Food Handlers Assessment 7 delves into the critical world of food safety, a topic often overlooked yet profoundly impactful. Think of it as a journey into the unseen, where potential hazards lurk, and vigilance is the key to safeguarding public health. We’ll explore the core principles that transform food handlers into guardians of safety, ensuring that every meal is a source of nourishment, not a threat.

The assessments aren’t just tests; they’re a commitment to a culture of care, where knowledge and responsibility converge.

We’ll journey through essential topics, from the basics of personal hygiene to the complexities of allergen awareness and the legal requirements that govern food handling. Consider each section as a chapter in a vital story, where understanding is paramount. You’ll learn how to navigate the often-unseen dangers, like cross-contamination, and master techniques like proper handwashing, creating a safe and thriving environment.

Overview of Food Handler Assessments (Food Handlers Assessment 7)

Food handler assessments are crucial components of a robust food safety system, designed to protect public health by ensuring that individuals involved in food preparation and service possess the necessary knowledge and skills to handle food safely. These assessments, such as Food Handlers Assessment 7, serve as a critical check on food safety practices, helping to minimize the risk of foodborne illnesses.

Purpose of a Food Handler Assessment

The primary purpose of a food handler assessment is to evaluate an individual’s understanding of food safety principles and their ability to apply these principles in a practical setting. This assessment verifies that food handlers are aware of potential hazards and are equipped to prevent contamination.

- Identifying Knowledge Gaps: Assessments pinpoint areas where food handlers may lack understanding, allowing for targeted training and education. For example, if a food handler incorrectly answers questions about cross-contamination, further training can be provided on proper handwashing and the use of separate cutting boards for raw and cooked foods.

- Promoting Safe Food Handling Practices: Assessments reinforce the importance of adhering to safe food handling procedures, such as proper cooking temperatures and safe food storage.

- Ensuring Compliance with Regulations: Food handler assessments help food establishments comply with local, state, and federal food safety regulations. These regulations often mandate that food handlers receive training and demonstrate competency in food safety practices.

- Reducing the Risk of Foodborne Illness: By ensuring that food handlers understand and follow safe food handling practices, assessments contribute to a significant reduction in the risk of foodborne illnesses. This is crucial because foodborne illnesses can lead to serious health consequences, including hospitalization and even death.

Brief History of Food Safety Regulations and Assessments

The evolution of food safety regulations reflects a growing understanding of the causes of foodborne illnesses and the importance of preventative measures. Early food safety regulations focused primarily on sanitation and the adulteration of food products.

- Early Regulations: In the late 19th and early 20th centuries, concerns about food safety led to the passage of early food safety laws, such as the Pure Food and Drug Act of 1906 in the United States. These laws aimed to prevent the sale of adulterated or misbranded food products.

- The Rise of Modern Food Safety: The mid-20th century saw the development of more sophisticated food safety practices, including Hazard Analysis and Critical Control Points (HACCP). HACCP is a systematic approach to identifying and controlling food safety hazards.

- HACCP and Risk-Based Approaches: HACCP principles shifted the focus from end-product testing to proactive hazard identification and control throughout the food production process. This approach emphasized the importance of training and assessments to ensure that food handlers understood and implemented these controls.

- Current Regulations: Today, food safety regulations are comprehensive and often require food handlers to undergo training and pass assessments to demonstrate their knowledge of food safety practices. These assessments are an integral part of ensuring compliance with these regulations.

Importance of Regular Assessment Updates for Food Handlers

Regular updates and assessments are essential to maintain a high level of food safety knowledge and to adapt to evolving food safety standards and practices.

- Staying Current with Best Practices: Food safety best practices are constantly evolving based on scientific research and real-world experience. Regular assessments ensure that food handlers stay informed about the latest recommendations and guidelines.

- Addressing Emerging Food Safety Issues: New food safety hazards and risks can emerge, such as new pathogens or changes in food production methods. Updated assessments help food handlers understand and address these emerging issues.

- Reinforcing Knowledge and Skills: Regular assessments help to reinforce food safety knowledge and skills, preventing the degradation of knowledge over time. Frequent testing can improve retention of key information.

- Adaptation to Changes in Regulations: Food safety regulations are subject to change. Periodic assessments ensure that food handlers are aware of any updates to the regulations and how they impact their work.

- Examples of Real-World Cases: Consider a scenario where a new strain of

-E. coli* is identified as a significant threat in a specific food product. Regular assessments can quickly inform food handlers about the new hazard, its symptoms, and the preventive measures they need to take to protect consumers. This might include changes in cooking temperatures, cleaning protocols, or supplier selection.

Assessment Content

A food handler assessment is a critical tool for ensuring the safety of the food supply. These assessments evaluate a food handler’s understanding of key principles and practices designed to prevent foodborne illnesses. Successful completion of the assessment indicates a basic level of competency in food safety, enabling individuals to handle food responsibly and protect public health.

Essential Topics Covered in Food Handler Assessments

Food handler assessments typically cover a range of topics, all crucial for maintaining food safety. These topics provide a comprehensive understanding of how to prevent contamination and ensure food is safe for consumption.

- Foodborne Illnesses: Identifying common foodborne illnesses, their symptoms, and the microorganisms that cause them. This includes understanding the difference between bacterial, viral, and parasitic infections.

- Personal Hygiene: Emphasizing the importance of personal cleanliness, including proper handwashing, hair restraints, and appropriate attire to prevent contamination.

- Cross-Contamination Prevention: Understanding and implementing practices to prevent the transfer of harmful microorganisms from one food or surface to another. This includes using separate cutting boards and utensils for raw and cooked foods.

- Proper Food Handling Procedures: Learning about safe food handling practices, including cooking temperatures, cooling procedures, and storage guidelines.

- Cleaning and Sanitizing: Knowing the difference between cleaning and sanitizing, and understanding how to effectively clean and sanitize food contact surfaces and equipment.

- Pest Control: Recognizing signs of pests and implementing measures to prevent and control infestations in food service establishments.

- Food Allergies and Sensitivities: Understanding common food allergens, how to prevent cross-contact, and how to respond to customer inquiries about ingredients.

The Importance of Personal Hygiene in Food Handling

Personal hygiene is a cornerstone of food safety. Food handlers must maintain high standards of cleanliness to prevent the transfer of harmful microorganisms to food. Failure to do so can lead to foodborne illnesses and outbreaks.

Examples of the impact of poor personal hygiene include:

- Norovirus Outbreaks: Norovirus is highly contagious and can easily spread through contaminated food. A food handler infected with norovirus who doesn’t wash their hands properly after using the restroom can contaminate food, leading to widespread outbreaks. According to the CDC, Norovirus is the most common cause of foodborne illness in the United States.

- Staphylococcus Aureus Contamination: Staphylococcus aureus, often found on the skin and in the nose, can produce toxins that cause food poisoning. A food handler with a cut or sore on their hand who does not use a bandage and wash their hands can contaminate food, leading to illness.

- Salmonella Infections: Salmonella can be transmitted through contaminated food. A food handler who does not wash their hands after touching raw poultry or eggs can contaminate other foods, causing salmonellosis.

Proper Handwashing Techniques and Their Significance

Proper handwashing is the single most important step in preventing the spread of foodborne illnesses. Effective handwashing removes harmful microorganisms from hands, preventing them from contaminating food and food contact surfaces.

The steps for proper handwashing are as follows:

- Wet hands with warm, running water.

- Apply soap and lather thoroughly, including the backs of hands, between fingers, and under fingernails.

- Scrub hands for at least 20 seconds. A helpful guide is to sing the “Happy Birthday” song twice.

- Rinse hands thoroughly under warm, running water.

- Dry hands with a single-use paper towel or a hand dryer.

The significance of each step is as follows:

- Warm Water: Warm water helps to loosen dirt and microorganisms from the skin.

- Soap: Soap helps to break down grease and remove microorganisms.

- Lathering and Scrubbing: Lathering and scrubbing for at least 20 seconds ensures that all areas of the hands are cleaned effectively.

- Rinsing: Rinsing removes soap and any loosened microorganisms.

- Drying: Drying hands prevents the re-contamination of hands from surfaces.

Common Foodborne Illnesses and Their Causes

Foodborne illnesses, also known as food poisoning, are caused by consuming food contaminated with harmful microorganisms or toxins. Understanding the causes of these illnesses is crucial for preventing them.

Common foodborne illnesses and their causes include:

- Salmonellosis: Caused by bacteria of the Salmonella genus. Often associated with poultry, eggs, and contaminated produce. Symptoms include diarrhea, fever, and abdominal cramps.

- Norovirus Infection: Caused by the norovirus. Highly contagious and often spread through contaminated food or surfaces. Symptoms include vomiting, diarrhea, nausea, and stomach cramps.

- Campylobacteriosis: Caused by Campylobacter bacteria. Often associated with raw or undercooked poultry, unpasteurized milk, and contaminated water. Symptoms include diarrhea, fever, and abdominal cramps.

- E. coli Infection: Caused by Escherichia coli bacteria, particularly the Shiga toxin-producing E. coli (STEC). Often associated with undercooked ground beef, contaminated produce, and unpasteurized juice. Symptoms include bloody diarrhea, abdominal cramps, and in severe cases, kidney failure.

- Listeriosis: Caused by Listeria monocytogenes bacteria. Often associated with ready-to-eat foods such as deli meats, soft cheeses, and smoked seafood. Symptoms include fever, muscle aches, and gastrointestinal symptoms.

- Hepatitis A: Caused by the hepatitis A virus. Often spread through contaminated food or water. Symptoms include fatigue, jaundice, abdominal pain, and nausea.

Assessment Content: Cross-Contamination and Food Safety

Food safety is paramount in the food service industry, directly impacting public health. This section delves into the critical aspects of cross-contamination and its prevention, emphasizing the importance of proper food handling practices. Understanding and implementing these measures are essential for protecting consumers from foodborne illnesses.

Browse the multiple elements of super glue safe for food to gain a more broad understanding.

Dangers of Cross-Contamination in a Food Preparation Environment

Cross-contamination, the transfer of harmful bacteria or other microorganisms from one surface or food to another, poses a significant threat in food preparation environments. This transfer can occur directly, such as when raw chicken juices drip onto ready-to-eat vegetables, or indirectly, through contaminated equipment, utensils, or even the hands of food handlers. The consequences of cross-contamination can range from mild discomfort to severe illness, even death.

For instance,

- Salmonella* and

- E. coli* are common culprits, often found in raw meats and poultry. If these pathogens contaminate other foods, they can rapidly multiply, especially at room temperature, leading to outbreaks of foodborne illness. According to the Centers for Disease Control and Prevention (CDC), foodborne illnesses sicken an estimated 48 million people in the United States each year, resulting in thousands of hospitalizations and deaths.

These statistics underscore the urgency of implementing effective cross-contamination control measures.

Methods to Prevent Cross-Contamination, Food handlers assessment 7

Preventing cross-contamination requires a multifaceted approach, encompassing various practices within the food preparation environment. These practices, when consistently applied, significantly reduce the risk of spreading harmful microorganisms.

- Separate Raw and Ready-to-Eat Foods: Store raw meats, poultry, and seafood separately from ready-to-eat foods in the refrigerator. If storage space is limited, store raw foods below ready-to-eat foods to prevent drippage. Use separate cutting boards, utensils, and equipment for raw and cooked foods.

- Practice Proper Handwashing: Wash hands thoroughly with soap and warm water for at least 20 seconds before and after handling food, especially after touching raw meat, poultry, or seafood, and after using the restroom. Handwashing is one of the most effective methods for preventing the spread of pathogens.

- Clean and Sanitize Surfaces and Equipment: Regularly clean and sanitize all food contact surfaces, including cutting boards, countertops, and equipment, using an approved sanitizer. Follow the manufacturer’s instructions for sanitizing solutions.

- Use Separate Utensils: Use separate utensils for raw and cooked foods. Avoid using the same utensils for different tasks without proper cleaning and sanitizing in between.

- Control Pests: Implement pest control measures to prevent pests, such as rodents and insects, from contaminating food. These pests can carry and spread harmful bacteria.

- Train Food Handlers: Provide regular training to food handlers on proper food safety practices, including cross-contamination prevention. This training should cover all aspects of food handling, from receiving and storage to preparation and service.

Importance of Proper Food Storage, Including Temperature Control

Proper food storage is a critical component of food safety, as it helps to control the growth of bacteria and prevent cross-contamination. Maintaining the correct temperatures is particularly important. Bacteria thrive in the “danger zone,” which is between 40°F (4°C) and 140°F (60°C).

The USDA Food Safety and Inspection Service provides specific guidelines for safe food storage. For instance:

- Refrigeration: Refrigerate perishable foods promptly, ideally within two hours of purchase or preparation. Refrigerators should be maintained at 40°F (4°C) or below. This slows the growth of bacteria.

- Freezing: Freeze food at 0°F (-18°C) or below. Freezing does not kill bacteria but prevents them from multiplying.

- Temperature Control: Use a food thermometer to verify the temperature of food during storage, cooking, and holding.

- FIFO (First-In, First-Out): Rotate food stocks using the FIFO method to ensure that older products are used before newer ones.

- Proper Packaging: Store food in airtight containers or packaging to prevent contamination and maintain quality.

Step-by-Step Procedure for Thawing Frozen Food Safely

Thawing frozen food safely is crucial to prevent bacterial growth. Improper thawing can allow bacteria to multiply to dangerous levels, increasing the risk of foodborne illness. The following methods are considered safe:

- In the Refrigerator: This is the safest method. Place the frozen food in the refrigerator, allowing ample time for thawing. Smaller items may thaw overnight, while larger items may take several days. Once thawed, food can remain in the refrigerator for an additional 1-2 days before cooking.

- In Cold Water: Place the frozen food in a leak-proof bag and submerge it in cold water. Change the water every 30 minutes to ensure it remains cold. Cook the food immediately after thawing.

- In the Microwave: Use the defrost setting on the microwave. Cook the food immediately after thawing. Microwaving can sometimes begin cooking the food, so it’s important to cook it right away.

- As Part of the Cooking Process: Some foods, like certain vegetables, can be cooked directly from the frozen state. Follow the recipe instructions carefully.

Avoid thawing food at room temperature (on the counter), as this allows bacteria to multiply rapidly in the “danger zone.”

Assessment Content: Time and Temperature Control

Food safety is paramount in preventing foodborne illnesses. Time and temperature control are critical factors in this process, playing a significant role in inhibiting the growth of harmful microorganisms in food. By carefully monitoring and managing these variables, food handlers can drastically reduce the risk of contamination and ensure the safety of the food they serve.

Significance of Time and Temperature Control in Food Safety

Controlling time and temperature is a fundamental principle in food safety because it directly impacts the rate at which bacteria, yeasts, and molds grow and multiply in food. Most foodborne pathogens thrive in specific temperature ranges, often referred to as the ‘Danger Zone.’ Understanding and effectively managing these factors are essential to preventing foodborne illnesses.The effectiveness of time and temperature control is rooted in the following scientific principles:

- Microbial Growth Rates: The rate at which microorganisms multiply is directly influenced by temperature. Within the ‘Danger Zone’, bacterial growth can occur rapidly, with populations potentially doubling every 20 minutes under optimal conditions.

- Temperature’s Impact on Enzymes: Enzymes present in food can cause spoilage. Temperature control slows down or inactivates these enzymes, preserving the quality and extending the shelf life of food.

- Food Chemistry: The chemical reactions that cause food spoilage and deterioration are temperature-dependent. Controlling temperature slows these reactions.

- Effect on Toxins: While cooking often destroys bacteria, some toxins produced by bacteria, such as those from Staphylococcus aureus, are heat-stable and may remain active even after cooking. Proper temperature control can prevent the formation of these toxins.

Safe Cooking Temperatures for Various Foods

Reaching the correct internal temperature during cooking is crucial for eliminating harmful microorganisms. The following table provides guidelines for safe cooking temperatures for various food items, based on recommendations from the FDA and other food safety authorities. This table is a reference to be used during food preparation.

| Food Item | Minimum Internal Cooking Temperature (°F) | Reason for Temperature |

|---|---|---|

| Poultry (whole or ground) | 165 | Kills Salmonella and other pathogens commonly found in poultry. |

| Ground Meat (beef, pork, veal, lamb) | 160 | Ensures the destruction of E. coli and other bacteria that may be present. |

| Beef, Pork, Veal, Lamb (steaks, roasts, chops) | 145 (with a 3-minute rest time) | Safe for consumption when cooked to this temperature, allowing for the inactivation of surface bacteria. |

| Fish | 145 | Eliminates bacteria and parasites that may be present in fish. |

| Eggs (cooked to serve immediately) | 145 | Destroys Salmonella, a common contaminant. |

| Reheated foods | 165 | Ensures that any bacteria that may have grown during storage are destroyed. |

The ‘Danger Zone’ for Food

The ‘Danger Zone’ is a critical concept in food safety. It refers to the temperature range within which foodborne pathogens grow most rapidly. Understanding the ‘Danger Zone’ is fundamental for implementing effective time and temperature control measures.The ‘Danger Zone’ is generally defined as:

Temperatures between 41°F (5°C) and 135°F (57°C).

Here’s what happens to food within this temperature range:

- Rapid Bacterial Growth: Bacteria, such as Salmonella, E. coli, and Listeria, can multiply rapidly within this temperature range, doubling their population every 20 minutes under ideal conditions.

- Toxin Production: Some bacteria produce toxins that are not destroyed by cooking. If food is left in the ‘Danger Zone’ long enough, these toxins can accumulate and cause illness.

- Spoilage: Even if bacteria are not harmful, their growth leads to food spoilage, altering the taste, texture, and appearance of the food.

- Increased Risk of Foodborne Illness: The longer food remains in the ‘Danger Zone,’ the greater the risk of foodborne illness. This risk increases exponentially with time.

Using a Food Thermometer Correctly

Using a food thermometer correctly is essential for accurately measuring the internal temperature of food and ensuring it has reached a safe cooking temperature. An accurate reading is crucial for food safety.To use a food thermometer correctly:

- Calibration: Always calibrate the thermometer before use. This can be done using the ice water method or the boiling water method. Refer to the manufacturer’s instructions.

- Insertion: Insert the thermometer stem into the thickest part of the food, avoiding bones, fat, or gristle.

- Placement: Ensure the thermometer is inserted far enough to measure the internal temperature accurately, typically at least 1 inch (2.5 cm) deep.

- Waiting Time: Allow the thermometer to register the temperature for at least 15-20 seconds, or until the reading stabilizes.

- Multiple Readings: Take readings in several locations, especially with large items like roasts, to ensure uniform cooking.

- Types of Thermometers:

- Bimetallic Stem Thermometers: These are common and easy to use, with a dial that displays the temperature.

- Thermocouple Thermometers: These thermometers use a probe to measure temperature and provide a rapid reading. They are generally more accurate.

- Digital Thermometers: These thermometers provide a digital readout and can be more accurate and easier to read.

Assessment Content: Cleaning and Sanitizing

Maintaining a safe food environment hinges on rigorous cleaning and sanitizing practices. These processes, though often used together, serve distinct purposes in preventing foodborne illnesses. This section delves into the specifics of cleaning and sanitizing, outlining procedures and detailing the approved methods for ensuring food safety in a food service setting.

Distinction Between Cleaning and Sanitizing

Cleaning and sanitizing are fundamental components of food safety, but they address different aspects of contamination. Cleaning physically removes dirt, food particles, and grease from surfaces. Sanitizing, on the other hand, reduces the number of microorganisms to a safe level. It is crucial to clean before sanitizing because sanitizers are less effective when organic matter is present.

Procedure for Washing Dishes by Hand

Washing dishes by hand, while seemingly simple, requires a methodical approach to ensure effective cleaning and sanitization. This process typically involves several steps, each contributing to the overall hygiene of the dishware.

- Scraping and Pre-Rinsing: Remove food scraps and pre-rinse dishes with warm water to remove loose debris. This prevents the wash water from becoming excessively soiled.

- Washing: Wash dishes in hot, soapy water (at least 110°F or 43°C). Use a detergent specifically designed for dishwashing. The detergent emulsifies grease and loosens food particles.

- Rinsing: Rinse dishes thoroughly with clean, warm water to remove detergent residue. Residual detergent can affect the taste of food and reduce the effectiveness of sanitizers.

- Sanitizing: Sanitize dishes using an approved sanitizer. Follow the manufacturer’s instructions for the correct concentration and contact time. The sanitizer must come into contact with the surface for the specified time to be effective.

- Air Drying: Allow dishes to air dry. Avoid using towels, as they can recontaminate the dishes. Air drying ensures the sanitizer has adequate contact time and prevents the transfer of bacteria from towels.

Proper Use of Sanitizers

The effective use of sanitizers is crucial for reducing the risk of foodborne illness. Sanitizers are chemicals that kill or reduce the number of microorganisms to safe levels. Their effectiveness depends on several factors, including concentration, contact time, and temperature.

The effectiveness of a sanitizer is influenced by several factors:

- Concentration: Using the correct concentration is essential. Too little sanitizer may not kill enough microorganisms, while too much can leave a residue and may be unsafe. Always follow the manufacturer’s instructions.

- Contact Time: Sanitizers need sufficient contact time to be effective. The contact time varies depending on the sanitizer and the surface being sanitized.

- Temperature: Some sanitizers are more effective at certain temperatures. The temperature range is usually specified by the manufacturer.

- Water Hardness: Hard water can reduce the effectiveness of some sanitizers. Test the water hardness and adjust the sanitizer concentration as needed.

- Surface Cleanliness: Surfaces must be cleaned before sanitizing. Dirt and food particles can inactivate the sanitizer.

The Centers for Disease Control and Prevention (CDC) recommends that food contact surfaces should be sanitized with a concentration of at least 50 ppm (parts per million) of chlorine-based sanitizers and a contact time of at least 30 seconds.

Approved Sanitizing Chemicals and Their Uses

Several sanitizing chemicals are approved for use in food service settings. Each has its own advantages and disadvantages, so selecting the appropriate sanitizer depends on the specific application. The following is a list of commonly used sanitizers and their uses.

- Chlorine-Based Sanitizers (Bleach):

- Uses: Effective for sanitizing food contact surfaces, equipment, and utensils. They are also effective for sanitizing cutting boards and dishware.

- Advantages: Inexpensive, readily available, and effective against a wide range of microorganisms.

- Disadvantages: Corrosive to some surfaces, can irritate skin, and effectiveness is reduced by organic matter and high temperatures. The concentration is typically between 50-100 ppm.

- Quaternary Ammonium Compounds (Quats):

- Uses: Effective for sanitizing food contact surfaces, equipment, and utensils. They are also effective for sanitizing cutting boards and dishware.

- Advantages: Non-corrosive, odorless, and stable in the presence of organic matter.

- Disadvantages: Can be inactivated by hard water and some detergents. Contact time can be longer than with other sanitizers. The concentration is typically between 200-400 ppm.

- Iodine-Based Sanitizers:

- Uses: Effective for sanitizing food contact surfaces, equipment, and utensils. They are also effective for sanitizing cutting boards and dishware.

- Advantages: Effective against a wide range of microorganisms and are less affected by organic matter than chlorine.

- Disadvantages: Can stain surfaces, and effectiveness is reduced by high temperatures and hard water. The concentration is typically between 12.5-25 ppm.

Assessment Content: Allergens and Food Safety

Food handlers play a critical role in ensuring food safety, and understanding and managing food allergens is a vital component of this responsibility. Allergic reactions can range from mild discomfort to life-threatening anaphylaxis, making allergen awareness and control paramount in any food service setting. Neglecting allergen protocols can lead to serious health consequences and legal repercussions.

Importance of Allergen Awareness

Allergen awareness is crucial to protect customers from potentially fatal reactions. This involves understanding the nature of food allergies, the common allergens, and how to prevent cross-contact. It also includes knowing how to respond to an allergic reaction. Food handlers must be trained to identify ingredients, read labels accurately, and communicate effectively with customers about potential allergens in dishes. This proactive approach is essential to create a safe and inclusive dining experience for everyone.

Major Food Allergens

The Food Allergen Labeling and Consumer Protection Act of 2004 (FALCPA) mandates that food labels clearly identify the presence of the eight major food allergens, which account for 90% of all food-allergic reactions in the United States. Understanding these allergens is the first step in preventing allergic reactions.

- Milk: This includes all forms of milk, such as cow’s milk, goat’s milk, and milk-derived ingredients like casein and whey. Examples include dairy products such as cheese, yogurt, and butter.

- Eggs: Both egg whites and egg yolks can trigger allergic reactions. Eggs are frequently used in baked goods, sauces, and coatings.

- Fish: This encompasses various types of finned fish. Fish allergens are potent and can cause severe reactions.

- Crustacean Shellfish: This group includes shrimp, crab, lobster, and crayfish. Shellfish allergies are among the most common and severe food allergies.

- Tree Nuts: This includes almonds, walnuts, pecans, cashews, and other tree nuts. Cross-contamination with tree nuts is a significant concern due to their prevalence in various food products.

- Peanuts: Peanuts are legumes, but they are often grouped with tree nuts due to the severity of peanut allergies. Peanut allergies are a leading cause of anaphylaxis.

- Wheat: Wheat contains gluten, which can trigger allergic reactions or celiac disease in susceptible individuals. Wheat is a staple ingredient in many foods, including bread, pasta, and baked goods.

- Soybeans: Soybeans and soy-derived ingredients, such as soy sauce and tofu, are common allergens. They are often used as a protein source and in various processed foods.

Preventing Cross-Contact with Allergens

Cross-contact occurs when an allergen is unintentionally transferred from one food to another. This can happen through shared equipment, utensils, or surfaces. Preventing cross-contact requires strict adherence to specific procedures.

- Dedicated Equipment: Use separate cutting boards, utensils, and cookware for preparing allergen-free foods. For example, use a specific color-coded cutting board for preparing foods without peanuts to avoid any cross-contamination.

- Thorough Cleaning and Sanitizing: Clean and sanitize all surfaces, equipment, and utensils that come into contact with food, especially after preparing foods containing allergens. This includes dishwashers, countertops, and cooking surfaces.

- Proper Food Storage: Store allergen-containing foods separately from allergen-free foods to prevent accidental contamination. Ensure that all food items are properly labeled and sealed.

- Handwashing: Food handlers must wash their hands thoroughly with soap and water before preparing allergen-free foods and after handling allergen-containing foods.

- Staff Training: Regularly train all food handlers on allergen awareness, cross-contact prevention, and how to handle customer inquiries about allergens. Include practical exercises such as simulating allergen scenarios.

- Ingredient Review: Always review ingredient labels to identify potential allergens. Be aware of hidden allergens in sauces, seasonings, and processed foods.

Communicating Allergen Information to Customers

Effective communication is essential to help customers make informed decisions about their food choices. This involves providing clear and accurate information about the presence of allergens in menu items.

- Menu Labeling: Clearly label menu items that contain common allergens. This can be done using symbols, icons, or a separate allergen key. For example, a small “G” symbol next to a dish could indicate the presence of gluten.

- Allergen Information Sheets: Provide readily available allergen information sheets or charts that list all menu items and their allergen content. These sheets should be easily accessible to both customers and staff.

- Staff Training on Allergen Information: Ensure that all staff members are trained to answer customer questions about allergens accurately and confidently. Staff should be able to identify potential allergens in dishes and explain the steps taken to prevent cross-contact.

- Customer Communication: Encourage customers to inform staff about any food allergies or dietary restrictions before ordering. This allows staff to make appropriate recommendations and take necessary precautions.

- Online Information: Provide allergen information on your restaurant’s website or mobile app. This allows customers to review allergen information before they visit the restaurant.

- Ingredient Availability: Make it possible for customers to request the ingredients used in a specific dish, or provide the ingredient list upon request.

Reporting Illness and Food Safety

Food safety hinges on the vigilance of food handlers, and a critical aspect of this is recognizing and reporting illnesses. This section details the crucial responsibilities of food handlers in reporting illnesses, the symptoms that necessitate reporting, the procedures for handling ill food handlers, and the potential consequences of failing to report. Understanding and adhering to these guidelines is essential for preventing foodborne illnesses and ensuring the safety of the public.

Food Handler’s Responsibility Regarding Reporting Illness

Food handlers are legally and ethically obligated to report any illness or symptoms that could potentially contaminate food. This responsibility is not just a matter of following regulations; it’s a fundamental aspect of safeguarding public health. Food handlers are the first line of defense against foodborne illnesses. They must prioritize the safety of the food they handle above all else, and reporting illness is a critical part of this commitment.

Examples of Symptoms That Must Be Reported

Certain symptoms are highly indicative of illnesses that can be transmitted through food. Food handlers exhibiting these symptoms must report them immediately to their supervisor.

- Vomiting: Vomiting can spread pathogens directly onto food or food contact surfaces. Norovirus, a common cause of foodborne illness, often presents with vomiting.

- Diarrhea: Diarrhea is another key symptom, as it indicates the presence of infectious agents in the digestive tract. Bacteria like

-Salmonella* and

-Shigella* can cause diarrhea and are easily transmitted through contaminated food. - Jaundice: Jaundice, a yellowing of the skin and eyes, indicates a liver problem, often associated with Hepatitis A, which is highly contagious and can be spread through contaminated food.

- Sore throat with fever: This combination can indicate a bacterial or viral infection, such as

-Strep throat* or influenza, which may be spread to food through sneezing or coughing. - Lesions containing pus: Lesions, particularly those on the hands, wrists, or exposed body parts, that contain pus can harbor

-Staphylococcus aureus*, which produces toxins that can cause food poisoning.

Procedures for Handling Ill Food Handlers

When a food handler reports illness or exhibits symptoms, specific procedures must be followed to prevent food contamination. These procedures often include:

- Exclusion: The ill food handler must be immediately excluded from working with food, food equipment, utensils, and food-contact surfaces. This is the primary step to prevent the spread of pathogens.

- Reporting: The supervisor must report the illness to the local health authority if the food handler is diagnosed with, or suspected of having, a reportable illness, such as Hepatitis A,

-Salmonella*,

-Shigella*, or Norovirus. - Documentation: The incident should be documented, including the symptoms, the actions taken, and the date. This documentation is essential for tracking and preventing future outbreaks.

- Medical Clearance: The food handler may need to provide medical clearance from a healthcare professional before returning to work. This is especially important for illnesses like Hepatitis A.

- Reassignment: If possible, the ill food handler may be reassigned to a non-food handling role until they are symptom-free and/or have received medical clearance.

Consequences of Not Reporting Illnesses

Failure to report illnesses can have severe consequences, both for the individual food handler and the establishment. These consequences include:

- Increased risk of foodborne illness outbreaks: The most significant consequence is the potential for widespread illness among customers. This can lead to hospitalizations, and in some cases, fatalities.

- Legal and financial penalties: Food establishments can face fines, legal action, and even closure if they fail to comply with food safety regulations. These penalties can be substantial and can damage the business’s reputation.

- Damage to the establishment’s reputation: A foodborne illness outbreak can severely damage the reputation of a restaurant or food service operation. This can lead to a loss of customers and revenue.

- Health risks for the food handler: The food handler may experience a worsening of their own illness due to continued exposure to food and food-contact surfaces.

- Loss of employment: Repeated failures to report illnesses can lead to disciplinary action, including termination of employment.

Assessment Structure and Format

Understanding the structure and format of a food handler assessment is crucial for successful completion. This knowledge provides a framework for effective studying and test-taking strategies, ultimately leading to a better grasp of food safety principles. Familiarity with the assessment’s layout and question types helps reduce test anxiety and allows individuals to focus on demonstrating their understanding of essential food safety practices.

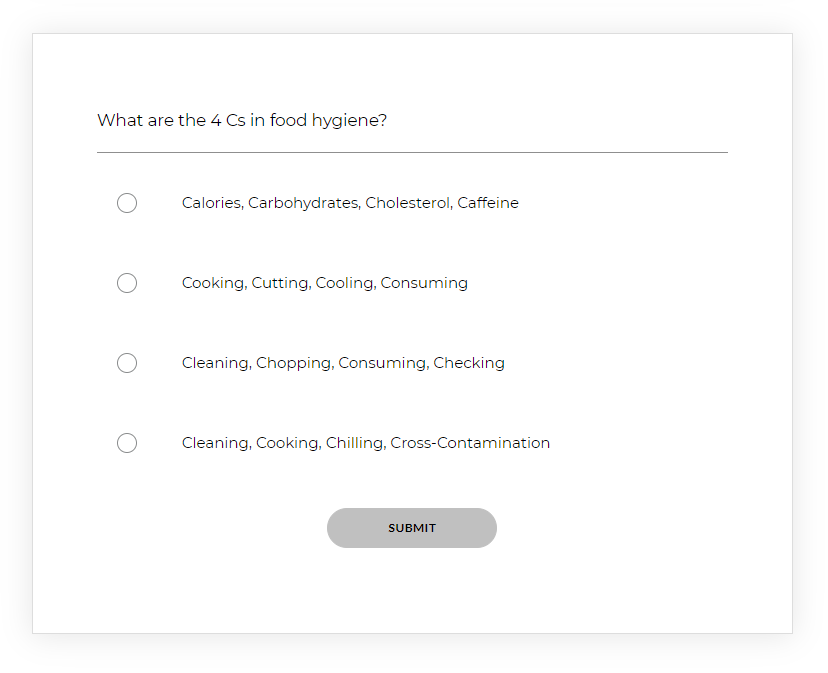

Common Formats of Food Handler Assessments

Food handler assessments typically employ a variety of formats designed to evaluate a candidate’s understanding of food safety principles. The most common formats include multiple-choice questions, true/false statements, and sometimes, short-answer or matching exercises. These formats are designed to assess different levels of knowledge and comprehension.

- Multiple-Choice Questions: This format presents a question or statement followed by several possible answers, from which the candidate must select the best or most correct option. These questions are often used to assess factual recall and the ability to apply knowledge to specific scenarios.

- True/False Questions: These questions present a statement, and the candidate must determine whether the statement is accurate (true) or inaccurate (false). This format is useful for assessing a basic understanding of food safety facts and principles.

- Short-Answer Questions: In some assessments, candidates may be asked to provide brief written responses to questions. This format allows for a more in-depth assessment of understanding and the ability to explain concepts.

- Matching Exercises: This format requires candidates to match terms, definitions, or concepts from two different lists. It’s a way to test knowledge of specific vocabulary and their definitions within the context of food safety.

- Scenario-Based Questions: Some assessments include scenarios that describe real-world food handling situations. Candidates must then apply their knowledge to identify potential hazards, recommend corrective actions, or determine the best course of action.

Comparison of Multiple-Choice and True/False Question Types

Multiple-choice and true/false questions represent two fundamental assessment formats, each with distinct advantages and disadvantages in evaluating food safety knowledge. The choice of format often depends on the specific learning objectives and the type of knowledge being assessed.

- Multiple-Choice:

- Advantages: Offers a wider range of options, allowing for more nuanced assessment of understanding. It can test the ability to apply knowledge to various situations. It reduces the chance of guessing correctly compared to true/false.

- Disadvantages: Can be time-consuming to create effective distractors (incorrect answer choices). Requires careful wording to avoid ambiguity.

- True/False:

- Advantages: Simple to create and quickly assesses basic factual knowledge. Can cover a broad range of topics in a short amount of time.

- Disadvantages: More susceptible to guessing, as there’s a 50% chance of answering correctly. Less effective at assessing complex understanding or application of knowledge.

Passing Score Typically Required for a Food Handler Assessment

The passing score for a food handler assessment is generally set to ensure that individuals possess a sufficient level of knowledge to safely handle food. The specific passing score can vary depending on the jurisdiction, the assessment provider, and the specific requirements.

- Typical Range: The passing score is usually between 70% and 80%. This range indicates that a candidate must correctly answer a significant portion of the questions to demonstrate an acceptable level of understanding.

- Rationale: A passing score in this range ensures that food handlers possess a solid grasp of critical food safety principles, such as preventing cross-contamination, controlling time and temperature, and practicing proper hygiene. This level of knowledge is essential to minimize the risk of foodborne illness.

- Consequences of Failing: Failing a food handler assessment typically requires the individual to retake the exam. Some jurisdictions may limit the number of attempts allowed within a certain timeframe.

Examples of Questions That Might Appear on the Assessment

Food handler assessments typically include a variety of questions designed to evaluate a candidate’s understanding of food safety principles. These questions cover a range of topics, including cross-contamination, time and temperature control, cleaning and sanitizing, and allergen management.

- Multiple-Choice Example:

Which of the following is the best way to prevent cross-contamination?

- Using the same cutting board for raw meat and vegetables.

- Washing hands thoroughly after handling raw meat.

- Storing raw meat above cooked foods in the refrigerator.

- Using the same utensils for different food items.

Correct Answer: Washing hands thoroughly after handling raw meat.

- True/False Example:

It is safe to thaw frozen food at room temperature.

Answer: False

- Scenario-Based Example:

A food handler notices a customer has a severe allergic reaction after eating a dish. What is the FIRST action the food handler should take?

- Call the customer’s doctor.

- Administer an epinephrine auto-injector if the customer has one and the food handler is trained.

- Ask the customer what they are allergic to.

- Offer the customer a glass of water.

Correct Answer: Administer an epinephrine auto-injector if the customer has one and the food handler is trained.

Training Methods and Resources

Effective food handler training is the cornerstone of food safety, acting as a preventative measure against foodborne illnesses. It equips individuals with the knowledge and skills necessary to handle food safely, from receiving and storing ingredients to preparing and serving meals. A well-designed training program, coupled with readily available resources, empowers food handlers to make informed decisions that protect public health.

Different Training Methods

The effectiveness of food safety training hinges on the methods employed. A diverse approach, incorporating various learning styles, maximizes knowledge retention and practical application. Different training methods cater to different learning preferences and work environments.

- In-Person Training: This traditional method involves a trainer delivering information in a classroom setting. It allows for immediate interaction, Q&A sessions, and practical demonstrations. Instructors can observe and correct techniques, ensuring proper understanding.

- Online Training: Online courses offer flexibility and accessibility. Learners can access modules at their own pace, and often include interactive elements such as quizzes, videos, and simulations. This method is particularly useful for remote workers or those with busy schedules.

- On-the-Job Training (OJT): OJT involves training food handlers directly at their workplace. This method allows for hands-on experience and practical application of food safety principles in a real-world setting. Mentorship from experienced staff is often a key component.

- Blended Learning: This approach combines in-person and online training components. It offers a balanced learning experience, leveraging the benefits of both methods. This approach is often the most effective for long-term retention.

- Role-Playing and Simulations: These methods involve creating scenarios that simulate real-life situations food handlers might encounter. This approach allows them to practice applying their knowledge and develop problem-solving skills in a safe environment.

Recommended Resources for Food Safety Training

Access to reliable and up-to-date resources is crucial for food safety training. These resources provide essential information, guidelines, and tools to ensure food handlers are well-informed and equipped to prevent foodborne illnesses.

- Food Safety Manuals: These manuals provide comprehensive information on food safety principles, best practices, and regulations. They serve as a valuable reference guide for food handlers.

- Government Agencies: Organizations such as the Food and Drug Administration (FDA) and the Centers for Disease Control and Prevention (CDC) offer a wealth of resources, including guidelines, training materials, and food safety alerts.

- Industry Associations: Associations like the National Restaurant Association (NRA) and the Association of Food and Drug Officials (AFDO) provide training programs, certifications, and resources tailored to the food service industry.

- Training Videos: Videos offer visual demonstrations of food safety practices, such as proper handwashing techniques, cross-contamination prevention, and safe food handling procedures.

- Posters and Visual Aids: Posters and visual aids can reinforce key food safety messages and serve as reminders for food handlers in the workplace. These can include handwashing guidelines, allergen information, and safe food temperature charts.

Online Food Handler Training Courses

Online food handler training courses offer convenience and flexibility, making food safety education accessible to a wider audience. These courses utilize interactive modules, quizzes, and assessments to enhance learning and knowledge retention.

- Convenience and Flexibility: Learners can access courses anytime, anywhere, and at their own pace. This is especially beneficial for individuals with busy schedules or those working in remote locations.

- Interactive Learning: Online courses often incorporate interactive elements such as videos, animations, and quizzes to engage learners and reinforce key concepts.

- Cost-Effectiveness: Online courses can be more affordable than in-person training, reducing the cost of travel, materials, and instructor fees.

- Certification and Documentation: Upon completion of a course, learners typically receive a certificate of completion, which serves as proof of training and compliance with food safety regulations.

- Examples: Numerous platforms offer online food handler training, including StateFoodSafety, ServSafe, and Learn2Serve. These courses are typically state-approved and provide comprehensive food safety education.

Benefits of In-Person Training

In-person training offers unique advantages, providing a more immersive and interactive learning experience. This approach fosters direct interaction between the trainer and the food handlers, promoting better understanding and skill development.

- Direct Interaction and Feedback: In-person training allows for immediate interaction between the trainer and the participants. This enables trainers to answer questions, clarify concepts, and provide personalized feedback.

- Hands-on Demonstrations and Practice: Trainers can demonstrate proper food handling techniques, such as handwashing and knife skills, and provide opportunities for participants to practice these skills under supervision.

- Enhanced Engagement and Motivation: In-person training can be more engaging and motivating than online courses. The social interaction and group activities can enhance the learning experience and foster a sense of community.

- Improved Skill Development: Hands-on practice and direct feedback from a trainer can significantly improve skill development and ensure that food handlers can apply their knowledge in real-world situations.

- Real-World Application: In-person training often incorporates real-world scenarios and case studies, allowing participants to apply their knowledge to practical situations. This can enhance their problem-solving skills and prepare them for the challenges they may face in the workplace.

Legal and Regulatory Aspects

Food safety is not just a matter of good practice; it’s a legal imperative. Compliance with regulations protects public health, safeguards businesses, and ensures a consistent standard of food handling. Understanding the legal framework is crucial for all food handlers to operate safely and responsibly.

Legal Requirements for Food Handler Assessments

Food handler assessments are mandated by various levels of government to ensure food handlers possess the necessary knowledge to prevent foodborne illnesses. These requirements often stem from public health codes and regulations designed to protect consumers. The specific details, such as the frequency of assessments and the content covered, can vary.

- State and Local Laws: Generally, food safety regulations are primarily governed by state and local health departments. These departments often adopt the Food and Drug Administration (FDA) Food Code as a model, or develop their own regulations. These laws dictate the necessity of food handler assessments, specifying who needs to be assessed, the required content, and the approved assessment providers.

- Employee Training: Regulations usually mandate that food handlers receive adequate training. This training must cover key areas like personal hygiene, cross-contamination prevention, time and temperature control, cleaning and sanitizing, and allergen management. The assessment verifies that the training has been effective.

- Assessment Content: The assessments must cover specific topics deemed critical for food safety. These topics include, but are not limited to, the correct handling of food, understanding the risks associated with improper practices, and knowing how to report illnesses.

- Certification and Documentation: Upon successful completion of an assessment, food handlers often receive a certificate or other form of documentation. This proof of certification is frequently required to be displayed or readily available at the food establishment.

Local Health Department Regulations

Local health departments play a crucial role in enforcing food safety regulations. They act as the primary regulatory body, overseeing food establishments within their jurisdiction. Their responsibilities encompass inspections, investigations, and the enforcement of health codes.

- Inspections: Health inspectors regularly visit food establishments to ensure compliance with food safety standards. These inspections assess various aspects of food handling, from storage and preparation to employee practices.

- Permitting: Food establishments typically require permits to operate. The health department issues these permits and ensures that establishments meet the necessary requirements, including the training and assessment of food handlers.

- Enforcement Actions: When violations are identified during inspections, the health department can take enforcement actions. These actions can range from warnings and fines to the suspension or revocation of permits.

- Variations in Regulations: It’s important to understand that local health department regulations can vary. The specifics of training requirements, assessment content, and enforcement actions may differ depending on the jurisdiction. Food handlers should always be aware of the regulations applicable to their specific location.

Consequences of Non-Compliance with Food Safety Regulations

Failure to comply with food safety regulations can have serious consequences, impacting both public health and the food establishment’s reputation and viability. The severity of these consequences varies depending on the nature and frequency of the violations.

- Public Health Risks: The primary concern is the potential for foodborne illnesses. Non-compliance with food safety practices increases the risk of contamination and the spread of pathogens, leading to outbreaks and illness among consumers.

- Legal Penalties: Violations of food safety regulations can result in a range of legal penalties. These can include fines, warnings, the suspension or revocation of permits, and even criminal charges in severe cases.

- Reputational Damage: Foodborne illness outbreaks and repeated violations can severely damage a food establishment’s reputation. Negative publicity can lead to a loss of customers, decreased sales, and long-term financial repercussions.

- Closure of Establishments: In extreme cases, particularly with repeated or serious violations, health departments may order the temporary or permanent closure of a food establishment. This can result in significant financial losses and the potential loss of employment for staff.

Levels of Food Safety Violations and Penalties

Health departments typically categorize food safety violations based on their severity. These categories determine the corresponding penalties, which can range from warnings to fines and more severe actions. The specific classifications and penalties can vary by jurisdiction, but a general framework is provided in the table below.

| Violation Level | Description | Examples | Potential Penalties |

|---|---|---|---|

| Minor Violation | Presents a low risk to food safety; does not directly cause foodborne illness. | Improper labeling, minor cleaning deficiencies, lack of handwashing signage. | Warning, short timeframe for correction. |

| Major Violation | Presents a moderate risk; could lead to foodborne illness if not corrected. | Improper temperature control, poor personal hygiene practices, cross-contamination risks. | Fine, follow-up inspection, potential for permit suspension. |

| Critical Violation | Presents a high risk of causing foodborne illness; directly impacts food safety. | Presence of pests, sewage contamination, evidence of food spoilage, unsafe food temperatures. | Immediate closure, substantial fines, potential for permit revocation, legal action. |

| Repeat Violation | Any violation that is repeated after a previous inspection. | Any violation that is repeated after a previous inspection. | Increased fines, intensified scrutiny, potential for permit suspension or revocation. |

Practical Application: Food Handlers Assessment 7

Food safety knowledge is crucial, but its true value lies in practical application. This section moves beyond theory, presenting real-world scenarios and case studies to illustrate the consequences of food safety violations and the importance of diligent adherence to established protocols. The goal is to equip food handlers with the skills to identify, address, and prevent food safety hazards in their daily work.

Designing Scenarios Involving Food Safety Violations

Food safety violations can occur in numerous ways within a food service environment. Understanding common violations allows for proactive measures.

- Scenario 1: Cross-Contamination in the Kitchen: A cook uses the same cutting board and knife to prepare raw chicken and then, without proper washing and sanitizing, uses them to chop vegetables for a salad. This is a clear violation of cross-contamination protocols. The risk is the transfer of pathogens, such as Salmonella or Campylobacter, from the raw chicken to the ready-to-eat vegetables.

- Scenario 2: Temperature Abuse During Food Holding: A buffet line is set up, and hot foods, like cooked rice and steamed vegetables, are held at temperatures below 135°F (57°C) for an extended period. This creates an ideal environment for bacterial growth, specifically Bacillus cereus, which produces toxins.

- Scenario 3: Improper Handwashing and Personal Hygiene: A food handler returns from a break, touches their face and hair, and immediately begins preparing food without washing their hands. This introduces potential contaminants from the handler’s skin and environment into the food. This includes Staphylococcus aureus, which can produce toxins that cause food poisoning.

- Scenario 4: Inadequate Cleaning and Sanitizing of Equipment: A meat slicer is used to slice deli meats, but it is not disassembled, cleaned, and sanitized at the end of each shift. Bacteria, such as Listeria monocytogenes, can accumulate on the slicer’s surfaces and contaminate subsequent batches of sliced meat.

- Scenario 5: Failure to Properly Label and Date Food: Cooked food stored in a refrigerator is not properly labeled with the date it was prepared or the “use-by” date. This makes it difficult to track the age of the food and increases the risk of serving food that has passed its expiration date, potentially leading to the consumption of spoiled or pathogen-contaminated food.

Responding to Food Safety Violations in a Workplace Setting

Effective responses to food safety violations require a combination of immediate action and long-term prevention strategies.

- Immediate Correction: If a violation is observed, the first step is to immediately correct it. For example, if cross-contamination is identified, the contaminated food should be discarded, and the affected surfaces and equipment should be thoroughly cleaned and sanitized.

- Reporting the Violation: Food handlers must report any observed violations to their supervisor or the person in charge. This allows for proper documentation and follow-up actions.

- Training and Education: The incident should be used as a teaching opportunity. Retraining the involved staff on proper food safety procedures is essential.

- Corrective Actions: Implement corrective actions to prevent future occurrences. This could include revising standard operating procedures (SOPs), conducting regular inspections, or improving employee training programs.

- Documentation: Maintain detailed records of all violations, corrective actions, and training efforts. This documentation is crucial for demonstrating due diligence and compliance with food safety regulations.

Case Studies of Foodborne Illness Outbreaks and Their Causes

Examining real-world outbreaks provides valuable insights into the impact of food safety failures.

- Case Study 1: The E. coli Outbreak in a Restaurant Chain : In 2006, an outbreak of E. coli O157:H7 was linked to a national restaurant chain. The source was identified as contaminated spinach. The outbreak resulted in hundreds of illnesses and multiple deaths. The investigation revealed that the spinach had been contaminated during the harvesting or processing stages. This case highlights the importance of proper food sourcing and rigorous food safety practices throughout the supply chain.

- Case Study 2: The Salmonella Outbreak from Contaminated Peanut Butter : In 2008-2009, a widespread Salmonella outbreak was traced to contaminated peanut butter produced by a major manufacturer. The outbreak caused over 700 illnesses and several deaths. The investigation revealed poor sanitation practices and inadequate testing procedures at the processing facility. This case underscores the need for robust sanitation programs, regular environmental testing, and thorough product testing to prevent contamination.

- Case Study 3: The Listeria Outbreak Linked to Deli Meats : Outbreaks of Listeria monocytogenes are frequently linked to ready-to-eat deli meats. The bacteria can grow at refrigeration temperatures. In 2011, a Listeria outbreak associated with sliced deli meats resulted in several deaths. The investigation often points to inadequate cleaning and sanitizing of slicing equipment and improper temperature control during storage as contributing factors.

Demonstrating the Importance of Following Food Safety Protocols

Adherence to food safety protocols is not merely a set of rules; it is a critical component of protecting public health.

- Protecting Public Health: Food safety protocols are designed to prevent foodborne illnesses, which can cause a range of symptoms from mild discomfort to severe illness and even death. Adhering to these protocols is the primary responsibility of food handlers.

- Preventing Economic Loss: Foodborne illness outbreaks can lead to significant economic losses for food businesses, including product recalls, lawsuits, loss of consumer trust, and business closures. Following protocols helps minimize these risks.

- Maintaining Reputation: A food business’s reputation is vital. A single foodborne illness incident can severely damage its reputation, leading to a decline in customer loyalty and sales.

- Ensuring Legal Compliance: Food businesses are legally obligated to comply with food safety regulations. Failure to do so can result in fines, legal action, and even closure.

- Promoting Employee Safety: Food safety protocols also protect food handlers from potential hazards. Proper handling procedures, the use of personal protective equipment, and safe work practices help prevent injuries and illnesses in the workplace.

Updates and Recertification

Maintaining food safety is an ongoing process, not a one-time event. The food service industry is constantly evolving, with new scientific discoveries, updated regulations, and emerging food safety challenges. Therefore, food handler certifications require regular updates and recertification to ensure that food handlers possess the most current knowledge and skills to protect public health. This continuous learning approach is crucial for preventing foodborne illnesses and maintaining consumer trust.

Importance of Updating Food Handler Certifications

Food handler certifications must be updated to reflect the latest scientific understanding and best practices in food safety. This is not merely a matter of compliance but a vital component of public health protection. Failure to update certifications can lead to outdated practices that increase the risk of foodborne illnesses.

- Evolving Science: Scientific research constantly reveals new information about foodborne pathogens, their behavior, and effective control measures. For instance, advancements in understanding the survival rates of

-Listeria monocytogenes* at refrigeration temperatures necessitate updated protocols for food handling and storage. - Regulatory Changes: Food safety regulations are dynamic and vary by region, state, and even local jurisdiction. These changes may involve updated hazard analysis and critical control points (HACCP) plans, new labeling requirements, or revised standards for food preparation and storage.

- Emerging Threats: The food industry faces evolving challenges, including the rise of antibiotic-resistant bacteria, new food allergens, and emerging contaminants. Recertification helps food handlers stay informed about these threats and learn how to mitigate associated risks.

- Best Practices: Continuous updates incorporate proven best practices that improve food safety outcomes. This can include improved sanitation techniques, more effective allergen management strategies, or enhanced employee training methods.

Typical Recertification Period for Food Handlers

The recertification period for food handlers varies depending on the specific regulations of the governing health authority. This period is typically between two and five years, ensuring that food handlers regularly refresh their knowledge and skills.

- Common Intervals: A two-year recertification cycle is a common standard, providing a balance between knowledge retention and minimizing the burden on food handlers. However, some jurisdictions may require recertification every three, four, or five years.

- State and Local Variations: Regulations vary significantly by location. Food handlers must check the specific requirements of their local health department or regulatory agency to determine their recertification deadline.

- Consequences of Non-Compliance: Failure to maintain a valid food handler certification can result in penalties, including fines, warnings, or even the suspension of a food establishment’s operating permit.

Maintaining Up-to-Date Knowledge of Food Safety

Beyond formal recertification, food handlers should proactively seek opportunities to enhance their food safety knowledge. This includes continuous learning through various resources.

- Professional Development: Participate in workshops, seminars, and conferences offered by industry associations, health departments, or food safety training providers.

- Online Resources: Utilize online training modules, webinars, and educational materials provided by reputable organizations such as the FDA, CDC, and state health departments.

- Industry Publications: Subscribe to industry publications, newsletters, and journals to stay informed about the latest food safety trends, scientific findings, and regulatory updates.

- Mentorship and Collaboration: Seek guidance from experienced food safety professionals, supervisors, and colleagues to learn from their expertise and share best practices.

- Internal Training: Actively participate in in-house training programs conducted by the food establishment, including refresher courses, hands-on demonstrations, and regular reviews of standard operating procedures (SOPs).

Finding the Latest Food Safety Guidelines and Regulations

Staying informed about current food safety guidelines and regulations is essential for maintaining compliance and protecting public health. The following resources are valuable for accessing the most up-to-date information.

- Government Agencies:

- FDA (Food and Drug Administration): The FDA’s website ([https://www.fda.gov/](https://www.fda.gov/)) provides comprehensive information on food safety regulations, guidance documents, and inspection reports.

- CDC (Centers for Disease Control and Prevention): The CDC ([https://www.cdc.gov/](https://www.cdc.gov/)) offers valuable data on foodborne illnesses, outbreak investigations, and prevention strategies.

- State and Local Health Departments: Each state and local health department maintains its own website with specific regulations and guidelines applicable within its jurisdiction.

- Industry Associations: Organizations such as the National Restaurant Association and the Association of Food and Drug Officials (AFDO) provide valuable resources, including publications, training materials, and advocacy efforts.

- Legal Databases: Legal databases and services offer access to federal, state, and local laws and regulations.

- Food Safety Training Providers: Reputable food safety training providers typically stay abreast of regulatory changes and incorporate them into their training programs and materials.

Wrap-Up

In conclusion, food handlers assessment 7 isn’t merely about passing a test; it’s about embracing a mindset of constant learning and unwavering dedication. It is a call to action for all those involved in the food industry. By understanding the core principles of food safety, and recognizing your role, you become an essential part of the safety network. Remember, every practice learned, every regulation understood, is a step towards a safer, healthier future for all.

It’s about safeguarding public health, one meal at a time.