Food trailer layout is more than just arranging equipment; it’s about crafting a mobile culinary experience. This comprehensive guide delves into every aspect of designing a food trailer that not only meets health and safety regulations but also maximizes efficiency and profitability. From initial considerations like menu planning and customer flow to advanced techniques in space optimization and equipment selection, we’ll explore the secrets to creating a successful mobile food business.

We’ll navigate the intricacies of workflow, interior design, compliance, and budgeting. Discover how to select the right equipment, optimize your workspace, and create an inviting atmosphere that keeps customers coming back for more. We’ll also cover the critical aspects of ventilation, customization, and future-proofing your food trailer to ensure long-term success. Prepare to transform your food trailer dreams into a thriving reality.

Initial Considerations for Food Trailer Design

Designing a food trailer is a multifaceted process, demanding careful consideration of various factors to ensure operational efficiency, compliance with regulations, and a positive customer experience. This section explores the crucial initial steps in planning a successful food trailer venture, focusing on health and safety, menu planning, and customer flow.

Essential Health and Safety Regulations for Food Trailers in California

Operating a food trailer in California requires strict adherence to health and safety regulations enforced by the California Department of Public Health (CDPH) and local county health departments. These regulations are designed to protect public health by preventing foodborne illnesses and ensuring safe food handling practices.

- Permitting and Licensing: Obtaining the necessary permits and licenses is the first step. This includes a food facility permit from the local county health department, a business license, and potentially a seller’s permit for collecting sales tax. The permit application process typically involves submitting detailed plans of the trailer layout, equipment specifications, and operational procedures.

- Food Safety Training: Food handlers are required to obtain a food handler’s card, demonstrating knowledge of safe food handling practices. This training covers topics such as proper handwashing, cross-contamination prevention, and temperature control. In California, the food handler card must be obtained from a California Department of Public Health approved training provider.

- Equipment Requirements: The food trailer must be equipped with specific equipment to ensure food safety. This includes:

- Refrigeration: Adequate refrigeration units (refrigerators and freezers) are essential for storing potentially hazardous foods at safe temperatures (below 41°F or 5°C).

- Cooking Equipment: Cooking equipment must be commercial-grade and approved by the local health department. This includes ovens, stoves, grills, and fryers.

- Handwashing Stations: A three-compartment sink for washing, rinsing, and sanitizing utensils and equipment is required. A separate handwashing sink with hot and cold running water, soap, and paper towels is also mandatory.

- Water Supply and Waste Disposal: A potable water supply and wastewater disposal system are critical. This may involve a water tank for fresh water and a separate tank for wastewater. Both tanks must be of sufficient capacity for the trailer’s operational needs. Wastewater must be disposed of at an approved disposal site.

- Food Handling Practices: Strict food handling practices are mandated to prevent contamination. This includes:

- Proper handwashing: Washing hands frequently and thoroughly with soap and water.

- Cross-contamination prevention: Preventing the transfer of bacteria from raw foods to cooked foods or ready-to-eat foods. This can be achieved by using separate cutting boards, utensils, and storage areas.

- Temperature control: Maintaining food at safe temperatures to prevent bacterial growth. This includes cooking foods to the proper internal temperature and storing foods at the correct temperatures.

- Pest Control: Food trailers must be protected from pests. This may involve regular pest control services and the implementation of preventative measures, such as sealing any cracks or openings that could allow pests to enter.

- Inspections: Food trailers are subject to regular inspections by the local health department to ensure compliance with all regulations. Violations can result in fines, temporary closures, or revocation of the food facility permit.

Menu Planning’s Influence on Food Trailer Layout

The menu’s composition significantly impacts the food trailer’s layout, dictating the required equipment, workflow, and space allocation. A well-planned menu streamlines operations and optimizes efficiency.

- Burger-Focused Menu: A burger-focused menu typically requires a grill, a flat-top griddle, a fry station (if serving fries), and ample refrigeration for storing burger patties, toppings, and condiments. The layout might prioritize a cook line with the grill and griddle, followed by a food preparation area for assembling burgers, and a service window for order fulfillment.

- Example: A burger trailer might have a 6-foot griddle, a double-basket fryer, a refrigerator for storing burger patties, and a separate refrigerator for storing toppings like lettuce, tomatoes, and onions.

- Taco-Focused Menu: A taco-focused menu often necessitates a plancha or griddle for cooking meats, a steam table for keeping fillings warm, and a dedicated area for assembling tacos. The layout may include a designated area for food preparation and a separate area for serving.

- Example: A taco trailer could feature a plancha, a steam table with various fillings, a salsa bar, and a tortilla warmer.

The layout would prioritize efficient assembly of tacos.

- Example: A taco trailer could feature a plancha, a steam table with various fillings, a salsa bar, and a tortilla warmer.

- Menu Complexity: The complexity of the menu also influences the layout. A menu with a wider variety of dishes requires more equipment, more storage space, and a more complex workflow. A simpler menu allows for a more compact and efficient layout.

- Ingredient Storage: Adequate storage space for ingredients is essential. This includes refrigeration for perishable items, dry storage for non-perishable items, and shelving for supplies. The amount of storage needed will depend on the menu and the volume of sales.

- Workflow Optimization: The layout should be designed to optimize the workflow. This means placing equipment and stations in a logical sequence to minimize movement and maximize efficiency.

Significance of Customer Flow in Food Trailer Design

Customer flow, the path customers take through the food trailer, significantly impacts the overall customer experience and operational efficiency. A well-designed customer flow minimizes congestion, reduces wait times, and enhances the overall customer experience.The following flowchart illustrates a typical customer flow in a food trailer:

The flowchart begins with ” Customer Arrival” (represented by a rounded rectangle).

From ” Customer Arrival,” an arrow leads to ” Order Placement” (represented by a rectangle).

From ” Order Placement,” an arrow branches to ” Payment” (represented by a rectangle).

Following ” Payment,” an arrow leads to ” Order Preparation” (represented by a rectangle).

From ” Order Preparation,” an arrow leads to ” Order Fulfillment/Pick-up” (represented by a rectangle).

Finally, an arrow from ” Order Fulfillment/Pick-up” leads to ” Customer Departure” (represented by a rounded rectangle).

The design should consider the following:

- Order Placement Area: This area should be easily accessible and clearly marked. Consider providing menus, order forms, and payment options.

- Waiting Area: A designated waiting area, if space permits, can reduce congestion. Providing seating or a waiting line system can improve the customer experience.

- Pick-up Window/Area: This area should be clearly marked and easily accessible for customers to collect their orders. Ensure sufficient space for customers to receive their food without obstructing the flow of other customers.

- Service Window Design: The service window should be designed to facilitate efficient order fulfillment. This includes providing enough space for staff to hand out orders and for customers to receive them.

- Accessibility: The food trailer should be accessible to customers with disabilities, including ramps, wide doorways, and accessible service counters.

Space Optimization Techniques

Food trailer design is a delicate balance of functionality and efficiency. Maximizing the available space is crucial for smooth operations, allowing for comfortable movement and optimized workflow. Clever design strategies and thoughtful equipment placement can transform a cramped space into a productive kitchen on wheels. This section delves into techniques that can significantly improve space utilization within a 16-foot food trailer.

Equipment Placement Strategies for a 16-Foot Food Trailer

Proper equipment placement is the cornerstone of an efficient food trailer layout. Different strategies can be employed to maximize space, minimize wasted movement, and create a smooth workflow. The following table details four distinct equipment placement strategies, each illustrated with an example, for a 16-foot food trailer.

| Strategy | Description | Example Equipment | Visual Description of Example |

|---|---|---|---|

| Linear Layout | Arranging equipment along a single wall, maximizing the open space. This layout is suitable for trailers with limited width. | Griddle, refrigerator, prep table, and sink aligned along one wall. | Imagine a 16-foot trailer. Along the left wall, a 36-inch griddle is positioned closest to the serving window. Adjacent to it, a 24-inch refrigerator stands, followed by a 48-inch stainless steel prep table. Finally, a double-basin sink sits at the end of the line, near the water supply. The opposite wall is left relatively open, creating a clear walkway. |

| Island Layout | Placing key equipment, such as a cooking line or a prep area, in the center of the trailer, creating a ‘kitchen island’. This allows for easy access from all sides. | A central cooking island with a range, fryer, and exhaust hood. Surrounding it are prep tables and refrigerators. | Picture the trailer’s interior. A robust stainless steel island, about 6 feet long and 3 feet wide, dominates the center. It houses a 4-burner range and a deep fryer, both under a commercial-grade exhaust hood. Prep tables are positioned on either side of the island, and refrigerators are strategically placed around the perimeter, within easy reach. |

| Zone Layout | Dividing the trailer into distinct zones based on function: cooking, prep, washing, and serving. This helps streamline workflow. | Cooking zone with a griddle and oven; prep zone with a prep table and food storage; washing zone with a sink and dishwasher; serving zone with a serving window and register. | Visualize the trailer divided into four distinct zones. The cooking zone, near the rear, features a griddle and a convection oven, both strategically placed under an exhaust hood. The prep zone, closer to the front, has a large prep table and ample food storage. The washing zone, with a three-compartment sink and a dishwasher, is situated near the rear entrance. The serving zone, adjacent to the serving window, houses the register and any display cases. |

| L-Shaped Layout | Utilizing the corner of the trailer to create an L-shaped workflow. This is effective in maximizing corner space. | Griddle and fryer along one wall; prep table and refrigerator along the adjacent wall. | Imagine the trailer’s interior. Along the rear wall, a griddle and a deep fryer are installed, creating the short side of the “L”. The adjacent wall, forming the longer side, houses a prep table and a refrigerator. This layout creates an efficient workflow, with the cook moving seamlessly between cooking and prep stations. |

Common Mistakes in Food Trailer Layout and Solutions

Inefficient layouts can significantly hinder food trailer operations. Identifying and correcting common mistakes is vital for creating a functional and profitable business. Here are three common layout mistakes and their corresponding solutions.

- Mistake: Insufficient Counter Space. Limited counter space restricts food preparation and assembly, leading to bottlenecks during peak hours.

- Solution: Incorporate fold-down counters, extend existing countertops, or add a separate prep table. Consider the addition of wall-mounted shelving above prep areas to store frequently used ingredients, freeing up valuable counter space.

- Mistake: Poor Workflow Design. A poorly designed workflow forces staff to travel excessive distances between stations, increasing the time it takes to prepare and serve food.

- Solution: Analyze the menu and map out the steps required for each dish. Position equipment based on this workflow, minimizing unnecessary movement. This may involve relocating equipment, adjusting the placement of prep stations, or modifying the overall layout to create a more efficient flow.

- Mistake: Inadequate Storage. Insufficient storage space for ingredients, supplies, and equipment leads to clutter, disorganization, and reduced efficiency.

- Solution: Utilize every available space for storage. Consider installing overhead shelving, under-counter storage, and incorporating vertical storage solutions. Implement a system for inventory management to optimize storage space and reduce waste.

Innovative Storage Solutions for Small Food Trailer Spaces

Maximizing storage in a small food trailer requires creative thinking. These five innovative storage solutions can significantly increase storage capacity without sacrificing valuable workspace.

- Overhead Shelving with Sliding Doors: Installing overhead shelving above the cooking line and prep areas maximizes vertical space. Sliding doors prevent obstructions and enhance accessibility.

- Under-Counter Shelving and Drawers: Utilizing the space under countertops for shelving and drawers provides easy access to frequently used items and ingredients. Consider installing custom-built drawers and shelving units.

- Wall-Mounted Spice Racks and Organizers: Wall-mounted organizers for spices, condiments, and utensils keep essential items within easy reach, freeing up counter space.

- Fold-Down Shelves and Tables: Incorporating fold-down shelves and tables allows for flexible storage and workspace options. These can be deployed when needed and stowed away when not in use.

- Vertical Storage Racks: Implementing vertical storage racks for sheet pans, cutting boards, and other flat items optimizes space and keeps items organized. These racks can be positioned on walls or inside cabinets.

Equipment Selection and Placement: Food Trailer Layout

Selecting and arranging equipment is crucial for a food trailer’s functionality and efficiency. The right choices and their strategic placement can significantly impact workflow, food quality, and operational ease. Careful consideration of factors like power needs, dimensions, and workflow is essential for a successful mobile food business.

Factors for Equipment Selection

Choosing the correct commercial kitchen equipment requires a detailed assessment of several critical factors. These factors influence both the initial investment and the ongoing operational costs of the food trailer.

- Menu Requirements: The specific menu dictates the necessary equipment. For example, a trailer specializing in fried foods will require fryers, while a pizza trailer will need an oven. Consider the volume of food to be prepared and choose equipment with appropriate capacity.

- Power Requirements: Each piece of equipment has specific power needs, typically measured in volts (V) and amps (A). Determine the total power load by adding the amperage of all equipment. Ensure the trailer’s electrical system can handle the load. This may involve upgrading the power supply, using a generator, or both.

- Dimensions and Space: The size of the equipment must fit within the trailer’s dimensions. Account for clearances needed for operation, maintenance, and ventilation. Prioritize space-saving equipment and consider the overall layout to maximize efficiency.

- Budget: Equipment costs vary significantly. Establish a realistic budget and prioritize essential equipment. Consider used equipment to reduce costs, but ensure it meets quality and safety standards.

- Efficiency and Energy Consumption: Select energy-efficient appliances to reduce operating costs. Look for equipment with Energy Star ratings. Consider equipment that minimizes heat output to reduce the load on the air conditioning system.

- Durability and Reliability: Commercial kitchen equipment must withstand heavy use. Choose equipment made from durable materials and from reputable brands. Read reviews and check warranties.

- Safety and Compliance: All equipment must meet local health and safety codes. Ensure equipment has the necessary certifications. Consider features like fire suppression systems for cooking equipment.

- Maintenance and Cleaning: Select equipment that is easy to clean and maintain. Regular maintenance extends the equipment’s lifespan and prevents costly breakdowns. Consider the accessibility of components for cleaning and repair.

Optimal Equipment Placement

Efficient equipment placement streamlines workflow and maximizes the available space in a food trailer. A well-designed layout minimizes movement, reduces potential hazards, and optimizes the food preparation process.

- Workflow Optimization: Design the layout to follow a logical workflow, typically from receiving raw ingredients to serving the finished product. This includes designated areas for food storage, preparation, cooking, assembly, and serving.

- Cooking Area: Position cooking equipment, such as ovens, ranges, and fryers, in a central location. Ensure adequate ventilation above the cooking area to remove smoke and grease.

- Refrigeration: Place refrigeration units near the prep and cooking areas for easy access to ingredients. Consider reach-in refrigerators and freezers for convenience and under-counter units to save space.

- Prep Area: Establish a dedicated prep area with ample counter space for chopping, slicing, and assembling food. Position the prep area near refrigeration and cooking equipment to facilitate workflow.

- Serving Area: Locate the serving area near the customer access point. Include a point-of-sale (POS) system, warming equipment, and any necessary display cases.

- Storage: Designate areas for dry goods, non-perishable items, and cleaning supplies. Utilize shelving units, cabinets, and under-counter storage to maximize space.

- Ergonomics: Consider the height and accessibility of equipment for the comfort and safety of the staff. Ensure adequate counter space for food preparation and assembly.

- Safety: Ensure sufficient space around equipment for safe operation and movement. Install fire suppression systems and fire extinguishers as required by local regulations.

- Example Layout: Imagine a trailer serving burgers. The layout might start with a receiving area for supplies, leading to a refrigerator for storing patties and produce. A prep area with cutting boards and a salad station would be next. The cooking area would feature a griddle and fryers, followed by an assembly station for building burgers and a serving window for customers.

Calculating Power Load

Accurately calculating the power load is essential to ensure the food trailer’s electrical system can handle the equipment’s demand. Overloading the system can lead to tripped breakers, equipment failure, and safety hazards.

The power load calculation involves summing the amperage of all electrical equipment. The result is then used to determine the size of the generator or the electrical service required.

Formula:

Total Amperage = Amperage (Equipment 1) + Amperage (Equipment 2) + … + Amperage (Equipment N)

Example:

Consider a food trailer with the following equipment:

- Refrigerator: 120V, 8A

- Griddle: 240V, 30A

- Fryer: 240V, 25A

- Microwave: 120V, 15A

- Lighting: 120V, 5A

Calculation:

- Refrigerator: 8A

- Griddle: 30A

- Fryer: 25A

- Microwave: 15A

- Lighting: 5A

- Total Amperage: 8A + 30A + 25A + 15A + 5A = 83A

Power Source Requirement:

The trailer requires a power source that can provide at least 83A at the appropriate voltage (120V or 240V, depending on the equipment). This might necessitate a generator or a connection to a commercial power supply with sufficient capacity.

Workflow and Operational Efficiency

Optimizing workflow and operational efficiency is crucial for a food trailer’s success. A well-designed layout streamlines food preparation and service, leading to faster order fulfillment, reduced waste, and increased profitability. This section details how to achieve this optimization through strategic design choices and operational procedures.

Step-by-Step Food Preparation and Service Process

A clear, efficient process is fundamental to a food trailer’s success. Each stage, from receiving ingredients to serving the customer, should be carefully planned and executed.The process can be broken down into the following stages:

- Receiving and Storage: This initial step involves the delivery and immediate storage of all incoming food items.

- Inspect all deliveries for quality and freshness.

- Immediately refrigerate or freeze perishable items at the appropriate temperatures.

- Organize storage areas (refrigerators, freezers, dry storage) for easy access and inventory management.

- Prepping: This stage focuses on preparing ingredients for cooking.

- Wash, chop, and portion ingredients according to recipes.

- Store prepped ingredients in designated containers, properly labeled and dated.

- Maintain a “FIFO” (First In, First Out) system to minimize waste.

- Cooking: This is where the actual cooking of the food takes place.

- Follow recipes and cooking instructions accurately.

- Monitor cooking times and temperatures using timers and thermometers.

- Maintain a clean and organized cooking station.

- Assembly: This stage involves putting together the final dishes.

- Assemble the cooked components with the prepared ingredients.

- Ensure correct portion sizes and presentation.

- Double-check orders for accuracy.

- Service: This is the final step, where the food is handed to the customer.

- Serve the food promptly and with a friendly attitude.

- Handle cash or process payments efficiently.

- Maintain a clean and organized service window area.

Strategic Placement of Service Windows and Customer Waiting Areas

The placement of service windows and customer waiting areas significantly impacts the flow of customers and the efficiency of service. Thoughtful design can prevent bottlenecks and improve the overall customer experience.Consider these points:

- Service Window Location: The service window should be positioned for optimal visibility and accessibility. It should ideally face the primary customer traffic flow, and be easily accessible from both inside and outside the trailer.

- Customer Waiting Area: The waiting area should be strategically located to avoid obstructing the service window or the food preparation area. It should be large enough to accommodate peak customer volumes, and ideally offer some form of shelter (e.g., awning) or seating.

- Order Pickup Area: This area should be clearly designated and separate from the order placement area. It should be easily accessible for customers picking up their orders and allow staff to efficiently hand out food.

- Traffic Flow: Design the layout to guide customers smoothly from the order placement area to the waiting area, and then to the order pickup area. Signage and visual cues can help to direct traffic flow.

- Example: A popular food truck in Austin, Texas, successfully implemented a system where customers ordered at a window, waited in a designated area marked with social distancing guidelines, and then picked up their food at a separate window. This minimized congestion and streamlined service, leading to increased customer satisfaction and higher sales.

Benefits of a Well-Organized Food Trailer Layout

A well-organized food trailer layout is not just about aesthetics; it directly impacts the bottom line. Efficient use of space and strategic placement of equipment contribute to reduced food waste and increased profits.The advantages include:

- Minimized Food Waste: A well-organized kitchen ensures ingredients are stored properly, reducing spoilage. “FIFO” (First In, First Out) inventory management is easier to implement, leading to less waste.

- Faster Preparation Times: With ingredients and equipment readily accessible, staff can prepare food more quickly. This increases the volume of orders that can be processed.

- Reduced Labor Costs: Efficient workflow minimizes the time required to prepare and serve each order, which can translate into reduced labor costs.

- Improved Customer Satisfaction: Faster service and accurate order fulfillment lead to happier customers, which encourages repeat business and positive word-of-mouth marketing.

- Increased Profitability: Reduced waste, faster service times, and lower labor costs all contribute to higher profit margins. A well-designed trailer can increase the number of orders processed per hour, directly impacting revenue.

- Example: A food truck specializing in gourmet sandwiches, optimized its layout by placing the grill, prep station, and service window in a straight line. This arrangement reduced the average time to prepare a sandwich by 30 seconds, allowing them to serve an additional 10-15 customers per hour during peak times. This directly resulted in a significant increase in daily revenue.

Interior Design and Aesthetics

The interior design of a food trailer significantly impacts the customer experience, influencing their perception of the food, the brand, and the overall ambiance. A well-designed space creates a welcoming atmosphere, encouraging customers to linger and enjoy their meal. Thoughtful design choices, from lighting and color to materials and layout, can transform a simple food trailer into a memorable destination.The strategic use of lighting and color schemes profoundly affects the customer experience.

Warm, inviting lighting, such as soft, recessed LEDs or Edison-style bulbs, creates a cozy and comfortable atmosphere. Conversely, harsh fluorescent lighting can feel clinical and unappealing. Color plays a crucial role in setting the mood; vibrant colors can energize and excite, while more muted tones can create a sense of calm and sophistication. For example, a trailer serving Mexican food might utilize warm reds, oranges, and yellows, evoking a sense of energy and authenticity, while a coffee trailer might employ calming browns, greens, and creams to promote relaxation.

Interior Design Elements Enhancing Branding and Appeal

Interior design elements provide opportunities to reinforce branding and enhance the overall appeal of the food trailer. These elements work together to create a cohesive and memorable experience for the customer.

Check what professionals state about food rodeo aberdeen nc and its benefits for the industry.

- Branding Graphics: Incorporating the food trailer’s logo, tagline, and brand colors throughout the interior is essential. This can be achieved through wall decals, menu boards, and even the design of the equipment. For instance, a food trailer specializing in gourmet burgers might feature a large, eye-catching logo on the serving window and a menu board with a clean, modern design, reflecting the quality and sophistication of the food.

- Material Selection: The choice of materials can significantly impact the aesthetic and functionality of the trailer. Durable and easy-to-clean materials are crucial for a food trailer. Wood paneling can add warmth and character, while stainless steel provides a professional and hygienic appearance. The use of reclaimed wood can also add a rustic and eco-friendly touch, appealing to environmentally conscious customers.

- Seating and Waiting Areas: If space allows, incorporating seating or a designated waiting area can enhance the customer experience. This could include bar stools along a counter, a small bench, or even a few strategically placed outdoor tables. Comfortable seating encourages customers to stay longer, increasing the likelihood of repeat business. The design of these areas should align with the overall brand aesthetic, using consistent materials and colors.

- Decorative Elements: Adding decorative elements can personalize the space and create a more inviting atmosphere. This could include plants, artwork, or unique light fixtures. For example, a trailer serving Italian food might feature framed photographs of Italian landscapes or a small herb garden, adding a touch of authenticity and visual interest.

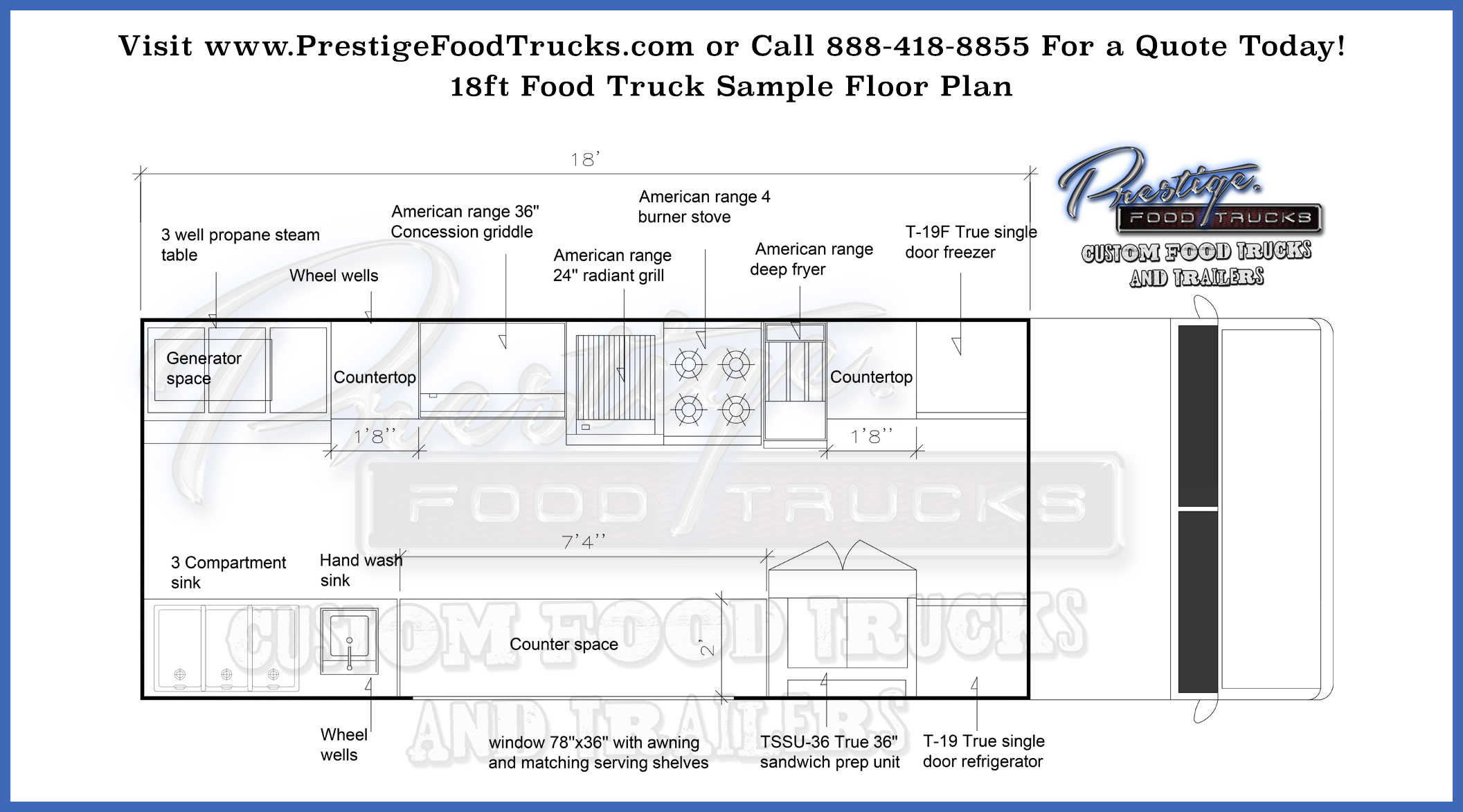

Sample Layout Plan

A well-planned layout is crucial for optimizing space and ensuring efficient workflow within the food trailer. This blockquote showcases a sample layout, highlighting equipment placement and dimensions.

Food Trailer Layout Plan:

Dimensions: 16 ft (L) x 8 ft (W)

Equipment Placement:

- Serving Window Area (4 ft): Cash register, menu board, and point-of-sale system.

- Cooking Area (6 ft): Flat-top grill, deep fryer, and range.

- Preparation Area (4 ft): Refrigerated prep table, cutting boards, and food storage.

- Handwashing Station (1 ft): Required for hygiene.

- Refrigeration/Freezer (1 ft): Upright refrigerator/freezer unit.

Workflow:

- Customers order at the serving window.

- Orders are prepared in the cooking and preparation areas.

- Completed orders are passed through the serving window.

Compliance and Regulations

Operating a food trailer successfully requires navigating a complex web of regulations. Adhering to these rules is not just about avoiding penalties; it’s about ensuring public safety, building trust with customers, and establishing a sustainable business. This section delves into the critical compliance aspects, providing a clear understanding of the permits, accessibility requirements, and health inspection protocols necessary for lawful and thriving food trailer operations.

Necessary Permits and Licenses

Before a food trailer can serve its first customer, a series of permits and licenses must be obtained. The specific requirements vary significantly depending on the city and county of operation. It is essential to conduct thorough research and understand the local regulations before investing in a food trailer. Failure to comply can result in hefty fines, business closure, and legal repercussions.For example, in Los Angeles County, California, a food trailer operator typically needs the following:

- Business License: This is a general license required to operate any business within the county or city limits. The application process usually involves providing basic business information, such as the business name, address, and owner details.

- Health Permit: Issued by the local health department, this permit is crucial for ensuring food safety standards are met. The health department will inspect the trailer to ensure it meets specific requirements for food handling, storage, and sanitation.

- Mobile Food Facility Permit: This permit specifically authorizes the operation of a mobile food facility. It often involves more detailed inspections and regulations compared to a standard business license.

- Fire Safety Permit: Depending on the location and equipment used, a fire safety permit may be required. This ensures the trailer meets fire safety standards, including the proper installation of fire suppression systems and fire extinguishers.

- Zoning Permit: Zoning regulations dictate where a food trailer can be located. This permit ensures the trailer’s location complies with local zoning laws, which may restrict operations in certain areas.

- Seller’s Permit (Sales Tax Permit): This permit allows the trailer to collect and remit sales tax on its sales.

It’s crucial to remember that these are just examples, and specific requirements vary greatly. Researching the local regulations is paramount. Contacting the local city or county government and the health department is the best way to obtain accurate and up-to-date information.

Americans with Disabilities Act (ADA) Requirements for Food Trailer Accessibility

Ensuring accessibility for all customers, including those with disabilities, is not just a matter of legal compliance but also of ethical business practice. The Americans with Disabilities Act (ADA) mandates specific accessibility requirements for food trailers. Adhering to these requirements ensures that individuals with disabilities can enjoy the food trailer experience with the same ease and dignity as everyone else.Key ADA considerations for food trailers include:

- Ramp Access: If the serving counter is elevated, a ramp must be provided for wheelchair access. The ramp must meet specific slope and width requirements to ensure safe and easy access. The maximum slope is typically 1:12. For example, a ramp that rises 1 inch requires 12 inches of horizontal run.

- Clear Floor Space: Sufficient clear floor space must be available for individuals using wheelchairs or other mobility devices to maneuver comfortably. This space should be free from obstructions and allow for easy access to the ordering counter, seating areas (if applicable), and any other service points.

- Counter Height: The serving counter should have a portion that is accessible and at a height that allows for easy interaction for individuals in wheelchairs. This often means a counter height of no more than 34 inches.

- Aisles and Pathways: Aisles and pathways within and around the food trailer should be wide enough to accommodate wheelchairs and other mobility devices. Clear pathways should lead to the ordering counter, service windows, and any seating areas.

- Signage: Clear and accessible signage is crucial for guiding customers with disabilities. Signage should include Braille and raised characters.

Failure to comply with ADA regulations can result in legal action and significant financial penalties. Furthermore, it is important to remember that ADA compliance is an ongoing process. Regular inspections and adjustments may be necessary to ensure continued accessibility.

Preparing for Health Inspections and Ensuring Compliance with Food Safety Standards

Health inspections are a critical part of operating a food trailer, and they are designed to protect public health by ensuring food safety. Preparing thoroughly for these inspections is essential for maintaining a good reputation and avoiding penalties. Understanding and implementing food safety standards are paramount.Key steps to prepare for health inspections:

- Food Safety Training: Ensure all employees have completed a certified food handler course. This training covers essential food safety practices, including proper handwashing, food storage, and cross-contamination prevention.

- Maintain Cleanliness: Regularly clean and sanitize all food preparation surfaces, equipment, and utensils. This includes washing, rinsing, and sanitizing all surfaces. A written cleaning schedule helps to maintain a clean environment.

- Proper Food Storage: Store food at the correct temperatures to prevent bacterial growth. Refrigerated foods should be kept below 41°F (5°C), and hot foods should be held at 135°F (57°C) or higher. Use a food thermometer to monitor food temperatures.

- Prevent Cross-Contamination: Prevent cross-contamination by using separate cutting boards, utensils, and storage containers for raw and cooked foods. Wash hands thoroughly between handling different food types.

- Pest Control: Implement a pest control plan to prevent rodents and insects from entering the food trailer. Seal any cracks or openings and regularly inspect for signs of pests.

- Record Keeping: Maintain accurate records of food temperatures, cleaning schedules, and any other relevant food safety practices. These records will be reviewed during health inspections.

- Waste Disposal: Dispose of waste properly to prevent contamination and attract pests. This includes using appropriate waste containers and disposing of waste regularly.

The health inspector will likely examine these areas during the inspection. A passing inspection indicates that the food trailer meets the required food safety standards. Regular adherence to these standards is key to a successful and compliant food trailer business.

Budgeting and Cost Considerations

Creating a successful food trailer requires careful financial planning. This involves understanding the various costs associated with design, construction, equipment, and ongoing operations. A well-defined budget is crucial for securing funding, managing expenses, and ultimately, achieving profitability. This section provides a detailed breakdown of costs, strategies for cost-effectiveness, and a comparative analysis of layout designs based on investment and potential return.

Detailed Cost Breakdown for a Food Trailer Layout

Understanding the financial commitment required is essential before embarking on a food trailer venture. The costs can be broken down into several key areas, each contributing significantly to the overall investment.

- Trailer Shell and Construction: This represents the foundational cost. It includes the purchase of a new or used trailer, and any modifications needed to prepare it for food service.

- New Trailer: Costs range from $15,000 to $50,000 or more, depending on size, features, and customization options. A 10-foot trailer might be at the lower end, while a 20-foot or larger trailer with extensive features could reach the higher end.

- Used Trailer: Can be a more budget-friendly option, with prices varying from $5,000 to $25,000. However, inspection and potential repairs are critical. Consider the cost of fixing any damage.

- Construction and Customization: This covers modifications like window and door installation, plumbing, electrical work, insulation, and interior finishing. Costs can range from $5,000 to $30,000 or higher, depending on the complexity of the design and the labor involved.

- Equipment: The equipment costs can vary greatly depending on the menu and the volume of food preparation required.

- Cooking Equipment: Ranges, ovens, fryers, grills, and charbroilers are essential. Prices vary significantly based on size, brand, and features. A commercial-grade range could cost from $2,000 to $10,000.

- Refrigeration: Refrigerators, freezers, and potentially refrigerated prep tables are necessary for food storage. Costs range from $1,000 to $10,000.

- Prep and Serving Equipment: Sinks, food prep tables, serving counters, and point-of-sale (POS) systems are essential. Expect to spend $2,000 to $10,000.

- Smallwares: Utensils, cookware, and other small items add to the overall cost, typically $500 to $2,000.

- Design and Permits: This includes the cost of professional design services, if used, and the permits required to operate a food trailer.

- Design Services: Hiring a professional designer to create a layout and choose aesthetics can range from $1,000 to $5,000.

- Permits and Inspections: Costs vary depending on local regulations. Expect to pay for health permits, business licenses, and inspections, potentially totaling $500 to $2,000 or more.

- Other Expenses: These are the less obvious, but essential costs.

- Initial Inventory: Stocking up on food and supplies for the first few weeks of operation. Costs vary based on menu, but consider $1,000 to $5,000.

- Marketing and Branding: Creating a brand identity, designing a logo, and marketing materials. This could cost $500 to $3,000.

- Insurance: Food trailer insurance is essential to protect the business. Premiums vary. Expect to pay $1,000 to $3,000 annually.

- Utilities and Waste Disposal: Costs for electricity, water, propane, and waste disposal. These costs vary based on usage. Budget $200 to $500 monthly.

Strategies for Cost-Effective Equipment Procurement and Space Optimization

Strategic planning can help reduce initial investment costs while maximizing space and efficiency within the food trailer. This section discusses effective strategies for procurement and space management.

- Procurement Strategies: Careful consideration of how equipment is obtained can significantly impact the budget.

- Buying Used Equipment: Purchasing used commercial kitchen equipment can save a considerable amount of money. Inspect equipment thoroughly and ensure it is in good working condition.

- Negotiating with Suppliers: Negotiating prices with equipment suppliers can help lower the overall cost. Consider bulk purchases or seasonal promotions.

- Leasing Equipment: Leasing equipment is a viable option, especially for high-cost items. This can reduce the initial capital outlay and provide flexibility.

- Focusing on Essential Equipment: Prioritize the essential equipment needed to prepare the core menu items. Avoid unnecessary gadgets or equipment.

- Space Optimization Techniques: Efficient use of space is crucial in a food trailer.

- Layout Planning: A well-designed layout can maximize workflow and minimize wasted space.

- Vertical Storage: Utilize vertical space with shelving units to store supplies and equipment.

- Multifunctional Equipment: Choose equipment that serves multiple purposes, such as a combination oven or a prep table with built-in refrigeration.

- Compact Equipment: Select compact equipment models that fit the available space without compromising functionality.

Comparative Analysis of Different Food Trailer Layout Designs Based on Initial Investment and Potential Return on Investment

Comparing different layout designs involves analyzing their initial investment costs and potential for generating revenue. The optimal design will balance these factors to maximize the return on investment (ROI).

Consider the following three hypothetical food trailer layouts:

- Layout A (Simple Setup): Focuses on a limited menu with minimal equipment. The estimated initial investment is lower, but the potential for high volume sales is limited.

- Example Menu: Hot dogs and simple sandwiches.

- Equipment: Grill, small refrigerator, and a single-basin sink.

- Estimated Initial Investment: $25,000 – $35,000

- Potential Daily Revenue: $500 – $1,000

- Advantages: Lower startup costs, quicker setup.

- Disadvantages: Limited menu, lower revenue potential.

- Layout B (Mid-Range Setup): Offers a more diverse menu with more equipment. The investment is moderate, and the potential for revenue is higher.

- Example Menu: Burgers, fries, and milkshakes.

- Equipment: Grill, fryer, refrigerator, freezer, prep table, and a double-basin sink.

- Estimated Initial Investment: $40,000 – $60,000

- Potential Daily Revenue: $1,000 – $2,000

- Advantages: Broader menu, increased revenue potential.

- Disadvantages: Higher initial investment, more complex operations.

- Layout C (High-End Setup): Features a complex menu with extensive equipment. The investment is high, but the potential for high revenue is also present.

- Example Menu: Gourmet tacos, elaborate sides, and craft beverages.

- Equipment: Multiple grills, fryers, ovens, refrigeration units, prep tables, and a three-basin sink.

- Estimated Initial Investment: $70,000 – $100,000+

- Potential Daily Revenue: $2,000+

- Advantages: High revenue potential, ability to offer a unique and differentiated menu.

- Disadvantages: Highest initial investment, complex operations, higher risk.

Comparative Analysis Table:

| Layout | Estimated Initial Investment | Potential Daily Revenue | Menu Complexity | ROI Considerations |

|---|---|---|---|---|

| A (Simple) | $25,000 – $35,000 | $500 – $1,000 | Low | Faster ROI due to lower initial investment. However, limited growth potential. |

| B (Mid-Range) | $40,000 – $60,000 | $1,000 – $2,000 | Medium | Moderate ROI. Offers a balance between investment and revenue potential. |

| C (High-End) | $70,000 – $100,000+ | $2,000+ | High | Slower ROI due to higher initial investment, but the potential for significant profits is higher if executed well. |

The best layout choice depends on the entrepreneur’s goals, risk tolerance, and the target market. A simple layout may be suitable for those with limited capital or who are testing the market. A mid-range layout offers a balance between investment and revenue potential. A high-end layout may be ideal for experienced operators with a unique concept and a desire to maximize profits.

Ventilation and Environmental Control

Maintaining a comfortable and safe environment inside a food trailer is crucial for both food safety and the well-being of the staff. Proper ventilation and environmental control systems are essential for achieving this. They remove smoke, grease, and odors, regulate temperature and humidity, and ensure compliance with health codes. Neglecting these aspects can lead to poor air quality, food spoilage, and potential health hazards.

Importance of Ventilation Systems and Selection Factors

An effective ventilation system is paramount in a food trailer for several reasons. It directly impacts the health of employees by removing harmful fumes and heat generated by cooking equipment. Furthermore, it prevents the buildup of grease, which can create a fire hazard. The choice of ventilation system depends on the type of cooking performed, the size of the trailer, and local regulations.

- Type of Cooking: High-volume frying or grilling operations generate significantly more smoke and grease than simple sandwich preparation. For example, a trailer primarily focused on deep-fried foods, such as a fish and chips operation, requires a more robust system than one serving pre-made salads.

- Trailer Size: Larger trailers necessitate more powerful exhaust fans and larger hood systems to effectively remove contaminants. A 16-foot trailer needs a smaller system compared to a 24-foot one.

- Local Regulations: Health codes and fire safety regulations dictate the required CFM (cubic feet per minute) rating for exhaust fans and the type of hood and fire suppression systems. These regulations often vary by location.

- Hood Type: Different hood designs, such as wall-mounted, island, or downdraft hoods, are suitable for different cooking setups. A wall-mounted hood is commonly used in smaller trailers, while an island hood is appropriate for central cooking areas.

- Fan Power (CFM): The CFM rating of the exhaust fan determines its ability to remove air. It must be calculated based on the size of the cooking equipment and the trailer. Insufficient CFM leads to inadequate ventilation.

- Make-up Air: Supplying clean air to replace the exhausted air is essential. Without it, the exhaust system may not function efficiently, and the trailer could experience negative air pressure, making it difficult to open doors.

- Grease Filters: These filters capture grease particles before they enter the exhaust ductwork, preventing grease buildup and reducing the risk of fire. They require regular cleaning.

- Fire Suppression System: A fire suppression system, often integrated into the hood, is mandatory in most food trailers. It automatically detects and extinguishes fires caused by cooking equipment.

Managing Temperature and Humidity, Food trailer layout

Controlling temperature and humidity within a food trailer is critical for preserving food quality and ensuring a comfortable working environment. Excessive heat and humidity can accelerate food spoilage, breed bacteria, and cause discomfort for the staff. Conversely, inadequate temperature control can compromise food safety and reduce operational efficiency.

- HVAC System: An HVAC (Heating, Ventilation, and Air Conditioning) system is crucial for regulating temperature and humidity. The size and capacity of the HVAC unit should be proportional to the trailer’s size and the heat generated by cooking equipment. A system sized for a 20-foot trailer with moderate cooking activity will differ significantly from one needed for a 30-foot trailer with heavy frying.

- Insulation: Proper insulation in the walls, ceiling, and floor of the trailer minimizes heat transfer, reducing the load on the HVAC system and improving energy efficiency. Spray foam insulation is a highly effective option.

- Airflow Management: Strategically placed vents and air conditioning ducts promote proper airflow, ensuring even temperature distribution and preventing hot spots. Consider the placement of vents in relation to cooking equipment and areas where staff work.

- Humidity Control: High humidity can lead to condensation and mold growth. The HVAC system should have a dehumidification function to maintain humidity levels below 60%. Using a separate dehumidifier may be necessary in humid climates.

- Regular Maintenance: Regularly cleaning and maintaining the HVAC system, including changing filters, ensures optimal performance and prevents the spread of mold and bacteria. Neglecting maintenance reduces efficiency and can shorten the system’s lifespan.

- Food Storage Practices: Properly storing food items at the correct temperatures is essential. Refrigerated and freezer units should be well-maintained and regularly monitored to prevent food spoilage. This includes adhering to the “first in, first out” (FIFO) method for food rotation.

Installation of Ventilation Hood and Exhaust System

Installing a ventilation hood and exhaust system is a complex process that requires careful planning and adherence to safety regulations. Professional installation is often recommended to ensure proper functionality and compliance with local codes. However, understanding the steps involved is beneficial.

- Planning and Design: Determine the appropriate hood size, type, and CFM rating based on the cooking equipment and trailer size. Consult with a ventilation specialist to create a detailed design plan that complies with local codes.

- Hood Mounting: Securely mount the hood to the ceiling or wall, ensuring it is level and properly aligned with the cooking equipment. This involves using appropriate fasteners and ensuring the hood is structurally sound.

- Ductwork Installation: Install the exhaust ductwork, ensuring it is properly sealed to prevent leaks and runs directly to the outside of the trailer. Use fire-rated ductwork and maintain proper clearances from combustible materials.

- Fan Installation: Mount the exhaust fan on the roof or exterior wall, ensuring it is securely fastened and wired according to electrical codes. Ensure the fan is properly sized and rated for the hood and cooking equipment.

- Grease Filter Installation: Install the grease filters in the hood, ensuring they are properly positioned and accessible for cleaning. Choose filters appropriate for the type of cooking and frequency of use.

- Make-up Air System Installation: Install a make-up air system to replace the air exhausted by the fan. This may involve installing a separate fan and ductwork to bring in fresh, filtered air.

- Fire Suppression System Installation (if required): Install the fire suppression system, ensuring it is properly connected to the hood and cooking equipment. Follow the manufacturer’s instructions for installation and testing.

- Electrical Wiring: Connect the exhaust fan, make-up air system, and fire suppression system to the electrical panel, ensuring all wiring complies with local electrical codes. Hire a qualified electrician for this task.

- Testing and Inspection: Test the entire system to ensure it is functioning correctly and meets all requirements. Schedule an inspection by the local health and fire departments to obtain necessary permits.

- Maintenance and Cleaning: Establish a regular maintenance schedule for cleaning the grease filters, inspecting the ductwork, and maintaining the fan and fire suppression system. This will help ensure the system’s longevity and effectiveness.

Customization and Personalization

The ability to customize and personalize a food trailer is crucial for establishing a strong brand identity and operational efficiency. This section explores the process of tailoring a food trailer’s layout to a specific culinary concept, contrasting the benefits and drawbacks of custom builds versus pre-fabricated options, and providing visual descriptions of layout variations based on different food service models.

Designing a Personalized Layout for a Culinary Concept

Personalizing a food trailer layout begins with a deep understanding of the culinary concept and brand identity. The layout must support the specific menu, service style, and desired customer experience. This involves carefully considering workflow, equipment needs, storage requirements, and aesthetic preferences to create a cohesive and functional space.

- Menu Analysis: Evaluate the menu’s complexity and production requirements. A menu featuring complex dishes with multiple cooking steps will necessitate a different layout than a menu focused on quick-service items. For instance, a gourmet burger trailer might require a dedicated grill station, a fry station, and a topping assembly area, whereas a simple hot dog stand needs less equipment and space.

- Workflow Optimization: Design the layout to minimize movement and maximize efficiency. The flow should ideally progress from food receiving to storage, preparation, cooking, service, and finally, dishwashing and waste disposal. Consider the placement of equipment, the width of walkways, and the location of service windows to ensure smooth operations.

- Equipment Selection and Placement: Choose equipment based on menu needs and space constraints. The placement of equipment directly impacts workflow and efficiency. Placing a refrigerator near the prep area and a fryer near the serving window can streamline operations.

- Branding Integration: Incorporate brand elements into the interior design. This includes color schemes, materials, signage, and lighting. For example, a vibrant color palette and playful graphics can enhance the appeal of a food trailer serving Mexican street food.

- Customer Experience: Consider how the layout affects the customer experience. A clear service window, well-organized menu boards, and comfortable waiting areas (if applicable) contribute to a positive impression.

Custom-Built vs. Pre-Fabricated Food Trailers

The decision to choose a custom-built or pre-fabricated food trailer involves weighing the advantages and disadvantages of each option.

- Custom-Built Food Trailers:

- Advantages: Complete customization to meet specific needs, including unique equipment, workflow optimization, and brand integration. Offers the greatest flexibility in terms of size, shape, and design.

- Disadvantages: Higher initial cost, longer construction time, and the need to work closely with a designer and fabricator. May require navigating more complex permitting processes.

- Pre-Fabricated Food Trailers:

- Advantages: Lower initial cost, faster turnaround time, and often easier permitting. Standardized designs can be more readily available and require less planning.

- Disadvantages: Limited customization options, may not perfectly fit specific needs, and may require compromises in terms of equipment and layout. The design might not fully reflect the brand identity.

The choice between custom-built and pre-fabricated depends on the specific needs, budget, and timeline of the food trailer business.

Visual Descriptions of Layout Options

The following descriptions illustrate different layout options tailored to various food concepts.

- Coffee Shop Food Trailer: Imagine a trailer with a warm, inviting atmosphere. The front section features a large service window with a custom-built counter for taking orders and serving drinks. Behind the counter, a barista station with an espresso machine, grinders, and a refrigerator for milk and syrups is positioned for optimal workflow. A small pastry display case showcases baked goods. Storage is strategically placed beneath the counter and in overhead cabinets.

The color scheme uses earthy tones, with wooden accents and soft lighting. The exterior showcases the coffee shop’s logo and branding prominently.

- Pizza Food Trailer: Picture a food trailer designed for efficient pizza production. The core of the layout includes a large pizza oven dominating the back wall. Adjacent to the oven is a prep table with ample space for dough preparation and topping assembly. Refrigerated units store ingredients such as cheese, sauces, and toppings. A dough mixer and a dough sheeter might be included if the trailer produces its own dough.

A service window allows for direct customer interaction, and a small waiting area with seating is available outside the trailer. The interior design includes stainless steel surfaces for easy cleaning and a pizza-themed graphic on the exterior.

- Taco Truck Food Trailer: Envision a taco truck layout designed for fast and efficient service. A griddle and a plancha take center stage for cooking meats and vegetables. A steam table keeps tortillas warm and ready to serve. Refrigerated compartments hold prepped ingredients like salsa, guacamole, and toppings. The service window is large and positioned for easy customer access.

The exterior design features bold colors, vibrant murals, and the taco truck’s branding.

Future-Proofing Your Food Trailer

Designing a food trailer isn’t just about the present; it’s about anticipating the future. The culinary landscape is constantly evolving, with trends, technologies, and customer preferences shifting rapidly. A well-designed food trailer should be adaptable, allowing for menu changes, operational expansions, and integration of new technologies. This foresight ensures longevity and maximizes the return on investment.

Adapting to Menu Changes and Business Expansion

The ability to adjust your menu and scale your operation is crucial for long-term success. A future-proofed layout considers these possibilities from the outset.A versatile food trailer design should incorporate the following features:

- Modular Equipment Placement: Consider equipment on wheels or with easily adjustable connections. This allows for rearranging the kitchen layout to accommodate new equipment or optimize workflow for different menu items. For instance, if you initially focus on sandwiches and later want to add a fryer for french fries, a modular design simplifies the process.

- Sufficient Power and Utility Capacity: Plan for future electrical and plumbing needs. Install a panel with extra breaker space and consider oversizing your water heater and holding tanks. This prevents costly upgrades later. A good example is a trailer designed for 30 amps that is later required to be upgraded to 50 amps to support new appliances.

- Flexible Counter Space: Incorporate ample counter space that can be reconfigured. Utilize stainless steel tables that can be moved or added to, depending on the needs of the menu. Think of this as a “blank canvas” that can be adapted to different food preparation styles.

- Adequate Storage: Include sufficient storage space, both dry and refrigerated, to accommodate potential menu expansions and increased inventory. Consider shelving systems that can be adjusted to different heights.

- Considerations for Mobile Ordering and Pickup: If you plan to offer mobile ordering or curbside pickup, designate a pickup window or area. This could be a simple shelf outside the serving window or a more elaborate setup.

Incorporating Technology in the Food Trailer Layout

Technology can significantly enhance efficiency, customer experience, and data collection. Integrating it seamlessly into your layout is a key aspect of future-proofing.Implementing technology involves strategic planning:

- Point-of-Sale (POS) System Integration: The POS system is the central hub of your operation. Ensure adequate counter space for the POS terminal, printer, and any associated hardware. Consider cable management to keep the area tidy and prevent tripping hazards.

- Digital Menu Boards: Digital menu boards offer flexibility and ease of updating. Position them strategically, ensuring visibility for customers. Consider the electrical requirements for the displays and any associated networking equipment.

- Online Ordering Systems: Designate a space for order fulfillment, potentially with a dedicated prep area or staging area for pickup orders. This streamlines the process and reduces congestion.

- Inventory Management Systems: Integrate space for tablets or computer displays for inventory tracking. This allows for real-time monitoring of stock levels and helps prevent waste.

- Security Systems: Plan for the installation of security cameras and alarm systems, including the placement of monitors and control panels.

Flexibility and Scalability in Food Trailer Design

Flexibility and scalability are interconnected and essential for adapting to market changes. A design that prioritizes these aspects allows you to grow your business without requiring a complete overhaul.The benefits of flexibility and scalability include:

- Adaptability to Trends: A flexible layout allows you to quickly adjust your menu to capitalize on new food trends or customer preferences. For example, if a new food trend emerges, you can easily rearrange your equipment to accommodate the preparation of those dishes.

- Expansion of Operations: A scalable design allows you to expand your operations, such as adding staff or increasing your service hours. This is easier if the layout is not overly constrained.

- Cost Efficiency: Avoiding major renovations in the future saves money. By anticipating potential changes, you can make initial investments that pay off in the long run.

- Increased Revenue Potential: By adapting to market changes and expanding your offerings, you can increase your revenue potential. For example, adding a second serving window can significantly increase the number of customers served during peak hours.

- Improved Customer Experience: A well-designed and adaptable layout enhances the customer experience, leading to repeat business and positive reviews. For instance, a streamlined ordering and pickup process, facilitated by technology and a well-organized layout, makes for a more enjoyable experience.

Last Word

In conclusion, mastering the art of food trailer layout is paramount for any aspiring mobile food entrepreneur. By focusing on functionality, aesthetics, and compliance, you can create a dynamic and profitable business. Remember that thoughtful design, strategic equipment placement, and a commitment to efficiency are the cornerstones of success. Embrace the journey, stay adaptable, and watch your food trailer flourish.