Food safe hose is more than just a piece of equipment; it’s a critical component in maintaining the integrity and safety of products across various industries. From the bustling food and beverage sector to the meticulous world of pharmaceuticals and cosmetics, the right hose ensures that materials are transported without contamination. This guide delves into the intricacies of food safe hoses, exploring their construction, applications, and the vital role they play in ensuring consumer safety and operational efficiency.

We’ll explore the specific materials that make up these hoses, such as silicone, PVC, and EPDM, highlighting their unique properties like chemical resistance and flexibility. You’ll discover the international standards and certifications that define a food safe hose, ensuring they meet the highest hygiene standards. This guide will also cover the practical aspects of hose selection, cleaning, maintenance, and the latest innovations in hose technology, providing you with a comprehensive understanding of this essential equipment.

Defining Food Safe Hose

Food safe hoses are essential components in a wide range of industries, from food and beverage production to pharmaceutical manufacturing. Their primary function is to safely convey fluids and semi-solids that come into direct contact with consumables, ensuring product integrity and preventing contamination. This presentation will define food safe hoses, Artikel their critical material compositions, and detail the necessary standards and certifications that guarantee their suitability for use in these sensitive applications.

Definition and Significance of Food Safe Hoses

Food safe hoses are specifically designed and manufactured to prevent the leaching of harmful chemicals or the harboring of microorganisms that could contaminate food or other consumable products. Their significance stems from their role in maintaining product purity, protecting consumer health, and complying with stringent regulatory requirements. Failure to utilize appropriate food safe hoses can result in product recalls, legal liabilities, and damage to brand reputation.

Materials Used in Food Safe Hoses

The selection of materials for food safe hoses is critical to their performance and safety. These materials must be inert, non-toxic, and resistant to degradation from the substances they convey and the cleaning agents used.

- Rubber Compounds: Various rubber compounds, such as EPDM (Ethylene Propylene Diene Monomer) and NBR (Nitrile Butadiene Rubber), are commonly employed. EPDM exhibits excellent resistance to ozone, UV radiation, and a wide range of chemicals, making it suitable for both hot and cold applications. NBR offers good resistance to oils and fats, often used for conveying fatty foods.

- Thermoplastic Elastomers (TPEs): TPEs, including thermoplastic polyurethane (TPU) and thermoplastic vulcanizates (TPV), offer flexibility, durability, and resistance to a broad spectrum of chemicals. TPU is often used in applications requiring high abrasion resistance, while TPV provides excellent resistance to temperature extremes.

- Silicone Rubber: Silicone rubber is known for its high-temperature resistance, flexibility, and inertness. It is frequently used in applications where the hose must withstand repeated sterilization cycles.

- Polyethylene (PE) and Polypropylene (PP): These thermoplastics offer excellent chemical resistance and are cost-effective options for conveying a variety of food products. They are often used in conjunction with other materials in hose construction.

Each material undergoes rigorous testing to ensure compliance with food safety regulations.

International Standards and Certifications for Food Safe Hoses

To be considered food safe, hoses must adhere to specific international standards and certifications. These standards and certifications validate the safety and suitability of the hose for food contact applications. Compliance is typically demonstrated through third-party testing and certification processes.

- FDA (Food and Drug Administration) Compliance: In the United States, hoses must comply with FDA regulations, specifically 21 CFR 177.2600, which addresses the use of rubber articles intended for repeated use in contact with food. This standard Artikels the permitted materials and their extractable limits.

- EU Regulation 1935/2004: This European Union regulation sets out general requirements for all materials and articles intended to come into contact with food. It mandates that materials must not transfer their constituents to food in quantities that could endanger human health or alter the composition, taste, or odor of the food.

- EU Regulation 10/2011: This regulation provides specific rules for plastic materials and articles intended to come into contact with food, including positive lists of permitted substances and migration limits.

- Other Certifications: Additional certifications, such as NSF (National Sanitation Foundation) and 3-A Sanitary Standards, are often sought to demonstrate compliance with specific industry requirements. These certifications typically involve comprehensive testing and audits of manufacturing processes.

Obtaining and maintaining these certifications is crucial for manufacturers to ensure their hoses meet the highest standards of food safety and quality.

Applications of Food Safe Hoses

Food safe hoses are critical components in various industries, ensuring the integrity and safety of products intended for human consumption or use. Their unique construction and material properties allow them to handle a wide range of substances while preventing contamination. These hoses are designed to meet stringent regulatory standards and are vital for maintaining product quality and consumer safety.

Food and Beverage Industry Applications

The food and beverage industry heavily relies on food safe hoses for a multitude of processes. From raw material handling to final product packaging, these hoses play a crucial role in maintaining hygiene and preventing the introduction of contaminants.

- Processing of Raw Ingredients: Hoses are used to transfer liquids and semi-solids like milk, fruit juices, and vegetable purees from storage tanks to processing equipment. For example, in a dairy processing plant, food safe hoses connect the milk receiving bay to pasteurization units.

- Filling and Packaging: Food safe hoses are integral in filling bottles, cartons, and other packaging materials with beverages, sauces, and other food products. These hoses must be flexible and durable to withstand the constant movement and cleaning cycles. An example is the use of hoses in bottling lines for soft drinks, where they connect the filling machines to the storage tanks containing the beverages.

- Cleaning-in-Place (CIP) Systems: CIP systems use food safe hoses to circulate cleaning and sanitizing solutions through processing equipment without disassembly. This ensures thorough cleaning and reduces downtime. These hoses are designed to resist the harsh chemicals used in the cleaning process.

- Transfer of Ingredients and Products: Food safe hoses facilitate the transfer of various ingredients and finished products throughout the manufacturing process. This includes the movement of syrups, oils, and flavorings. For instance, in a brewery, these hoses transfer beer from fermentation tanks to filtration systems and finally to the packaging lines.

Pharmaceutical and Cosmetic Manufacturing Applications

Food safe hoses, due to their inert properties and ability to maintain purity, find extensive applications in pharmaceutical and cosmetic manufacturing. These industries demand the highest levels of cleanliness and product integrity.

- Ingredient Transfer: Hoses are used to transfer raw materials, such as solvents, active pharmaceutical ingredients (APIs), and cosmetic ingredients, from storage containers to mixing vessels or reactors. These hoses must be resistant to chemical degradation and prevent any leaching of contaminants into the product. For example, a pharmaceutical company uses food safe hoses to transfer sterile water for injection (WFI) to manufacturing equipment.

- Filling of Dosage Forms: Hoses are employed in filling processes for various dosage forms, including liquids, creams, and ointments. The hoses must be compatible with the product and ensure accurate dosing. For example, in a cosmetic manufacturing plant, hoses are used to fill bottles with lotions and creams.

- Cleaning and Sanitization: Similar to the food industry, CIP systems are used to clean and sanitize equipment in pharmaceutical and cosmetic manufacturing. Food safe hoses are used to circulate cleaning agents and sterilizing solutions. These hoses are designed to withstand repeated exposure to these chemicals.

- Biopharmaceutical Applications: Food safe hoses are often employed in the production of biopharmaceuticals, where maintaining sterility and purity is critical. These hoses are used to transfer cell culture media, harvest cell cultures, and deliver purified proteins.

Agricultural Applications: Dairy Farms

In agricultural settings, particularly dairy farms, food safe hoses are essential for the efficient and hygienic handling of milk.

- Milk Transfer: Food safe hoses are used to transfer milk from the milking parlor to bulk storage tanks. These hoses must be able to withstand the rigors of daily use and prevent any contamination of the milk. For example, the hose connects the milking machine to the bulk milk tank.

- Cleaning and Sanitization of Milking Equipment: Food safe hoses are used in CIP systems to clean and sanitize milking equipment, including milking machines, pipelines, and storage tanks. The hoses must be able to resist the cleaning agents and sanitizers used in the process.

- Transfer of Cleaning Solutions: Hoses are used to transfer cleaning solutions and sanitizers to various parts of the dairy farm, including the milking parlor and equipment storage areas. This helps maintain a clean and hygienic environment.

- Feed and Water Systems: In some cases, food safe hoses are used in feed and water systems for livestock. While not directly related to human consumption, these hoses help maintain the quality of animal feed and water, indirectly impacting food safety.

Materials and Construction

Food safe hoses are critical components in the food and beverage industry, designed to safely convey various substances. Their construction and the materials used are paramount to prevent contamination, maintain product integrity, and ensure operational efficiency. Understanding these aspects is vital for selecting the appropriate hose for specific applications.

Materials Used in Food Safe Hoses

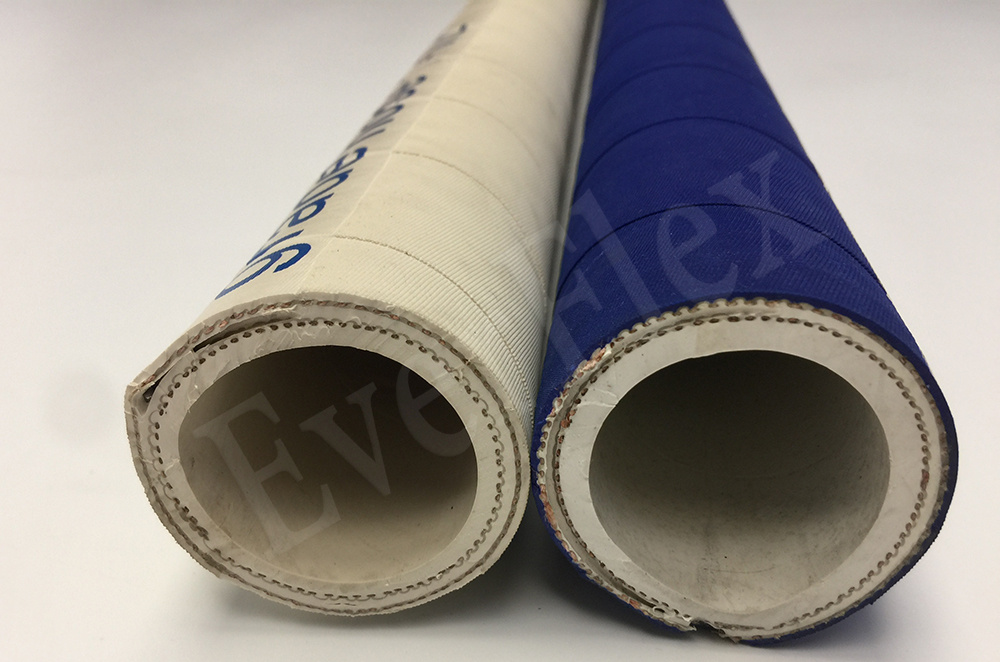

Food safe hoses are manufactured from a range of materials, each offering unique properties regarding chemical resistance, flexibility, and temperature tolerance. The selection of the appropriate material depends on the specific application and the substances being conveyed. These materials are chosen for their inertness and ability to withstand the harsh environments often encountered in food processing.The primary materials used in the construction of food-safe hoses include:* Silicone: Silicone hoses are prized for their exceptional flexibility, temperature resistance (ranging from -70°C to 260°C), and inertness.

They are highly resistant to a wide range of chemicals, including acids, bases, and solvents, making them suitable for various applications. Silicone’s flexibility allows for easy handling and maneuverability, while its smooth surface prevents bacterial buildup.* Polyvinyl Chloride (PVC): PVC hoses are a cost-effective option and offer good chemical resistance to many substances. They are generally less flexible than silicone and EPDM, but they are still relatively easy to handle.

Food-grade PVC is formulated to be non-toxic and compliant with food safety regulations. However, PVC’s temperature range is typically more limited than silicone or EPDM.* Ethylene Propylene Diene Monomer (EPDM): EPDM hoses provide excellent resistance to ozone, UV radiation, and a wide range of chemicals. They exhibit good flexibility and temperature resistance, making them suitable for both hot and cold applications.

EPDM is a robust material often chosen for its durability and longevity in demanding environments.* Thermoplastic Rubber (TPR): TPR hoses combine the flexibility of rubber with the processability of thermoplastics. They are often used in food-grade applications because of their good resistance to abrasion and various chemicals. TPR can be formulated to meet food safety standards and offers a balance of performance and cost-effectiveness.* Polyurethane (PU): Polyurethane hoses are known for their abrasion resistance, making them suitable for applications involving abrasive materials.

They offer good chemical resistance and flexibility. PU hoses are often used in conveying dry food products or materials with abrasive characteristics.The chemical resistance of each material varies. For instance, silicone demonstrates superior resistance to a broader spectrum of chemicals compared to PVC. EPDM excels in ozone and UV resistance, while PU offers excellent abrasion resistance.

Construction Methods of Food Safe Hoses

The construction of food-safe hoses varies depending on the material and the intended application. These methods are designed to ensure the hose’s durability, flexibility, and ability to withstand the pressures and temperatures encountered during operation.The primary construction methods include:* Extrusion: Extrusion is a common manufacturing process for producing hoses. The chosen material (e.g., silicone, PVC, EPDM) is heated and forced through a die, which shapes the hose into the desired profile.

This method allows for continuous production and precise control over the hose’s dimensions and wall thickness. Extruded hoses are often used for single-layer constructions.* Braiding: Braiding involves reinforcing the hose with a layer of braided material, typically textile or wire. This construction method enhances the hose’s pressure resistance and flexibility. Braiding is frequently employed in applications where the hose must withstand higher pressures.

The braided layer is usually encapsulated within the hose material.* Spiral Reinforcement: Spiral reinforcement uses a wire or rigid plastic spiral embedded within the hose wall. This construction method provides excellent kink resistance and crush resistance, making the hose suitable for vacuum applications or situations where the hose might be subjected to external forces. The spiral reinforcement is usually embedded within the hose material.* Multi-Layer Construction: Multi-layer construction combines different materials to optimize the hose’s performance.

For instance, a hose might have an inner layer of food-grade material (e.g., silicone) for contact with the conveyed substance, a reinforcing layer (e.g., braided textile), and an outer layer for abrasion resistance (e.g., EPDM).The construction method significantly impacts the hose’s flexibility, pressure rating, and overall durability. For example, a braided hose will typically have a higher pressure rating than an extruded hose.

Pros and Cons of Different Hose Materials

The following table provides a comparison of the pros and cons of different hose materials commonly used in food-safe applications. This information can aid in selecting the most suitable hose for a specific need.

| Material | Pros | Cons | Typical Applications |

|---|---|---|---|

| Silicone |

|

|

|

| PVC |

|

|

|

| EPDM |

|

|

|

| TPR |

|

|

|

Hose Selection and Sizing

Selecting and sizing the correct food-safe hose is crucial for maintaining the integrity of food products, ensuring efficient processing, and preventing contamination. This section Artikels the key considerations and provides practical guidance on determining the appropriate hose specifications for various applications. Careful attention to these details is essential for compliance with food safety regulations and optimal operational performance.

Factors for Hose Selection

Several factors must be considered when selecting a food-safe hose. These factors impact the hose’s suitability for a particular application, influencing its performance, durability, and safety.

- Fluid Compatibility: The hose material must be chemically compatible with the food product being conveyed. Consider the product’s pH, temperature, and any potential for reaction with the hose material. Refer to material compatibility charts provided by hose manufacturers. For example, a hose designed for dairy products may not be suitable for acidic fruit juices.

- Temperature Range: Determine the operating temperature range of the application. Select a hose rated for both the minimum and maximum temperatures the food product and the surrounding environment will reach. Exceeding the hose’s temperature rating can lead to degradation, cracking, and potential contamination.

- Pressure Rating: Assess the system’s operating pressure, including any pressure surges or spikes. The hose’s working pressure rating must exceed the maximum anticipated pressure. A hose rated for 100 psi may be sufficient for a gravity-fed system, while a pump-fed system might require a hose rated for 200 psi or higher.

- Cleaning and Sanitization Requirements: Consider the cleaning and sanitization protocols used in the application. The hose material must be resistant to the cleaning agents and sanitizers employed. Hoses should be able to withstand high-pressure washdowns, steam cleaning, and chemical sanitization without degradation.

- Abrasion Resistance: Evaluate the potential for abrasion, especially in applications involving the transfer of abrasive food products or where the hose is dragged or moved frequently. Hoses with reinforced construction and abrasion-resistant covers are often preferred in these situations.

- Flexibility: Consider the need for flexibility, especially in applications where the hose must bend around corners or in tight spaces. The hose’s flexibility impacts its ease of use and its ability to maintain a consistent flow rate.

- Regulatory Compliance: Ensure the hose meets all relevant food safety regulations, such as those established by the FDA (Food and Drug Administration) in the United States or the European Union’s regulations on food contact materials. Look for certifications or markings that indicate compliance.

- Size and Length: Determine the required hose diameter and length based on flow rate requirements, pressure drop considerations, and the distance the food product must travel.

Determining Hose Diameter and Length, Food safe hose

Calculating the appropriate hose diameter and length is critical for achieving the desired flow rate and minimizing pressure drop. Several factors influence these calculations, and understanding these relationships is essential for optimal system performance.

- Flow Rate: The required flow rate (typically measured in gallons per minute – GPM or liters per minute – LPM) is the primary driver for determining hose diameter. A higher flow rate necessitates a larger hose diameter to maintain the desired velocity and minimize pressure drop.

- Fluid Viscosity: The viscosity of the food product affects the pressure drop. More viscous fluids experience greater friction within the hose, leading to a higher pressure drop. This needs to be accounted for in the hose sizing calculations.

- Pressure Drop: Pressure drop refers to the reduction in pressure as the fluid flows through the hose. Excessive pressure drop can reduce pump efficiency and potentially damage the product. Minimizing pressure drop is important for maintaining product quality and reducing energy consumption.

- Hose Length: Longer hose lengths increase the pressure drop. The total equivalent length of the hose run, including fittings and bends, must be considered in the calculations.

- Velocity: Maintaining an appropriate fluid velocity within the hose is important. Too low a velocity can lead to settling of solids, while too high a velocity can cause excessive pressure drop and potential damage to the hose. Typical recommended velocities for food processing applications are between 3 and 10 feet per second (fps).

- Calculating Hose Diameter: While precise calculations require specialized hydraulic formulas, a general guideline is to use the following formula to estimate the hose diameter (D) in inches:

D = √( (0.408

– Q) / V )Where:

- Q = Flow rate in GPM

- V = Fluid velocity in feet per second (fps)

- Example: If the desired flow rate is 100 GPM and the recommended velocity is 5 fps, the estimated hose diameter would be approximately 2 inches.

Common Hose Sizes and Applications

A range of hose sizes is available for food-safe applications. The appropriate size depends on the specific requirements of the application, including flow rate, pressure, and the nature of the food product being conveyed.

- 1/2 inch to 1 inch ID hoses:

- Applications: Dispensing of small quantities, filling of bottles and containers, laboratory applications, and small-scale processing. Often used for flavorings, additives, and other minor ingredients.

- 1 inch to 2 inch ID hoses:

- Applications: Transfer of liquids such as milk, juice, and syrups. Also used for CIP (Clean-in-Place) systems in smaller facilities.

- 2 inch to 4 inch ID hoses:

- Applications: Bulk transfer of liquids and semi-solids in food processing plants. Examples include pumping of fruit purees, vegetable oils, and sauces. CIP systems in larger facilities.

- 4 inch and larger ID hoses:

- Applications: Large-scale transfer of high-volume products such as water, slurries, and bulk ingredients. Typically found in large food processing plants and breweries. Used for unloading tankers and railcars.

Cleaning and Maintenance

Maintaining the integrity and safety of food-safe hoses is crucial for preventing contamination and ensuring product quality. Regular cleaning and proper maintenance are essential practices that not only adhere to regulatory standards but also extend the lifespan of the hoses. Neglecting these aspects can lead to microbial growth, the formation of biofilms, and the potential for cross-contamination, all of which pose significant risks to consumer health and product efficacy.

Recommended Cleaning Procedures for Food Safe Hoses

Effective cleaning of food-safe hoses involves a multi-step process designed to remove all traces of food residue and potential contaminants. The specific procedures may vary depending on the type of hose, the food product handled, and the operational environment.

- Pre-rinse: Before any cleaning process, a thorough pre-rinse with potable water is essential. This initial step removes loose debris and residual product, preventing it from adhering to the hose walls during subsequent cleaning stages. The water temperature should be appropriate for the specific food product, typically between 20°C and 40°C.

- Detergent Cleaning: Use a suitable food-grade detergent, specifically formulated for the food processing industry. The detergent type depends on the nature of the food product and the type of contaminants. For example, alkaline detergents are effective against fats and proteins, while acidic detergents are better for removing mineral deposits. Follow the manufacturer’s instructions for detergent concentration, contact time, and water temperature.

- Rinse: After detergent cleaning, thoroughly rinse the hose with potable water to remove all detergent residues. This is critical to avoid any chemical contamination of subsequent food products. Ensure that the rinse water is free from any visible detergent traces.

- Inspection: After cleaning, inspect the hose for any signs of damage, such as cracks, abrasions, or discoloration. These can harbor contaminants and compromise the hose’s integrity. Replace damaged hoses immediately.

- Post-Rinse: A final rinse with potable water is recommended to ensure that no cleaning agents remain. This step further safeguards against potential chemical contamination.

Methods for Sanitizing Food Safe Hoses

Sanitizing food-safe hoses is a critical step in eliminating microorganisms and preventing the growth of biofilms. This process follows cleaning and involves the use of specific sanitizing agents. The selection of the sanitizing agent should be based on its effectiveness, safety, and compatibility with the hose material.

- Sanitizing Agents: Commonly used sanitizing agents include:

- Chlorine-based Sanitizers: Effective and inexpensive, but can corrode certain materials and may leave a residual taste or odor. The concentration of chlorine solution used should be within the recommended range, typically 50-200 ppm (parts per million) of available chlorine, depending on the specific regulations and the application. For instance, in the dairy industry, it is crucial to adhere to the standards set by regulatory bodies like the FDA.

- Quaternary Ammonium Compounds (Quats): Effective against a wide range of microorganisms, and generally safe to use. However, they can be inactivated by hard water and organic matter. The concentration is usually between 100 and 400 ppm.

- Peracetic Acid (PAA): A highly effective sanitizer with a broad spectrum of antimicrobial activity. It is biodegradable and leaves no harmful residues. PAA solutions typically used at concentrations of 50-200 ppm.

- Hydrogen Peroxide: Effective, readily available, and breaks down into water and oxygen. However, it can be less effective in the presence of organic matter. Concentrations typically range from 100 to 500 ppm.

- Sanitization Procedure:

- After cleaning and rinsing, prepare the sanitizing solution according to the manufacturer’s instructions.

- Introduce the sanitizing solution into the hose, ensuring that all internal surfaces are in contact with the solution for the recommended contact time, usually between 1 and 10 minutes, depending on the sanitizer used and the type of contamination expected.

- Allow the sanitizer to drain completely from the hose.

- Rinse the hose with potable water, if required by the sanitizing agent’s instructions or regulatory requirements.

Best Practices for Storing Food Safe Hoses

Proper storage of food-safe hoses is essential for preventing contamination, extending their lifespan, and ensuring their readiness for use. Adhering to these best practices helps maintain the integrity of the hoses and minimizes the risk of product contamination.

- Clean and Dry: Prior to storage, ensure that the hoses are thoroughly cleaned, sanitized, and completely dried. Moisture can promote the growth of mold and bacteria.

- Protected Environment: Store the hoses in a clean, dry, and well-ventilated area, away from direct sunlight, extreme temperatures, and sources of contamination. Exposure to UV light can degrade the hose material over time.

- Proper Positioning: Store hoses in a manner that prevents kinking or sharp bends, which can damage the hose structure and reduce its lifespan. Consider hanging the hoses vertically or storing them in a coil, depending on the size and type of hose.

- Separate Storage: Store food-safe hoses separately from other equipment and chemicals to prevent cross-contamination. Designate a specific storage area for food-safe hoses only.

- Identification: Clearly label the hoses with information such as the date of cleaning and sanitization, the type of product they are approved for, and any other relevant details. This ensures traceability and proper usage.

- Regular Inspection: Regularly inspect the hoses for any signs of damage, such as cracks, abrasions, or discoloration. Replace any damaged hoses immediately.

- Covering or Wrapping: If the hoses are stored in an area where they could be exposed to dust or other airborne contaminants, consider covering or wrapping them with a protective material. This provides an additional layer of protection.

Common Problems and Solutions

The reliable operation of food safe hoses is crucial for maintaining the integrity of food products and ensuring consumer safety. However, these hoses are susceptible to various issues that can compromise their performance and pose risks. Understanding the common problems and implementing appropriate solutions are essential for preventing contamination, reducing downtime, and extending the lifespan of these critical components.

Cracking and Degradation

Hoses used in food processing can experience cracking and degradation due to several factors. These issues can compromise the hose’s integrity, potentially leading to leaks and contamination.

- Causes of Cracking:

- Material Degradation: Exposure to harsh chemicals, extreme temperatures, or UV radiation can break down the hose material over time. For example, hoses used in cleaning processes with strong sanitizers may exhibit accelerated degradation.

- Ageing: Over time, the hose material naturally degrades, becoming less flexible and more prone to cracking.

- Mechanical Stress: Bending, twisting, or kinking the hose repeatedly can create stress points that lead to cracking.

- Solutions for Cracking and Degradation:

- Material Selection: Choose hoses made from materials resistant to the specific chemicals, temperatures, and environmental conditions present in the application. For example, silicone hoses are often preferred for high-temperature applications, while EPDM hoses are suitable for many cleaning solutions.

- Proper Storage: Store hoses in a cool, dry place away from direct sunlight and sources of ozone.

- Regular Inspection: Conduct regular visual inspections for signs of cracking, discoloration, or other damage.

- Replacement: Replace hoses immediately if any signs of cracking or degradation are observed.

Kinking and Restriction of Flow

Kinking, or bending the hose sharply, is a common problem that can restrict the flow of product, leading to operational inefficiencies and potential damage to the hose.

- Causes of Kinking:

- Improper Handling: Bending the hose beyond its minimum bend radius can cause kinking.

- Inadequate Support: Lack of support, especially for long hoses, can lead to sagging and kinking.

- External Pressure: Pressure from equipment or other objects can compress and kink the hose.

- Solutions for Kinking and Restriction of Flow:

- Proper Handling Techniques: Avoid sharp bends and ensure the hose is not twisted during use.

- Hose Supports: Use hose supports, such as clamps or hangers, to prevent sagging and kinking, particularly for long or flexible hoses.

- Appropriate Hose Length: Use the correct length of hose to avoid excessive bending or stretching.

- Selection of Flexible Hoses: Consider using hoses with greater flexibility to reduce the likelihood of kinking in applications with tight bends.

Leaks and Contamination

Leaks in food safe hoses pose a significant risk of product contamination and loss, potentially leading to health hazards and financial losses.

- Causes of Leaks:

- Damage to the Hose Wall: Cracks, punctures, or abrasions can create pathways for leakage.

- Loose or Failing Connections: Improperly installed or maintained fittings can cause leaks at the connection points.

- Material Degradation: Degradation of the hose material can lead to a loss of integrity and subsequent leaks.

- Solutions for Leaks and Contamination:

- Regular Inspections: Conduct frequent visual inspections of the hose and connections for signs of leaks.

- Proper Installation: Ensure fittings are correctly installed and tightened according to the manufacturer’s specifications.

- Preventative Maintenance: Implement a regular maintenance schedule, including hose replacement, to prevent leaks.

- Sanitation Practices: Maintain rigorous sanitation protocols to minimize the risk of microbial contamination.

Impact of Improper Hose Usage

Improper hose usage can have a direct and detrimental impact on food safety and product quality. These consequences can lead to significant operational and financial setbacks.

- Food Safety Risks:

- Contamination: Leaks or cracks in the hose can allow contaminants, such as bacteria, chemicals, or foreign objects, to enter the food product.

- Cross-Contamination: If hoses are not properly cleaned and sanitized between uses, they can transfer allergens or pathogens to different food products.

- Product Recalls: Contamination can necessitate costly product recalls, damaging the brand’s reputation and leading to financial losses.

- Product Quality Issues:

- Flavor and Odor Changes: Hose materials that degrade or leach can impart off-flavors or odors to the food product.

- Appearance Issues: Contamination with particulate matter can affect the appearance of the food product.

- Reduced Shelf Life: Microbial contamination can accelerate spoilage and reduce the shelf life of the product.

- Operational and Financial Consequences:

- Downtime: Hose failures can lead to production stoppages, resulting in lost productivity and revenue.

- Increased Costs: Repairing or replacing damaged hoses, cleaning up spills, and addressing contamination issues can be expensive.

- Legal and Regulatory Penalties: Failure to comply with food safety regulations can result in fines and other penalties.

Regulations and Compliance

The use of food safe hoses is subject to a variety of regulations and guidelines designed to protect public health and ensure the safety of food products. Compliance with these standards is critical for manufacturers, processors, and distributors involved in the food industry. Adhering to these regulations minimizes the risk of contamination, maintains product integrity, and facilitates trade across international borders.

Relevant Regulations and Guidelines

Several organizations and governmental bodies establish and enforce regulations related to food safe hoses. These regulations often vary by region, but the underlying goal remains consistent: to prevent the introduction of harmful substances into the food supply. Compliance is not merely a legal requirement but a crucial component of responsible food production practices.The following are some of the key regulatory bodies and their corresponding standards:

- United States: The Food and Drug Administration (FDA) plays a central role in regulating food contact materials, including hoses. The primary regulation is 21 CFR (Code of Federal Regulations) Part 177, which specifies the acceptable materials and formulations for food contact.

- European Union: The European Food Safety Authority (EFSA) sets standards and provides scientific advice on food safety. The main regulation is Regulation (EC) No 1935/2004, which Artikels the general requirements for all food contact materials.

Specific regulations, such as Regulation (EU) No 10/2011, detail the requirements for plastic materials and articles intended to come into contact with food.

- Canada: Health Canada’s Food Directorate regulates food contact materials under the Food and Drugs Act and Regulations. Materials must meet the requirements for safety and suitability for their intended use.

- Other Regions: Many other countries and regions have their own food safety regulations, often based on international standards or adapting them to local contexts.

These may include specific requirements for hose materials, labeling, and testing.

Importance of Compliance with Food Safety Standards

Compliance with food safety standards is paramount for several reasons, including public health, consumer confidence, and business continuity. Failure to comply can lead to severe consequences, including product recalls, legal penalties, and damage to a company’s reputation.Here’s why compliance is essential:

- Public Health: Food safety regulations are designed to prevent contamination by harmful substances such as bacteria, chemicals, and toxins. Compliance ensures that food products are safe for consumption, protecting consumers from illness and potential long-term health problems.

- Consumer Confidence: Consumers trust that the food they purchase is safe and produced under hygienic conditions. Compliance with food safety standards builds and maintains consumer confidence in food products and brands.

- Product Integrity: Food safe hoses are designed to maintain the integrity of the food product by preventing the leaching of harmful substances from the hose material into the food. This maintains the quality, flavor, and nutritional value of the food.

- Legal and Financial Implications: Non-compliance can result in product recalls, fines, and legal action. These consequences can be financially devastating for food businesses.

- Market Access: Compliance with food safety standards is often a prerequisite for selling products in various markets.

Adherence to regulations facilitates trade and allows businesses to access a wider customer base.

- Operational Efficiency: Implementing and maintaining a robust food safety program can improve operational efficiency by reducing waste, preventing contamination, and streamlining processes.

Summary of Regulations

The following blockquotes provide summaries of key regulations and their implications. These summaries are simplified and should not be considered a complete legal interpretation.

United States (FDA – 21 CFR Part 177): This regulation establishes the standards for food contact materials, including hoses. It defines acceptable materials, formulations, and testing requirements to ensure that substances from the hose do not migrate into the food in harmful amounts. The regulation covers various aspects, including the specific polymers and additives permitted for use in food contact applications.

European Union (Regulation (EC) No 1935/2004): This regulation sets the general requirements for all food contact materials, emphasizing that they must be safe and not transfer substances to food in quantities that could endanger human health. It requires materials to be manufactured according to Good Manufacturing Practices (GMP) and provides a framework for specific regulations on different material types.

European Union (Regulation (EU) No 10/2011): This regulation specifies the requirements for plastic materials and articles intended to come into contact with food. It includes a positive list of authorized substances, migration limits, and testing protocols. The regulation is designed to ensure that plastic materials are safe and do not pose a risk of contamination.

Canada (Food and Drugs Act and Regulations): This legislation requires that food contact materials be safe and suitable for their intended use. The Food Directorate assesses materials based on their composition and potential for migration into food. The regulations aim to prevent any migration of harmful substances into the food supply.

Food Safe Hose Accessories

Food safe hoses, while crucial, are only part of the equation when it comes to maintaining a hygienic and efficient fluid transfer system. The accessories used with these hoses play a vital role in ensuring the integrity of the food product, preventing contamination, and facilitating ease of use. The proper selection and application of these components are just as important as the hose itself.

Fittings, Clamps, and Couplings

The accessories connected to food safe hoses are varied, each serving a specific purpose in the overall functionality of the system. These components ensure secure connections, prevent leaks, and allow for easy assembly and disassembly for cleaning and maintenance.

- Fittings: Fittings connect the hose to equipment or other hoses. They come in various types, including:

- Cam and Groove Fittings: These are quick-connect fittings commonly used for transferring liquids. They consist of a male adapter and a female coupler that are connected using levers or “cams.”

- Tri-Clamp Fittings (also known as Sanitary Fittings): Widely used in the food and beverage industry due to their sanitary design, these fittings feature a clamp that compresses a gasket between two ferrules. This creates a crevice-free connection that minimizes the risk of bacterial growth.

- NPT (National Pipe Thread) Fittings: These threaded fittings are used for general-purpose applications and are available in various materials, including stainless steel and brass. They are less common in food-grade applications due to the potential for harboring bacteria in the threads.

- Clamps: Clamps secure the hose to the fittings, preventing leaks and ensuring a tight seal. Different types of clamps include:

- Hose Clamps: These are generally adjustable and can be tightened using a screw or other mechanism. They are suitable for lower-pressure applications.

- Ear Clamps: Also known as Oetiker clamps, these are typically installed using a special tool and provide a secure, tamper-resistant connection.

- Band Clamps: These are used for high-pressure applications and consist of a band that is tightened using a bolt.

- Couplings: Couplings allow for the connection of two hoses or the connection of a hose to equipment. Types of couplings include:

- Quick-Disconnect Couplings: These allow for rapid connection and disconnection of hoses without the need for tools.

- Swivel Couplings: These allow for the hose to rotate freely, preventing kinking and twisting.

Selecting Accessories for Different Applications

Choosing the right accessories depends on several factors, including the type of food product being transferred, the operating pressure and temperature, and the cleaning and sanitization protocols in place. Careful consideration of these elements is crucial to ensure both the safety and efficiency of the system.

- Food Product Compatibility: The accessories must be made of materials that are compatible with the food product being transferred. This means that the materials should not react with the food product, impart any taste or odor, or leach any harmful substances. Stainless steel is a common choice due to its inertness and resistance to corrosion.

- Pressure and Temperature Ratings: The fittings, clamps, and couplings must be rated for the operating pressure and temperature of the system. Exceeding these ratings can lead to leaks, hose failure, and potential safety hazards.

- Cleanability: The accessories should be designed for easy cleaning and sanitization. Crevice-free designs, such as those found in Tri-Clamp fittings, are preferred to prevent the buildup of bacteria and other contaminants.

- Regulatory Compliance: All accessories must comply with relevant food safety regulations, such as those established by the FDA in the United States and the European Union.

For example, when transferring milk, which is a highly perishable product, the entire system, including the hose and all accessories, must be constructed of food-grade materials. The fittings must be Tri-Clamp or similar sanitary fittings, and all components must be regularly cleaned and sanitized to prevent bacterial growth. The system must be able to withstand the pressures and temperatures involved in the milk processing operation.

Examine how mexican jewish food can boost performance in your area.

In contrast, when transferring a less sensitive product, such as fruit juice, the requirements may be slightly less stringent, but the accessories still need to be food-grade and suitable for the operating conditions.

Food Safe Hose Assembly: A Detailed Description

A food safe hose assembly is a system designed to transfer food products safely and efficiently. It consists of a hose, fittings, clamps, and other components that work together to create a secure and leak-proof connection. The following is a detailed description of a typical food safe hose assembly.

- Hose: The hose is the primary component of the assembly, providing the pathway for the food product. It is typically made of food-grade materials such as EPDM, silicone, or PTFE (Teflon). The hose is selected based on the type of food product, the operating pressure and temperature, and the cleaning and sanitization requirements.

- Fittings: Fittings connect the hose to equipment or other hoses. As mentioned before, Tri-Clamp fittings are often used in food processing due to their sanitary design. These fittings provide a crevice-free connection that minimizes the risk of bacterial growth. The fitting material is selected to be compatible with the food product and the cleaning agents used.

- Gaskets: Gaskets are used to create a seal between the hose and the fittings. They are typically made of food-grade materials, such as EPDM or silicone, and must be compatible with the food product and cleaning agents.

- Clamps: Clamps secure the hose to the fittings, preventing leaks and ensuring a tight seal. Tri-Clamp fittings use a clamp to compress the gasket between the ferrules. The clamp is made of stainless steel or another corrosion-resistant material.

- Strain Relief: Strain relief is used to prevent the hose from kinking or bending at the fittings. It extends the life of the hose and prevents premature failure.

- Identification and Traceability: The assembly should be clearly labeled with information about the hose, fittings, and other components, including the manufacturer, material, and pressure rating. This information is crucial for traceability and maintenance.

A well-designed food safe hose assembly ensures the integrity of the food product, prevents contamination, and facilitates ease of use. Regular inspection and maintenance are essential to ensure the assembly continues to function correctly and complies with all relevant regulations. For instance, in a brewery, a food safe hose assembly might be used to transfer beer from the fermenter to the bottling line.

The hose would be constructed of a food-grade material, and Tri-Clamp fittings would be used to connect the hose to the equipment. The entire assembly would be cleaned and sanitized regularly to prevent contamination and ensure the quality of the beer.

Latest Innovations: Food Safe Hose

The food-safe hose industry is constantly evolving, driven by demands for enhanced hygiene, durability, and efficiency. Recent advancements focus on material science, design improvements, and the integration of smart technologies. These innovations aim to optimize food processing operations, minimize contamination risks, and reduce operational costs.

Advanced Materials and Construction

The selection of materials is critical for food-safe hoses. Manufacturers are increasingly using advanced polymers and composites to improve performance.

- Thermoplastic Elastomers (TPEs): TPEs offer a blend of rubber-like elasticity and thermoplastic processability. They are replacing traditional materials like PVC due to their superior flexibility, resistance to kinking, and broader temperature ranges. For example, some TPE hoses can withstand temperatures from -40°C to 150°C, expanding their application possibilities in various food processing environments.

- Fluoropolymers (e.g., PTFE, FEP): Fluoropolymers provide exceptional chemical resistance and inertness, making them ideal for handling aggressive cleaning agents and a wide range of food products. They have a low coefficient of friction, which facilitates easier cleaning and reduces the risk of bacterial buildup. Consider a dairy processing plant using a PTFE hose for transporting milk; its resistance to cleaning chemicals and its smooth internal surface are critical for maintaining product quality and preventing contamination.

- Multi-Layer Construction: Innovative hose designs incorporate multiple layers to enhance durability and performance. These constructions often feature a food-contact layer, a reinforcement layer (e.g., braided or spiral), and an outer protective layer. This design improves pressure resistance, flexibility, and abrasion resistance. A common example is a hose used in beverage production, where the multi-layer construction provides both flexibility for maneuvering around equipment and robustness to withstand the constant pressure fluctuations.

Smart Hose Technology

The integration of smart technology is a growing trend in the food-safe hose industry, leading to enhanced monitoring and management capabilities.

- Embedded Sensors: Hoses can now incorporate embedded sensors to monitor critical parameters such as temperature, pressure, and flow rate. This data can be transmitted wirelessly to a central control system, enabling real-time monitoring and early detection of potential issues. For instance, a meat processing plant could use hoses with embedded temperature sensors to ensure that the product remains within the required temperature range, thus preserving its quality and safety.

- RFID Tagging: Radio-frequency identification (RFID) tags can be embedded in hoses to track their location, usage, and maintenance history. This technology streamlines inventory management, facilitates compliance with regulatory requirements, and helps prevent the use of hoses beyond their recommended service life. A brewery, for example, could use RFID-tagged hoses to track the frequency of cleaning cycles, ensuring adherence to hygiene protocols and minimizing the risk of cross-contamination.

Features of a Cutting-Edge Food Safe Hose

A cutting-edge food-safe hose incorporates several advanced features to optimize performance and ensure safety.

- Smooth, Non-Porous Inner Layer: The inner layer is constructed from a food-grade material like a fluoropolymer or a specially formulated TPE, offering a smooth, non-porous surface. This design minimizes the risk of bacterial growth and makes cleaning easier and more effective. This surface prevents food particles from adhering, ensuring thorough cleaning and minimizing contamination risks.

- Reinforced Construction: The hose features a robust reinforcement layer, typically a braided or spiraled construction, to withstand high pressures and prevent kinking or collapse. This design ensures the hose maintains its shape and functionality even under challenging operating conditions, such as those encountered in high-pressure cleaning systems.

- Durable Outer Layer: The outer layer is made from a material that is resistant to abrasion, chemicals, and UV exposure. This protective layer extends the hose’s lifespan and prevents damage from external factors, ensuring it remains safe and effective over time. This design reduces the risk of premature failure and associated downtime and costs.

- Integrated Sensor Technology (Optional): The hose may incorporate embedded sensors to monitor key parameters such as temperature, pressure, and flow rate. This feature provides real-time data to the user, allowing for proactive maintenance and early detection of potential issues. For example, a dairy plant could use hoses with temperature sensors to ensure that milk remains within the required temperature range.

- Color-Coded or Traceable Materials: To enhance safety and prevent cross-contamination, the hose might be color-coded or made from traceable materials. This feature allows for easy identification and verification of the hose’s food-safe status. This helps prevent the use of hoses in unauthorized applications, reducing the risk of contamination and ensuring compliance with regulations.

Conclusion

In conclusion, understanding the nuances of food safe hoses is paramount for industries prioritizing product safety and operational excellence. From selecting the right materials and sizes to adhering to stringent cleaning and maintenance protocols, every detail contributes to the overall integrity of the process. By staying informed about the latest innovations and regulations, businesses can ensure their operations remain compliant and efficient, ultimately safeguarding consumer health and upholding product quality.

The journey through food safe hoses highlights the importance of informed choices and the commitment to maintaining the highest standards of hygiene and safety.