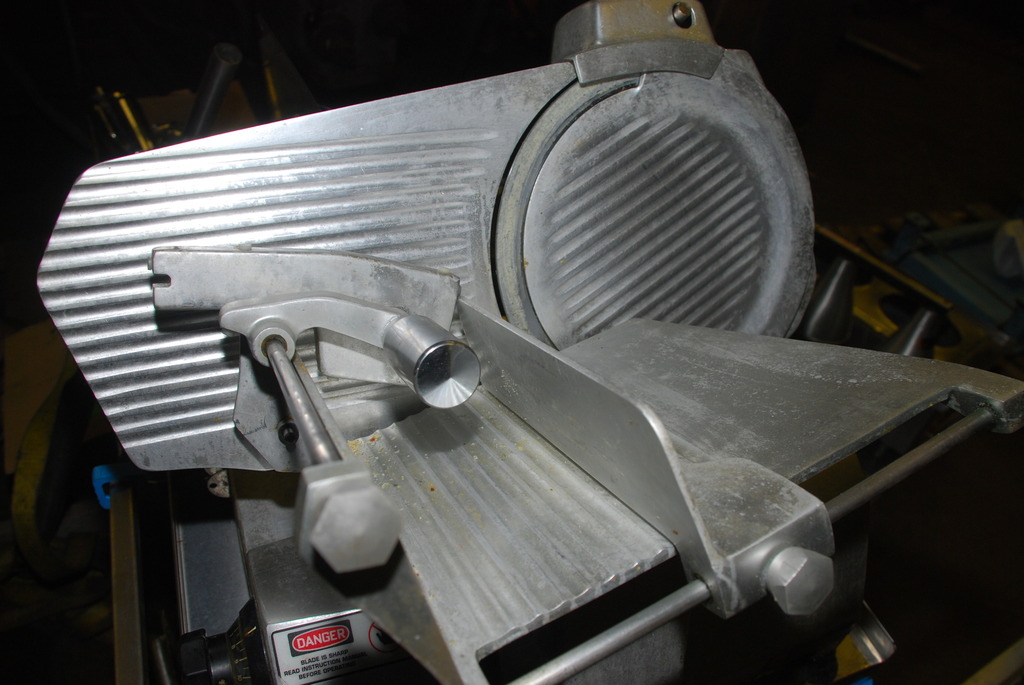

Introduction to Univex Food Slicers

Univex, a name synonymous with quality and durability in the food service industry, has been a trusted provider of commercial kitchen equipment for decades. Their food slicers, in particular, have earned a reputation for precision, reliability, and ease of use, making them a staple in restaurants, delis, and other food preparation environments. The company’s commitment to innovation and customer satisfaction has solidified its position as a leader in the market.

Univex Brand History and Reputation

Univex Corporation was founded in 1948, originally specializing in dough processing equipment. Over the years, they expanded their product line to include a wide range of food service equipment, including slicers, mixers, and vegetable cutters. Univex quickly gained recognition for its robust construction and dependable performance. Their slicers, in particular, became known for their ability to handle high-volume slicing tasks with consistent results.

The brand’s reputation is built on several key factors:

- Durability: Univex equipment is built to withstand the rigors of a busy commercial kitchen. The use of high-quality materials and solid construction ensures a long lifespan.

- Performance: Univex slicers deliver precise and consistent slicing, minimizing waste and maximizing efficiency.

- Ease of Use: The user-friendly design makes Univex slicers easy to operate, clean, and maintain, reducing downtime and simplifying operations.

- Innovation: Univex continually introduces new features and technologies to improve its products and meet the evolving needs of the food service industry.

Types of Univex Food Slicers

Univex offers a comprehensive range of food slicers to meet the diverse needs of its customers. These slicers are categorized primarily by their operational method: manual and automatic. The choice between the two often depends on the volume of slicing required and the level of automation desired.

- Manual Slicers: These slicers require the operator to manually move the product across the blade. They are typically more affordable and suitable for lower-volume slicing needs. The operator controls the thickness of the slices and the speed of the slicing process.

- Automatic Slicers: These slicers feature a carriage that automatically moves the product across the blade, allowing for hands-free operation. This is particularly useful for high-volume slicing, as it increases efficiency and reduces operator fatigue. Automatic slicers often include features such as automatic shut-off and portion control.

Additionally, Univex slicers are available in various sizes and blade configurations to accommodate different food products and slicing requirements. For instance, some models are designed specifically for slicing deli meats, while others are better suited for vegetables or cheeses. The specific model chosen depends on the type of food being sliced and the desired output.

Primary Uses of Univex Food Slicers

Univex food slicers are essential tools in various commercial food preparation environments. Their versatility and precision make them indispensable for a wide range of applications.

- Restaurants: Restaurants use Univex slicers for preparing ingredients for sandwiches, salads, and entrees. They are used to slice meats, cheeses, vegetables, and other ingredients, ensuring consistent portioning and presentation.

- Delis: Delis rely heavily on Univex slicers for slicing deli meats, cheeses, and other prepared foods. The slicers enable delis to quickly and efficiently prepare custom orders for customers.

- Supermarkets: Supermarkets use Univex slicers in their deli and meat departments to slice meats, cheeses, and other products for sale. This allows them to offer customers freshly sliced products.

- Catering Companies: Catering companies use Univex slicers to prepare large quantities of food for events. They can slice meats, cheeses, and vegetables quickly and efficiently, ensuring consistent portioning for each serving.

The benefits of using Univex food slicers in these environments include:

- Consistent Slicing: Ensuring uniform slices, which improves presentation and portion control.

- Reduced Waste: Minimizing waste by providing precise slicing and reducing product give-away.

- Increased Efficiency: Streamlining food preparation, saving time, and improving productivity.

- Improved Food Safety: Designed with features that promote hygiene and ease of cleaning.

Features and Benefits of Univex Slicers

Univex food slicers are designed to meet the rigorous demands of commercial kitchens and food service establishments. They are built with a focus on durability, performance, and safety, making them a preferred choice for professionals. This section will delve into the key features and benefits that set Univex slicers apart, providing a comprehensive understanding of their capabilities.

Blade Quality and Construction

The blade is the heart of any food slicer, and Univex understands this. Their slicers are renowned for their superior blade quality and construction, ensuring consistent and precise slicing.Univex slicers utilize high-quality, hardened steel blades. These blades are engineered to maintain their sharpness for extended periods, reducing the need for frequent sharpening. The blade’s construction is also a key differentiator:* The blades are typically made from high-carbon stainless steel, providing excellent corrosion resistance and durability.

- The blade’s design often incorporates a hollow-ground edge, which contributes to sharper cuts and reduces friction, making slicing easier and more efficient.

- Some models feature a hard-chrome-plated blade, which further enhances the blade’s durability and resistance to wear.

The combination of these features results in a blade that delivers exceptional slicing performance, even with high-volume use.

The quality of the blade directly impacts the consistency and efficiency of the slicing process.

Safety Features

Safety is paramount in any commercial kitchen environment. Univex slicers are designed with a range of safety features to minimize the risk of accidents and protect users.Univex slicers incorporate several safety mechanisms:* A blade guard covers the blade when not in use, preventing accidental contact.

- Some models include a safety interlock system that prevents the slicer from operating unless all safety components are properly engaged.

- The carriage and food pusher designs often feature hand guards to keep hands away from the blade during operation.

- Non-slip feet ensure the slicer remains stable on the countertop, reducing the risk of movement during use.

These safety features provide peace of mind for users, allowing them to operate the slicer with confidence and focus on their tasks.

Efficiency, Consistency, and Waste Reduction

Univex slicers are engineered to optimize efficiency, consistency, and waste reduction in food preparation. These benefits translate into significant advantages for food service businesses.* Efficiency: The powerful motors and sharp blades of Univex slicers allow for rapid slicing of large quantities of food, saving time and labor.

Consistency

Univex slicers deliver uniform slices every time, ensuring consistent portion sizes and presentation. This is crucial for maintaining quality and controlling food costs.

Waste Reduction

The precision of Univex slicers minimizes food waste by allowing for precise slicing, maximizing yield, and reducing the amount of food trimmed or discarded.By streamlining the slicing process, Univex slicers contribute to a more productive and profitable operation. For example, a deli can slice meats and cheeses with consistent thickness, ensuring each sandwich is prepared to the same standard, leading to customer satisfaction and reduced waste.

Univex Slicer Model Comparison, Univex food slicer

The following table provides a comparison of key features for several Univex slicer models:

| Model Number | Blade Size (inches) | Motor Power (HP) | Material |

|---|---|---|---|

| Univex US25 | 10 | 1/3 | Anodized Aluminum |

| Univex US30 | 12 | 1/2 | Anodized Aluminum |

| Univex US35 | 13 | 3/4 | Stainless Steel |

This table provides a glimpse into the variety of Univex slicer models available, allowing businesses to select the model that best suits their specific needs and volume requirements. The choice of material, blade size, and motor power contributes to the overall performance and durability of the slicer.

Univex Slicer Models and Specifications

Now that we’ve explored the introduction, features, and benefits of Univex food slicers, let’s dive into the specifics of the various models available. Understanding the nuances of each model, including blade types, specifications, materials, and intended applications, is crucial for making an informed decision that aligns with your specific culinary needs. This section will provide a comprehensive overview to help you choose the perfect Univex slicer for your kitchen.

Blade Types and Applications

Univex slicers offer a selection of blade types, each designed for optimal performance with specific food items. The choice of blade significantly impacts the quality and efficiency of your slicing.Serrated blades are ideal for slicing foods with a tougher exterior and a softer interior, such as:* Bread: The serrated edge easily cuts through the crust without tearing the soft crumb.

Tomatoes

The serrations minimize the squashing of the delicate flesh.

Roast meats

The blade provides a clean cut, preventing the meat from shredding.Straight blades, on the other hand, are better suited for precision slicing of dense and firm foods, including:* Cheese: They produce clean, even slices.

Cold cuts

These blades ensure uniform thickness and presentation.

Vegetables

They are excellent for slicing cucumbers, onions, and other firm vegetables.The specific blade type required will depend on the typical food items being sliced. Consider the range of products you will be slicing when choosing a Univex slicer.

Univex Slicer Model Specifications

Univex slicers are available in a range of models, each designed to meet different operational needs. Specifications vary depending on the model, so careful consideration of dimensions, weight, and electrical requirements is important. The information presented below is illustrative and based on commonly available Univex models. Actual specifications may vary; always refer to the manufacturer’s documentation for the most accurate and up-to-date details.

| Model | Blade Diameter | Dimensions (approximate) | Weight (approximate) | Electrical Requirements |

|---|---|---|---|---|

| Univex US40 | 12 inches | 22″ L x 20″ W x 18″ H | 70 lbs | 120V, 60Hz, 1-Phase |

| Univex US50 | 13 inches | 24″ L x 22″ W x 20″ H | 85 lbs | 120V, 60Hz, 1-Phase |

| Univex US60 | 13 inches | 26″ L x 24″ W x 22″ H | 100 lbs | 120V, 60Hz, 1-Phase |

The dimensions listed above are approximate and may vary slightly depending on the specific configuration and features of each model. Always ensure the slicer fits comfortably in your workspace and meets your electrical outlet requirements. The weight is also a significant factor, especially if the slicer needs to be moved frequently. The electrical requirements must match your available power supply to ensure safe and efficient operation.

Materials and Construction

The materials used in the construction of Univex slicers play a vital role in their durability, sanitation, and overall performance. High-quality materials ensure the slicer can withstand the rigors of daily use in a commercial kitchen.Univex slicers typically utilize the following materials:* Stainless steel: Used for the blade, carriage, and other food-contact surfaces due to its resistance to corrosion, ease of cleaning, and compliance with food safety standards.

Anodized aluminum

Used for the base and housing, providing a durable and lightweight structure. Anodization also enhances the corrosion resistance of the aluminum.

High-impact plastic

Used for components like the blade guard and some control elements, providing durability and electrical insulation.These materials contribute to the slicer’s longevity and its ability to meet strict sanitation standards. Regular cleaning and maintenance are essential to preserving the slicer’s performance and lifespan. The combination of these materials ensures that the Univex slicers are built to last and are easy to clean.

Check what professionals state about goat food supplements and its benefits for the industry.

Typical Applications for Each Univex Slicer Model

Different Univex slicer models are designed to excel in various kitchen environments. Understanding the specific applications of each model helps in selecting the right slicer for your needs. Here’s a breakdown of typical applications, though this is not an exhaustive list.* Univex US40:

Ideal for smaller operations.

Suitable for slicing deli meats, cheeses, and vegetables.

Compact size makes it perfect for restaurants with limited counter space.

Easy to clean and operate.

* Univex US50:

A versatile slicer for medium-volume operations.

Suitable for slicing a wider variety of foods, including larger cuts of meat.

Provides increased capacity compared to the US40.

Offers improved slicing speed.

* Univex US60:

Designed for high-volume slicing needs.

Suitable for commercial kitchens and large-scale food processing.

Capable of handling large cuts of meat, cheeses, and vegetables efficiently.

Offers features such as a larger carriage and powerful motor for increased throughput.

Operation and Maintenance of Univex Slicers

Keeping your Univex food slicer running smoothly and safely requires a commitment to proper operation and consistent maintenance. This ensures not only the longevity of your slicer but also the safety of the user and the quality of the food being sliced. Regular maintenance prevents breakdowns, optimizes performance, and adheres to health and safety regulations.

Proper Procedures for Operating an Univex Food Slicer

Operating a Univex food slicer correctly is crucial for both safety and efficiency. Always prioritize safety by following these essential steps:

- Before operating, visually inspect the slicer for any damage, loose parts, or obstructions. Ensure the blade guard is securely in place.

- Make sure the slicer is placed on a stable, level surface.

- Plug the slicer into a properly grounded electrical outlet.

- Adjust the slice thickness using the thickness adjustment knob.

- Place the food item securely in the carriage. If the food is small or oddly shaped, use the food pusher to maintain a safe distance from the blade.

- Turn the slicer on and begin slicing. Use a consistent, controlled motion.

- Never force the food through the blade. If the food is not slicing easily, adjust the thickness or examine the blade.

- Once slicing is complete, turn the slicer off and unplug it before cleaning or performing any maintenance.

- Always keep hands and fingers away from the blade.

Cleaning and Sanitizing an Univex Slicer

Cleaning and sanitizing your Univex slicer after each use is paramount for food safety and hygiene. Proper cleaning removes food particles and prevents bacterial growth.

- Unplug the slicer: Always disconnect the slicer from the power source before cleaning.

- Disassemble (if applicable): Remove any removable parts, such as the food carriage, blade guard, and deflector plate, following the manufacturer’s instructions.

- Rinse: Rinse all disassembled parts and the slicer body with warm water to remove loose food debris.

- Wash: Wash all parts thoroughly with a food-safe detergent and warm water. Pay close attention to areas where food may accumulate.

- Rinse again: Rinse all parts again with clean, warm water to remove any detergent residue.

- Sanitize: Sanitize all parts using a food-safe sanitizer solution, following the manufacturer’s instructions for dilution and contact time.

- Air Dry: Allow all parts to air dry completely before reassembling the slicer. Never use towels to dry the blade, as this can be dangerous.

- Wipe Down: Wipe down the slicer body with a clean, damp cloth.

- Reassemble: Reassemble the slicer, ensuring all parts are correctly positioned and secure.

Routine Maintenance Tasks for Univex Slicers

Regular maintenance extends the life of your Univex slicer and ensures its optimal performance. These tasks should be performed routinely to prevent potential problems.

- Blade Inspection: Regularly inspect the blade for nicks, dullness, or other damage. A dull blade will not slice effectively and can be a safety hazard.

- Lubrication: Lubricate moving parts, such as the carriage slides and blade shaft, with food-grade lubricant as recommended by the manufacturer. This reduces friction and ensures smooth operation.

- Belt Check: Inspect the drive belt for wear and tear. Replace the belt if it shows signs of cracking or fraying.

- Electrical Cord Inspection: Examine the electrical cord for any damage. Replace the cord if it is frayed or damaged.

- Cleaning and Sanitizing: As detailed previously, regular cleaning and sanitizing are essential for hygiene and preventing the buildup of food particles that can affect performance.

- Professional Servicing: Consider scheduling professional servicing annually or as recommended by the manufacturer for a thorough inspection and maintenance.

Sharpening the Blade of a Univex Slicer

Sharpening the blade of your Univex slicer is a critical maintenance task that ensures efficient and safe slicing. Follow these steps to sharpen your blade:

- Prepare the Slicer: Unplug the slicer and ensure the blade guard is in place for safety.

- Locate the Sharpener: Find the built-in sharpener, which is usually located on the slicer itself.

- Prepare the Sharpener: Remove any protective covers from the sharpener.

- Position the Blade: Carefully position the blade against the sharpening stones according to the manufacturer’s instructions. Some models require you to rotate the blade.

- Sharpen the Blade: Activate the sharpener. The process usually involves running the blade through the sharpening stones for a specific amount of time, as indicated in the manual.

- Deburr the Blade: After sharpening, the blade may have a burr (a small edge). Use the deburring stone or mechanism to remove the burr.

- Clean the Blade: Clean the blade thoroughly to remove any metal shavings.

- Test the Blade: After sharpening, test the blade by slicing a piece of food. If the blade still doesn’t slice effectively, repeat the sharpening process or consult a professional.

- Reassemble and Sanitize: Replace the blade guard and any other protective covers. Clean and sanitize the slicer before resuming use.

Slicing Techniques and Food Applications

Mastering the art of slicing with your Univex slicer unlocks a world of culinary possibilities. This section delves into specific techniques for various food types, offering insights into achieving perfect slices and maximizing the potential of your slicer. From delicate prosciutto to hearty vegetables, we’ll explore how to adjust your technique and settings to create consistently exceptional results.

Slicing Meats

Precise meat slicing is crucial for both presentation and taste. Using the Univex slicer correctly ensures uniform slices, contributing to even cooking and a more enjoyable dining experience.

- Roast Beef: For perfectly sliced roast beef, start with a chilled roast. This firms up the meat, making it easier to slice thinly and evenly. Set the slice thickness to your desired level, typically between 1/8 to 1/4 inch for sandwiches or thinner for elegant presentations. A sharp blade is paramount.

- Prosciutto and other cured meats: These delicate meats require a gentle touch. Ensure the meat is properly chilled and use a very thin slice setting. Slicing too quickly can tear the meat, so a slower, more controlled feed rate is recommended.

- Steaks: Slicing steak for dishes like Philly cheesesteaks or steak sandwiches requires a slightly thicker setting, around 1/4 to 3/8 inch, depending on preference. The Univex slicer makes achieving uniform slices a breeze.

Illustration: A perfectly sliced roast beef presentation. The slices are uniformly thin, with a slight sheen from the meat’s natural juices. The edges are clean and well-defined, showcasing the marbling and color variations of the roast. The slices are arranged artfully on a serving platter, creating an appealing visual. This uniformity allows for even cooking and a consistent flavor profile in every bite.

Slicing Cheeses

Cheese slicing presents unique challenges, depending on the cheese’s texture. The Univex slicer excels in providing consistent and precise results, enhancing the visual appeal and flavor of any cheese board or dish.

- Hard Cheeses (Cheddar, Parmesan): These cheeses are relatively easy to slice. Use a medium slice thickness, typically around 1/8 inch. A sharp blade and a steady feed rate will produce clean, even slices.

- Semi-Hard Cheeses (Swiss, Gouda): These cheeses may have some air pockets. Adjust the feed rate to prevent the cheese from tearing.

- Soft Cheeses (Brie, Camembert): Soft cheeses require a gentle approach. Chill the cheese slightly to firm it up. Use a very thin slice setting and a slow, deliberate feed rate. The goal is to avoid crushing the cheese.

Slicing Vegetables

The Univex slicer isn’t just for meats and cheeses; it’s also a valuable tool for preparing vegetables. Consistent vegetable slices improve cooking times and enhance the overall presentation of a dish.

- Tomatoes: For uniform tomato slices, select ripe but firm tomatoes. Use a medium slice thickness, about 1/4 inch, and a steady feed rate.

- Onions: Slicing onions on the Univex slicer is quick and efficient. Use a medium slice thickness, and be mindful of the blade’s sharpness to avoid tearing the onion.

- Cucumbers: Cucumbers can be sliced for salads or sandwiches. A medium to thin slice, approximately 1/8 inch, is usually ideal.

Adjusting Slice Thickness

The Univex slicer allows for precise control over slice thickness. The adjustable dial on the machine is the key to achieving the desired results.

- Understanding the Dial: The dial typically features a scale indicating slice thickness, usually in millimeters or inches. Consult your slicer’s manual for specific markings.

- Practice and Adjustment: Start with a small amount of food and adjust the dial incrementally until you achieve the desired thickness. It’s always better to start with a slightly thicker setting and adjust thinner.

- Factors to Consider: The ideal slice thickness depends on the food type, desired application, and personal preference. For example, deli meats are typically sliced very thinly, while steak may require a thicker slice.

Troubleshooting Common Issues

Maintaining a Univex food slicer is crucial for ensuring its longevity and optimal performance. Even with proper care, issues can arise. Understanding these common problems, their causes, and how to address them empowers users to troubleshoot effectively and minimize downtime. This section provides a comprehensive guide to resolving typical Univex slicer malfunctions.

Uneven Slicing

Uneven slicing is a common frustration. Several factors can contribute to this issue, often stemming from blade-related problems or improper setup.

- Dull Blade: A dull blade struggles to cut cleanly, leading to inconsistent slice thickness. The blade’s sharpness degrades with use and requires regular sharpening or replacement.

- Blade Wobble: Loose blade components or a bent blade can cause the blade to wobble during operation, resulting in uneven cuts.

- Product Movement: If the food item shifts or moves during slicing, the slices will be inconsistent. This can be due to improper food placement or an unstable product holder.

- Incorrect Thickness Setting: If the thickness setting is not properly adjusted, the slices will not be uniform.

Blade Slippage

Blade slippage poses a safety hazard and indicates a mechanical issue.

- Loose Blade: If the blade is not securely fastened to the slicer, it can slip during operation.

- Worn Blade: Over time, the blade may wear down, reducing its grip and increasing the likelihood of slippage.

- Excessive Force: Applying too much pressure while slicing can cause the blade to slip, particularly with tough or frozen foods.

Motor Failure

Motor failure is a more serious problem that can halt slicing operations entirely.

- Overheating: Continuous heavy use without sufficient cooling periods can cause the motor to overheat and shut down.

- Electrical Issues: Faulty wiring or a power surge can damage the motor’s internal components.

- Mechanical Obstruction: If food or debris obstructs the motor’s movement, it can strain and potentially damage the motor.

Troubleshooting Table

The following table summarizes common Univex slicer issues, their potential causes, and recommended solutions.

| Issue | Potential Causes | Solutions |

|---|---|---|

| Uneven Slicing | Dull blade, blade wobble, product movement, incorrect thickness setting | Sharpen or replace the blade; check and tighten blade components; ensure food is securely positioned; adjust the thickness setting. |

| Blade Slippage | Loose blade, worn blade, excessive force | Ensure the blade is securely fastened; inspect and replace the blade if worn; avoid excessive force during slicing. |

| Motor Failure | Overheating, electrical issues, mechanical obstruction | Allow the motor to cool down; check the power supply and wiring; clear any obstructions. |

| Slicer Doesn’t Turn On | Power supply issue, switch failure, motor failure | Check the power cord and outlet; inspect and replace the switch; contact a professional for motor repair or replacement. |

When to Contact a Professional

While many issues can be addressed through basic troubleshooting, certain situations necessitate professional intervention.

- Persistent Issues: If problems persist after attempting the recommended solutions, it indicates a more complex underlying issue.

- Motor Problems: Any motor-related issues, such as unusual noises, burning smells, or complete failure, should be handled by a qualified technician.

- Electrical Issues: Dealing with electrical components can be dangerous. Any suspected electrical faults should be addressed by a professional.

- Blade Replacement or Sharpening: While blade sharpening kits are available, proper sharpening requires expertise. Blade replacement also needs specific tools and knowledge to ensure correct installation and safety.

Purchasing and Pricing of Univex Slicers: Univex Food Slicer

Choosing the right Univex slicer is a crucial decision for any food service business. This section will guide you through the essential factors to consider, where to find these reliable machines, and how to understand the pricing structure to make an informed investment. We’ll explore the different models, accessories, and their practical applications to ensure you select the perfect slicer to meet your specific needs.

Factors for Choosing the Right Univex Slicer

Selecting the appropriate Univex slicer involves a careful evaluation of several factors to ensure it aligns perfectly with your business’s demands and budget. Consider these points before making a purchase:

- Volume of Production: Assess the daily slicing volume. High-volume establishments, such as busy delis or large restaurants, will require a more robust and powerful slicer with a larger carriage and blade. A smaller establishment might find a compact model sufficient.

- Type of Food Products: Different slicers are designed to handle different types of food. Consider what you’ll be slicing most often. If you primarily slice meats, a slicer designed for that purpose is crucial. For versatile slicing of vegetables, fruits, and cheeses, a model with adjustable settings and a wider carriage may be preferable.

- Blade Size and Type: The blade size dictates the maximum slice size. Univex offers blades in various sizes, and different blade types (e.g., carbon steel, stainless steel, serrated, smooth) suit different foods.

- Features and Functionality: Evaluate features like automatic operation, built-in sharpeners, and carriage size. Automatic slicers can significantly improve efficiency in high-volume settings. Built-in sharpeners maintain blade sharpness, and larger carriages accommodate larger food items.

- Safety Features: Prioritize safety features such as blade guards, interlocks, and easy-to-clean designs. These features are essential for preventing accidents and ensuring compliance with food safety regulations.

- Budget: Establish a budget before shopping. Univex slicers range in price depending on the model and features. Consider the long-term value and the potential return on investment (ROI) based on increased efficiency and reduced food waste.

- Space Availability: Measure the available counter space. Ensure the chosen slicer fits comfortably in your kitchen or workspace without impeding workflow.

Where to Purchase Univex Slicers

Univex slicers are available through various channels, including authorized dealers and online retailers. Knowing where to shop ensures you receive genuine products, warranty support, and reliable customer service.

- Authorized Dealers: Univex has a network of authorized dealers across the country and globally. Purchasing from an authorized dealer provides the assurance of genuine products, expert advice, and warranty coverage. Dealers can also provide local support and maintenance services.

- Online Retailers: Reputable online retailers, such as those specializing in commercial kitchen equipment, often carry Univex slicers. These retailers offer a wide selection and competitive pricing. Verify the retailer’s reputation and customer reviews before making a purchase.

- Restaurant Supply Stores: Many restaurant supply stores stock Univex slicers. These stores often offer the convenience of in-person inspection and immediate purchase.

- Manufacturer’s Website: The Univex website may list authorized dealers or offer direct purchasing options, along with detailed product information and specifications.

Pricing Comparison of Univex Slicer Models and Accessories

The pricing of Univex slicers varies depending on the model, features, and included accessories. Comparing prices across different models and retailers is crucial for making a cost-effective decision.

The price can vary significantly based on the model’s capacity, features, and build quality. Entry-level models, designed for light-duty use, might be available for around $1,500 to $2,500. Mid-range models, suitable for moderate-volume establishments, typically range from $2,500 to $4,500. High-end, heavy-duty slicers with advanced features and larger capacities can cost upwards of $4,500 or more. Accessories, such as extra blades, sharpening stones, and cleaning kits, add to the overall cost, but they can enhance the slicer’s functionality and longevity.

Example: A small deli might opt for the Univex 622, a compact and efficient slicer priced around $2,000. A busy restaurant, however, could choose the Univex 750, a more robust model, priced at around $3,500. Consider the cost of accessories like a spare blade (approximately $100-$200) and a cleaning kit (around $50-$100) when budgeting.

Essential Accessories for Univex Slicers

Accessories play a vital role in maintaining the performance, safety, and longevity of your Univex slicer. These accessories enhance the user experience and ensure optimal slicing results.

- Spare Blades: Having a spare blade allows for uninterrupted operation when the primary blade requires sharpening or replacement. Different blade types (serrated, smooth) may be needed for different foods.

- Blade Sharpening Stone/System: Regular blade sharpening is essential for maintaining slice quality and preventing food waste. Some Univex slicers come with built-in sharpening systems, while others require external sharpening stones or systems.

- Cleaning Kit: A cleaning kit, including brushes and cleaning solutions, facilitates thorough cleaning and sanitization of the slicer, ensuring food safety and preventing cross-contamination.

- Carriage Extension: A carriage extension increases the capacity of the slicer, allowing it to handle larger cuts of meat or cheese.

- Food Catch Tray: A food catch tray collects sliced food, making it easier to gather and handle the product.

- Gloves: Cut-resistant gloves provide an extra layer of safety during cleaning and blade handling.

Safety Guidelines and Regulations

Operating a Univex food slicer in a commercial environment requires strict adherence to safety regulations and guidelines to protect both employees and customers. Failure to comply with these measures can lead to serious injuries, legal liabilities, and operational disruptions. This section Artikels the critical safety protocols necessary for responsible and compliant use of Univex slicers.

Importance of Staff Training

Thorough training is paramount to safe and efficient operation of a Univex slicer. Untrained staff are significantly more likely to experience accidents. A well-trained team is a safer and more productive team. Training should be comprehensive and ongoing.

Personal Protective Equipment (PPE) Recommendations

Appropriate personal protective equipment (PPE) is essential to minimize the risk of injury when using a Univex slicer. Proper PPE usage is mandated by occupational safety standards. The following are recommended:

- Cut-Resistant Gloves: These gloves are crucial to protect hands from accidental blade contact. Choose gloves that meet or exceed relevant safety standards.

- Eye Protection: Safety glasses or goggles should be worn to shield eyes from flying debris.

- Apron: A protective apron can prevent food splatters and potential cross-contamination.

- Non-Slip Shoes: These are important to reduce the risk of slips and falls, especially in a kitchen environment.

Essential Safety Precautions for Operating a Univex Food Slicer

Adhering to these precautions is vital for preventing injuries and ensuring safe operation:

- Read the Manual: Always refer to the Univex slicer’s user manual before operation. This manual provides specific instructions and safety guidelines for the particular model.

- Blade Guard: Ensure the blade guard is in place and properly secured when the slicer is not in use. The blade guard serves as a critical barrier against accidental contact.

- Power Off Before Cleaning: Always unplug the slicer from the power source before cleaning, disassembling, or performing any maintenance. This eliminates the risk of electrical shock or accidental start-up.

- Blade Adjustment: Adjust the blade thickness only when the slicer is turned off. Use the thickness adjustment knob carefully.

- Food Placement: Position food items securely on the food carriage before starting the slicer. Avoid overloading the carriage, which can lead to instability and potential injury.

- Use the Food Pusher: Always use the food pusher to guide the food towards the blade. Never attempt to slice food by hand.

- Clean Regularly: Clean the slicer thoroughly after each use. Remove all food particles and debris. This prevents cross-contamination and ensures optimal performance.

- Blade Sharpness: Regularly check the blade’s sharpness. A dull blade requires more force and increases the risk of injury. Follow the manufacturer’s instructions for sharpening or replacing the blade.

- Emergency Stop: Be familiar with the location of the emergency stop button and know how to use it in case of an emergency.

- Inspect the Slicer: Before each use, inspect the slicer for any damage or wear. Report any issues to the supervisor immediately.

- Proper Ventilation: Ensure the area around the slicer is well-ventilated to prevent the build-up of food odors and maintain a comfortable working environment.

- Avoid Distractions: Concentrate on the task at hand. Avoid distractions while operating the slicer.

Concluding Remarks

So, there you have it. The univex food slicer: not just a machine, but a culinary enabler. It’s about efficiency, consistency, and the ability to slice a mountain of meat or cheese without breaking a sweat (or your bank account). Whether you’re a seasoned chef or a kitchen newbie, this thing can up your food game. Now, if you’ll excuse me, I’m off to slice some… well, something.

Maybe even a whole roast chicken. Wish me luck!