Direct to food printer technology is poised to transform the food industry, moving beyond traditional production methods and into a realm of personalized and customized food creation. This technology, at its core, involves the precise deposition of food materials, layer by layer, to construct three-dimensional edible objects. The direct to food printer offers an innovative approach to food manufacturing, bringing the potential for complex designs, customized nutritional profiles, and reduced food waste.

This exploration delves into the fundamental components, printing technologies, and materials that constitute direct to food printers. We will examine the various applications, from commercial settings to personal use, including a glimpse into the regulatory landscape and food safety considerations. Furthermore, the article provides a comprehensive guide to the printing process, software applications, market trends, and the economic aspects associated with adopting this revolutionary technology.

It culminates in a visionary look at the future of direct to food printers, anticipating the advancements that will shape the culinary landscape.

Introduction to Direct to Food Printers

Direct to food printing, a revolutionary technology, merges the precision of 3D printing with the art of culinary creation. It offers a new realm of possibilities for food production, allowing for intricate designs, personalized creations, and enhanced efficiency. This innovative approach is reshaping how we think about and interact with food.

Fundamental Concept of Direct to Food Printing

Direct to food printing, at its core, is a process that deposits edible materials layer by layer to construct three-dimensional food items. This process allows for the creation of complex shapes, textures, and customized designs that are difficult or impossible to achieve through traditional food production methods. The technology utilizes computer-aided design (CAD) software to create digital models, which are then translated into instructions for the printer.

These instructions dictate the precise placement of food-grade inks, pastes, or powders, ultimately building the desired food item.

Primary Components of a Direct to Food Printer

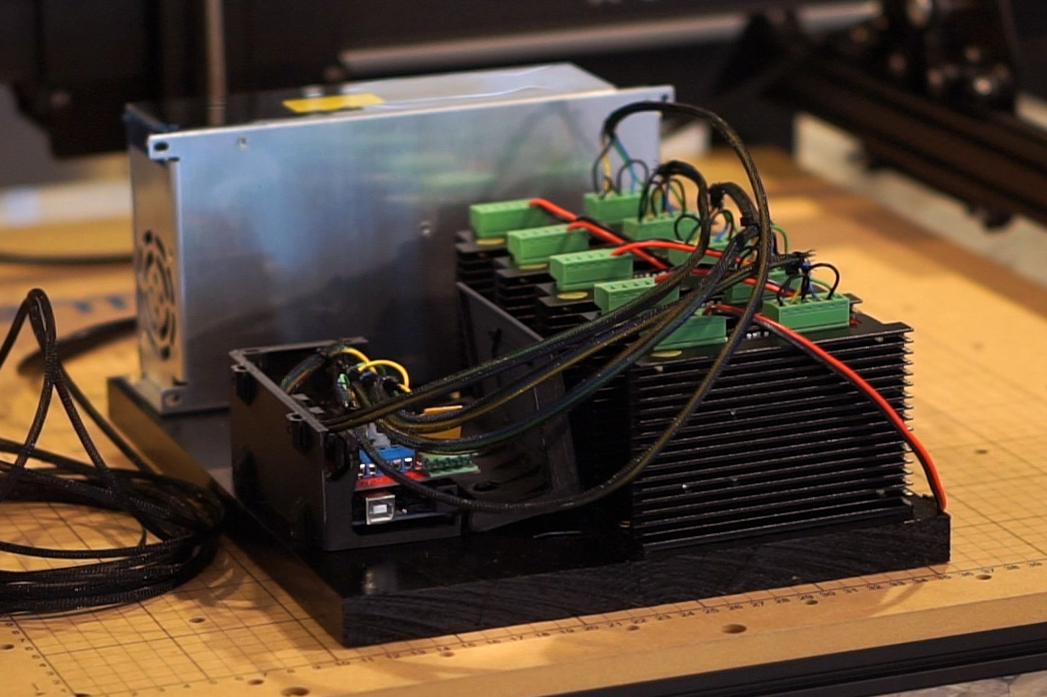

A direct to food printer, much like its industrial counterparts, comprises several key components working in concert to bring culinary designs to life. These components are essential for the accurate and consistent deposition of food materials.

- Print Head: The print head is the core of the printer, responsible for dispensing the edible materials. It moves across the build platform, depositing the material in precise layers. The print head’s design varies depending on the type of food being printed, employing techniques like inkjet, extrusion, or powder bed fusion.

- Build Platform: This platform provides the base upon which the food item is constructed. It is often temperature-controlled to ensure optimal conditions for the printing process. The platform’s size determines the maximum size of the food item that can be printed.

- Material Cartridges/Supply System: These cartridges or supply systems hold the edible materials, such as food-grade inks, pastes, or powders. The system ensures a continuous supply of materials to the print head, allowing for uninterrupted printing.

- Control System: The control system is the “brain” of the printer, managing all aspects of the printing process. It receives instructions from the CAD software, controls the movement of the print head and build platform, and regulates material deposition.

- Enclosure (Optional): Some printers feature an enclosure to maintain a controlled environment, protecting the food from external contaminants and maintaining consistent temperature and humidity levels.

History of Food Printing, Highlighting Key Milestones

The journey of food printing has been marked by significant milestones, each pushing the boundaries of culinary innovation. From conceptual ideas to tangible products, the evolution of this technology is a testament to human ingenuity.

- Early Concepts (Early 2000s): The initial concepts of food printing emerged in the early 2000s, primarily within academic and research settings. Researchers began experimenting with different printing technologies and food materials to explore the potential of creating customized food items.

- First Functional Prototypes (Mid-2000s): Several research groups developed the first functional prototypes of food printers. These early machines were often experimental and focused on printing simple shapes and designs using materials like chocolate and icing. An example of this includes the work by Dr. Hod Lipson’s lab at Cornell University, which developed one of the earliest food printers capable of printing chocolate.

- Commercialization and Market Entry (2010s): The 2010s witnessed the commercialization of food printing technology, with several companies launching food printers for both professional and consumer use. These printers offered increased functionality, improved print quality, and a wider range of compatible food materials. One example is the ChefJet, one of the first 3D food printers targeting consumers.

- Advancements in Materials and Applications (Late 2010s – Present): Recent years have seen significant advancements in the types of materials that can be printed, including complex food structures and multi-material printing. The technology has expanded into various applications, from personalized nutrition and restaurant applications to large-scale food production. For instance, companies are now exploring printing plant-based meats with realistic textures and flavors.

Technologies Used in Direct to Food Printing

The realm of direct-to-food printing is a fascinating intersection of culinary artistry and technological innovation. It offers the potential to reshape food production, personalization, and presentation. Understanding the core technologies underpinning this process is essential for appreciating its current capabilities and future potential. This section delves into the key technologies, materials, and their respective characteristics.

Printing Technologies

The methods employed in direct-to-food printing vary, each with its unique strengths and weaknesses. The choice of technology depends on factors like desired resolution, material viscosity, and production volume.

The following table offers a comparative overview of the primary printing technologies:

| Technology | Description | Advantages | Disadvantages |

|---|---|---|---|

| Inkjet Printing | Utilizes nozzles to deposit tiny droplets of food-grade ink onto a substrate. Commonly used in printing patterns on confectionery and baked goods. | High speed, relatively low cost, suitable for intricate designs and color printing. | Limited to low-viscosity materials (liquids), potential for nozzle clogging, may require specific ink formulations for food safety and taste. |

| Extrusion Printing | Deposits food materials layer by layer through a nozzle. The material is typically a paste or gel. | Versatile, can handle a wide range of materials with varying viscosities, allows for 3D structures. | Slower than inkjet, lower resolution compared to some inkjet systems, layer adhesion can be a challenge. |

| Laser Sintering/Melting | Uses a laser to fuse powdered food materials together, layer by layer, to create three-dimensional objects. | High precision, enables complex geometries, suitable for creating structurally sound food items. | High cost, limited material selection (primarily powders), potential for degradation of food materials due to heat. |

| Binder Jetting | A binder is selectively sprayed onto a powder bed, causing the powder particles to fuse together. | Capable of producing complex 3D shapes, can utilize various powdered materials. | Requires post-processing steps (e.g., removal of unbound powder), binder selection is crucial for food safety and taste. |

Materials Used in Food Printing

The materials employed in direct-to-food printing are as diverse as the culinary world itself. Food safety, printability, and the desired final product characteristics dictate the selection of these materials.

The primary materials and their characteristics are:

- Edible Inks: These are the workhorses of inkjet printing. They come in a wide array of colors and are formulated to be safe for consumption. They are typically water-based and contain food-grade dyes and additives. Their viscosity and surface tension are crucial for ensuring proper droplet formation and adhesion to the food substrate. For example, companies like CakePrint offer edible ink cartridges specifically designed for food printers, with certifications for food safety.

- Food Pastes and Gels: These materials are often used in extrusion-based printers. They are created by mixing food ingredients like chocolate, dough, or icing with additives to achieve the desired viscosity and printability. The consistency of the paste is a critical factor, influencing the precision of the printed structure. For instance, in the production of custom-shaped chocolates, a specific chocolate paste recipe with carefully controlled viscosity is essential for maintaining the desired shape during the printing process.

- Powdered Food Materials: These materials are employed in laser sintering and binder jetting techniques. Examples include powdered sugar, cocoa powder, and various types of flours. The particle size and flow properties of the powder are important considerations. These factors impact the ability of the printer to distribute the material evenly and to build up the desired shapes layer by layer. For example, some companies are exploring the use of powdered proteins to create customized nutrition bars using binder jetting technology.

- Hydrocolloids: These are water-soluble polymers, like gelatin or alginate, used to create food structures. They can be printed in various forms and are often used in combination with other materials to improve texture or stability. They are useful for creating three-dimensional food structures with specific textures. For example, in the production of vegan gummy candies, hydrocolloids like agar-agar are used to achieve the desired texture and shape through extrusion printing.

- Flavorings and Additives: Flavorings and additives are incorporated into the food materials to enhance taste, texture, and appearance. This includes sweeteners, stabilizers, and preservatives. The compatibility of these additives with the printing technology and the overall food safety profile is carefully considered. For example, in printing personalized cookies, flavoring agents are often added to the dough or icing to achieve the desired flavor profile.

Applications of Direct to Food Printers

The path of Direct to Food Printing unfolds, revealing its transformative impact on the culinary landscape. Its applications span a spectrum, from established commercial settings to the burgeoning realm of personalized nourishment. Each application represents a step toward a future where food is not just sustenance, but a canvas for creativity, health, and individual expression.

Current Usage Examples

Direct to Food Printers are already making their mark in various sectors, offering novel solutions and efficiencies. Their adoption reflects a shift toward customization and precision in food production.

- Confectionery Industry: Direct to Food Printers are widely used for decorating cakes, cookies, and other pastries with intricate designs, logos, and personalized messages. This capability allows bakeries and confectioners to offer customized products with ease and speed, enhancing customer experience.

- Food Service: Restaurants and cafes utilize these printers to create custom designs on items like lattes, pancakes, and even pizza crusts. This adds a unique visual appeal to dishes, elevating the dining experience.

- Chocolate Manufacturing: Direct to Food Printers enable the creation of detailed patterns and designs on chocolate products, including chocolates, truffles, and chocolate bars. This technology allows for intricate and customized designs, increasing the aesthetic appeal and value of the product.

- Event Catering: Event organizers employ direct-to-food printing to personalize food items with event logos, names, and themes. This enhances brand visibility and adds a memorable touch to corporate events, weddings, and other special occasions.

- Pharmaceuticals: In some cases, direct-to-food printing is used to print edible coatings or markings on pills and medications, aiding in identification and dosage accuracy.

Potential Applications in the Food Industry

The potential of Direct to Food Printers extends far beyond current applications, promising to reshape the food industry at both commercial and personal levels.

- Commercial Food Production: Large-scale food manufacturers can leverage these printers for mass customization of products. This includes printing unique designs on snacks, breakfast cereals, and ready-to-eat meals. The ability to personalize packaging and product appearance enhances brand differentiation and consumer engagement. This is especially useful for seasonal products or promotional campaigns.

- Restaurant Innovation: Restaurants can use Direct to Food Printers to create intricate and visually stunning dishes, offering customers a unique dining experience. Chefs can print complex designs, patterns, and even edible images directly onto food items, expanding creative possibilities and attracting customers.

- Personalized Food Services: Food delivery services and meal kit providers can utilize Direct to Food Printers to offer customized meals based on dietary restrictions, allergies, and taste preferences. Customers can receive meals tailored to their individual needs, improving health and satisfaction.

- Home Use: Compact and user-friendly Direct to Food Printers could become common kitchen appliances. Individuals could print custom designs on food, create personalized meals based on dietary requirements, and experiment with various recipes.

- Educational Purposes: Direct to Food Printers can be utilized in culinary schools and educational settings to teach students about food design, printing techniques, and culinary arts. This technology can serve as a valuable tool for hands-on learning and innovation.

Personalized Nutrition Scenario

Envision a future where personalized nutrition is seamlessly integrated into daily life.

A person consults with a nutritionist who designs a dietary plan based on their individual health profile, genetic predispositions, and lifestyle. This plan includes specific macronutrient ratios, vitamin requirements, and food preferences.

The nutritionist then sends this dietary plan to a Direct to Food Printer. The printer, equipped with cartridges containing a variety of nutrient-rich ingredients, creates meals tailored to the individual’s needs. For example, the printer could create a breakfast consisting of a protein-rich waffle with a personalized design, fortified with vitamins and minerals. The same printer could produce a lunch that is a 3D-printed salad with a mix of colorful vegetables, lean proteins, and healthy fats.

The meals are not only nutritious but also visually appealing and customizable to the person’s taste preferences. This process reduces food waste, ensures precise nutrient intake, and simplifies meal preparation. This personalized approach to food can help improve health outcomes, manage chronic conditions, and promote overall well-being.

Food Safety and Regulations

The path of direct-to-food printing, though promising in its creative and efficient capabilities, is paved with the fundamental need for unwavering food safety. It is a realm where the tangible meets the invisible – where artistry and technology must harmoniously align with rigorous standards to ensure the well-being of the consumer. The regulations governing this technology are not mere hurdles, but rather, guardians of public health, shaping the industry’s evolution and fostering trust in its creations.

Food Safety Considerations for Direct to Food Printing, Direct to food printer

The safety of food produced via direct-to-food printing hinges on meticulous attention to detail, encompassing every stage from ink composition to the final product. Contamination is the primary adversary, demanding a proactive approach.

- Ink Composition and Toxicity: The inks employed must be demonstrably food-safe, formulated from ingredients approved for consumption or for contact with food. This necessitates comprehensive toxicological assessments to ensure the absence of harmful substances that could leach into the food. An example of a crucial consideration is the avoidance of heavy metals or other contaminants that could pose a health risk.

- Material Interactions: The interaction between the ink, the printing substrate (e.g., the food itself), and any subsequent processing steps must be thoroughly evaluated. The potential for ink components to migrate into the food must be minimized through appropriate ink formulations and printing parameters. This is vital to prevent any undesirable chemical reactions or the transfer of harmful substances.

- Microbial Control: Direct-to-food printing processes must be designed to prevent microbial contamination. This involves the use of sterile or sanitized equipment, hygienic printing environments, and inks that do not support microbial growth. Consider the example of printing on pastries, where preventing the introduction of bacteria or mold is paramount.

- Equipment Hygiene and Maintenance: The printers themselves, along with all associated equipment, must be regularly cleaned, sanitized, and maintained to prevent cross-contamination. This includes nozzles, print heads, and any surfaces that come into contact with food. A detailed cleaning protocol, with documented procedures and frequency, is essential.

- Cross-Contamination Prevention: The printing process must be isolated from other food preparation activities to avoid cross-contamination from allergens or other substances. This may involve dedicated printing areas, the use of separate equipment, and strict adherence to allergen control protocols.

- Traceability and Documentation: A robust system for tracing the origin of all materials, including inks and substrates, is crucial. Comprehensive documentation of the printing process, including printing parameters and quality control checks, is also necessary. This ensures that any food safety issues can be quickly identified and addressed.

Regulations and Certifications Relevant to Food Printing

Navigating the regulatory landscape is essential for any entity involved in direct-to-food printing. Compliance with established standards demonstrates a commitment to consumer safety and facilitates market access.

- Food and Drug Administration (FDA) Regulations (USA): The FDA plays a pivotal role in regulating food contact materials, including inks used in direct-to-food printing. Compliance with FDA regulations, such as those Artikeld in 21 CFR (Code of Federal Regulations), is mandatory for products sold in the United States. These regulations address ink composition, material safety, and labeling requirements.

- European Food Safety Authority (EFSA) Regulations (Europe): EFSA sets the standards for food safety in the European Union. The framework includes regulations concerning food contact materials, ensuring that inks and other materials used in food printing do not pose a risk to human health. Regulations such as those related to good manufacturing practice (GMP) and specific material authorizations are crucial.

- Good Manufacturing Practices (GMP): GMP guidelines, established by regulatory bodies like the FDA and EFSA, dictate the standards for food production processes. Adherence to GMP principles is vital for ensuring food safety and quality. This includes aspects such as equipment maintenance, hygiene practices, and process control.

- Certifications: Certifications, such as those offered by the Food Safety System Certification 22000 (FSSC 22000), provide assurance of a company’s commitment to food safety. These certifications are often sought after by food producers and can enhance consumer trust. Obtaining such certifications involves audits and assessments of food safety management systems.

- Specific Ink Certifications: Certain inks may undergo specific certifications to demonstrate their food safety compliance. These certifications often involve independent testing and verification of ink composition and performance. Examples include certifications related to migration testing and overall suitability for food contact.

Importance of Food-Safe Inks and Materials

The foundation of safe direct-to-food printing rests upon the use of food-safe inks and materials. These materials act as the gatekeepers, preventing harmful substances from entering the food supply.

- Ink Composition: Food-safe inks are formulated with ingredients that are approved for food contact, ensuring that they do not pose a health risk. These inks undergo rigorous testing to verify their safety and suitability for use in direct-to-food printing.

- Migration Testing: Migration testing is performed to assess the potential for ink components to migrate from the printed surface into the food. This testing is conducted under various conditions to simulate real-world usage. The results of migration testing determine whether the ink is suitable for a particular food application.

- Material Selection: The choice of materials used in direct-to-food printing, including substrates and equipment, is crucial. These materials must be compatible with the inks and the food product to prevent any adverse reactions or contamination.

- Allergen Control: Careful consideration of allergen control is essential. Inks and materials must be free from common allergens, or procedures must be in place to prevent cross-contamination. This is particularly important for individuals with food allergies.

- Durability and Stability: Food-safe inks should be durable and stable under various conditions, such as temperature changes and exposure to light. This ensures that the printed image remains intact and that no harmful substances are released over time.

- Transparency and Traceability: Full transparency and traceability of ink and material sourcing are essential. This allows for rapid identification and resolution of any food safety issues that may arise.

Printing Process and Techniques

The journey of a food print, from concept to consumption, is a dance of precision and creativity, guided by the wisdom of technology and the spirit of culinary artistry. It’s a process that demands a harmonious blend of technical skill and a deep understanding of the ingredients and the machine that brings them to life.

Steps Involved in Creating a Food Print

The creation of a food print unfolds through a series of carefully orchestrated steps, each crucial in bringing a digital design into a tangible, edible form. This methodical approach ensures both the aesthetic appeal and the structural integrity of the final product.

- Design Creation: The process begins with the digital design phase. Specialized software is used to create the 3D model or 2D image that will be printed. The designer carefully considers the desired shape, texture, and color of the food print. Software allows for intricate detailing and customization.

- Material Selection and Preparation: The appropriate food-safe materials are selected based on the design and desired outcome. These materials can range from edible inks and powders to pastes and gels. Each material requires specific preparation, which might include mixing, heating, or dissolving to achieve the correct consistency for printing.

- Printer Setup: The food printer is prepared for the print job. This includes loading the selected food materials into the printer’s cartridges or reservoirs, calibrating the printer, and adjusting print settings such as layer height, print speed, and temperature.

- Printing Process: The food printer executes the print job, layer by layer, based on the digital design. The printer dispenses the food material through nozzles, precisely depositing it onto the build platform. The printing process can take varying amounts of time, depending on the complexity and size of the design.

- Post-Processing: Once the printing is complete, the food print undergoes post-processing. This might involve removing the print from the build platform, trimming excess material, and allowing the print to set or harden. Further steps may include applying glazes, coatings, or additional edible decorations.

- Quality Control and Inspection: The final step involves quality control, where the printed food is inspected for accuracy, structural integrity, and aesthetic appeal. This ensures that the final product meets the required standards and is ready for consumption.

Demonstrating the Process of Preparing Food for Printing

Preparing food for printing is a critical aspect of the process, as it directly influences the print’s quality, texture, and overall success. The methods employed vary depending on the food type and the printing technology being used. This phase is a delicate balance of science and culinary skill.

Consider the example of printing a chocolate design. The chocolate must first be melted to a precise temperature. Too hot, and it may burn or become grainy; too cold, and it will clog the printer nozzles. The ideal temperature, usually between 30-32°C (86-90°F) for dark chocolate, ensures a smooth, consistent flow. The melted chocolate is then loaded into the printer’s reservoir, ready to be dispensed.

Another example involves preparing a fruit puree for printing. The fruit must be pureed to a specific consistency, often using a food processor or blender. The puree is then filtered to remove any seeds or pulp that could obstruct the printer nozzles. The prepared puree is loaded into the printer’s cartridge, ready for printing.

In the case of edible inks, the process is generally simpler. The ink cartridges are pre-filled and ready to be inserted into the printer. The key is to ensure that the ink is compatible with the food being printed and that the printer is properly calibrated to dispense the ink accurately.

Creating a Detailed Procedure for Cleaning and Maintaining a Food Printer

Maintaining a food printer is paramount to ensuring its longevity, accuracy, and hygiene. Regular cleaning and maintenance prevent contamination, maintain print quality, and safeguard the machine’s operational efficiency. This is a sacred duty, a commitment to the purity of the process.

This procedure Artikels the steps necessary for the proper care and maintenance of a direct-to-food printer:

- Daily Cleaning: After each printing session, the print head and any surfaces that came into contact with food materials should be cleaned. This can be done using a food-safe cleaning solution, such as a mild detergent or a specific cleaning solution recommended by the printer manufacturer. The cleaning solution is gently applied with a soft cloth or brush, and the surfaces are wiped down to remove any residue.

- Nozzle Cleaning: The printer nozzles are prone to clogging, particularly with thicker food materials. Regular nozzle cleaning is essential. This can be done using the printer’s built-in cleaning function, which forces cleaning solution through the nozzles. Alternatively, a manual cleaning method can be employed, using a fine needle or specialized cleaning tool to remove any blockages.

- Material Reservoir Cleaning: The material reservoirs or cartridges should be cleaned regularly, especially if different food materials are used. This prevents cross-contamination and ensures that the materials remain fresh. The reservoirs are emptied, cleaned with a food-safe cleaning solution, and thoroughly rinsed before refilling.

- Build Platform Cleaning: The build platform, where the food is printed, must be kept clean. Any food residue or debris should be removed after each print. The platform can be wiped down with a food-safe cleaning solution. The cleaning process also ensures the proper adhesion of the food material to the platform.

- Regular Maintenance: The printer’s moving parts, such as the print head carriage and the feeding mechanisms, should be lubricated regularly with food-grade lubricants. This ensures smooth operation and prevents wear and tear. The manufacturer’s instructions should be followed for lubrication frequency and type.

- Calibration and Alignment: The printer should be calibrated regularly to ensure accurate printing. This involves adjusting the printer’s settings to ensure that the print head is aligned correctly and that the food materials are dispensed accurately. The manufacturer’s calibration instructions should be followed.

- Software Updates: The printer’s software should be kept up-to-date. Software updates often include performance improvements, bug fixes, and new features. The printer manufacturer’s website should be checked for software updates.

- Storage: When the printer is not in use, it should be stored in a clean, dry environment. The printer should be covered to protect it from dust and debris. The food materials should be stored according to the manufacturer’s instructions, typically in a cool, dry place.

Software and Design Considerations

The ethereal dance of creation takes a tangible form in the realm of direct-to-food printing, where software and design considerations become the brushstrokes of edible artistry. These digital tools, like enlightened guides, shape the very essence of what can be printed, ensuring that each creation is not just visually stunning but also structurally sound and safe for consumption. Mastering these considerations unlocks the full potential of food printing, allowing us to manifest culinary visions with precision and grace.

Software for Food Print Design

The digital realm provides the architects of food printing with a variety of specialized software. These programs are the keys that unlock the potential for designing intricate and complex food structures.* Specialized 3D Modeling Software: Programs like Autodesk Fusion 360 and Blender, although not exclusively for food, offer powerful 3D modeling capabilities. They enable the creation of complex geometries, allowing for the design of multi-layered structures, intricate patterns, and custom shapes that can be perfectly translated into edible forms.

This is like the alchemist’s workshop, where digital clay is molded into a vision.

Slicing Software

Essential for translating 3D models into instructions the printer can understand, slicing software such as Cura and Simplify3D are employed. They dissect the 3D design into thin layers, generating the precise paths the printer’s nozzle must follow to deposit the food material. Think of it as the blueprint for the divine meal.

Food-Specific Design Software

Some companies offer software tailored specifically for food printing. These programs may include pre-designed food templates, ingredient libraries, and tools optimized for food-safe design considerations. This is akin to having a direct line to the source of inspiration.

Essential Design Considerations for Food Printing

The creation of edible masterpieces demands careful consideration of various design parameters. These factors determine the final product’s appearance, texture, structural integrity, and, most importantly, its safety.* Resolution: Resolution, measured in dots per inch (DPI) or layer thickness, directly impacts the level of detail achievable. Higher resolution allows for finer lines, sharper edges, and more intricate designs.

However, higher resolution often means longer print times.

The ideal resolution is a balance between desired detail and practical printing speed.

* Layer Thickness: Layer thickness, or the height of each deposited layer, influences both the surface finish and the structural strength of the printed food. Thinner layers create smoother surfaces and finer details but also increase print time. Thicker layers can speed up the process but may result in a coarser texture.

Material Properties

Remember to click cheese and wine party food to understand more comprehensive aspects of the cheese and wine party food topic.

The viscosity, flow rate, and setting characteristics of the food material are critical. These properties affect how the material behaves during printing, influencing its ability to maintain its shape and adhere to previous layers.

Support Structures

Similar to 3D printing with other materials, support structures may be necessary to print overhanging features or complex geometries. These structures are typically made of a food-safe material that can be easily removed after printing.

Food Safety

The design must consider food safety regulations and hygiene standards. This includes the selection of food-safe materials, the design of easily cleanable surfaces, and the avoidance of any features that could harbor bacteria or contaminants.

Examples of Innovative Food Designs

The convergence of software and design has unleashed a wave of creativity in food printing. Here are some examples of innovative food designs:* Personalized Chocolate: Chocolate printers utilize design software to create custom chocolate shapes, incorporating personalized messages, intricate patterns, and even portraits. This is the embodiment of tailored sweetness.

Custom Cakes and Decorations

Food printing allows for the creation of elaborate cake decorations, including edible figurines, logos, and complex geometric designs, far beyond the capabilities of traditional methods. This is where the cake becomes a canvas.

3D-Printed Pasta

Software enables the design of custom pasta shapes, allowing for unique textures and filling combinations. This transforms the humble pasta into a culinary adventure.

Nutritional Food Printing

In the realm of personalized nutrition, food printing is used to create meals tailored to specific dietary needs, with precise control over ingredients and nutritional content. This is the future of mindful eating.

Edible Art Installations

Artists and chefs are collaborating to create large-scale edible installations, using food printing to construct complex structures and immersive culinary experiences. This is where art meets appetite.

Market Analysis and Trends

The direct to food printing market, a realm where culinary artistry meets technological innovation, is undergoing a profound transformation. It is a dynamic landscape, influenced by shifting consumer preferences, advancements in printing technologies, and evolving regulatory landscapes. Understanding these trends and analyzing the key players is crucial for navigating the opportunities and challenges within this burgeoning sector. The market’s trajectory points towards significant expansion, driven by factors such as personalization, efficiency, and the ability to create novel food experiences.

Current Market Trends

The direct to food printing market is currently characterized by several key trends. These trends reflect the evolving demands of consumers and the capabilities of the technology.

- Personalization and Customization: Consumers increasingly seek unique and personalized food experiences. Direct to food printing allows for the creation of customized designs, messages, and patterns on food items, catering to individual preferences and special occasions. This trend is evident in the growing demand for personalized cakes, cookies, and other food products.

- Focus on Health and Sustainability: There is a rising emphasis on healthy eating and sustainable practices. Direct to food printing facilitates the use of healthier ingredients and reduces food waste by allowing for precise portioning and design. The ability to print on plant-based proteins and other alternative ingredients further aligns with this trend.

- Automation and Efficiency: Food manufacturers are constantly seeking ways to streamline their production processes. Direct to food printing offers the potential for automation, reducing labor costs and increasing production efficiency. This is particularly relevant in the mass production of food items with intricate designs or branding elements.

- Novel Food Experiences: Direct to food printing enables the creation of innovative and visually appealing food products that were previously impossible. This includes 3D-printed food with complex structures, edible art, and interactive food experiences. Restaurants and food service providers are leveraging this technology to differentiate themselves and attract customers.

- Expansion into New Applications: The application of direct to food printing is expanding beyond traditional confectionery and bakery products. It is now being used in areas such as pharmaceutical food, nutraceuticals, and even in the creation of personalized pet food.

Key Players in the Direct to Food Printer Market

The direct to food printing market is populated by a diverse range of companies, from established printer manufacturers to innovative startups. These key players are driving innovation and shaping the future of the industry.

- 3D Systems: 3D Systems is a well-established player in the 3D printing industry, with a strong presence in the food printing sector. They offer a range of food printers and materials, catering to both commercial and industrial applications. They provide machines such as the ChefJet series for confectionery and other food items.

- Natural Machines: Natural Machines is a company specializing in direct to food printing technology. Their flagship product, the Foodini, is a versatile food printer designed for both professional and home use. They are focused on creating personalized food items.

- Rize: Rize, now part of Desktop Metal, is another prominent player, offering advanced 3D printing solutions, including food printing applications. They focus on providing high-quality printing and material options for a variety of food products.

- Digital Food: Digital Food is an example of a company concentrating on the production of high-end food printers and offering services in the food printing sector. They are focused on innovation in the food industry, providing tailored solutions.

- HP: HP is entering the market with advanced printing technologies and focuses on expanding its market share. HP’s entry suggests a potential for technological advancements and wider adoption of food printing technologies.

- Other Manufacturers and Startups: In addition to the major players, there are numerous smaller companies and startups that are contributing to the growth of the direct to food printing market. These companies often focus on niche applications or innovative printing techniques.

Forecast for the Future Growth of the Direct to Food Printing Market

The direct to food printing market is poised for substantial growth in the coming years. Several factors support this optimistic outlook.

- Market Size and Growth Rate: Market research reports predict significant growth in the direct to food printing market over the next decade. The market is expected to expand at a considerable compound annual growth rate (CAGR), driven by the increasing adoption of the technology across various food sectors. For example, reports project the global 3D food printing market to reach several billion USD by 2030.

- Technological Advancements: Ongoing advancements in printing technologies, materials science, and software will further enhance the capabilities of direct to food printers. These advancements will lead to improved print quality, faster printing speeds, and the ability to print a wider range of food products.

- Increased Adoption by Food Businesses: Food businesses, including restaurants, bakeries, and food manufacturers, are expected to increasingly adopt direct to food printing technology. This adoption will be driven by the desire to offer personalized products, streamline production processes, and create innovative food experiences.

- Expansion into New Applications: The application of direct to food printing is expected to expand into new areas, such as pharmaceutical food, personalized nutrition, and sustainable food production. This expansion will further fuel market growth.

- Regulatory Support: Supportive regulatory frameworks and food safety standards will be crucial for the growth of the direct to food printing market. Clear guidelines on food safety, labeling, and ingredient compatibility will foster consumer confidence and encourage wider adoption of the technology.

The direct to food printing market represents a significant opportunity for innovation and growth. The ability to create personalized food products, streamline production processes, and offer novel food experiences will drive the adoption of this technology across various food sectors. Continued technological advancements, increased adoption by food businesses, and supportive regulatory frameworks will pave the way for the market’s continued expansion.

Advantages and Disadvantages

The path of the Direct to Food Printer, like any technology, is paved with both blessings and challenges. Understanding these aspects is crucial for navigating its potential and harnessing its power with wisdom. This section delves into the benefits and drawbacks, providing a balanced perspective on its transformative influence.

Advantages of Direct to Food Printers

Direct to Food Printers offer a multitude of benefits, reshaping the landscape of food production and presentation. These advantages empower creativity, efficiency, and personalization, opening new avenues for culinary expression.

- Enhanced Customization: Direct to food printing allows for unparalleled customization. Chefs and food producers can create intricate designs, personalized messages, and unique patterns directly onto food items. This level of personalization was previously unattainable through traditional methods.

- Increased Efficiency: Automation streamlines the food decoration process. Printers can handle complex designs quickly and consistently, reducing labor costs and production time. This is especially beneficial for high-volume production runs.

- Reduced Waste: The precise application of edible inks minimizes waste. Only the required amount of ink is used, and designs can be easily modified or corrected, reducing spoilage and material waste compared to traditional methods like stenciling or hand-painting.

- Improved Food Safety: Direct to food printers utilize food-grade inks and materials. This ensures that the printing process adheres to stringent food safety regulations, minimizing the risk of contamination.

- Novelty and Innovation: The technology enables the creation of innovative and visually stunning food presentations. It opens doors to new culinary experiences, attracting customers with unique and memorable designs. Consider, for example, the possibility of printing intricate logos on cookies or personalized messages on cakes.

- Cost-Effectiveness (in certain applications): While the initial investment in a direct to food printer can be significant, the long-term cost-effectiveness can be realized through reduced labor, waste, and improved efficiency, especially in mass production scenarios.

Disadvantages of Direct to Food Printers

While offering numerous advantages, Direct to Food Printers also present certain limitations. These challenges must be considered to ensure informed decision-making and realistic expectations.

- High Initial Investment: The cost of purchasing a direct to food printer, along with necessary software and supplies, can be substantial. This can be a barrier to entry for smaller businesses or startups.

- Limited Food Compatibility: Not all food items are suitable for direct printing. The surface texture, moisture content, and shape of the food can affect print quality and adhesion.

- Ink Cost: Food-grade inks can be relatively expensive. The ongoing cost of ink replenishment can impact profitability, especially for businesses with high-volume printing needs.

- Technical Complexity: Operating and maintaining a direct to food printer requires technical expertise. Training is often necessary to ensure optimal performance and troubleshoot potential issues.

- Print Speed Limitations: The printing speed of some direct to food printers may be slower than traditional decoration methods, particularly for high-volume applications.

- Maintenance and Cleaning: Regular maintenance and cleaning are crucial to ensure the printer’s longevity and maintain print quality. This requires dedicated time and resources.

Comparison of Direct to Food Printing with Traditional Food Production Methods

The following table provides a comparative analysis of direct to food printing versus traditional food production methods across key aspects.

| Feature | Direct to Food Printing | Traditional Food Production | Example/Illustration | Considerations |

|---|---|---|---|---|

| Customization | High; allows for intricate designs and personalization. | Limited; often relies on stencils, molds, or hand-painting. | Printing a custom logo on a cookie versus using a pre-made stencil. | DTF excels in creating unique and complex designs. |

| Efficiency | Potentially high; automates decoration, reducing labor. | Variable; can be labor-intensive, especially for intricate designs. | Printing hundreds of identical cupcake designs versus hand-decorating them. | DTF can significantly increase production speed in certain scenarios. |

| Waste | Low; precise ink application minimizes waste. | Higher; potential for waste from materials, errors, and spoilage. | Printing a specific image on a cake versus using frosting bags that may produce more waste. | DTF reduces material waste by using only what is needed. |

| Cost | High initial investment, potential for lower long-term costs. | Variable; depends on labor costs and materials. | The initial cost of a DTF machine versus the ongoing costs of hiring decorators and buying decorating tools. | Long-term cost savings can be achieved with increased efficiency. |

Cost and Investment

The path of direct-to-food printing, much like the journey toward enlightenment, requires a careful consideration of resources and potential rewards. Understanding the financial landscape is crucial for making informed decisions and ensuring a sustainable venture. This section delves into the monetary aspects of this innovative technology, providing insights into the associated costs, price determinants, and potential returns on investment.

Costs of Purchasing and Operating a Direct to Food Printer

The initial investment in a direct-to-food printer is significant, akin to the commitment required to embark on a spiritual quest. Ongoing operational costs, like the daily practice of mindfulness, also demand attention.

- Printer Hardware: The price of the printer itself varies considerably based on its capabilities. Entry-level models might be available for several thousand dollars, suitable for simpler applications and smaller production volumes. More advanced, industrial-grade printers, offering higher resolution, faster printing speeds, and multi-material capabilities, can cost tens or even hundreds of thousands of dollars. Consider the longevity and reliability of the machine; a higher upfront cost may translate to lower maintenance expenses in the long run.

- Ink and Consumables: Food-grade inks are a recurring expense. The cost per unit of ink depends on the type of ink (e.g., edible inks, colorants), the print volume, and the printer’s ink consumption efficiency. Regular replacement of print heads, cartridges, and other consumables also adds to the operational budget. The specific formulation of ink also affects the price, with more complex or specialized inks commanding a higher price.

- Software and Licensing: Specialized software for design, image manipulation, and printer control is often necessary. This can involve initial purchase costs and ongoing subscription fees for updates and support. This is analogous to the continuous study and practice required to deepen one’s spiritual understanding.

- Maintenance and Repairs: Like any complex machinery, direct-to-food printers require regular maintenance to ensure optimal performance. Service contracts, spare parts, and potential repair costs must be factored into the overall budget. A preventative maintenance schedule can help minimize downtime and extend the printer’s lifespan.

- Labor Costs: Operating the printer requires skilled personnel for design, setup, printing, and post-processing. The labor costs will depend on the complexity of the printing process and the volume of production. Training costs for operators also need to be considered.

- Food Substrates: The cost of the food items being printed on (e.g., cookies, cakes, candies) is a significant operational expense. The type and quality of the food substrate will influence the final cost of the printed product.

- Workspace and Infrastructure: A dedicated workspace, with appropriate environmental controls (temperature, humidity), and necessary infrastructure (electricity, ventilation) is essential. The cost of this space and its related utilities adds to the overall operational expenses.

Factors Influencing the Price of Food Printing

The price of food printing is determined by a confluence of elements, much like the interconnectedness of all things.

- Print Volume and Complexity: The more intricate the design and the larger the print area, the higher the cost. The volume of items printed also affects the cost per unit. Mass production generally results in lower per-unit costs.

- Ink Usage: The amount of ink used directly impacts the cost. Designs with full-color coverage and high resolution will consume more ink than simpler designs.

- Food Substrate: The type and cost of the food substrate being printed on significantly influence the final price. High-quality or specialty food items will command a higher price.

- Printer Technology: The type of printer (e.g., inkjet, laser) and its capabilities (e.g., resolution, speed) affect the cost. More advanced technologies often come with higher initial investments and operational costs, but may offer greater efficiency and print quality.

- Labor Costs: The time required for design, setup, printing, and post-processing directly affects the cost. Highly skilled labor will be reflected in the price.

- Market Demand: The overall demand for food printing services in a particular market influences pricing. High demand can lead to higher prices.

- Competition: The presence of competitors in the market will affect pricing strategies. Businesses may need to adjust their prices to remain competitive.

- Regulations and Certifications: Compliance with food safety regulations and certifications can add to the cost, potentially affecting the final price of the printed food product.

Potential Return on Investment for Businesses Using Food Printers

The potential for a return on investment (ROI) in direct-to-food printing is significant, mirroring the rewards that come from dedicated effort and mindful practice.

- Increased Revenue: Food printing allows businesses to offer unique and customized products, attracting new customers and increasing sales. The ability to personalize food items can command a premium price.

- Reduced Waste: Direct-to-food printing can minimize food waste by allowing for on-demand printing, producing only what is needed. This is particularly beneficial for items with short shelf lives.

- Operational Efficiency: Automation of the printing process can streamline production and reduce labor costs, leading to improved efficiency.

- Brand Differentiation: The ability to create custom designs and logos on food items helps businesses differentiate themselves from competitors and build brand recognition.

- New Market Opportunities: Direct-to-food printing opens up new market opportunities, such as personalized gifts, promotional items, and customized food for events.

- Examples of ROI:

- A bakery invests in a food printer to offer custom-decorated cakes. They increase sales by 20% and reduce waste by 10% within the first year, resulting in a positive ROI.

- A food manufacturer uses a food printer to print logos on cookies for a promotional campaign. The campaign increases brand awareness and generates a 15% increase in product sales.

- A restaurant uses a food printer to create personalized desserts for special occasions. This enhances the customer experience and leads to repeat business, resulting in a significant increase in revenue.

- Important Formula:

ROI = ((Net Profit / Cost of Investment) – 100)

This formula is a practical guide for measuring the financial success of your investment.

Future Developments

The horizon of direct-to-food printing shimmers with the promise of revolutionary advancements. This field, still in its nascent stages, is poised to transform the way we interact with food, from production and personalization to sustainability and nutritional value. Understanding these future trajectories allows us to envision a world where food is not just sustenance, but an art form, a personalized experience, and a powerful tool for health and well-being.

Emerging Technologies in Food Printing

The evolution of direct-to-food printing is fueled by several key technological advancements. These innovations are not isolated but rather interwoven, creating a synergistic effect that accelerates progress.

- Advanced Materials: The exploration of new food-grade materials is paramount. Scientists are investigating the use of hydrogels, biopolymers, and even cultivated meat cells as printing inks. This expansion allows for the creation of complex structures and customized nutritional profiles. For example, researchers are experimenting with printing personalized vitamin supplements directly into food items.

- Multi-Material Printing: The capability to print with multiple materials simultaneously is crucial. This enables the creation of intricate food designs with varying textures, flavors, and nutritional compositions. Imagine a single printed dish containing a protein-rich core, a vegetable-based outer layer, and a flavorful sauce, all created in a single pass. This technology is already being tested with chocolate and complex pastries.

- Improved Printing Resolution: Achieving higher printing resolutions is essential for creating detailed food structures and replicating intricate culinary designs. This includes advancements in nozzle technology and precise control over ink deposition. This will allow for the printing of micro-structures, creating novel textures and enhancing flavor release.

- AI-Driven Design and Optimization: Artificial intelligence is playing a critical role in optimizing food printing processes. AI algorithms can analyze recipes, ingredient properties, and printing parameters to automatically design and optimize food structures for optimal taste, texture, and nutritional value.

- Closed-Loop Systems: The integration of sensors and feedback mechanisms will enable closed-loop systems. These systems can monitor the printing process in real-time, making adjustments to ensure consistency and quality. This can be applied to temperature control, ink viscosity, and layer deposition.

Vision of the Future of Direct-to-Food Printing in 10 Years

Looking ahead a decade, direct-to-food printing is poised to reshape the food landscape significantly. The changes will touch every aspect of the food industry, from farm to table.

- Personalized Nutrition: Individuals will have access to food printers capable of creating meals tailored to their specific dietary needs and preferences. This will include customized macronutrient ratios, vitamin supplements, and allergen-free options. Imagine a printer that analyzes your health data and creates a breakfast optimized for your current metabolic needs.

- Sustainable Food Production: Food printing will contribute to more sustainable food systems by enabling the utilization of alternative protein sources, reducing food waste, and minimizing transportation costs. Printed meals could be created from locally sourced ingredients or even cultivated meat.

- Revolutionized Culinary Experiences: Restaurants and chefs will utilize food printers to create innovative and artistic dishes with unprecedented complexity and detail. Food will become an art form, with printed creations that are visually stunning and offer unique sensory experiences.

- Decentralized Food Production: Food printing could enable decentralized food production, allowing individuals and communities to produce food locally. This could lead to greater food security and reduce reliance on centralized food systems.

- Enhanced Food Safety and Traceability: Food printing will allow for greater control over the food production process, leading to enhanced food safety and traceability. The origin and composition of each printed food item can be precisely tracked, reducing the risk of contamination and facilitating rapid response to food safety incidents.

Design of a Hypothetical, Futuristic Food Printer and Its Features

Imagine a food printer of the future, a sleek and sophisticated appliance that seamlessly integrates into the home or professional kitchen. This printer would be far more than just a machine; it would be an intelligent culinary companion.

- Modular Design: The printer would have a modular design, allowing for the easy exchange of printing modules. These modules could be specialized for different food categories, such as desserts, savory dishes, or nutritional supplements.

- Integrated Ingredient Management: The printer would incorporate an intelligent ingredient management system. This system would automatically store and dispense ingredients, monitor their freshness, and even suggest recipes based on available ingredients. It would also be able to connect with online ingredient suppliers, automatically ordering needed items.

- Advanced Printing Technologies: The printer would utilize a combination of printing technologies, including multi-material extrusion, inkjet printing for flavor and color, and laser sintering for creating complex textures. This would enable the creation of highly detailed and customized food structures.

- AI-Powered Recipe Generation: The printer would be equipped with an AI-powered recipe generation system. This system would allow users to input their dietary restrictions, preferences, and desired nutritional goals. The AI would then generate customized recipes and printing instructions.

- Holographic Interface: The printer would feature a holographic interface, allowing users to visualize the printing process and interact with the food being created in a three-dimensional space. This interface would also provide real-time feedback on the printing process, ensuring optimal results.

- Connectivity and Cloud Integration: The printer would be fully connected to the internet, allowing for software updates, access to a vast library of recipes, and remote control. Users could share their creations with others and download new designs from a global community of food artists and chefs.

Final Review

In conclusion, the direct to food printer represents a significant leap forward in food technology, promising a future where food production is more efficient, customizable, and sustainable. From personalized nutrition to intricate food designs, the possibilities are vast. While challenges related to cost, food safety, and technological advancements remain, the potential for direct to food printers to revolutionize the food industry is undeniable.

The continuous development and refinement of this technology will undoubtedly lead to exciting culinary innovations and transform the way we create, consume, and interact with food in the years to come.