Food truck fire inspection checklist: It’s a crucial topic, and for good reason. Food trucks, those mobile culinary havens, present unique fire safety challenges. From sizzling grills to high-powered electrical systems, the potential for fire is ever-present. This isn’t just about regulations; it’s about protecting lives, businesses, and the vibrant food truck culture we all enjoy.

This guide dives deep into the world of food truck fire safety. We’ll explore the essential elements of a thorough inspection, covering everything from fire suppression systems and cooking equipment to electrical safety and emergency exits. We’ll also look at the fire codes and regulations that govern these mobile eateries, ensuring you’re well-informed and prepared. The goal is simple: to help food truck owners and operators create a safe environment for themselves, their staff, and their customers, while also safeguarding their valuable investments.

Introduction to Food Truck Fire Safety

The bustling food truck industry, offering culinary delights on wheels, presents unique fire safety challenges. Ensuring the safety of both the operators and the public is paramount, given the confined spaces, high heat, and the presence of flammable materials inherent in food truck operations. Neglecting fire safety can lead to devastating consequences, including significant financial losses, injuries, and even fatalities.

Critical Importance of Fire Safety in Food Trucks

Fire safety is not merely a regulatory requirement but a fundamental aspect of running a successful and responsible food truck business. The inherent risks associated with cooking operations, combined with the mobility of these establishments, necessitate a proactive and comprehensive approach to fire prevention and mitigation. A food truck fire can quickly escalate, fueled by cooking oils, propane tanks, and the close proximity of combustible materials.

Common Fire Hazards in Food Truck Operations

Several factors contribute to the heightened fire risk in food trucks. Understanding these hazards is crucial for implementing effective preventative measures.

- Cooking Equipment: The use of deep fryers, grills, and stovetops generates significant heat and the potential for grease fires. Regular cleaning and maintenance are essential to prevent grease buildup.

- Electrical Systems: Overloaded circuits, faulty wiring, and the use of improper extension cords can spark fires. Electrical inspections and adherence to safety standards are critical.

- Propane and Fuel Storage: Improper storage and handling of propane tanks pose a significant explosion hazard. Leaks and damage to tanks can lead to fires.

- Ventilation Systems: Inadequate ventilation can lead to grease accumulation in exhaust systems, creating a fire hazard. Regular cleaning and maintenance of ventilation systems are crucial.

- Cooking Oil Disposal: Improper disposal of used cooking oil can lead to fires. Adhering to proper disposal procedures is essential.

Statistics on Food Truck Fires and Their Impact

Food truck fires, while not as frequently reported as residential or commercial fires, can have a significant impact. According to reports from the National Fire Protection Association (NFPA), food truck fires can cause substantial property damage and business interruption. The economic consequences of a food truck fire can be devastating, including the loss of equipment, inventory, and revenue. Moreover, the potential for injuries to operators and customers is a serious concern.

The NFPA estimates that thousands of food truck fires occur annually, resulting in millions of dollars in property damage and numerous injuries.

The emotional toll on the owners and employees involved can be substantial, and the impact on the community, including loss of a local business, should also be considered.

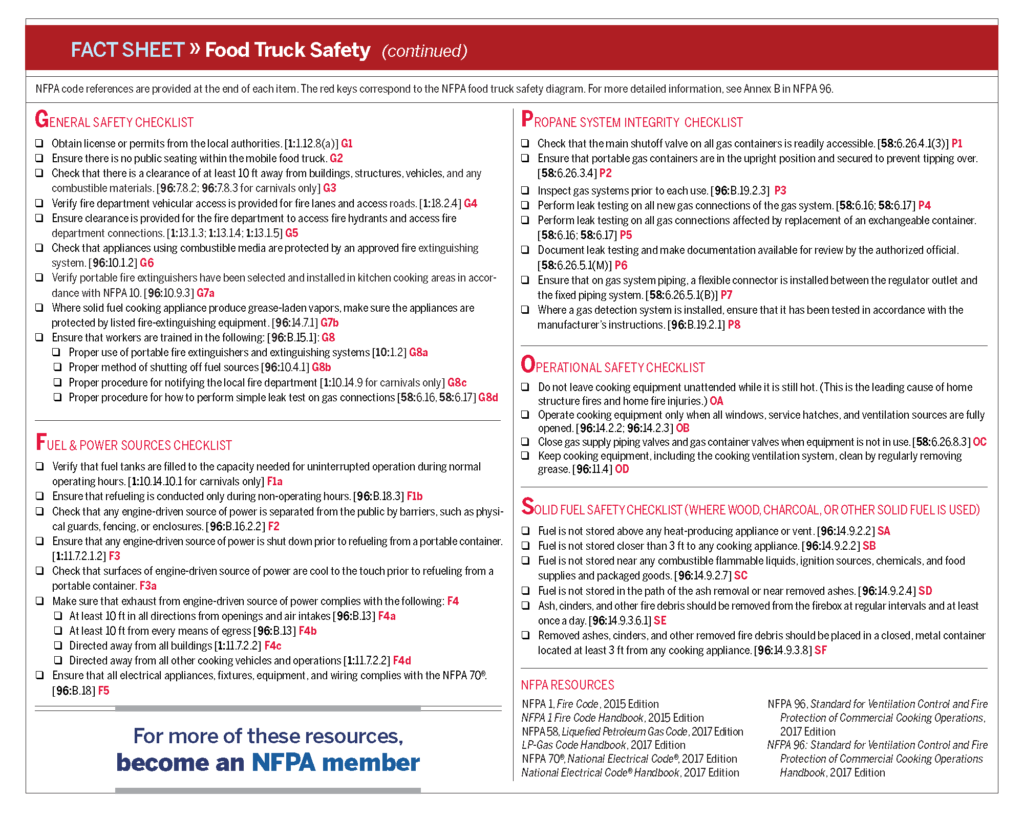

Understanding Fire Codes and Regulations: Food Truck Fire Inspection Checklist

Navigating the complex landscape of fire codes and regulations is crucial for food truck owners. Compliance not only ensures the safety of employees and customers but also prevents costly fines and potential business shutdowns. Understanding the specific requirements of each jurisdiction is paramount, as regulations can vary significantly from state to state and even city to city.

Relevant Fire Codes and Jurisdictional Variations

Fire safety standards for food trucks are primarily governed by local, state, and sometimes federal regulations. These codes are typically based on model fire codes, such as the National Fire Protection Association (NFPA) codes and the International Fire Code (IFC), but local jurisdictions often adopt and modify these codes to suit their specific needs and risk profiles. This leads to significant variations in requirements across different areas.

- National Fire Protection Association (NFPA): The NFPA develops and publishes numerous codes and standards related to fire safety. NFPA 1, Fire Code, and NFPA 96, Ventilation Control and Fire Protection of Commercial Cooking Operations, are particularly relevant to food trucks.

- International Fire Code (IFC): The IFC is a widely adopted model code that addresses fire safety requirements for various occupancies, including food trucks. It provides a framework for fire prevention and protection measures.

- Local Amendments: Cities and counties frequently amend the model codes to address local conditions and concerns. These amendments can cover everything from the type of fire extinguishers required to the spacing between food trucks.

Comparing Fire Safety Requirements Across Jurisdictions

The specific fire safety requirements for food trucks vary considerably depending on the location. A food truck operating in one city might face different regulations than one operating just a few miles away in another city or county. These variations can impact everything from the equipment needed to the operational procedures required.For example:

- Fire Suppression Systems: Some jurisdictions may require a specific type of fire suppression system, such as a wet chemical system, for cooking appliances, while others may allow for alternative systems or have different maintenance requirements.

- Ventilation: Ventilation requirements, including the type of hood and ductwork, the use of grease filters, and the frequency of cleaning, can differ. For instance, one city might mandate a specific filter type, while another might focus on regular inspection and cleaning schedules.

- Fire Extinguishers: The number, type, and placement of fire extinguishers are subject to local regulations. A jurisdiction might require a specific class of extinguisher based on the types of cooking oils used, while another may mandate a certain number of extinguishers based on the size of the truck.

- Fuel Storage: The regulations concerning the storage of propane or other fuels, including tank size, placement, and ventilation, vary significantly. Some areas may have strict limitations on the amount of fuel allowed on the truck.

- Permitting and Inspections: The permitting process and the frequency of fire safety inspections also differ. Some cities may require annual inspections, while others might conduct inspections more or less frequently. The cost of permits and inspections can also vary.

Specific Sections of Fire Codes Relevant to Food Truck Inspections

Food truck fire inspections focus on several key areas Artikeld in fire codes. Inspectors check for compliance with regulations related to cooking equipment, ventilation, fire suppression systems, and fuel storage.The following sections of the fire codes are particularly relevant:

- Cooking Equipment and Hoods (NFPA 96, IFC Chapter 6): This section addresses the design, installation, and maintenance of cooking appliances and ventilation systems, including grease removal devices, exhaust hoods, and ductwork. Inspectors examine the type of cooking equipment, the presence and condition of grease filters, and the frequency of hood cleaning.

- Fire Suppression Systems (NFPA 17A, IFC Chapter 9): This covers the requirements for fire suppression systems, including the type of system, its installation, maintenance, and inspection. Inspectors verify that the system is appropriate for the cooking appliances and that it has been properly inspected and serviced.

- Portable Fire Extinguishers (NFPA 10, IFC Chapter 9): This section Artikels the requirements for portable fire extinguishers, including the type, size, placement, and inspection of extinguishers. Inspectors ensure that the correct types of extinguishers are present and that they are readily accessible and in good working order.

- Fuel Storage and Handling (IFC Chapter 6): This covers the safe storage and handling of flammable liquids and gases, including propane. Inspectors check the location, ventilation, and security of fuel storage tanks.

- Electrical Systems (NFPA 70, National Electrical Code, IFC Chapter 6): This section covers electrical wiring, equipment, and appliances, and is vital for preventing electrical fires. Inspectors check for proper wiring, grounding, and the use of approved electrical equipment.

- Means of Egress (IFC Chapter 10): Although a food truck is a small space, inspectors still evaluate means of egress, ensuring there are clear pathways for escape in case of a fire. This includes ensuring that doors and windows are unobstructed.

Understanding these sections and their specific requirements is crucial for food truck owners to ensure compliance and pass fire safety inspections.

The Food Truck Fire Inspection Checklist

Food truck owners must navigate a complex landscape of regulations to ensure the safety of their operations and comply with local fire codes. A critical tool in this process is the fire inspection checklist. This document serves as a comprehensive guide, outlining the specific areas and items that inspectors will evaluate to determine if a food truck meets the required safety standards.

Successful completion of the inspection is crucial for obtaining the necessary permits to operate legally.

The Food Truck Fire Inspection Checklist: Overview

The fire inspection checklist is designed to be a standardized document used by fire marshals and other authorized inspectors. It provides a structured framework for evaluating a food truck’s fire safety measures. The checklist ensures that all critical areas are assessed, promoting consistency and fairness across inspections. It is not merely a list of items; it is a critical component of the fire safety system.A typical food truck fire inspection checklist will cover various aspects of fire safety.

The following table Artikels key areas and items commonly included in such checklists, along with the required actions and space for inspector notes. This information is presented to give a general overview and should not be considered a substitute for the official checklist provided by the local fire department.

Obtain recommendations related to food trucks in brooklyn ny that can assist you today.

| Inspection Area | Specific Item | Required Action | Inspector Notes |

|---|---|---|---|

| Fire Suppression System | Type of system (e.g., Ansul, Pyro-Chem) | System must be appropriate for the type of cooking equipment and meet the required standards. | Note the system’s make, model, and last inspection date. Verify certification. |

| Fire Suppression System | Nozzles and Coverage | Ensure all nozzles are properly positioned to protect cooking surfaces. Coverage must be complete. | Inspect for obstructions and ensure nozzles are free of grease buildup. |

| Fire Suppression System | System Inspection Tag | A current inspection tag must be visibly displayed. | Verify the inspection date and the name of the certified technician. |

| Fire Extinguishers | Type and Placement | Food trucks must have the correct type and number of fire extinguishers (typically Class K for cooking oil fires and Class ABC for general fires). They must be easily accessible. | Note the type, size, and location of each extinguisher. Check for any obstructions. |

| Fire Extinguishers | Inspection and Maintenance | Extinguishers must be inspected monthly and maintained annually by a certified professional. | Verify inspection tags and maintenance records. Check for pressure gauge readings. |

| Fuel Systems | Propane Tanks | Propane tanks must be properly secured, vented, and have appropriate safety valves. | Inspect for leaks, damage, and proper distance from cooking equipment. Verify tank size compliance. |

| Fuel Systems | Fuel Lines | Fuel lines must be in good condition, free of leaks, and properly routed. | Inspect for wear and tear. Ensure lines are protected from heat and physical damage. |

| Electrical Systems | Wiring and Outlets | Wiring must be properly installed and meet electrical code requirements. Outlets must be GFCI-protected. | Check for frayed wires, overloaded circuits, and the use of extension cords. |

| Electrical Systems | Generator (if applicable) | Generators must be properly vented and maintained. They should be positioned away from cooking areas. | Check for proper ventilation, fuel storage, and exhaust routing. |

| Cooking Equipment | Grease Buildup | Cooking equipment, including hoods and vents, must be kept clean to prevent grease fires. | Inspect for grease accumulation and ensure regular cleaning schedules are in place. |

| Cooking Equipment | Clearances | Maintain proper clearances between cooking equipment and combustible materials. | Verify distances between equipment and walls, ceilings, and other items. |

| Ventilation System | Hood and Ductwork | Hoods and ductwork must be properly installed, cleaned regularly, and meet ventilation requirements. | Inspect for grease buildup, proper filtration, and compliance with ventilation codes. |

| Emergency Procedures | Fire Safety Plan | A written fire safety plan must be in place, outlining procedures for fire emergencies. | Review the plan and ensure it is accessible to all employees. |

| Emergency Procedures | Employee Training | All employees must be trained on fire safety procedures, including the use of fire extinguishers. | Verify training records and observe employee knowledge of procedures. |

Fire Suppression Systems and Equipment

Food truck operators face unique fire safety challenges due to the confined spaces, high heat, and presence of flammable cooking oils and grease. Ensuring adequate fire suppression systems and equipment is paramount for protecting lives, property, and business continuity. This section details the essential requirements, maintenance procedures, and inspection protocols for fire suppression systems in food trucks.

Fire Suppression System Requirements and Installation

Food trucks, by their very nature, pose a significant fire risk. The presence of cooking oils, open flames, and electrical equipment creates a dangerous environment. To mitigate these risks, fire suppression systems are mandated in most jurisdictions, offering crucial protection against kitchen fires.Fire suppression systems typically include:

- Automatic Wet Chemical Systems: These systems are designed to automatically detect and suppress fires, especially those involving cooking oils and grease. They use a wet chemical agent that smothers the fire and cools the cooking surfaces. These systems are often installed above cooking appliances like fryers, grills, and stovetops.

- Handheld Fire Extinguishers: Complementing the automatic systems, handheld fire extinguishers are essential for fighting smaller fires or for use when the automatic system is not activated. Type K extinguishers are specifically designed for kitchen fires involving cooking oils and fats, while ABC extinguishers are suitable for other common fire types.

- System Components: The system encompasses various components, including nozzles, detection devices (e.g., fusible links), a control unit, and the wet chemical agent reservoir. These components work together to detect a fire, activate the agent release, and suppress the flames.

Installation must comply with local fire codes and regulations, often adhering to standards set by organizations like the National Fire Protection Association (NFPA). Professional installation by a certified technician is crucial to ensure the system functions correctly and meets all safety requirements. The system should be regularly inspected and maintained to guarantee its operational readiness. A well-maintained system is a crucial investment for safety.

Fire Extinguisher Maintenance and Inspection Procedures

Fire extinguishers are the first line of defense against fires. Regular maintenance and inspections are crucial to ensure these life-saving devices are always ready for use. Neglecting these procedures can render extinguishers ineffective, potentially leading to catastrophic consequences.The inspection process involves several key steps:

- Visual Inspection: The extinguisher should be examined for any physical damage, such as dents, corrosion, or missing parts. The pressure gauge should be checked to ensure it is within the recommended operating range.

- Accessibility: Ensure the extinguisher is easily accessible and not obstructed by equipment or other items. Clear signage indicating the location of the extinguisher is also essential.

- Hydrostatic Testing: This test involves subjecting the extinguisher cylinder to high pressure to check for leaks or structural weaknesses. Hydrostatic testing is typically required at specific intervals, as mandated by local regulations.

- Monthly Inspections: Regular monthly inspections should be conducted by the food truck operator. These inspections involve checking the pressure gauge, ensuring the extinguisher is in its designated place, and verifying that the tamper seal is intact.

- Annual Maintenance: Annual maintenance, performed by a certified fire protection company, is required to ensure the extinguisher is in good working order. This maintenance includes a more thorough inspection, recharging if necessary, and replacing any worn or damaged parts.

Proper documentation of all inspections and maintenance activities is essential. Keep records of inspection dates, maintenance performed, and any repairs or replacements. This documentation provides a valuable record of compliance and helps ensure the ongoing effectiveness of the fire extinguishers.

Inspector’s Questions About Fire Suppression Systems

During a fire safety inspection, the inspector will evaluate the fire suppression system to ensure it meets all applicable codes and regulations. The inspector’s inquiries are designed to assess the system’s functionality, maintenance, and compliance. Understanding these potential questions can help food truck operators prepare for inspections and maintain a safe environment.The inspector might inquire about:

- System Type and Certification: Confirmation of the type of fire suppression system installed and whether it is approved by a recognized testing laboratory, such as Underwriters Laboratories (UL).

- Installation Documentation: Review of the installation certificate and any related documentation, verifying that the system was installed by a qualified technician and according to the manufacturer’s instructions.

- Maintenance Records: Examination of the maintenance records, including inspection reports, service records, and any documentation of repairs or replacements.

- Inspection Frequency: Confirmation that the system is being inspected and maintained at the required intervals, typically semi-annually for the automatic system and annually for the fire extinguishers.

- Agent Type and Quantity: Verification of the type and quantity of the extinguishing agent used in the system, ensuring it is appropriate for the types of hazards present in the food truck.

- Nozzle Coverage: Assessment of the coverage provided by the nozzles, confirming that they effectively protect all cooking appliances and other potential fire hazards.

- Manual Activation: Confirmation of the location and accessibility of the manual activation device, such as a pull station, and its proper functioning.

- Employee Training: Inquiries about employee training on the use of fire extinguishers and the operation of the fire suppression system, including proper procedures in case of a fire.

- Recent Service: Verification of the date of the last service and any findings or recommendations from the service provider.

Cooking Equipment and Ventilation

Ensuring the safety of cooking equipment and maintaining effective ventilation are critical aspects of food truck fire safety. These elements directly impact the potential for grease fires and the spread of smoke and flames. Neglecting these areas can lead to significant fire hazards, posing risks to both the operators and the public. Regular inspections and diligent maintenance are therefore non-negotiable for any food truck.

Cooking Equipment Inspection Points

The cooking equipment within a food truck demands meticulous attention during fire safety inspections. Fryers, grills, ovens, and other appliances are potential ignition sources and require careful assessment.

- Fryers: Fryers are a significant fire hazard due to the high temperatures of cooking oil. Inspectors should examine the fryer’s thermostat to ensure it is functioning correctly and preventing overheating. They should also check for oil leaks, which can ignite upon contact with a heat source. The inspection includes verifying the presence and functionality of a high-limit safety device, designed to shut down the fryer if the oil temperature exceeds a safe threshold.

Additionally, the cleanliness of the fryer, particularly the area around the oil container, is crucial, as grease buildup can fuel a fire.

- Grills and Stoves: Grills and stoves also pose risks, particularly those fueled by propane or natural gas. Inspectors must assess the integrity of gas lines and connections for leaks using a gas leak detector. They should confirm that all burners are lighting correctly and that the flame is the appropriate color, indicating complete combustion. The inspection includes ensuring that grease traps are in place and regularly cleaned to prevent grease accumulation.

The distance between the grill and any combustible materials must also be verified to prevent accidental fires.

- Ovens: Ovens, whether conventional or convection, require inspection of their heating elements and thermostats. Inspectors must ensure that the oven door seals properly to prevent heat from escaping and potentially igniting nearby materials. They also need to check for grease buildup inside the oven and on the exterior surfaces, which can be a fire hazard. The presence and functionality of the oven’s safety features, such as automatic shut-off mechanisms, must be verified.

- General Equipment: Inspectors must verify that all cooking equipment is positioned at a safe distance from walls, other appliances, and any combustible materials. This includes ensuring that there are no obstructions near the equipment that could hinder fire suppression efforts. Regular cleaning and maintenance schedules for all equipment should be in place and followed to minimize fire risks.

Ventilation System Requirements

Proper ventilation is essential for removing smoke, grease-laden vapors, and heat from the food truck, thereby preventing fire hazards.

- Hood and Duct System: The hood and duct system must be constructed of non-combustible materials, such as stainless steel. The hood should effectively capture grease-laden vapors from cooking appliances. The ductwork must be designed and installed to prevent grease buildup. The system must be inspected for any leaks or damage.

- Cleaning Schedule: A regular cleaning schedule for the hood and duct system is crucial. The frequency of cleaning depends on the type of cooking and the volume of food preparation.

The National Fire Protection Association (NFPA) Standard 96 provides guidelines for cleaning frequencies, with high-volume cooking operations often requiring monthly cleaning, moderate-volume operations quarterly, and light-volume operations semi-annually.

The cleaning process must be performed by a certified professional.

- Grease Filters: Grease filters must be in place and properly maintained. They should be cleaned or replaced regularly to ensure they effectively capture grease. Clogged filters reduce the ventilation system’s efficiency and increase the risk of grease buildup in the ductwork.

- Exhaust Fans: Exhaust fans must be in good working order and capable of effectively removing smoke and vapors. The fan blades should be clean and free of obstructions. The fan’s motor should be regularly inspected and maintained.

Ventilation System Visual Description

A properly installed and maintained ventilation system is a critical component of food truck fire safety. The following is a detailed description of a well-functioning system.The system starts with a stainless-steel hood positioned directly above the cooking appliances. This hood is designed with grease collection trays or filters to capture grease particles before they enter the ductwork. The hood is connected to a series of stainless-steel ducts that run upwards, away from the cooking area.

These ducts are properly sealed to prevent leaks and are constructed of non-combustible materials.The ducts lead to an exhaust fan located on the roof of the food truck. The exhaust fan is housed in a weatherproof enclosure and is powerful enough to remove smoke and grease-laden vapors efficiently. The fan’s motor is regularly inspected and maintained to ensure it operates correctly.

The entire system is designed to be easily accessible for cleaning and maintenance.The illustration should also include a detail of the cleaning access panels, which are strategically placed along the ductwork to allow for thorough cleaning by certified professionals. The cleaning schedule is documented and followed, with records of cleaning dates and inspection reports readily available. The area around the exhaust fan on the roof is clear of any obstructions, such as debris or other equipment, that could impede the fan’s performance.

The grease collection system is emptied regularly, and the grease filters are cleaned or replaced as needed. The entire system is inspected regularly for any signs of damage or wear.

Electrical Safety and Wiring

Food trucks, with their reliance on electricity for cooking, refrigeration, and lighting, present significant electrical hazards. Ensuring electrical safety is paramount to prevent fires, electrocution, and equipment damage. Regular inspections and adherence to safety standards are crucial for protecting both the food truck operators and the public.Electrical systems in food trucks are often subject to harsh conditions, including vibration, moisture, and extreme temperatures.

These factors can compromise wiring and lead to dangerous situations. Proper installation, maintenance, and inspection are therefore vital.

Importance of Proper Wiring and Grounding

Proper wiring and grounding are fundamental to electrical safety in food trucks. Faulty wiring and inadequate grounding are major contributors to electrical fires.

- Wiring Standards: All wiring must comply with the National Electrical Code (NEC) and local electrical codes. This includes using the correct gauge wire for the amperage of the circuits, ensuring wires are properly supported and protected from damage, and using appropriate connectors and junction boxes.

- Grounding: Grounding provides a safe path for electrical current in the event of a fault. All electrical equipment must be properly grounded to prevent electrocution. This involves connecting the metal frame of the equipment to the food truck’s chassis and ensuring the chassis is connected to a proper earth ground. A ground fault circuit interrupter (GFCI) is a crucial safety device, especially in areas near water sources.

- Overload Protection: Circuit breakers and fuses must be appropriately sized to protect the wiring and equipment from overloads. Overloading a circuit can cause the wires to overheat, potentially leading to a fire.

- Professional Installation: All electrical work should be performed by a licensed electrician who is familiar with the NEC and local codes. Improperly installed wiring can create hidden hazards that are difficult to detect.

Common Electrical Hazards to Watch For During an Inspection

During a food truck fire inspection, inspectors focus on identifying potential electrical hazards. The following list highlights common issues.

- Damaged Wiring: Look for frayed, cracked, or otherwise damaged wiring. This includes exposed wires, wires that are pinched or crushed, and wires that are routed through sharp edges. Damaged wiring can lead to short circuits and fires.

- Improper Connections: Inspect all electrical connections for loose connections, corrosion, and improper splicing. Loose connections can generate heat, leading to a fire. Corrosion can increase resistance and also cause overheating.

- Overloaded Circuits: Ensure that circuits are not overloaded. Check the amperage draw of all appliances and equipment to ensure it does not exceed the capacity of the circuit breakers. Overloaded circuits can overheat and cause fires.

- Lack of Grounding: Verify that all electrical equipment is properly grounded. Check for missing or improperly installed grounding wires. Lack of grounding can lead to electrocution.

- Use of Extension Cords: Minimize the use of extension cords. If extension cords are necessary, they must be rated for the amperage of the equipment and be in good condition. Overuse of extension cords can create a tripping hazard and overload circuits.

- Water Damage: Check for any signs of water damage, such as water stains or corrosion on electrical components. Water and electricity do not mix, and water damage can lead to short circuits and electrocution.

- Improperly Installed Equipment: Ensure all electrical equipment is installed according to the manufacturer’s instructions and local codes. Improper installation can create hazards.

- Unlabeled Circuits: Confirm that the electrical panel is properly labeled, clearly identifying each circuit and the equipment it serves. Without clear labeling, it is difficult to troubleshoot electrical problems.

Best Practices for Electrical Safety

Adhering to best practices for electrical safety helps mitigate risks. These practices contribute to a safer operating environment.

- Regular Inspections: Conduct regular inspections of the electrical system, including wiring, outlets, and equipment. These inspections should be performed by a qualified individual.

- Preventative Maintenance: Implement a preventative maintenance program to address potential electrical problems before they become hazards. This may include replacing worn wiring, tightening connections, and cleaning electrical components.

- Training: Train all food truck staff on electrical safety, including how to identify hazards, how to use electrical equipment safely, and what to do in the event of an electrical emergency.

- Proper Use of Extension Cords: Use extension cords only when necessary and ensure they are in good condition, properly rated for the load, and protected from damage. Avoid running extension cords through high-traffic areas.

- GFCI Protection: Install GFCI outlets or circuit breakers in areas where electrical equipment may come into contact with water, such as near sinks and cooking areas.

- Proper Ventilation: Ensure that electrical panels and equipment are adequately ventilated to prevent overheating. Overheating can damage components and increase the risk of fire.

- Professional Repairs: Only allow qualified electricians to perform electrical repairs and modifications. Never attempt to repair electrical problems yourself unless you are a qualified electrician.

- Emergency Procedures: Establish and practice emergency procedures for electrical incidents, including how to shut off power, how to safely evacuate the food truck, and how to contact emergency services.

Propane and Fuel Systems

Food truck operations rely heavily on propane and other fuel systems for cooking and power. Ensuring the safety of these systems is paramount to preventing fires and explosions. Rigorous inspections and adherence to safety protocols are crucial for protecting both food truck operators and the public. Understanding the inspection requirements and following proper procedures is essential for maintaining a safe and compliant mobile food business.

Inspection Requirements for Propane and Other Fuel Systems

Propane and other fuel systems in food trucks are subject to detailed inspections to verify their safety and compliance with local and national fire codes. These inspections typically cover the fuel tanks, piping, regulators, appliances, and ventilation systems. The frequency of inspections varies depending on the jurisdiction, but they are often conducted annually or more frequently.The inspection process often involves the following key elements:

- Fuel Tank Integrity: Inspectors examine the fuel tanks for any signs of damage, corrosion, or leaks. They verify that tanks are properly secured and meet all applicable safety standards.

- Piping and Hoses: All fuel lines, hoses, and fittings are inspected for leaks, cracks, and proper installation. Inspectors check for the use of approved materials and ensure that lines are routed and protected to prevent damage.

- Regulators and Valves: The inspection includes checking the function and condition of regulators and valves. Inspectors ensure that they are properly calibrated and functioning correctly to control fuel flow and pressure.

- Appliances and Equipment: All fuel-burning appliances, such as stoves, grills, and fryers, are inspected to ensure they are operating safely and are properly connected to the fuel supply. This includes checking for proper ventilation and the presence of safety devices.

- Ventilation Systems: Inspectors evaluate the ventilation systems to ensure they are adequate to remove combustion byproducts and prevent the buildup of hazardous gases. This includes checking the functionality of exhaust hoods and fans.

- Fuel Storage and Handling: Inspectors review the procedures for storing and handling fuel tanks to ensure they comply with safety regulations. This includes verifying proper tank placement, securing, and ventilation.

Proper Storage and Handling Procedures for Fuel Tanks

Safe storage and handling of fuel tanks are critical for preventing fires and explosions. Food truck operators must follow specific guidelines to ensure the safety of their operations and the public. Improper handling and storage can lead to leaks, explosions, and serious injuries.Here are the key aspects of safe storage and handling:

- Tank Placement: Propane tanks should be stored in a well-ventilated area, away from sources of ignition, such as open flames, sparks, and direct sunlight. Tanks should be placed upright and secured to prevent tipping or rolling.

- Tank Securing: Tanks must be securely mounted to the food truck to prevent movement during transit or operation. Straps, chains, or other approved securing devices should be used.

- Ventilation: The storage area should be well-ventilated to prevent the buildup of propane gas in case of a leak. Ventilation openings should be located at the top and bottom of the storage area.

- Protection from Damage: Tanks should be protected from physical damage. Avoid storing tanks where they could be struck by vehicles or other objects. Protective covers may be used.

- Regular Inspections: Tanks should be inspected regularly for leaks, corrosion, and damage. Any signs of damage or leakage should be addressed immediately.

- Proper Handling: When handling propane tanks, always use appropriate safety gear, such as gloves and eye protection. Avoid dropping or dragging tanks.

- Tank Filling: Propane tanks should only be filled by qualified and certified propane suppliers. Never attempt to fill a tank yourself.

- Emergency Procedures: Food truck operators should have a written emergency plan in place that includes procedures for dealing with propane leaks or fires. This plan should be readily available and understood by all employees.

Food Truck Propane and Fuel System Inspection Checklist

A comprehensive checklist is used by inspectors to ensure that all aspects of the propane and fuel systems meet safety standards. This checklist helps to identify potential hazards and ensures that all components are functioning correctly.The following is a sample checklist that an inspector might use:

| Item | Inspection Criteria | Compliance |

|---|---|---|

| Propane Tank Condition | Check for dents, corrosion, leaks, and proper labeling. | Pass/Fail |

| Tank Mounting | Verify tanks are securely mounted and protected from damage. | Pass/Fail |

| Tank Valves | Inspect for proper operation and absence of leaks. | Pass/Fail |

| Regulators | Check for proper pressure settings and functionality. | Pass/Fail |

| Piping and Hoses | Inspect for leaks, damage, and proper routing. Verify use of approved materials. | Pass/Fail |

| Appliances | Ensure appliances are properly connected and operating safely. | Pass/Fail |

| Ventilation | Verify proper ventilation of cooking equipment and fuel storage areas. | Pass/Fail |

| Fuel Shut-off Valves | Check for proper location and functionality of shut-off valves. | Pass/Fail |

| Fuel Storage Area | Verify proper ventilation, accessibility, and compliance with storage regulations. | Pass/Fail |

| Emergency Shut-off | Ensure the presence and functionality of an emergency shut-off switch. | Pass/Fail |

Fire Safety Training and Procedures

Ensuring the safety of food truck staff and customers is paramount, and a robust fire safety training program is a critical component. Regular training and the implementation of well-defined procedures are not just regulatory requirements; they are essential for preventing fires, minimizing damage, and protecting lives in the event of an emergency. This section Artikels the importance of comprehensive fire safety training and details crucial procedures every food truck operator should implement.

Importance of Fire Safety Training for Food Truck Staff

Proper fire safety training equips food truck employees with the knowledge and skills necessary to respond effectively to fire-related incidents. It empowers them to identify potential hazards, prevent fires, and act decisively in an emergency. This proactive approach significantly reduces the risk of fire-related injuries, property damage, and business interruption. Furthermore, trained staff are better equipped to ensure the safety of customers and minimize panic during a fire.

Essential Fire Safety Procedures for Food Trucks

Establishing clear and concise fire safety procedures is crucial for a safe operating environment. These procedures should be documented, regularly reviewed, and practiced by all staff members.

- Fire Prevention Practices: Implement daily checks for potential fire hazards. This includes inspecting cooking equipment for grease buildup, ensuring proper ventilation, and confirming that all electrical cords and appliances are in good working order. Staff should be trained to immediately address any identified hazards.

- Emergency Evacuation Plan: Develop a detailed evacuation plan that is prominently displayed within the food truck. This plan should include designated evacuation routes, assembly points, and procedures for assisting customers and staff with disabilities. Practice the evacuation plan regularly to ensure everyone knows what to do in an emergency.

- Fire Extinguisher Use: All staff members must be trained on how to use the fire extinguishers available in the food truck. Training should cover the different types of fire extinguishers, the types of fires they are designed to combat, and the proper techniques for using them. This includes understanding the PASS method: Pull the pin, Aim at the base of the fire, Squeeze the handle, and Sweep from side to side.

- Fire Suppression System Operation: If the food truck is equipped with a fire suppression system, staff must be trained on its operation, including how to manually activate it and what actions to take after activation. This training should cover the system’s specific components and how they work.

- Fuel Shut-Off Procedures: Establish procedures for safely shutting off fuel sources, such as propane tanks, in the event of a fire or other emergency. This includes knowing the location of shut-off valves and how to access them quickly.

- Reporting Procedures: Define clear procedures for reporting fires, including who to contact (e.g., 911), what information to provide, and the steps to take after the fire department has been notified.

Training Plan for Food Truck Employees

A comprehensive training plan should cover all aspects of fire safety, providing employees with the necessary knowledge and skills to respond effectively to fire-related incidents. The training plan should be regularly updated to reflect changes in equipment, regulations, and best practices.

- Training Topic: Fire Hazards and Prevention

- Duration: 1 hour

- Content: Identification of common fire hazards in food trucks (e.g., grease buildup, electrical issues, improper storage of flammable materials), fire prevention best practices, and the importance of maintaining a clean and organized workspace.

- Training Topic: Fire Extinguisher Use

- Duration: 1.5 hours (including hands-on practice)

- Content: Types of fire extinguishers, the PASS method, and practical exercises using a fire extinguisher simulator. Employees should practice extinguishing simulated fires.

- Training Topic: Fire Suppression System Operation (if applicable)

- Duration: 1 hour

- Content: Detailed explanation of the fire suppression system, including its components, operation, and manual activation procedures.

- Training Topic: Emergency Procedures and Evacuation

- Duration: 1 hour

- Content: Review of the food truck’s evacuation plan, designated evacuation routes, assembly points, and procedures for assisting customers and staff with disabilities. Practice evacuation drills.

- Training Topic: Fuel Shut-Off Procedures and Reporting

- Duration: 30 minutes

- Content: Location and operation of fuel shut-off valves, procedures for contacting emergency services (e.g., 911), and information to provide to the fire department.

The training plan should be conducted initially for all new hires and then at least annually for all staff. Regular refresher training ensures that employees remain proficient in fire safety procedures and are prepared to respond effectively to emergencies. Documentation of training, including dates, attendees, and content covered, is crucial for compliance and accountability. Consider incorporating a quiz or practical assessment at the end of each training session to evaluate employee understanding and retention of the information.

Emergency Exits and Egress

Ensuring safe and unobstructed emergency exits is paramount in food truck fire safety, providing occupants with a clear path to evacuate in the event of a fire. Compliance with egress requirements is critical to minimizing the risk of injury or death. This section Artikels the specific regulations, acceptable designs, and visual representations of compliant emergency exits for food trucks.

Requirements for Emergency Exits and Egress

Food trucks are required to adhere to specific regulations concerning emergency exits and egress pathways, dictated by fire codes and local ordinances. These requirements ensure that occupants can quickly and safely evacuate the vehicle in an emergency.

- Number of Exits: The number of required exits depends on the size of the food truck and the number of occupants. Typically, at least two exits are required.

- Exit Placement: Exits should be strategically located to provide multiple escape routes and minimize travel distances. They should be as far apart as possible.

- Exit Width and Height: Exits must meet minimum width and height requirements to allow for easy passage of individuals, considering potential disabilities or physical limitations. The minimum width is often 24 inches, and the minimum height is 6 feet 8 inches.

- Exit Door Swing: Exit doors should swing in the direction of egress and must not obstruct the exit path when opened. Outward-swinging doors are generally preferred.

- Clearance and Obstructions: Egress pathways must be kept clear of obstructions, including equipment, storage, and any items that could impede evacuation.

- Markings and Illumination: Exits must be clearly marked with illuminated exit signs and emergency lighting to ensure visibility during power outages or smoke conditions.

- Accessibility: Consideration should be given to accessibility requirements, ensuring that exits are usable by individuals with disabilities. This may involve ramps, wider doorways, and accessible hardware.

Acceptable and Unacceptable Exit Designs

The design of emergency exits significantly impacts their effectiveness. Certain designs are compliant with fire safety regulations, while others pose significant hazards and are unacceptable.

- Acceptable Exit Designs:

- Standard Door: A standard door that swings outward, meeting the minimum width and height requirements, and is readily accessible.

- Sliding Door: A sliding door that provides a clear opening and does not obstruct the egress path when opened.

- Emergency Escape Hatch: A roof-mounted hatch that provides an alternative escape route, especially in the event of a fire blocking other exits.

- Unacceptable Exit Designs:

- Doors that swing inward: Doors that swing inward can obstruct the egress path, especially if the area behind the door is crowded.

- Doors that are too narrow: Doors that are too narrow to allow easy passage, particularly for individuals carrying items or with disabilities.

- Exits blocked by equipment or storage: Exits that are obstructed by cooking equipment, storage, or other items, preventing or hindering egress.

- Exits without proper markings or lighting: Exits that are not clearly marked with exit signs or lack adequate emergency lighting, making them difficult to locate in low-visibility conditions.

Visual Description of a Safe and Compliant Emergency Exit

A safe and compliant emergency exit for a food truck would be a standard door that swings outward, allowing for immediate evacuation. The door would be at least 24 inches wide and 6 feet 8 inches high.The door would be constructed of fire-resistant materials and equipped with a clearly visible and illuminated “EXIT” sign above the door. An emergency light would be positioned near the door to illuminate the exit path during a power outage.

The area immediately surrounding the exit door would be clear of any obstructions, such as equipment, storage, or tables. The floor would be non-slip and free of trip hazards. The door would have a simple, easy-to-operate handle or push bar, accessible even with gloves. This design would ensure that occupants can quickly and safely evacuate the food truck in the event of a fire.

The door should also be tested and listed by a nationally recognized testing laboratory (NRTL).

Documentation and Record Keeping

Maintaining meticulous documentation is paramount for food truck fire safety. It not only demonstrates compliance with fire codes and regulations but also provides a valuable historical record for identifying potential hazards, tracking maintenance schedules, and ensuring the ongoing safety of both employees and the public. Accurate and readily available records are essential during fire inspections and can be crucial in the event of an incident, helping to determine the cause and contributing factors.

Importance of Fire Safety Documentation

Proper documentation is not merely a bureaucratic requirement; it serves as a comprehensive safety management tool. It facilitates proactive risk management, allowing food truck operators to identify and rectify potential fire hazards before they escalate. Furthermore, well-maintained records provide a clear audit trail, demonstrating a commitment to fire safety and minimizing liability in the event of an accident. They also assist in streamlining the inspection process, making it easier for inspectors to assess the overall safety of the food truck.

Types of Records to Keep

A comprehensive fire safety documentation system should include a variety of records. These records should be organized systematically and readily accessible. The following table Artikels the essential types of documents, their recommended frequency of review or maintenance, and the suggested retention period:

| Document Type | Frequency | Retention Period |

|---|---|---|

| Fire Inspection Reports | Annually or as required by local authorities | Minimum of 3 years |

| Fire Suppression System Maintenance Logs | Semi-annually or as per manufacturer’s recommendations | Minimum of 3 years |

| Fire Extinguisher Inspection and Maintenance Records | Monthly inspections, annual professional maintenance | Minimum of 3 years |

| Hood and Duct Cleaning Records | Quarterly or as per local regulations | Minimum of 3 years |

| Employee Fire Safety Training Records | Upon hiring and annually thereafter | Minimum of 3 years after employee termination |

| Propane and Fuel System Inspection Records | Annually or as required by local regulations | Minimum of 3 years |

| Electrical System Inspection Records | Annually or as required by local regulations | Minimum of 3 years |

| Emergency Exit Inspection and Maintenance Records | Monthly | Minimum of 1 year |

For instance, consider a scenario where a fire erupts in a food truck. If the operator can produce detailed records showing regular inspections of the fire suppression system and hood cleaning, it can help demonstrate that the operator took reasonable steps to prevent such an incident. Conversely, the absence of these records can significantly increase liability.

Common Inspection Violations and How to Avoid Them

Food truck fire inspections, while crucial for public safety, can be stressful for owners. Understanding the most frequent violations and implementing preventative measures can significantly reduce the risk of citations, fines, and operational disruptions. This section identifies common pitfalls and provides practical solutions to ensure food truck fire safety compliance.

Inadequate Fire Extinguisher Maintenance

Fire extinguishers are a food truck’s first line of defense, and their proper maintenance is paramount. Neglecting this aspect is a frequent violation, often leading to citations.

- Expired Extinguishers: Fire extinguishers have expiration dates, usually printed on the label. Expired extinguishers may not function effectively.

- Lack of Annual Inspections: Regular inspections by a certified fire extinguisher technician are essential to ensure the extinguisher is properly charged, accessible, and in good working order.

- Improper Placement: Extinguishers must be mounted in easily accessible locations, free from obstructions, and clearly visible.

To avoid these violations:

- Establish a Maintenance Schedule: Mark the calendar with the extinguisher’s expiration date and schedule annual inspections.

- Choose a Certified Technician: Hire a licensed professional for inspections and servicing. Ask for their credentials and check online reviews.

- Ensure Proper Placement: Mount extinguishers in visible, easily accessible locations near cooking areas and exits. Ensure they are not blocked by equipment or supplies.

Cooking Equipment Violations

Cooking equipment, being the primary source of fire hazards in food trucks, often faces scrutiny during inspections. These violations often stem from a lack of cleanliness and improper operation.

- Grease Buildup: Accumulation of grease on cooking surfaces, hoods, and ventilation systems poses a significant fire risk.

- Improper Hood Filters: Dirty or damaged hood filters compromise ventilation efficiency and increase the risk of fire spread.

- Insufficient Clearance to Combustibles: Maintaining inadequate distance between cooking equipment and flammable materials like paper towels, cleaning supplies, and packaging.

Preventative measures:

- Regular Cleaning: Implement a strict cleaning schedule for all cooking surfaces, hoods, and ventilation systems.

- Filter Maintenance: Replace hood filters regularly and clean them frequently according to the manufacturer’s instructions.

- Maintain Adequate Clearances: Adhere to the manufacturer’s recommended clearances between cooking equipment and combustible materials. Store flammable materials away from heat sources.

Electrical System Deficiencies

Electrical hazards are a common source of fire in food trucks, and these violations often involve overloaded circuits and improper wiring.

- Overloaded Circuits: Overloading electrical circuits with too many appliances can cause overheating and fire.

- Improper Wiring: Unsecured or damaged wiring, as well as the use of extension cords, can create electrical hazards.

- Lack of GFCI Protection: Ground Fault Circuit Interrupters (GFCIs) are essential in wet environments like food trucks to prevent electrical shock.

Preventative strategies:

- Proper Load Calculations: Before equipping a food truck, calculate the electrical load to ensure that the electrical system can handle the anticipated power consumption.

- Professional Installation and Inspection: Hire a licensed electrician to install and inspect the electrical system.

- Use of GFCIs: Install GFCIs in all outlets located near water sources. Test GFCIs monthly to ensure proper functionality.

Propane and Fuel System Issues, Food truck fire inspection checklist

Propane and fuel systems present a significant fire hazard, requiring careful attention during inspections. Common violations involve leaks and improper storage.

- Leaking Connections: Leaks in propane lines or connections can lead to gas accumulation and explosions.

- Improper Storage: Storing propane tanks incorrectly, such as indoors or in areas with poor ventilation, can be hazardous.

- Lack of Proper Ventilation: Inadequate ventilation in the propane storage area can lead to the buildup of flammable gases.

Solutions to avoid violations:

- Regular Leak Checks: Regularly inspect propane lines and connections for leaks using a soapy water solution.

- Safe Storage Practices: Store propane tanks upright, in a well-ventilated area, away from heat sources and direct sunlight.

- Professional Installation and Maintenance: Hire a qualified professional to install and maintain the propane system.

Lack of Fire Safety Training

Insufficient fire safety training is another recurring violation, highlighting the importance of preparedness.

- Lack of Employee Training: Employees must receive comprehensive training on fire safety procedures, including the use of fire extinguishers and evacuation protocols.

- Absence of Fire Drills: Regular fire drills are crucial to ensure employees know how to respond in an emergency.

- Inadequate Documentation: Failure to maintain records of fire safety training and drills.

To ensure compliance:

- Provide Comprehensive Training: Conduct regular fire safety training for all employees, covering fire prevention, extinguisher use, and evacuation procedures.

- Conduct Regular Fire Drills: Schedule and conduct fire drills at least quarterly.

- Maintain Accurate Records: Document all training sessions and fire drills, including dates, attendees, and topics covered.

The Inspection Process: Step-by-Step

Food truck owners must understand the fire inspection process to ensure compliance and safety. This process, typically conducted by local fire marshals or designated inspectors, involves a series of steps designed to evaluate fire safety measures within the mobile food unit. Thorough preparation can significantly streamline the inspection and reduce potential issues.

Typical Steps Involved in a Food Truck Fire Inspection

The inspection process generally follows a structured approach, beginning with initial contact and culminating in a final determination of compliance. Understanding these steps helps food truck operators prepare effectively.

- Scheduling the Inspection: The process usually begins with the food truck owner contacting the local fire department or relevant authority to schedule an inspection. This may involve submitting an application and providing information about the food truck’s operation.

- Pre-Inspection Review: Before the physical inspection, the inspector may review submitted documents, such as permits, operational plans, and records of fire safety training. This helps the inspector understand the scope of the food truck’s operations.

- Arrival and Introduction: The inspector will arrive at the food truck and introduce themselves. They will typically explain the purpose of the inspection and the areas they will be examining.

- Visual Inspection: A comprehensive visual inspection of the food truck’s interior and exterior is conducted. This includes examining cooking equipment, ventilation systems, electrical wiring, propane systems, fire suppression systems, and emergency exits.

- Equipment Testing: The inspector may test fire suppression systems, smoke detectors, and other safety equipment to ensure they function correctly. This may involve simulating a fire scenario or checking for proper maintenance.

- Documentation Review: The inspector will review required documentation, such as fire safety training records, maintenance logs for equipment, and permits. They will ensure that all documentation is up-to-date and compliant.

- Violation Identification: If any violations of fire codes or regulations are found, the inspector will identify them and provide details about the corrective actions required. This may include issuing a written notice of violation.

- Follow-Up Inspection (if necessary): If violations are identified, a follow-up inspection may be scheduled to verify that the necessary corrections have been made. This ensures that all safety concerns are addressed.

- Final Approval or Denial: Based on the inspection findings, the inspector will either grant final approval, indicating that the food truck meets all fire safety requirements, or deny approval, requiring the owner to address the identified violations.

Sample Timeline for a Fire Inspection

The duration of a fire inspection and the time required to achieve final approval can vary. However, a typical timeline provides a general understanding of the process.

- Day 1: Food truck owner contacts the fire department to schedule an inspection and submits the required documentation.

- Day 3-7: The fire department schedules the inspection, and the inspector reviews the submitted documents.

- Day 7-10: The physical inspection of the food truck is conducted, including equipment testing and documentation review.

- Day 10-14: The inspector provides a report of the inspection findings and identifies any violations. The owner receives a written notice of violation (if applicable).

- Day 14-30: The food truck owner addresses any violations identified by the inspector, making necessary repairs or adjustments.

- Day 30-45: A follow-up inspection is scheduled and conducted to verify that all violations have been corrected.

- Day 45: Final approval is granted, or further corrective actions are required if the follow-up inspection reveals unresolved issues.

Tips for Preparing for a Fire Inspection:

- Review Fire Codes: Familiarize yourself with the specific fire codes and regulations applicable to food trucks in your area.

- Conduct a Self-Inspection: Perform a pre-inspection of your food truck to identify and address potential issues before the official inspection.

- Maintain Equipment: Ensure all fire suppression systems, fire extinguishers, and other safety equipment are properly maintained and regularly inspected.

- Organize Documentation: Keep all required documentation, such as permits, training records, and maintenance logs, readily available for the inspector.

- Train Employees: Ensure that all employees are properly trained on fire safety procedures and the use of fire suppression equipment.

- Address Violations Promptly: If any violations are identified during the inspection, address them promptly and thoroughly to ensure compliance.

Final Wrap-Up

In conclusion, mastering the food truck fire inspection checklist is more than just ticking boxes; it’s a commitment to safety. By understanding the risks, adhering to regulations, and implementing proactive measures, food truck owners can significantly reduce the likelihood of fires. Remember, preparedness, ongoing maintenance, and consistent training are key. Embrace the checklist, stay informed, and keep those food trucks rolling safely, serving up deliciousness without the danger.