Food safe grill paint, denggan nauli, is the beginning of a tale that speaks of both practicality and the age-old art of preparing food over fire. This paint is more than just a coat; it is a shield against the elements, a guardian of your health, and a testament to the enduring spirit of the grill master. We will delve deep into the heart of food safe grill paint, uncovering its purpose, benefits, and the vital role it plays in ensuring the safety and longevity of your beloved grilling apparatus.

From the selection of the right paint to the meticulous preparation of the grill, and finally to the application and curing process, we will embark on a journey. We’ll explore the different types of paints, their unique characteristics, and the essential safety precautions to observe. This will enable you to transform your grill into a gleaming masterpiece, ready to serve up countless feasts for your family and friends.

Introduction to Food Safe Grill Paint

Food safe grill paint is a specialized coating designed to protect and enhance the appearance of your grill while ensuring it remains safe for food preparation. It’s formulated to withstand high temperatures and prevent the release of harmful chemicals or toxins into your food. Using food safe paint is crucial for maintaining the integrity of your grill and the health of those consuming the food cooked on it.This type of paint is specifically designed for use on surfaces that come into direct or indirect contact with food.

It differs significantly from regular paints, which are not formulated to withstand the heat and potential food contact associated with grilling.

Purpose of Food Safe Grill Paint

Food safe grill paint serves a dual purpose: protection and aesthetics. It creates a barrier that shields the grill from rust, corrosion, and the damaging effects of high heat and weather elements. This barrier extends the grill’s lifespan. At the same time, it provides a visually appealing finish, improving the grill’s appearance and making it easier to clean.

Benefits of Using Food Safe Grill Paint

Using food safe grill paint offers several advantages, including enhanced safety, durability, and aesthetics.

- Enhanced Safety: The primary benefit is the assurance that no harmful chemicals will leach into your food during the grilling process. Food safe paints are tested and certified to meet stringent safety standards, guaranteeing they are non-toxic and safe for contact with food.

- Durability and Heat Resistance: Food safe grill paints are specifically formulated to withstand the extreme temperatures generated during grilling. This heat resistance prevents the paint from peeling, cracking, or blistering, ensuring the grill’s protective coating remains intact over time.

- Corrosion Protection: These paints provide a robust barrier against rust and corrosion, which are common issues for grills exposed to the elements. This protection extends the life of the grill and maintains its structural integrity.

- Improved Aesthetics: Food safe grill paint can significantly enhance the appearance of your grill. They come in various colors and finishes, allowing you to restore or customize your grill to your liking.

- Ease of Cleaning: Many food safe grill paints have a smooth, non-stick surface that makes cleaning easier. This reduces the time and effort required to maintain your grill, allowing you to enjoy your grilling experience more fully.

Importance of Food Safe Paint Versus Regular Paint

The distinction between food safe paint and regular paint is critical for both health and the grill’s longevity. Regular paints are not designed to withstand high temperatures or contact with food and can pose significant risks.

- Toxicity: Regular paints often contain chemicals that can leach into food when heated. These chemicals can be harmful if ingested. Food safe paints, on the other hand, are formulated without these harmful substances.

- Heat Resistance: Regular paints are not designed to withstand the high temperatures of a grill. They can degrade, peel, and release fumes when exposed to heat, potentially contaminating the food. Food safe paints are specifically engineered to resist these effects.

- Durability: Regular paints are less durable than food safe paints and will likely deteriorate quickly on a grill. This means more frequent repainting and less protection for the grill itself. Food safe paints are built to last, providing long-term protection.

- Regulatory Compliance: Food safe paints are manufactured to meet specific safety standards and regulations. Regular paints do not undergo the same rigorous testing and certification processes.

The U.S. Food and Drug Administration (FDA) provides guidelines for materials that come into contact with food. Food safe grill paints adhere to these guidelines, ensuring they are safe for their intended use.

Types of Food Safe Grill Paint

Choosing the right food-safe grill paint is crucial for both the longevity of your grill and the safety of your food. Several types of paint are specifically designed for this purpose, each with unique properties. Understanding these differences allows you to select the best option for your grilling needs.

High-Heat Grill Paint

High-heat grill paint is a common and readily available option, formulated to withstand extremely high temperatures without peeling, cracking, or releasing harmful fumes. It is a popular choice for both professional and home grillers.

- Heat Resistance: High-heat paints typically withstand temperatures up to 1200°F (650°C), making them suitable for most grilling applications. Some premium formulations can endure even higher temperatures.

- Durability: This paint generally provides good durability, resisting rust, corrosion, and the effects of weather. However, the lifespan can vary depending on the specific formulation and how the grill is used and maintained.

- Application Methods: High-heat paints are available in spray and brush-on formulations. Spray paints offer a smoother finish and are often preferred for larger surfaces, while brush-on paints are suitable for touch-ups and smaller areas. Proper surface preparation, including cleaning and priming, is essential for optimal adhesion.

- Typical Ingredients: The primary components of high-heat grill paint include heat-resistant pigments, silicone resins or modified alkyd resins (which provide heat resistance and flexibility), solvents (to aid in application and drying), and additives (to enhance durability and corrosion resistance).

Ceramic-Based Grill Paint

Ceramic-based grill paints represent an advanced option, utilizing ceramic particles to enhance heat resistance and durability. These paints are often chosen for their superior performance in extreme conditions.

- Heat Resistance: Ceramic-based paints typically offer excellent heat resistance, often exceeding 1200°F (650°C), and some can withstand temperatures up to 2000°F (1093°C) or more. This makes them ideal for grills that reach very high temperatures, such as those used for searing or wood-fired cooking.

- Durability: These paints are known for their exceptional durability, providing superior resistance to rust, corrosion, and the effects of weathering. The ceramic particles create a hard, protective coating that can withstand the harsh conditions of grilling.

- Application Methods: Ceramic-based paints are available in spray and brush-on forms, with similar application requirements to high-heat paints. Thorough surface preparation is essential for optimal adhesion and performance. Due to the ceramic content, the paint may require more thorough mixing.

- Typical Ingredients: Ceramic-based grill paints contain ceramic particles (such as silicon carbide or aluminum oxide) that provide heat resistance and durability. They also include silicone resins (for binding), solvents, and additives to enhance the paint’s properties. The ceramic particles are what set these paints apart from other formulations.

Other Considerations

While high-heat and ceramic-based paints are the most common, other food-safe grill paint types exist.

- Specialty Formulations: Some manufacturers offer specialty paints designed for specific grill types or applications, such as paints formulated for smokers or those with enhanced resistance to grease and oil.

- Color Options: While black is the most common color, food-safe grill paints are available in various colors. Choose a color that complements the grill’s design while ensuring it meets the required heat resistance and safety standards.

Selecting the Right Food Safe Grill Paint

Choosing the correct food-safe grill paint is paramount for both the longevity of your grill and, more importantly, the safety of your food. This selection process involves careful consideration of your grill type, the paint’s certifications, and a thorough evaluation of its properties. Making an informed decision ensures a safe and enjoyable grilling experience.

Grill Type Considerations

Different grill types present unique challenges and requirements when selecting food-safe paint. The heat generated, the materials used in construction, and the intended use all play a crucial role in determining the best paint for your needs.For charcoal grills, the paint must withstand extremely high temperatures. Charcoal grills often reach temperatures exceeding 700°F (371°C). The paint needs to resist peeling, blistering, and burning.

Consider paints specifically formulated for high-heat applications. Furthermore, the paint must be resistant to the abrasive nature of charcoal and ash. Gas grills generally operate at lower, but still significant, temperatures. However, the presence of propane or natural gas introduces the possibility of chemical reactions. The paint should be resistant to the chemicals produced by the burning gas.

Look for paints designed to withstand the corrosive effects of gas combustion byproducts. Electric grills typically have lower overall operating temperatures compared to charcoal or gas grills. However, the paint must still be durable and able to resist heat fluctuations. Ensure the paint is suitable for the materials used in the electric grill’s construction, such as stainless steel or cast iron.

Certifications and Standards

Verifying certifications and adherence to established standards is critical to ensuring a paint is truly food-safe. These certifications provide assurance that the paint meets specific safety requirements and doesn’t pose a health risk when exposed to food.The most important certification to look for is FDA compliance. The Food and Drug Administration (FDA) in the United States sets standards for materials that come into contact with food.

This compliance means the paint’s ingredients and formulations have been assessed and deemed safe for food contact. Paints meeting FDA standards generally will not leach harmful chemicals into food when heated.Consider paints that have been tested and certified by independent laboratories. These labs rigorously evaluate the paint’s performance under various conditions.Some paints may carry certifications from other relevant organizations. These can provide additional assurance regarding the paint’s safety and performance.

Always check the manufacturer’s documentation and look for readily available information about the certification.

Evaluating Food Safe Grill Paint Products: A Checklist

Evaluating different food-safe grill paint products requires a systematic approach. This checklist provides a framework for assessing the suitability of a particular paint for your grill.Consider these points when choosing a food safe grill paint:

- Temperature Resistance: Verify the paint’s maximum operating temperature. It must exceed the expected temperatures of your grill. For example, high-heat paints are often rated for 1200°F (649°C) or higher, which is suitable for most grills.

- Food Contact Compliance: Confirm that the paint is FDA-compliant or meets equivalent food-safety standards. Check the product labeling or manufacturer’s website for this information.

- Durability: Assess the paint’s resistance to rust, corrosion, and weathering. Look for paints formulated to withstand outdoor conditions and frequent use.

- Material Compatibility: Ensure the paint is compatible with the materials of your grill (e.g., steel, cast iron). Some paints are specifically designed for certain materials.

- Application Method: Consider the application method. Some paints are available in spray-on form, while others require brushing. Choose the method that best suits your needs and skill level.

- Curing Time: Understand the required curing time. This is the time needed for the paint to fully dry and harden. Proper curing is essential for the paint’s performance and food safety.

- Color and Finish: Select a color and finish that meets your aesthetic preferences. Consider the long-term appearance of the paint.

- Reviews and Recommendations: Read reviews from other users to gain insights into the paint’s performance and durability. Consult online forums and websites for user feedback.

- Cost: Compare prices of different paint products, keeping in mind the quality and features. Balance cost with the paint’s performance and safety.

By carefully considering these factors, you can choose a food-safe grill paint that will keep your grill in top condition and your food safe.

Preparing the Grill for Painting

Before you can eventhink* about applying that food-safe grill paint, your trusty barbecue needs a thorough spa day. Neglecting proper preparation is like trying to build a house on quicksand – the paint won’t adhere correctly, and you’ll be back to square one sooner than you think. This section dives deep into the essential steps, tools, and techniques required to ensure a flawlessly painted grill, ready to withstand the heat and deliver delicious meals for years to come.

Cleaning and Degreasing the Grill

The first and arguably most crucial step is removing all the gunk, grease, and grime that has accumulated over countless grilling sessions. A clean surface is paramount for paint adhesion.

Here’s how to tackle this:

- Initial Cleaning: Begin by removing any loose debris. Use a stiff-bristled brush (wire brushes are generally discouraged for food-safe applications, as they can leave behind small metal fragments) to scrub the grill grates, the firebox, and any other surfaces.

- Degreasing: Apply a dedicated grill degreaser. Follow the product’s instructions carefully. Typically, you’ll spray the degreaser onto the surfaces, allow it to sit for the recommended time (usually 10-30 minutes), and then scrub vigorously. Pay special attention to areas where grease tends to build up, like the inside of the lid and the bottom of the firebox. Rinse thoroughly with water.

- Rinse and Dry: After degreasing, rinse the entire grill with clean water to remove all traces of the degreaser. Ensure all residue is removed, as this can interfere with paint adhesion. Allow the grill to dry completely. This may take several hours, or even a full day, depending on the humidity.

Sanding the Grill Surface, Food safe grill paint

Once the grill is clean and dry, the next step is to prepare the surface for optimal paint adhesion through sanding. Sanding creates microscopic scratches, providing the paint with something to “grab” onto.

Here’s what you need to know:

- Choosing the Right Sandpaper: Select sandpaper appropriate for metal. A grit between 120 and 220 is generally recommended. This provides enough abrasion to create a good surface without being overly aggressive.

- Sanding Techniques: Use a sanding block or an orbital sander (for larger surfaces) to ensure even sanding. Sand in a consistent pattern, overlapping each pass slightly. Avoid sanding in one spot for too long, as this can create uneven areas.

- Addressing Rust: If your grill has any rust, it’s crucial to remove it completely before painting. Sand the rusted areas thoroughly, going down to bare metal. You might need to use a coarser grit sandpaper initially to remove the bulk of the rust, followed by a finer grit to smooth the surface. Consider using a rust converter or primer if rust is extensive.

- Post-Sanding Cleaning: After sanding, thoroughly clean the grill again to remove all sanding dust. Use a tack cloth or a clean, damp cloth to wipe down the entire surface. Any dust left behind will compromise paint adhesion.

Masking Areas for Painting

Not every part of your grill needs to be painted. Masking is essential to protect areas you

don’t* want paint on, such as handles, control knobs, and the inside of the firebox (if it will be in direct contact with food).

Here’s a guide to effective masking:

- Gathering Materials: You’ll need painter’s tape (specifically designed for painting, as it removes cleanly without damaging surfaces) and masking paper or plastic sheeting.

- Taping Techniques: Carefully apply the painter’s tape to the edges of the areas you want to protect. Press the tape firmly to ensure a good seal. Overlap the tape slightly onto the surface you

-do* want to paint, ensuring a crisp edge. - Protecting Larger Areas: Use masking paper or plastic sheeting to cover larger areas, such as the handles, control panels, or the inside of the firebox. Secure the sheeting with painter’s tape.

- Checking Your Work: Before painting, take a final look at your masking job. Make sure all the areas you want to protect are completely covered and that the tape is securely adhered.

Applying Food Safe Grill Paint

Applying food-safe grill paint correctly is crucial for both the longevity of your grill and the safety of your food. The application process, from selecting the right tools to achieving the perfect finish, significantly impacts the paint’s performance and its ability to withstand high temperatures and constant exposure to the elements. Proper application ensures the paint adheres effectively, preventing chipping, peeling, and, most importantly, the potential for harmful substances to contaminate your food.

Application Methods for Food Safe Grill Paint

Different application methods cater to various preferences and project requirements. Understanding the pros and cons of each method allows you to select the most suitable approach for your specific grill and desired outcome.

- Brush Application: Brushing is a straightforward method, ideal for detailed work and smaller grills. It offers excellent control and allows for precise application, minimizing overspray. However, brush strokes can be visible, and it may take longer to cover larger surfaces.

- Spray Application: Spraying provides a smooth, even finish and is well-suited for large, flat surfaces. It’s generally faster than brushing. However, it requires a spray gun, compressor, and proper ventilation. Overspray can be a concern, necessitating careful masking of surrounding areas.

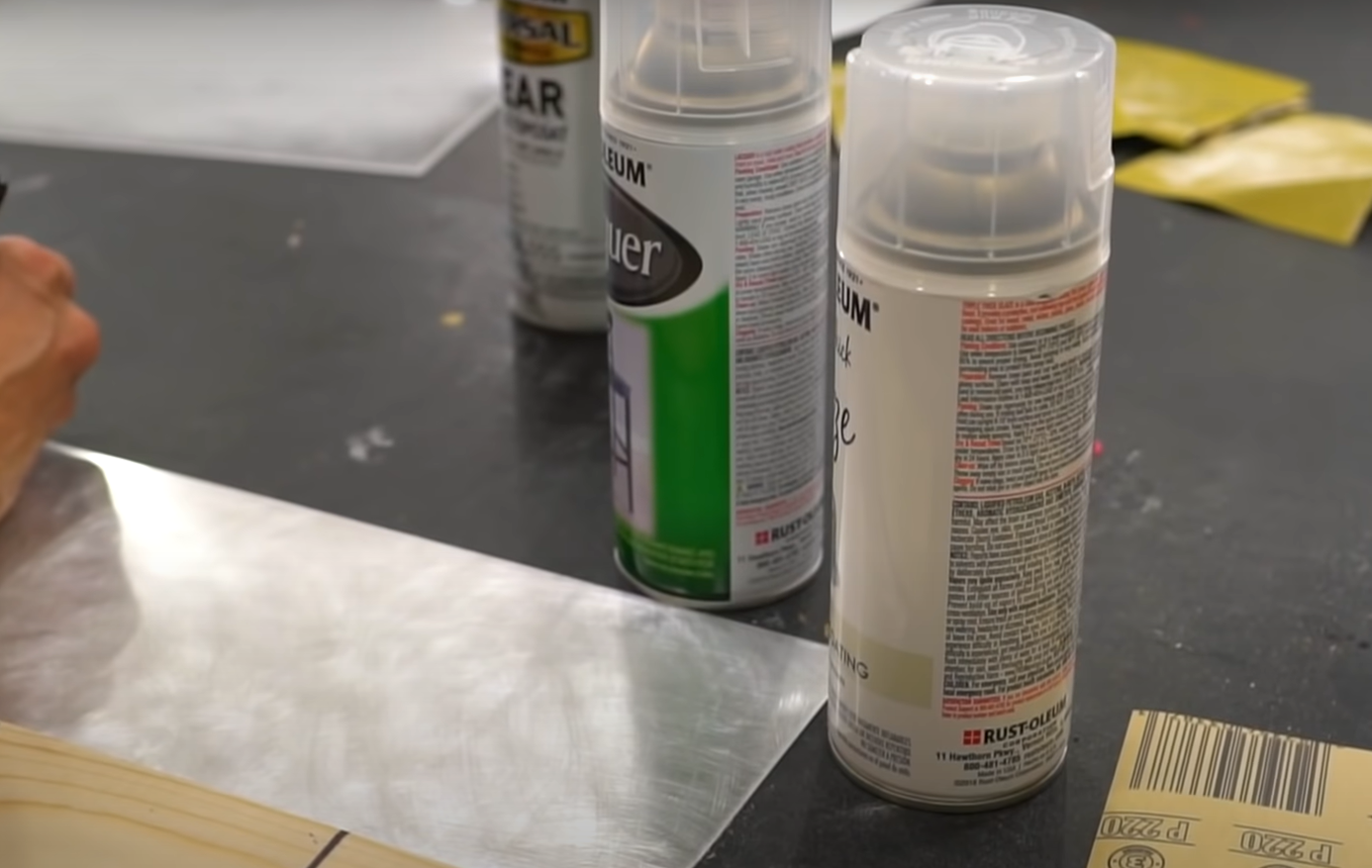

- Aerosol Spray Cans: Aerosol cans offer a convenient and easy-to-use option, especially for smaller touch-up jobs or areas that are difficult to reach with a brush or spray gun. The finish may not be as durable as that achieved with a professional spray gun, and control can be slightly less precise.

Step-by-Step Guide for Applying Food Safe Grill Paint

Following a methodical approach is essential for achieving optimal results. Adhering to recommended procedures, including the correct number of coats and drying times, ensures a durable and safe finish.

- Preparation: Ensure the grill surface is thoroughly cleaned and prepped, as described in the “Preparing the Grill for Painting” section. This includes removing rust, grease, and any loose paint.

- Mixing the Paint: If using paint that requires mixing, follow the manufacturer’s instructions carefully. Ensure the paint is thoroughly mixed to achieve a consistent color and texture.

- First Coat Application: Apply the first coat using your chosen method (brush, spray, or aerosol). Apply a thin, even coat, avoiding drips and runs. The goal is to cover the surface without applying too much paint.

- Drying Time (First Coat): Allow the first coat to dry completely. The drying time will vary depending on the paint type and environmental conditions (temperature, humidity). Refer to the paint manufacturer’s instructions for specific drying times, but generally, this could range from 30 minutes to a few hours.

- Second Coat Application (and Subsequent Coats): Once the first coat is completely dry, apply a second coat. For optimal durability and coverage, two coats are typically recommended, but some paints may require three. Apply each coat in the same manner as the first, focusing on even coverage.

- Drying Time (Between Coats): Allow sufficient drying time between coats, as specified by the paint manufacturer. This allows each layer to cure properly.

- Final Drying and Curing: After the final coat, allow the paint to dry and cure completely before using the grill. Curing times can vary significantly, ranging from a few days to a week or more. This process allows the paint to reach its maximum hardness and resistance to heat.

Visual Guide to Grill Paint Application

This visual guide provides a detailed illustration of the application process, emphasizing technique and common pitfalls to avoid.

Illustration 1: Brush Application Technique

Imagine a close-up of a grill surface being painted with a brush. The brush is loaded with paint, but not excessively, preventing drips. The user is applying the paint in smooth, even strokes, overlapping slightly to ensure complete coverage. The strokes are going in the same direction for a consistent look. The illustration emphasizes avoiding overloading the brush to prevent runs and drips.

The angle of the brush is maintained at a consistent 45-degree angle for optimal paint distribution.

Illustration 2: Spray Application Technique

The illustration shows a spray gun being used to paint a grill. The spray gun is held at a consistent distance from the grill surface (approximately 6-8 inches), and the user is moving the gun in a smooth, sweeping motion, overlapping each pass by about 50%. The illustration emphasizes the importance of maintaining a consistent speed to avoid uneven paint application and runs.

The nozzle is positioned perpendicular to the surface. There is a visual representation of overspray, highlighting the need for masking.

Illustration 3: Common Mistakes to Avoid

This illustration highlights several common mistakes. It depicts a grill with paint runs and drips, indicating the paint was applied too heavily. It also shows areas where the paint is thin or patchy, suggesting insufficient coverage. Another section of the grill is shown with visible brush strokes, demonstrating an issue with brush application technique. The illustration includes a note emphasizing the importance of proper surface preparation before applying paint.

Curing Food Safe Grill Paint

Curing is a crucial step in the application of food-safe grill paint. It’s the process by which the paint fully hardens and achieves its maximum performance characteristics. This process is essential for both food safety and the long-term durability of the painted surface, ensuring the grill can withstand high temperatures and regular use without compromising the paint’s integrity or releasing harmful chemicals.

The Importance of Curing

The curing process is vital for several reasons. It allows the solvents in the paint to evaporate completely, leaving behind a hardened, durable finish. This process is especially critical for food-safe paints because it ensures that any potentially harmful chemicals are locked within the paint matrix and don’t leach into food. Without proper curing, the paint may remain soft, susceptible to chipping, and prone to releasing volatile organic compounds (VOCs) when heated, potentially contaminating food.

Furthermore, curing enhances the paint’s resistance to heat, abrasion, and corrosion, extending the lifespan of the painted grill.

Curing Procedures for Different Paint Types

The specific curing process varies depending on the type of food-safe grill paint used. It’s imperative to always consult the manufacturer’s instructions for precise recommendations, as formulations can differ. However, general guidelines apply to common types of food-safe grill paints.* High-Heat, Air-Dry Paints: These paints typically cure through air exposure at room temperature, followed by a heat-curing cycle.* High-Heat, Oven-Cured Paints: These paints require baking in an oven at specific temperatures for a set duration to achieve full curing.* Ceramic-Based Paints: These paints often require a high-temperature curing process to fully bond with the metal surface and achieve their heat resistance.* Silicone-Based Paints: These paints usually have a curing process involving gradual heating to reach the desired hardness and heat resistance.

Curing Schedule Recommendations

The following table provides general guidelines for curing different types of food-safe grill paint. Always refer to the paint manufacturer’s instructions for the most accurate information. The temperature and time recommendations are approximations and can vary based on the specific paint formulation.

| Paint Type | Preparation | Temperature (°C/°F) | Time |

|---|---|---|---|

| High-Heat, Air-Dry | Allow paint to air dry for 24-72 hours (or as per manufacturer’s instructions). | 200-260°C (400-500°F) | 1-2 hours |

| High-Heat, Oven-Cured | Follow manufacturer’s instructions for drying time. | 175-200°C (350-400°F) | 1 hour |

| Ceramic-Based | Allow paint to dry according to manufacturer’s instructions. | 315-425°C (600-800°F) | 1-2 hours |

| Silicone-Based | Allow paint to dry at room temperature for the recommended time. | 200-260°C (400-500°F) | 1-2 hours, with gradual temperature increase |

Important Considerations:* Ventilation: Ensure adequate ventilation during the curing process, especially when using an oven. This helps to remove any fumes released during heating.

Oven Calibration

Verify the accuracy of your oven’s temperature settings using an oven thermometer.

Gradual Heating (for some paints)

Some paint types require a gradual increase in temperature to prevent blistering or cracking.

Cooling

Discover the crucial elements that make five loaves food shelf the top choice.

Allow the grill to cool completely before use.

Initial Burn-Off

After curing, it’s common to experience some smoke or odor during the first use of the grill. This is normal and is the remaining volatile compounds being released. Ensure good ventilation.

Safety First

Always wear appropriate safety gear, including gloves and eye protection, during the entire process.

Maintenance and Cleaning

Maintaining your food-safe grill paint is crucial for extending its lifespan and ensuring the safety of your food. Regular cleaning and proper care prevent rust, peeling, and other forms of damage, keeping your grill looking and performing its best for years to come. Neglecting maintenance can compromise the paint’s protective qualities and potentially contaminate your food.

Cleaning Products and Methods

Selecting the right cleaning products is essential for preserving the integrity of your food-safe grill paint. Harsh chemicals can damage the paint, leading to corrosion and flaking. The cleaning method you choose also influences the longevity of the painted surface.

- Gentle Soap and Water: The primary cleaning method should involve mild dish soap and warm water. This approach effectively removes grease, food residue, and light debris without damaging the paint. Use a soft sponge or cloth to gently scrub the painted surfaces. Rinse thoroughly with clean water.

- Avoid Abrasive Cleaners: Steer clear of abrasive cleaners, scouring pads, and steel wool. These can scratch the paint surface, creating opportunities for rust and damage. The goal is to clean without removing any of the protective paint layers.

- Non-Abrasive Grill Cleaners: If more cleaning power is needed, opt for non-abrasive grill cleaners specifically designed for painted surfaces. Always read the product label and test the cleaner in an inconspicuous area first to ensure it doesn’t damage the paint. Follow the manufacturer’s instructions carefully.

- Grill Brush Caution: While a grill brush is useful for cleaning grates, use it cautiously on painted surfaces. Avoid using a metal grill brush directly on painted areas, as it can scratch the paint. If you must use a grill brush near painted areas, opt for a brush with soft bristles or a non-metallic material.

Preventing Rust and Damage

Rust and other forms of damage can significantly shorten the lifespan of your grill’s painted surface. Taking proactive steps to prevent these issues is vital for maintaining your grill’s appearance and functionality.

- Regular Cleaning: Consistent cleaning removes food particles and grease that can contribute to rust formation. Cleaning your grill after each use, or at least regularly, is the first line of defense against damage.

- Proper Storage: Store your grill in a covered area or under a grill cover when not in use. This protects it from the elements, especially rain and snow, which can accelerate rust. Consider a garage, shed, or patio cover.

- Inspect Regularly: Periodically inspect the painted surfaces for any signs of damage, such as scratches, chips, or rust spots. Early detection allows for timely repairs, preventing the problem from worsening.

- Touch-Up Paint: If you notice small areas of damage, use food-safe touch-up paint to cover them promptly. This prevents rust from spreading and maintains the paint’s protective barrier. Follow the paint manufacturer’s instructions for application.

- Avoid Extreme Heat Fluctuations: Rapid temperature changes can stress the paint and lead to cracking or peeling. Avoid placing your grill in direct sunlight for extended periods, and allow it to cool gradually after use.

- Seasoning the Grill: After cleaning, consider seasoning the painted surfaces with a thin layer of cooking oil, particularly after significant cleaning or after curing a new paint application. This can provide an extra layer of protection against rust.

Safety Precautions: Food Safe Grill Paint

Working with food safe grill paint, while designed for safety, still requires adherence to specific precautions. This ensures both personal safety and the effectiveness of the paint application. Neglecting these steps can lead to health issues and compromise the grill’s performance.

Ventilation Requirements

Adequate ventilation is crucial when applying food safe grill paint. Proper airflow prevents the buildup of harmful fumes and ensures a safer working environment.

- Outdoor Application: The best practice is to apply the paint outdoors in a well-ventilated area. This allows for natural dispersal of paint fumes.

- Indoor Application Considerations: If painting indoors is unavoidable, use a well-ventilated space such as a garage with the door open or a room with open windows. Position a high-powered fan to direct fumes away from the painting area.

- Air Circulation Importance: Ensure air circulation by creating cross-ventilation. This involves opening windows or doors on opposite sides of the workspace to facilitate airflow.

- Respiratory Protection: Even with ventilation, consider wearing a respirator with an organic vapor cartridge, particularly if working in a confined space or if the paint manufacturer recommends it.

Personal Protective Equipment (PPE)

Employing the correct personal protective equipment (PPE) is paramount when working with any paint, including food safe grill paint. PPE minimizes exposure to potentially harmful substances.

- Eye Protection: Always wear safety glasses or goggles to shield the eyes from paint splatters and fumes.

- Respiratory Protection: A respirator with an organic vapor cartridge is recommended to prevent inhalation of paint fumes. Select a respirator that is NIOSH-approved.

- Skin Protection: Wear gloves, preferably made of nitrile or another solvent-resistant material, to protect the skin from contact with the paint. Also, wear long sleeves and pants to cover as much skin as possible.

- Clothing Recommendations: Use old clothing or a painting suit to protect clothing from paint splatters.

Potential Hazards and Mitigation

Several hazards are associated with applying food safe grill paint. Recognizing these and implementing appropriate mitigation strategies is essential for safety.

- Inhalation of Fumes: Paint fumes can cause respiratory irritation, headaches, and dizziness.

- Mitigation: Work in a well-ventilated area and use a respirator with an organic vapor cartridge.

- Skin Contact: Direct contact with paint can cause skin irritation or allergic reactions.

- Mitigation: Wear gloves, long sleeves, and pants. Wash skin immediately with soap and water if paint contact occurs.

- Eye Contact: Paint splatters can cause eye irritation or, in severe cases, damage.

- Mitigation: Wear safety glasses or goggles. Rinse eyes thoroughly with water if paint contact occurs.

- Fire Hazards: Some paints contain flammable solvents.

- Mitigation: Keep paint away from heat sources, sparks, and open flames. Ensure proper ventilation to prevent the buildup of flammable vapors.

- Improper Disposal: Incorrect disposal of paint and cleaning materials can harm the environment.

- Mitigation: Follow local regulations for paint disposal. Allow unused paint to dry completely or dispose of it at a hazardous waste collection site. Clean brushes and equipment with the appropriate solvent and dispose of the solvent properly.

Visual Representation of Recommended PPE

Imagine a visual representation depicting a person preparing to paint a grill. The person is wearing the following protective equipment:

- Eyes: The person has clear safety goggles covering their eyes, protecting them from splashes and fumes.

- Respiratory System: A respirator with an organic vapor cartridge is securely fitted over the person’s nose and mouth, providing a barrier against inhaling paint fumes.

- Skin: The person wears long-sleeved gloves, made of a material that is resistant to solvents, covering their hands and forearms. The person also wears long pants and an old shirt to protect their clothing and skin from paint contact.

Common Problems and Solutions

Painting your grill with food-safe paint is a rewarding project, but it can come with its share of challenges. Understanding these common issues and knowing how to address them ensures a successful and long-lasting finish. This section provides troubleshooting tips to help you achieve a beautiful and functional grill.

Bubbling or Blistering

Bubbling or blistering occurs when gas or air gets trapped under the paint film, creating raised imperfections. This can ruin the finish and compromise the protective qualities of the paint.

- Cause: This problem often arises from inadequate surface preparation, specifically when the surface isn’t thoroughly cleaned or degreased. Moisture trapped beneath the paint, either from the grill itself or the environment, can also cause bubbling. Applying the paint too thickly or in excessively humid conditions can exacerbate the issue.

- Solution: Ensure the grill surface is meticulously cleaned and degreased before painting. Use a dedicated grill cleaner and follow the manufacturer’s instructions. Allow the grill to dry completely. Apply thin, even coats of paint, allowing sufficient drying time between each coat, typically recommended by the paint manufacturer. Avoid painting in high humidity.

If bubbles appear, let the paint dry completely, then lightly sand the affected area, clean it, and reapply paint in thinner coats.

Peeling or Flaking

Peeling or flaking indicates that the paint isn’t adhering properly to the grill’s surface, resulting in unsightly damage and reduced protection.

- Cause: Poor surface preparation is a primary culprit. This can involve inadequate cleaning, failure to remove rust or loose paint, or not sanding the surface to provide a good “tooth” for the new paint to grip. Using the wrong type of paint for the grill’s material or exposing the grill to extreme temperatures before the paint has fully cured can also contribute.

- Solution: Thoroughly clean and degrease the grill. Remove any existing rust using a wire brush or sandpaper. Lightly sand the surface to create a slightly rough texture. Apply a primer specifically designed for high-heat applications if the paint manufacturer recommends it. Use a high-quality food-safe grill paint.

Allow the paint to cure completely according to the manufacturer’s instructions before exposing the grill to high heat.

Runs or Sagging

Runs or sagging appear when the paint flows unevenly down the surface, creating unsightly drips and uneven coverage.

- Cause: Applying the paint too thickly is the primary reason for runs and sagging. This is often combined with painting on a vertical surface or in an environment that doesn’t allow for proper drying.

- Solution: Apply the paint in thin, even coats. Avoid spraying too close to the surface, and maintain a consistent distance as specified by the paint manufacturer. If runs occur, allow the paint to dry completely, then lightly sand the affected area and reapply a thinner coat.

Color Fading or Discoloration

Color fading or discoloration occurs when the paint’s color degrades over time, making the grill look worn and less appealing.

- Cause: Exposure to high temperatures, direct sunlight, and the elements can cause color fading. Using low-quality paint or failing to cure the paint properly can also contribute to this issue.

- Solution: Use a high-quality food-safe grill paint that is specifically formulated for high-heat applications and UV resistance. Cure the paint completely according to the manufacturer’s instructions. Protect the grill from direct sunlight when not in use, perhaps by covering it with a grill cover. Consider applying a clear topcoat specifically designed for high-heat resistance and UV protection, if recommended by the paint manufacturer.

Poor Adhesion to Previously Painted Surfaces

When repainting a grill, poor adhesion can be a significant problem if the new paint doesn’t properly bond with the existing layer.

- Cause: Inadequate surface preparation is usually the main reason. This might include not properly cleaning and degreasing the old paint, not sanding it to provide a good surface for the new paint to adhere to, or using incompatible paints.

- Solution: Thoroughly clean and degrease the existing paint surface. Sand the existing paint to create a slightly rough surface for better adhesion. Ensure the new paint is compatible with the old paint; if unsure, consult the paint manufacturer. Consider using a primer designed for adhesion over existing coatings.

Frequently Asked Questions (FAQs)

This section provides answers to common questions about food-safe grill paint, offering valuable insights and practical advice.

- Is it really necessary to use food-safe paint? Yes, it is crucial to use food-safe paint. Standard paints may contain chemicals that can leach into food when exposed to high heat, posing health risks. Food-safe paints are specifically formulated to withstand high temperatures and prevent the release of harmful substances.

- How long should I wait before using my grill after painting? Always follow the paint manufacturer’s instructions. Typically, you should allow the paint to cure completely, which can take several days or even weeks. The curing process ensures the paint hardens fully and releases any trapped solvents.

- Can I use regular spray paint on my grill? No, regular spray paint is generally not suitable for grills. It may not withstand high temperatures and can release harmful chemicals. Always use a paint specifically designed for grills and labeled as food-safe.

- What’s the best way to clean my grill after painting? After the paint has fully cured, clean your grill with mild soap and water. Avoid using abrasive cleaners or scrub brushes that could damage the paint. If you need to remove stubborn grease, use a grill-specific cleaner that is safe for painted surfaces.

- How do I prevent rust from forming under the paint? Proper surface preparation is key. Remove all rust before painting. Consider using a rust-inhibiting primer before applying the food-safe paint. Ensure the paint forms a complete seal over the metal to prevent moisture from reaching the surface. Regularly inspect the painted surface for any chips or damage, and touch up any areas where rust might begin to form.

- Can I paint the inside of my grill with food-safe paint? It’s generally recommended to paint only the exterior surfaces of your grill. The intense heat and direct contact with food make it difficult for any paint, even food-safe paint, to last long on the interior surfaces. Consider using high-heat-resistant cooking grates and other interior components.

- What should I do if I accidentally get paint on my food? If you accidentally get paint on your food, discard the food immediately. Even food-safe paint is not meant to be ingested. Thoroughly clean the affected area of the grill before using it again.

- How do I know if my grill paint is truly food-safe? Look for paints specifically labeled as “food-safe” or “high-heat food-safe.” Check the manufacturer’s product information for details on the paint’s composition and safety certifications. Reputable brands will clearly state that their paints are safe for use on surfaces that may come into contact with food.

Alternatives to Food Safe Grill Paint

Beyond the realm of food-safe grill paint, a variety of approaches exist for maintaining and protecting your grill. These alternatives cater to different needs, budgets, and levels of grill restoration. Understanding these options allows you to make an informed decision about the best method for keeping your grilling experience safe and enjoyable.

Grill Grates: Replacement and Maintenance

One of the most common and often overlooked alternatives is focusing on the grill grates themselves. Grill grates are the primary surface that comes into contact with food, making their condition crucial for both safety and cooking performance.

- Replacement: Replacing worn or damaged grates is a straightforward solution. Different grate materials, such as stainless steel, cast iron, and porcelain-coated steel, offer varying levels of durability, heat retention, and ease of cleaning.

- Maintenance: Regular cleaning is essential. Scraping the grates after each use removes food debris, preventing rust and promoting even heat distribution. Seasoning cast iron grates with oil helps to create a non-stick surface and protects against corrosion.

Grill Covers: Protection from the Elements

Grill covers provide a layer of defense against the elements, shielding your grill from rain, snow, sun, and wind. This protection can significantly extend the lifespan of your grill and its components.

- Types of Covers: Grill covers are typically made from durable materials like heavy-duty polyester or vinyl. They come in various sizes and shapes to accommodate different grill models.

- Benefits: A grill cover prevents rust and corrosion caused by moisture, protects against UV damage that can fade paint and degrade components, and keeps the grill cleaner, reducing the need for frequent cleaning.

- Considerations: Ensure the cover is properly sized to fit your grill. Ventilation is crucial to prevent moisture buildup under the cover, which can lead to mold and mildew.

Grill Liners and Mats: Minimizing Contact

Grill liners and mats are designed to create a barrier between the food and the grill surface, offering an additional layer of protection and convenience.

- Types: These are typically made from heat-resistant materials like silicone or Teflon. They can be used on the grill grates or placed on the cooking surface.

- Advantages: Grill liners and mats prevent food from sticking, making cleanup easier. They can also reduce flare-ups by catching drippings.

- Disadvantages: They may not provide the same searing capabilities as direct contact with the grill grates. Some liners may not withstand very high temperatures, so it’s essential to choose a heat-resistant option.

Comparison of Alternatives

Each alternative offers unique advantages and disadvantages. The best choice depends on your specific needs and the condition of your grill.

| Alternative | Pros | Cons |

|---|---|---|

| Food Safe Grill Paint | Restores the grill’s appearance, protects against rust, can be applied to various surfaces. | Requires thorough preparation, proper application and curing, potential for chipping or peeling. |

| Grill Grates (Replacement) | Improves cooking performance, enhances food safety, can be customized to specific needs. | Requires purchasing new grates, may not address other rust or cosmetic issues on the grill body. |

| Grill Covers | Protects against the elements, extends the grill’s lifespan, reduces the need for cleaning. | Requires storage space, may not protect against all types of damage, needs to be properly sized and ventilated. |

| Grill Liners/Mats | Easy cleanup, reduces flare-ups, prevents food from sticking. | May affect searing capabilities, may not withstand very high temperatures, can be difficult to clean. |

Wrap-Up

In the end, this is the conclusion of our exploration into the world of food safe grill paint. It’s a journey through the science of protection, the art of restoration, and the enduring joy of sharing food around a fire. With knowledge, preparation, and a dash of Batak pride, you can transform your grill into a culinary sanctuary. May your grills be hot, your food delicious, and your gatherings filled with laughter and joy.

Horas!