Film packaging for food is a total game-changer, right? It’s like, the unsung hero of the food industry, keeping everything from your morning cereal to your late-night pizza fresh and safe. We’re talking about those flexible, often clear, wraps and pouches that basically act as a shield against the outside world, protecting our grub from spoilage and making sure it gets from the factory to your fridge in tip-top shape.

It’s not just about keeping food edible; it’s also about convenience, shelf life, and even the cool factor of how food is presented on the shelves.

This guide is gonna break down everything you need to know about film packaging. We’ll look at the different types of films, like plastics and their properties, how they’re used in different food sectors (think produce, meat, and baked goods), and even the science behind how they keep things fresh. We’ll also get into the nitty-gritty of printing, labeling, and the super important stuff about sustainability and regulations.

Buckle up, because we’re diving deep into the world of food packaging!

Introduction to Film Packaging for Food

Film packaging plays a critical role in preserving food quality and extending shelf life, minimizing food waste, and ensuring consumer safety. It provides a versatile and cost-effective method for protecting food products from environmental factors, such as oxygen, moisture, and light, while also facilitating transportation and distribution. This review explores the fundamentals of film packaging in the food industry, examining its functions, applications, and advantages.

Primary Function of Film Packaging

The primary function of film packaging in the food industry is to protect food products from spoilage and contamination, maintaining their quality and safety throughout their shelf life. This protection involves several key aspects. It acts as a barrier to external elements, such as oxygen, which can cause oxidation and rancidity in fats and oils; moisture, which can lead to microbial growth and textural changes; and light, which can degrade vitamins and alter color and flavor.

Furthermore, film packaging helps to contain the food product, preventing leaks and spills, and offering a surface for branding, labeling, and consumer information.

Examples of Food Products Packaged Using Film

A wide variety of food products are commonly packaged using film, reflecting its versatility and adaptability to different food types and packaging requirements.

- Fresh Produce: Fruits and vegetables, such as berries, leafy greens, and cucumbers, are often packaged in film to maintain freshness, reduce moisture loss, and protect against physical damage. Modified atmosphere packaging (MAP) films are frequently used to control the levels of oxygen and carbon dioxide, extending shelf life.

- Processed Meats: Sliced meats, sausages, and bacon are commonly packaged in film, providing a barrier against oxygen and moisture to prevent spoilage and maintain color and flavor. Vacuum packaging is often employed to further extend shelf life and enhance product presentation.

- Snack Foods: Chips, crackers, and other snack foods are packaged in film to protect against moisture, oxygen, and physical damage, maintaining their crispness and flavor. The films often incorporate barrier properties to prevent oil migration and maintain product quality.

- Baked Goods: Bread, pastries, and other baked goods are frequently packaged in film to retain moisture, prevent staling, and protect against contamination. Films can also be used to provide a barrier against oxygen and light, extending shelf life and preserving flavor.

- Dairy Products: Cheese, yogurt, and other dairy products are packaged in film for protection against moisture, oxygen, and light, maintaining their quality and safety. Films can also be designed to provide specific barrier properties, depending on the product’s needs.

Benefits of Film Packaging Over Alternative Methods

Film packaging offers several advantages over alternative packaging methods, such as rigid containers. These benefits contribute to its widespread use in the food industry.

- Cost-Effectiveness: Film packaging is often more cost-effective than rigid containers, particularly for large-scale production. The materials used in film packaging are generally less expensive, and the manufacturing processes are often more efficient.

- Weight and Space Efficiency: Film packaging is lightweight and takes up less space than rigid containers, reducing transportation costs and storage requirements. This is particularly important for products that are shipped long distances or require efficient use of shelf space.

- Flexibility and Versatility: Film packaging can be adapted to a wide range of food products and packaging formats, including pouches, bags, and wrappers. It can be customized with different barrier properties, sealing characteristics, and printing options to meet specific product requirements.

- Enhanced Product Presentation: Film packaging can be designed to enhance product presentation, allowing for clear visibility of the product and attractive graphics. This can improve consumer appeal and brand recognition.

- Reduced Environmental Impact: While the environmental impact of film packaging is a complex issue, modern film packaging technologies are increasingly focused on sustainability. This includes the use of thinner films, recycled materials, and biodegradable options, which can help to reduce waste and minimize the environmental footprint. For example, flexible packaging can require less energy and resources to produce compared to rigid containers.

Types of Film Packaging Materials

Film packaging materials are crucial for preserving food quality, extending shelf life, and ensuring consumer safety. The selection of appropriate film depends on the food product, its intended use, and the desired protection level. Various polymers and their combinations offer a wide range of properties tailored to meet diverse packaging needs.

Common Plastic Film Types

A variety of plastic films are used in food packaging, each offering unique characteristics. The most prevalent include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and others, often used in multilayer structures to achieve specific performance criteria.

- Polyethylene (PE): This is one of the most widely used polymers, available in various densities (LDPE, HDPE, LLDPE) offering flexibility, good moisture barrier properties, and cost-effectiveness. Low-density polyethylene (LDPE) is commonly used for flexible films, while high-density polyethylene (HDPE) is often used for rigid containers.

- Polypropylene (PP): PP exhibits good clarity, heat resistance, and barrier properties, making it suitable for hot-fill applications and microwaveable food containers. Oriented polypropylene (OPP) films are particularly valued for their transparency and printability.

- Polyethylene Terephthalate (PET): PET provides excellent clarity, strength, and a good barrier to gases and moisture. It is frequently used for bottles, trays, and films for various food products, including carbonated beverages and ready meals.

- Polyvinyl Chloride (PVC): PVC offers good clarity, flexibility, and resistance to grease and oils. It is often used for cling films and other packaging applications, although its use has decreased due to environmental concerns.

- Polyamide (PA, Nylon): Polyamide films provide excellent strength, puncture resistance, and barrier properties against oxygen, making them suitable for packaging products requiring extended shelf life, such as processed meats and cheeses.

- Ethylene Vinyl Alcohol Copolymer (EVOH): EVOH is an excellent barrier to oxygen and other gases. It is often used in multilayer films to extend the shelf life of oxygen-sensitive foods. However, it is sensitive to moisture, which often necessitates its use in combination with other polymers.

Properties of Film Materials

The properties of film materials determine their suitability for various food packaging applications. These properties include barrier properties, flexibility, sealability, and others, which are crucial for ensuring product protection and consumer satisfaction.

The following table compares and contrasts the properties of different film materials.

| Film Type | Properties | Applications |

|---|---|---|

| Polyethylene (PE) | Good moisture barrier, flexible, heat sealable, cost-effective | Flexible films, bags, wraps for produce, frozen foods |

| Polypropylene (PP) | Good clarity, heat resistance, good moisture barrier | Wraps, films for snacks, hot-fill containers, microwaveable food packaging |

| Polyethylene Terephthalate (PET) | Excellent clarity, good barrier to gases and moisture, strong | Bottles, trays, films for carbonated beverages, ready meals |

| Polyvinyl Chloride (PVC) | Good clarity, flexibility, resistance to grease and oils | Cling films, wraps (though use is declining) |

| Polyamide (PA, Nylon) | Excellent strength, puncture resistance, oxygen barrier | Packaging for processed meats, cheeses, vacuum packaging |

| Ethylene Vinyl Alcohol Copolymer (EVOH) | Excellent oxygen barrier | Multilayer films for extended shelf life of oxygen-sensitive foods |

Role of Additives in Film Packaging

Additives are incorporated into film packaging materials to enhance their properties and improve food preservation. These additives can significantly impact the film’s performance and the food’s shelf life.

- Antioxidants: These additives prevent the oxidation of fats and oils in food, which can lead to rancidity and off-flavors. For example, butylated hydroxytoluene (BHT) and butylated hydroxyanisole (BHA) are commonly used antioxidants in food packaging.

- UV Stabilizers: These additives protect the food from degradation caused by ultraviolet (UV) light exposure. They are particularly important for packaging products that are sensitive to light, such as dairy products and beverages.

- Slip Agents: Slip agents, such as erucamide, reduce the friction between film layers, improving the film’s machinability during packaging processes.

- Antistatic Agents: These additives prevent the build-up of static electricity, which can attract dust and dirt to the packaging.

- Colorants and Pigments: These additives provide color to the packaging, which can enhance the product’s visual appeal and brand recognition.

- Processing Aids: Processing aids improve the film’s manufacturing process, such as by enhancing the flow of the polymer during extrusion.

Additives play a critical role in extending shelf life. For instance, the use of oxygen scavengers in packaging can significantly reduce oxygen levels within the package, thus slowing down the oxidation process and preserving the food’s quality. This is particularly crucial for products such as processed meats and snacks, where oxidation can lead to spoilage and loss of flavor. Moreover, the choice of additives and their concentration is carefully regulated to ensure they are safe for food contact and do not migrate into the food product, adhering to strict guidelines from food safety authorities.

Film Packaging Applications for Food

Film packaging plays a critical role in the food industry, extending shelf life, maintaining food quality, and providing convenience for consumers. The versatility of film packaging allows it to be adapted to a wide variety of food products, offering protection against environmental factors like moisture, oxygen, and light. Its application spans across numerous sectors, each requiring specific film properties to meet the unique needs of the product.

Further details about food color orange is accessible to provide you additional insights.

Film Packaging in Various Food Sectors

Film packaging finds extensive application across diverse food sectors, providing tailored solutions for preservation and presentation. Different food types require specific film properties to ensure optimal protection and extend shelf life.

- Fresh Produce: Film packaging helps to maintain the freshness and extend the shelf life of fruits and vegetables. Modified Atmosphere Packaging (MAP) is commonly used, where the film’s permeability is controlled to regulate oxygen and carbon dioxide levels, slowing down respiration and decay. Examples include:

- Cling film: Used for wrapping fruits and vegetables to prevent moisture loss and maintain freshness.

- Flow wraps: Used for individual packaging of fruits and vegetables like apples or cucumbers.

- Pre-made bags: Often used for packaging leafy greens, allowing for modified atmosphere control to extend shelf life.

- Meat and Poultry: Film packaging provides a barrier against oxygen, preventing spoilage and discoloration. Vacuum packaging and skin packaging are frequently employed to extend shelf life and maintain the appearance of the product. Examples include:

- Vacuum pouches: Used for packaging processed meats, sausages, and steaks to remove oxygen and extend shelf life.

- Shrink films: Used for wrapping poultry and meat products, providing a tight fit and enhancing presentation.

- Modified Atmosphere Packaging (MAP) trays: Used for fresh meat products, controlling gas composition to preserve color and freshness.

- Dairy Products: Film packaging protects dairy products from contamination and maintains their quality. Different film types are chosen based on the product’s specific requirements, such as moisture barrier properties. Examples include:

- Yogurt containers: Often sealed with film lids to maintain product freshness and prevent leakage.

- Cheese packaging: Includes various film types for different cheese varieties, offering varying levels of oxygen and moisture protection.

- Milk and juice cartons: Lined with multi-layer films that provide excellent barrier properties.

- Baked Goods: Film packaging helps to maintain the freshness and prevent the drying out of baked goods. It also provides a barrier against moisture and oxygen. Examples include:

- Bread bags: Typically made from polyethylene or polypropylene films, providing moisture barrier and keeping the bread soft.

- Biscuit and cookie wrappers: Often utilize barrier films to maintain crispness and prevent oxidation.

- Cake packaging: May involve flow wrapping or tray sealing to protect the product and extend shelf life.

- Snack Foods: Film packaging protects snack foods from moisture, oxygen, and light, maintaining their crispness and flavor. Various formats are used, from pouches to flow wraps. Examples include:

- Chip bags: Often made from multi-layer films with excellent barrier properties to protect against moisture and oxygen.

- Candy wrappers: Designed to protect the product and provide attractive presentation.

- Pretzel bags: Utilize films with good barrier properties to maintain freshness.

Different Packaging Formats Using Film

Film packaging is utilized in a variety of formats to meet the specific needs of different food products. Each format offers unique advantages in terms of protection, presentation, and convenience.

- Pouches: Pouches are versatile packaging formats used for a wide range of food products. They can be pre-made or formed on packaging machines. Examples include:

- Stand-up pouches: Offer excellent shelf presence and are commonly used for products like snacks, coffee, and pet food.

- Three-side seal pouches: Simple and cost-effective, often used for single-serve portions and dry goods.

- Spouted pouches: Feature a spout for easy dispensing, ideal for liquids and semi-liquids like sauces and baby food.

- Flow Wraps: Flow wrapping is a horizontal packaging method where a product is wrapped in a film, sealed on the top and bottom, and then sealed at both ends. Examples include:

- Individual snack wrappers: Commonly used for candies, chocolate bars, and cookies.

- Produce packaging: Used for wrapping individual fruits and vegetables, like apples or cucumbers.

- Bakery items: Used for wrapping bread loaves, rolls, and pastries.

- Shrink Wraps: Shrink wrapping involves applying a film around a product or group of products, then shrinking the film using heat to create a tight fit. Examples include:

- Bundling: Used to group multiple items together, such as bottles of water or cans of soda.

- Overwrapping: Used to protect products from tampering and provide a tamper-evident seal.

- Meat and poultry packaging: Used to create a tight, secure package around products.

- Lidding Films: Lidding films are used to seal containers, such as trays and cups, providing a barrier against contamination and extending shelf life. Examples include:

- Yogurt cups: Sealed with aluminum foil or plastic films.

- Ready-meal trays: Sealed with films to maintain freshness and prevent leakage.

- Pre-packaged salad containers: Sealed with films to maintain freshness.

Packaging Process Flow Chart for a Specific Food Product

The packaging process varies depending on the food product and the packaging format used. The following flow chart illustrates the packaging process for pre-packaged sliced ham, which is commonly packaged in modified atmosphere packaging (MAP) to extend its shelf life.

Flow Chart: Packaging Process for Sliced Ham (Modified Atmosphere Packaging)

The flow chart begins with receiving the sliced ham. The product proceeds through the following steps:

| 1. Receiving Sliced Ham | Sliced ham arrives at the packaging facility. |

| 2. Portioning and Weighing | The sliced ham is portioned into desired serving sizes and weighed. |

| 3. Tray Filling | The ham portions are placed into pre-formed trays, typically made of plastic. |

| 4. Gas Flushing | The tray is placed inside a MAP machine. The air inside the tray is evacuated, and a specific gas mixture (typically nitrogen and carbon dioxide) is introduced to extend shelf life and preserve the product’s color and flavor. |

| 5. Tray Sealing | A film lid is sealed onto the tray, creating an airtight seal. The film provides a barrier to oxygen and moisture. |

| 6. Inspection | The sealed packages are inspected for seal integrity and visual defects. |

| 7. Labeling | Labels are applied to the package, including product information, expiration dates, and nutritional information. |

| 8. Packaging and Distribution | The packaged ham is placed into secondary packaging (e.g., cardboard boxes) and distributed to retailers. |

The process highlights the critical steps involved in packaging sliced ham using modified atmosphere packaging, emphasizing the importance of each step in ensuring product quality and extending shelf life. The specific film used in this application is designed to be a barrier to oxygen and moisture, preserving the product’s freshness.

Barrier Properties and Food Preservation

Film packaging plays a crucial role in preserving food quality and extending shelf life by acting as a barrier against external factors that can cause spoilage. These barriers protect food from degradation, maintaining its nutritional value, taste, and appearance. The effectiveness of these barriers is determined by the film’s material composition and thickness.

Oxygen Barrier Properties

Oxygen exposure is a primary cause of food spoilage, leading to oxidation, rancidity, and color changes. Film packaging designed to minimize oxygen transmission rate (OTR) is crucial for preserving the quality of oxygen-sensitive foods.

- Mechanism of Action: Barrier films prevent oxygen from permeating the packaging and reaching the food. This is achieved through the specific molecular structure of the film material. Materials like ethylene vinyl alcohol (EVOH) and certain metallized films are highly effective oxygen barriers.

- Examples of Application:

- Meat and Poultry: Vacuum-packed meats use films with low OTR to prevent oxidation, extending shelf life from days to weeks.

- Coffee and Tea: Packaging often includes multi-layer films with an oxygen barrier to preserve the aroma and flavor of roasted coffee beans and tea leaves.

- Processed Foods: Snacks like potato chips and crackers use films with oxygen barriers to prevent rancidity and maintain crispness.

- Impact on Shelf Life: Effective oxygen barriers can significantly increase the shelf life of perishable products. For example, modified atmosphere packaging (MAP) with oxygen barrier films can extend the shelf life of fresh produce by controlling the respiration rate and minimizing oxidation.

Moisture Barrier Properties

Moisture control is another critical function of film packaging, preventing both moisture gain and loss. This is essential for maintaining the texture, appearance, and overall quality of food products.

- Mechanism of Action: Moisture barrier films prevent water vapor transmission rate (WVTR). Films with low WVTR ratings, such as polyethylene (PE) and polypropylene (PP) films, are commonly used.

- Examples of Application:

- Baked Goods: Films protect baked goods like bread and pastries from drying out and becoming stale.

- Dry Foods: Packaging for cereals, crackers, and snacks prevents moisture absorption, maintaining crispness and preventing spoilage.

- Frozen Foods: Films prevent freezer burn, a condition caused by moisture loss, preserving the quality of frozen products.

- Consequences of Poor Moisture Barrier: Insufficient moisture barriers can lead to significant quality degradation. For example, in a humid environment, dry foods can absorb moisture, leading to clumping, textural changes, and spoilage. Conversely, in dry environments, products can lose moisture, becoming stale or shriveled.

Other Contaminant Barrier Properties

In addition to oxygen and moisture, film packaging also acts as a barrier against other contaminants, such as light, odors, and microorganisms.

- Light Barrier:

- Mechanism of Action: Certain films, especially those containing pigments or metalized layers, block UV and visible light.

- Examples of Application: Dairy products and oils are often packaged in opaque or dark-colored films to prevent light-induced degradation of fats and vitamins.

- Odor Barrier:

- Mechanism of Action: Films can prevent the escape of desirable aromas and the ingress of undesirable odors.

- Examples of Application: Coffee packaging utilizes films with odor barriers to retain the coffee’s aroma and prevent absorption of external odors.

- Microorganism Barrier:

- Mechanism of Action: The film itself, and often the sealing methods used, prevent the entry of microorganisms.

- Examples of Application: Aseptic packaging for milk and juices provides a sterile environment, extending shelf life without refrigeration.

Film Thickness and Barrier Performance

Film thickness is directly related to barrier performance; thicker films generally offer better protection. However, the relationship is not always linear and depends on the specific film material and its properties.

- Relationship:

Thicker films typically exhibit lower permeability rates for oxygen, moisture, and other contaminants.

This is because a thicker material provides a longer path for the permeation of molecules, reducing the rate at which they can pass through the film.

- Considerations:

- Material Properties: The inherent barrier properties of the film material are also crucial. Some materials are naturally better barriers than others, regardless of thickness.

- Cost and Sustainability: Thicker films can increase packaging costs and potentially impact sustainability. Therefore, the optimal film thickness is often a balance between performance, cost, and environmental considerations.

- Application-Specific Requirements: The required barrier performance varies depending on the food product and its shelf-life requirements. Highly perishable foods often require thicker, multi-layer films with superior barrier properties.

- Real-World Examples:

- Snack Food Packaging: Potato chip bags use thin, multi-layer films with metallization for oxygen and moisture barrier, extending shelf life and maintaining crispness.

- Medical Device Packaging: Medical devices often require thick, sterile barrier films to maintain the integrity of the device during storage and transport.

Printing and Labeling on Film Packaging

Printing and labeling are crucial aspects of food packaging, serving not only to convey essential information but also to attract consumers and reinforce brand identity. The printing process allows for the application of graphics, text, and other visual elements onto the film, while labeling provides vital details regarding the product’s contents, nutritional information, and usage instructions. The selection of printing techniques, inks, and coatings must adhere to stringent food safety regulations to prevent contamination and ensure consumer safety.

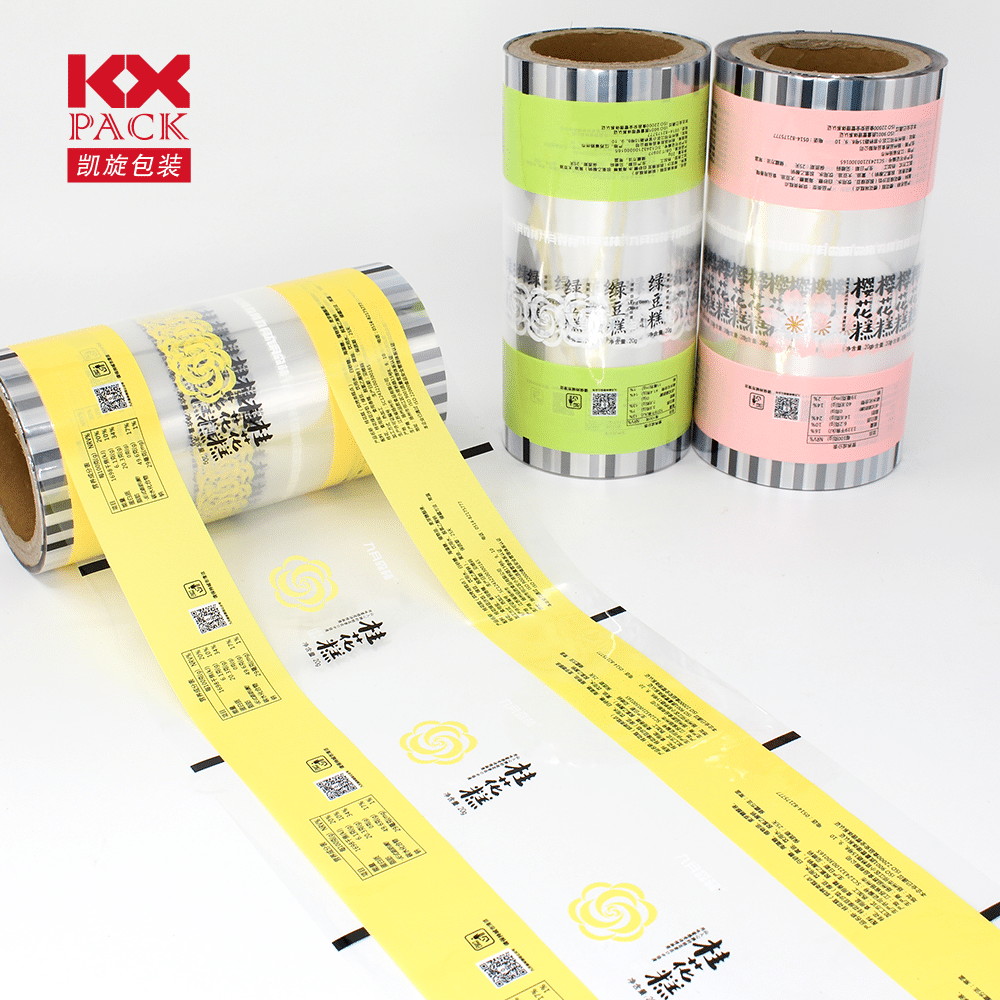

Printing Techniques Used on Food Packaging Film

Several printing techniques are employed to decorate and label food packaging films, each offering different advantages in terms of print quality, speed, and cost-effectiveness. The choice of technique often depends on factors such as the film material, the complexity of the design, and the volume of packaging required.

- Flexography: This is a widely used printing method that utilizes flexible rubber or photopolymer printing plates. It is suitable for a variety of film materials and is known for its versatility and relatively low cost, especially for large print runs. Flexography excels at printing on flexible substrates, making it ideal for packaging films. The process involves transferring ink from the printing plate to the film surface.

Flexography is particularly effective for printing continuous patterns and solid colors.

- Rotogravure: Rotogravure printing employs engraved cylinders to transfer ink onto the film. This technique delivers high-quality prints with excellent detail and color accuracy, making it suitable for complex designs and photographic images. It is often preferred for high-volume production runs due to its speed and efficiency. The cylinders are etched with tiny cells that hold the ink, which is then transferred to the film.

Rotogravure provides a superior finish compared to flexography, but it tends to be more expensive for short runs due to the cost of cylinder preparation.

- Digital Printing: Digital printing, such as inkjet printing, offers a flexible solution for short print runs and customized designs. It eliminates the need for printing plates, allowing for quick turnaround times and variable data printing. This is particularly useful for packaging with personalized messages or regional variations. While the initial cost is lower, the cost per unit can be higher than flexography or rotogravure for large volumes.

- Offset Printing: Although less common for flexible film packaging compared to the aforementioned techniques, offset printing is sometimes used, particularly for paper-based packaging or for applications where high-resolution imagery is crucial. Offset printing is known for its high-quality output and precision. The ink is transferred from a printing plate to a rubber blanket, which then transfers the ink to the film.

Types of Inks and Coatings Used for Food Packaging, Film packaging for food

The selection of inks and coatings for food packaging is critical to ensure the safety of the food product and the integrity of the packaging. Inks and coatings must be food-safe, meaning they do not contain harmful substances that could migrate into the food.

- Ink Types:

- Solvent-based inks: These inks use solvents to dissolve the colorants and other additives. They offer good adhesion and print quality but require careful handling due to the volatile organic compounds (VOCs) they contain. Regulations often limit the use of solvent-based inks.

- Water-based inks: Water-based inks are an environmentally friendly alternative to solvent-based inks. They use water as the primary solvent, reducing VOC emissions. They offer good adhesion and are suitable for a variety of film materials.

- UV-curable inks: UV-curable inks are cured using ultraviolet light, resulting in a fast-drying process and high-quality prints. They are often used for applications requiring excellent scratch resistance and durability.

- EB-curable inks: Electron beam (EB) curable inks are similar to UV-curable inks but use an electron beam to cure the ink. This offers the advantage of deeper curing and can be used for a wider range of substrates.

- Coatings:

- Barrier Coatings: These coatings provide an extra layer of protection against moisture, oxygen, and other gases, extending the shelf life of the food product. Examples include PVdC (polyvinylidene chloride) and silicon oxide (SiOx) coatings.

- Heat Seal Coatings: These coatings are applied to create a seal that prevents leakage and maintains the freshness of the food product. They are usually applied to the inner layer of the packaging film.

- Anti-fog Coatings: These coatings prevent condensation from forming on the packaging surface, maintaining clarity and visibility of the food product.

- Anti-static Coatings: These coatings prevent the buildup of static electricity, which can attract dust and other particles, maintaining the appearance and cleanliness of the packaging.

- Overprint Varnishes (OPVs): OPVs are applied over the printed ink to protect it from abrasion, enhance gloss, and improve the overall appearance of the packaging.

Best Practices for Incorporating Labels and Branding Elements on Film Packaging

Effective labeling and branding on food packaging are essential for communicating product information, attracting consumers, and building brand recognition. Following best practices ensures that the packaging meets regulatory requirements and effectively conveys the intended message.

- Compliance with Regulations: Packaging labels must comply with all relevant food labeling regulations, including those related to ingredient lists, nutritional information, allergen declarations, and net weight. In the United States, the Food and Drug Administration (FDA) sets labeling requirements. In Europe, the European Food Safety Authority (EFSA) sets similar requirements.

- Clear and Legible Information: All information on the label, including text and graphics, should be clear, legible, and easy to understand. Font sizes and styles should be appropriate for the target audience.

- Placement and Layout: The placement of information on the packaging should be logical and organized. Essential information, such as the product name, ingredients, and net weight, should be prominently displayed.

- Branding Elements: Branding elements, such as logos, brand colors, and taglines, should be incorporated to create brand recognition and appeal to consumers. The design should be consistent with the brand’s overall identity.

- Use of Barcodes and QR Codes: Barcodes and QR codes can be included on the packaging to facilitate inventory management, product tracking, and provide consumers with additional information.

- Sustainability Considerations: Packaging should be designed with sustainability in mind, considering the use of eco-friendly materials, reduced ink usage, and the recyclability of the packaging.

- Durability and Protection: Labels should be durable and resistant to moisture, abrasion, and other environmental factors to maintain their legibility and appearance throughout the product’s shelf life.

- Examples of Successful Branding: Consider the packaging of a well-known snack brand. The packaging often features bold colors, a prominent logo, and clear product descriptions. This design helps the product stand out on store shelves and creates brand recognition. Another example is a cereal box, where the nutritional information is clearly displayed.

Sustainability and Environmental Considerations

Film packaging for food, while offering crucial preservation and protection, significantly impacts the environment. Addressing these impacts and exploring sustainable alternatives is critical for a more responsible and circular approach to food packaging. This section will explore the environmental consequences of conventional film packaging, the advancements in sustainable materials, and the current trends shaping the future of food packaging.

Environmental Impact of Film Packaging

The environmental footprint of film packaging is substantial, primarily due to its reliance on fossil fuels and its contribution to waste accumulation. Understanding the specific challenges is crucial for developing effective solutions.

- Waste Generation: A significant issue is the generation of plastic waste. The majority of conventional film packaging is made from non-biodegradable plastics, such as polyethylene (PE) and polypropylene (PP). These materials persist in landfills and the environment for hundreds of years, contributing to pollution of land and oceans.

- Recycling Challenges: Recycling film packaging is often complex and inefficient.

- Material Composition: Many film packaging structures are multi-layered, combining different polymers and other materials (like adhesives and inks). This complexity makes it difficult to separate and recycle the components effectively.

- Contamination: Food residue can contaminate film packaging, further hindering recycling efforts. The presence of food waste can make the recycling process less efficient and lead to lower-quality recycled materials.

- Infrastructure Limitations: Recycling infrastructure for film packaging is often underdeveloped. Many communities lack the necessary facilities to collect, sort, and process film plastics, leading to a large portion of this waste ending up in landfills or incinerators.

- Greenhouse Gas Emissions: The production of plastic films contributes to greenhouse gas emissions at various stages.

- Fossil Fuel Extraction: The extraction of crude oil and natural gas, the primary raw materials for plastics, requires significant energy and releases greenhouse gases.

- Manufacturing Processes: The manufacturing of plastic films is an energy-intensive process, further contributing to greenhouse gas emissions.

- Waste Disposal: Incineration of plastic waste releases greenhouse gases into the atmosphere. Landfills can also contribute to emissions through the decomposition of organic matter.

Sustainable Alternatives to Conventional Plastic Films

The development and adoption of sustainable alternatives are vital for mitigating the environmental impact of film packaging. Several innovative materials offer promising solutions.

- Biodegradable Films: These films are designed to break down naturally in specific environments, such as composting facilities.

- Polylactic Acid (PLA): PLA is derived from renewable resources like corn starch or sugarcane. It is compostable under industrial composting conditions.

- Polyhydroxyalkanoates (PHAs): PHAs are produced by microorganisms and are biodegradable in various environments, including soil and marine environments.

- Cellulose-based Films: Films made from cellulose, a natural polymer found in plants, are biodegradable and can be derived from sustainable sources.

- Compostable Films: Compostable films are a subset of biodegradable films that break down into natural components in a composting environment. They are typically certified to meet specific composting standards.

- Bio-based Films: Bio-based films are made from renewable resources, but they may or may not be biodegradable. These films can reduce the reliance on fossil fuels.

- Bio-PE: Bio-PE is made from sugarcane ethanol and offers a drop-in replacement for conventional PE, utilizing existing recycling infrastructure.

- Bio-PP: Similar to bio-PE, bio-PP is produced from renewable sources and can be used in packaging applications.

- Recycled Content Films: Using recycled materials in film packaging reduces the demand for virgin plastics and promotes a circular economy.

- Post-Consumer Recycled (PCR) Films: These films incorporate plastic materials collected from consumers.

- Post-Industrial Recycled (PIR) Films: PIR films utilize plastic waste generated during manufacturing processes.

Current Trends in Sustainable Food Packaging

The food packaging industry is undergoing significant transformation, driven by consumer demand, regulatory pressures, and technological advancements. Several trends are shaping the future of sustainable food packaging.

- Increased Use of Recycled Content: Companies are actively increasing the proportion of recycled materials in their packaging. This trend is supported by advancements in recycling technologies and growing consumer acceptance.

- Development of Compostable Packaging: The demand for compostable packaging is rising, particularly for products with short shelf lives and those intended for use in compostable waste streams.

- Lightweighting and Design Optimization: Reducing the amount of packaging material used is a key strategy. This involves optimizing package designs to minimize material usage while maintaining functionality and product protection.

- Innovation in Barrier Properties: Research and development are focused on creating sustainable films with improved barrier properties. This is crucial for extending shelf life and reducing food waste. Examples include films with enhanced oxygen and moisture barrier characteristics.

- Collaboration and Partnerships: The transition to sustainable packaging requires collaboration across the entire value chain. This includes partnerships between material suppliers, packaging manufacturers, food producers, retailers, and recycling facilities.

- Regulatory Drivers: Governments worldwide are implementing regulations to promote sustainable packaging. Examples include extended producer responsibility (EPR) schemes and bans on single-use plastics. These regulations incentivize the adoption of sustainable packaging solutions.

Innovations in Film Packaging Technology

Film packaging technology is continuously evolving, driven by the need to enhance food safety, extend shelf life, reduce waste, and improve consumer convenience. Recent innovations leverage advancements in materials science, engineering, and digital technologies to create packaging solutions that are more effective, sustainable, and intelligent. These advancements are transforming the food industry, offering significant benefits across the supply chain, from producers to consumers.

Active Packaging

Active packaging goes beyond simply containing and protecting food; it actively interacts with the food product or its environment to extend shelf life, enhance safety, and improve quality. This is achieved through the incorporation of functional additives or components within the packaging film itself.Examples of active packaging include:

- Oxygen Scavengers: These are incorporated into the film or attached to the packaging to absorb oxygen, which can lead to spoilage, rancidity, and color changes in food products. For example, oxygen scavengers are commonly used in packaging for processed meats, coffee, and ready-to-eat meals to maintain freshness and prevent the growth of aerobic microorganisms.

- Antimicrobial Packaging: This type of packaging releases antimicrobial agents, such as silver nanoparticles or essential oils, to inhibit the growth of spoilage bacteria and pathogens on the food surface. Antimicrobial packaging is used in fresh produce packaging to extend shelf life and reduce the risk of foodborne illnesses.

- Moisture Absorbers: These materials, often silica gel sachets or incorporated into the film, absorb excess moisture to prevent the growth of mold and maintain the texture of food products. They are commonly found in packaging for dried foods, such as crackers and snacks.

- Ethylene Absorbers: Ethylene is a natural ripening agent released by fruits and vegetables. Ethylene absorbers, such as potassium permanganate, can be incorporated into packaging to remove ethylene, slowing down the ripening process and extending the shelf life of produce.

Intelligent Packaging

Intelligent packaging incorporates sensors and indicators to provide information about the condition of the food product and its environment. This technology allows consumers and retailers to make informed decisions about food safety and quality.Examples of intelligent packaging include:

- Time-Temperature Indicators (TTIs): These indicators change color in response to temperature fluctuations over time, providing a visual indication of the cumulative temperature exposure a product has experienced. TTIs are particularly useful for temperature-sensitive products, such as frozen foods and pharmaceuticals, ensuring that they have been stored and transported within the recommended temperature range.

- Freshness Indicators: These indicators, often based on enzymatic or chemical reactions, detect the presence of spoilage compounds or changes in pH, indicating the freshness of the food product. Freshness indicators can be used in packaging for meat, seafood, and dairy products to help consumers assess the product’s quality.

- Gas Sensors: These sensors detect changes in the gas composition inside the packaging, such as the increase in carbon dioxide or the decrease in oxygen, which can indicate spoilage. Gas sensors can be integrated into packaging for modified atmosphere packaging (MAP) applications to monitor the effectiveness of the gas flush and ensure product quality.

- RFID (Radio-Frequency Identification) Tags: These tags can be used to track products throughout the supply chain, providing real-time information on location, temperature, and other relevant data. RFID tags improve inventory management, reduce waste, and enhance traceability, particularly for perishable goods.

Benefits of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves modifying the composition of the gas within a package to extend the shelf life and maintain the quality of food products. This is achieved by flushing the package with a specific gas mixture, typically containing carbon dioxide, nitrogen, and oxygen, or a combination thereof, depending on the food product.MAP offers several advantages:

- Extended Shelf Life: By controlling the levels of oxygen and carbon dioxide, MAP can slow down the growth of spoilage microorganisms and enzymatic reactions, extending the shelf life of perishable foods. This reduces food waste and increases the time available for distribution and consumption.

- Preservation of Freshness and Quality: MAP helps maintain the color, flavor, texture, and nutritional value of food products. For example, the use of high carbon dioxide levels can inhibit the growth of bacteria and mold, while low oxygen levels can prevent oxidation and maintain the color of fresh-cut produce.

- Reduced Need for Preservatives: MAP can reduce or eliminate the need for chemical preservatives, providing consumers with fresher, more natural-tasting products. This is particularly important for health-conscious consumers who are looking for minimally processed foods.

- Improved Product Presentation: MAP can help maintain the visual appeal of food products, such as fresh produce, by preventing browning and wilting. This improves product presentation on store shelves and enhances consumer appeal.

A presentation detailing the benefits of MAP could include the following key elements:

- Introduction: Define MAP and its importance in food packaging. Explain the principles of MAP and how it works.

- Applications: Showcase examples of food products that benefit from MAP, such as fresh produce, meat, seafood, bakery products, and ready-to-eat meals. Include images or videos to illustrate the packaging of these products.

- Benefits: Detail the key benefits of MAP, including extended shelf life, preservation of freshness and quality, reduced need for preservatives, and improved product presentation. Provide data and statistics to support these claims. For example, cite studies showing the increased shelf life of packaged fresh-cut salads using MAP compared to traditional packaging methods.

- Gas Mixtures: Explain the different gas mixtures used in MAP and their specific effects on food products. Describe the role of carbon dioxide, nitrogen, and oxygen, and provide examples of their applications.

- Packaging Materials: Discuss the types of packaging materials used in MAP, such as films with barrier properties, and their role in maintaining the modified atmosphere.

- Equipment and Technology: Describe the equipment and technology used for MAP, including gas flushing machines, sealing equipment, and quality control systems.

- Case Studies: Present real-world examples of how MAP has been successfully implemented in the food industry, highlighting the positive impacts on product quality, shelf life, and profitability.

- Sustainability Considerations: Discuss the environmental benefits of MAP, such as reduced food waste and the potential for using recyclable packaging materials.

- Future Trends: Briefly touch upon emerging trends in MAP, such as the integration of active and intelligent packaging technologies.

The presentation should incorporate visuals such as graphs, charts, and images to enhance understanding and engagement. Data from reputable sources, such as food science journals and industry reports, should be used to support the claims and demonstrate the effectiveness of MAP. The presentation could also include a demonstration of the MAP process or a case study of a successful MAP implementation.

Testing and Quality Control of Film Packaging

Ensuring the quality and performance of film packaging is critical for protecting food products, maintaining shelf life, and complying with regulations. Rigorous testing and quality control procedures are essential throughout the manufacturing process to identify and rectify any defects, ensuring the packaging meets the required standards. This section details the tests performed, measurement methods, and a practical quality control checklist.

Testing Methods for Film Packaging

Various tests are conducted on film packaging to evaluate its suitability for food applications. These tests assess different aspects of the film’s properties, including its physical characteristics, barrier performance, and seal integrity. These evaluations help determine if the film is appropriate for its intended purpose.

- Tensile Strength and Elongation: These tests measure the film’s resistance to breaking under tension and its ability to stretch before breaking. Tensile strength is expressed in units such as megapascals (MPa) or pounds per square inch (psi). Elongation is expressed as a percentage. These properties are important for ensuring the film can withstand handling, transportation, and filling processes without tearing or puncturing.

- Impact Resistance: This test evaluates the film’s ability to withstand sudden impacts, such as drops or shocks. It is particularly important for packaging that needs to protect the food product from damage during shipping and handling. The test involves dropping a dart onto the film from a specified height and measuring the energy required to cause failure.

- Puncture Resistance: This test assesses the film’s resistance to penetration by sharp objects. It is critical for preventing leaks and maintaining the integrity of the food product. Puncture resistance is often measured using a probe with a standardized tip that is pushed through the film.

- Seal Strength: Seal strength tests determine the force required to separate the sealed edges of the film. This is crucial for ensuring the package remains sealed and prevents leakage or contamination. Seal strength is typically measured in Newtons per meter (N/m) or pounds per inch (lb/in).

- Barrier Properties: These tests measure the film’s ability to prevent the passage of gases, water vapor, and other substances. These properties are essential for maintaining the freshness, flavor, and safety of the food product. Barrier properties are usually expressed as the rate of transmission through the film over a specified period.

- Optical Properties: These tests evaluate the film’s transparency, haze, and gloss. These properties affect the appearance of the packaged food and its visibility to consumers.

Methods for Measuring Film Properties

Precise methods are used to measure the film’s thickness, seal strength, and barrier properties, ensuring accurate and reliable results. Standardized testing procedures are employed to maintain consistency and comparability across different batches and manufacturers.

- Film Thickness Measurement: Film thickness is a critical parameter affecting the film’s barrier properties and mechanical strength.

- Micrometer: A micrometer is a precision instrument used to measure the thickness of the film at multiple points. Measurements are taken across the film’s surface to determine the average thickness and identify any variations.

- Beta Gauge: This non-contact method uses beta particles to measure the film’s thickness. The amount of radiation that passes through the film is detected, and this measurement is correlated to the film’s thickness.

- Ultrasonic Thickness Gauges: These gauges use sound waves to measure film thickness, especially useful for multilayer films where different layers need to be measured separately.

- Seal Strength Measurement: Seal strength is measured using specialized testing equipment.

- Tensile Testing Machines: These machines apply a controlled force to the sealed edges of the film and measure the force required to break the seal. The results are typically expressed in Newtons per meter (N/m) or pounds per inch (lb/in).

- Peel Tests: Peel tests involve separating the sealed edges of the film at a specific angle, usually 180 degrees or 90 degrees, and measuring the force required.

- Barrier Properties Measurement: Barrier properties are measured using specialized testing equipment that measures the rate at which gases and water vapor pass through the film.

- Oxygen Transmission Rate (OTR): This test measures the rate at which oxygen passes through the film. It is critical for packaging oxygen-sensitive foods. The film is placed in a chamber, and oxygen is introduced on one side. Sensors measure the amount of oxygen that passes through the film over a specified time.

Results are usually expressed as cm 3/m 2/day.

- Water Vapor Transmission Rate (WVTR): This test measures the rate at which water vapor passes through the film. It is important for maintaining the moisture content of the food product. The film is placed in a chamber with a controlled humidity gradient, and the amount of water vapor that passes through the film is measured over time. Results are usually expressed as g/m 2/day.

- Carbon Dioxide Transmission Rate (CO2TR): This test measures the rate at which carbon dioxide passes through the film. It is essential for packaging carbonated beverages and products that generate CO2.

- Oxygen Transmission Rate (OTR): This test measures the rate at which oxygen passes through the film. It is critical for packaging oxygen-sensitive foods. The film is placed in a chamber, and oxygen is introduced on one side. Sensors measure the amount of oxygen that passes through the film over a specified time.

Quality Control Checklist for Film Packaging

A comprehensive quality control checklist is essential for ensuring consistent product quality and identifying potential issues early in the manufacturing process. The checklist should cover all critical aspects of film packaging production, from raw materials to finished products.

| Inspection Point | Description | Acceptance Criteria | Frequency |

|---|---|---|---|

| Raw Material Inspection | Incoming inspection of film rolls and other materials (inks, adhesives, etc.). | Verification of material specifications, dimensions, and visual defects. Compliance with supplier certifications. | Batch-wise or as per supplier’s certificate of analysis. |

| Film Thickness | Measurement of film thickness at various points on the roll. | Thickness within specified tolerances. | At the beginning of each production run, and periodically throughout. |

| Printing Quality | Inspection of print registration, color accuracy, and print defects. | Prints meet specified color standards (e.g., Pantone), no misprints, proper registration. | During the print run. |

| Seal Integrity | Seal strength tests, visual inspection of seals, and leak tests. | Seal strength meets specified requirements, no leaks, and no defects. | During and after the sealing process. |

| Barrier Properties | Testing of oxygen transmission rate (OTR) and water vapor transmission rate (WVTR). | OTR and WVTR within specified limits. | Periodic testing on finished packages or film samples. |

| Dimensional Accuracy | Verification of package dimensions (length, width, height). | Dimensions within specified tolerances. | During the packaging process. |

| Visual Inspection | Inspection of finished packages for defects (tears, wrinkles, contamination). | No visible defects, clean appearance. | Throughout the packaging process and final inspection. |

| Labeling | Verification of label accuracy and legibility. | Labels are accurate, legible, and properly applied. | During the packaging process and final inspection. |

| Packaging Performance | Drop tests, vibration tests, and other simulated handling tests. | Packages withstand handling and transportation without damage. | Periodically, especially for new packaging designs. |

| Documentation | Maintaining records of all inspections, tests, and corrective actions. | Complete and accurate records. | Ongoing. |

Future Trends in Food Film Packaging

The food packaging industry is in constant evolution, driven by consumer demands, technological advancements, and environmental concerns. Future trends in food film packaging are poised to reshape the industry, offering enhanced functionalities, improved sustainability, and increased convenience for consumers. These innovations aim to extend shelf life, minimize food waste, and reduce the environmental impact of packaging materials.

Nanotechnology in Food Film Packaging

Nanotechnology is being integrated into food film packaging to enhance various properties. This involves manipulating materials at the nanoscale (1-100 nanometers) to create films with superior performance.

- Improved Barrier Properties: Nanoparticles, such as nanoclay or titanium dioxide, are incorporated into film matrices to create tighter structures, significantly reducing the permeability of gases like oxygen and carbon dioxide. This helps to preserve food quality and extend shelf life by preventing spoilage. For example, films containing nanoclay have shown a significant reduction in oxygen transmission rates, crucial for preserving the freshness of meat and dairy products.

- Enhanced Mechanical Strength: Nanomaterials can increase the tensile strength and flexibility of films, making them more resistant to tearing and puncturing. This enhances the protection of food products during transportation and handling.

- Active Packaging: Nanotechnology enables the development of active packaging that interacts with the food to maintain or improve its condition. This includes films that release antimicrobial agents to inhibit microbial growth or absorb oxygen to prevent oxidation. For example, films containing silver nanoparticles can release antimicrobial agents to extend the shelf life of fresh produce.

- Smart Packaging: Nanotechnology facilitates the creation of smart packaging that can sense and report changes in food quality. This includes sensors that detect spoilage or changes in temperature, providing consumers with real-time information about the product’s condition. Color-changing labels that indicate the freshness of the food are examples of this technology.

Edible Films and Coatings in Food Packaging

Edible films and coatings represent a sustainable approach to food packaging, offering an alternative to traditional plastic films. These films are made from food-grade materials and are designed to be consumed along with the food product.

- Materials Used: Edible films are typically made from polysaccharides (starch, cellulose, chitosan), proteins (whey protein, gelatin, soy protein), lipids (beeswax, carnauba wax), and combinations of these. The choice of material depends on the desired properties, such as barrier function, mechanical strength, and sensory characteristics.

- Applications: Edible films and coatings can be applied to a wide range of food products. They can be used to coat fruits and vegetables to reduce moisture loss and extend shelf life. They can also be used as a primary packaging material for products like candies and snacks. For example, a coating of chitosan can extend the shelf life of strawberries by inhibiting mold growth.

- Benefits: Edible films offer several advantages, including biodegradability, reduced waste, and the potential to incorporate functional ingredients. They can act as a barrier to moisture, oxygen, and other gases, protecting the food from spoilage.

- Challenges: The development of edible films faces challenges, including maintaining mechanical integrity, controlling moisture permeability, and ensuring consumer acceptance. Cost and scalability are also important considerations.

The Role of Consumer Preferences in Shaping Future Packaging Designs

Consumer preferences play a crucial role in shaping the future of food film packaging. The industry must adapt to meet the evolving demands of consumers, focusing on convenience, sustainability, and safety.

- Convenience: Consumers increasingly seek convenient packaging options, such as resealable pouches, easy-open features, and single-serve portions. Packaging designs must prioritize ease of use and portability.

- Sustainability: Growing environmental awareness is driving demand for sustainable packaging solutions. Consumers prefer packaging made from recycled materials, biodegradable materials, or packaging that minimizes waste. This includes the use of bio-based films and reduced packaging materials.

- Food Safety and Transparency: Consumers are concerned about food safety and want to know the origin and ingredients of the food they consume. Packaging designs must provide clear and accurate information about the product, including nutritional information, ingredient lists, and expiration dates. Smart packaging can also enhance transparency by providing real-time information about the product’s condition.

- Aesthetics and Branding: Packaging design plays a critical role in attracting consumers and building brand loyalty. Attractive designs, clear labeling, and effective branding are essential for success in the competitive food market. Packaging must communicate the brand’s values and resonate with the target audience.

Final Conclusion

So, there you have it: the lowdown on film packaging for food. From the essential barrier properties to the innovative technologies shaping the future, it’s clear that this field is constantly evolving. As we move forward, sustainability and consumer preferences will continue to drive innovation, meaning even cooler and more eco-friendly packaging solutions are on the horizon. It’s a fascinating area where science, design, and environmental responsibility all come together to keep our food safe, delicious, and ready to enjoy.

Pretty neat, huh?