The national food laboratory plays a pivotal role in safeguarding public health and ensuring the integrity of our food supply. This vital institution is dedicated to the rigorous testing and analysis of food products, from farm to table, protecting consumers from potential hazards and maintaining the quality standards that we expect. This exploration delves into the multifaceted world of these laboratories, uncovering their essential functions, intricate processes, and the significant impact they have on our daily lives.

These laboratories are established with the primary mission of protecting public health by ensuring the safety and quality of food products. They achieve this through a combination of advanced scientific methods, stringent regulatory compliance, and dedicated professionals. Their history is marked by a continuous evolution, adapting to emerging threats and technological advancements. The core values of these laboratories revolve around accuracy, reliability, integrity, and a commitment to public service.

They are responsible for a wide range of functions, including the detection of contaminants, the assessment of nutritional content, and the enforcement of food safety regulations. They analyze a vast array of food products, from fresh produce and processed foods to beverages and dietary supplements.

Overview of the National Food Laboratory

The National Food Laboratory (NFL) plays a critical role in ensuring the safety, quality, and nutritional value of the food supply. These laboratories are vital components of a nation’s public health infrastructure, operating as centers for scientific investigation, regulatory support, and consumer protection. Their multifaceted roles contribute significantly to public trust in the food industry and the overall well-being of the population.

Primary Mission and Objectives

The primary mission of a typical National Food Laboratory is multifaceted, encompassing a range of crucial objectives designed to safeguard public health and promote a robust food system. The core functions are centered on scientific analysis, regulatory compliance, and consumer protection.

- Food Safety Assurance: The NFL rigorously tests food products for the presence of harmful contaminants, including bacteria (like Salmonella and E. coli), viruses, parasites, and chemical toxins (such as pesticides and heavy metals). This involves employing advanced analytical techniques, such as chromatography and mass spectrometry, to detect even trace amounts of these substances. A visual example: imagine a chromatogram displaying peaks that represent different food components, with any elevated peak indicating a potential contaminant requiring further investigation.

- Quality Control and Standardization: These laboratories establish and enforce standards for food composition, labeling accuracy, and overall quality. They ensure that food products meet specific criteria regarding ingredients, nutritional content, and sensory characteristics (taste, texture, appearance). This involves conducting detailed analyses of food samples to verify that they conform to established standards. For example, a laboratory might test a sample of olive oil to confirm its acidity level and ensure it meets the standards for extra virgin olive oil, as defined by international regulations.

- Nutritional Analysis and Labeling Compliance: The NFL plays a crucial role in verifying the accuracy of nutritional information provided on food labels. This involves analyzing food samples to determine their content of macronutrients (proteins, carbohydrates, fats), micronutrients (vitamins and minerals), and other relevant components. The laboratories then compare the analytical results with the information presented on the label to ensure compliance with regulations.

- Research and Development: Many NFLs conduct research to develop new methods for food analysis, improve food safety practices, and investigate emerging food-related issues. This can include studies on foodborne illnesses, the impact of processing methods on food quality, and the development of new food products. A practical example is the ongoing research into rapid detection methods for food allergens, like gluten, in processed foods.

- Regulatory Support and Enforcement: The NFL provides scientific support to regulatory agencies, such as food safety authorities. This includes providing analytical data for regulatory decision-making, assisting in the development of food safety regulations, and supporting enforcement actions against food manufacturers that violate these regulations. For instance, an NFL might provide evidence to support a recall of a food product found to be contaminated with a harmful substance.

History of Establishment and Evolution

The establishment and evolution of National Food Laboratories have been shaped by evolving public health concerns, scientific advancements, and the increasing complexity of the global food supply chain. The timeline reveals a progression from basic testing to sophisticated scientific analysis and regulatory oversight.

- Early Beginnings: The earliest forms of food testing and analysis can be traced back to the late 19th and early 20th centuries, driven by concerns about adulteration and mislabeling of food products. The initial focus was on identifying basic contaminants and ensuring that food products met rudimentary standards. This period saw the establishment of early food inspection agencies and the development of basic analytical techniques.

- Growth and Expansion: The mid-20th century witnessed a significant expansion in the role and scope of food laboratories. The rise of industrial food production, coupled with increasing awareness of foodborne illnesses, fueled the need for more comprehensive food safety measures. This period saw the establishment of more sophisticated testing methods, including microbiological analysis and chemical analysis.

- Technological Advancements: The late 20th and early 21st centuries have been marked by rapid technological advancements in food analysis. The development of advanced analytical techniques, such as chromatography, mass spectrometry, and polymerase chain reaction (PCR), has significantly enhanced the ability to detect and identify food contaminants, allergens, and other substances. The use of these technologies has dramatically improved the precision and speed of food analysis.

- Globalization and Supply Chain Complexity: The increasing globalization of the food supply chain has presented new challenges for food safety and quality control. National Food Laboratories have adapted to these challenges by developing methods for tracing food products back to their source, detecting emerging food safety threats, and collaborating with international food safety agencies.

Core Values and Principles

The operations of National Food Laboratories are guided by a set of core values and principles that underpin their commitment to scientific integrity, public health, and consumer protection. These principles ensure the laboratories operate with transparency, accuracy, and ethical conduct.

- Scientific Integrity: The foundation of all activities is scientific integrity. This includes the commitment to using validated analytical methods, adhering to rigorous quality control procedures, and ensuring the accuracy and reliability of all data and findings. It also involves avoiding conflicts of interest and maintaining objectivity in all scientific endeavors.

- Transparency and Openness: The NFL operates with a commitment to transparency and openness in its operations. This includes making information about its activities and findings accessible to the public, collaborating with stakeholders, and fostering open communication.

- Accuracy and Precision: The laboratories strive for the highest levels of accuracy and precision in all their analytical work. This involves using calibrated instruments, following standardized procedures, and regularly participating in proficiency testing programs to ensure the reliability of their results.

- Impartiality and Objectivity: The NFL maintains impartiality and objectivity in all its activities. This means that they conduct their work without bias and based solely on scientific evidence. They do not have any conflicts of interest and provide services to all stakeholders fairly and equitably.

- Continuous Improvement: The NFL is committed to continuous improvement in its methods, processes, and capabilities. This involves regularly evaluating its performance, adopting new technologies, and participating in training and development programs to enhance the skills and knowledge of its staff.

Functions and Responsibilities

A National Food Laboratory plays a critical role in safeguarding public health and ensuring the integrity of the food supply. Its functions encompass a wide array of activities, from routine testing and analysis to complex research and development, all aimed at upholding food safety standards and protecting consumers. These laboratories operate under strict regulatory frameworks, often working in close collaboration with government agencies to enforce food safety regulations and guidelines.

Specific Functions of a National Food Laboratory

The core functions of a National Food Laboratory are multifaceted, contributing to a comprehensive food safety system. These functions involve detailed scientific analysis and rigorous quality control measures.

- Food Analysis and Testing: This is the cornerstone function, involving the systematic examination of food samples for various parameters. This includes:

- Nutritional Analysis: Determining the macronutrient (proteins, carbohydrates, fats) and micronutrient (vitamins, minerals) content of food products. This information is crucial for accurate labeling and informing consumer dietary choices. For example, a laboratory might analyze a sample of fortified breakfast cereal to verify the levels of added vitamins and minerals against the manufacturer’s claims.

- Microbiological Testing: Detecting and quantifying the presence of harmful microorganisms such as bacteria (e.g., Salmonella, E. coli), viruses, and fungi. This helps to identify potential sources of foodborne illnesses. Imagine a laboratory receiving a batch of pre-packaged salads; they would test for the presence of Listeria monocytogenes, a bacterium that can cause severe illness.

- Chemical Analysis: Assessing the presence and levels of chemical contaminants, including pesticides, heavy metals (e.g., lead, mercury), and food additives. This is vital to ensure that food products meet safety standards and do not pose a health risk. Consider a laboratory testing imported fruits for pesticide residues to ensure they comply with national regulations.

- Sensory Evaluation: Evaluating the appearance, taste, smell, and texture of food products. This involves trained sensory panels that assess the overall quality and acceptability of a product. This may be used to compare the taste of two different batches of ice cream.

- Research and Development: Conducting research to develop new analytical methods, improve food safety practices, and understand emerging food safety challenges. This includes exploring new technologies and techniques for food analysis. An example would be a laboratory investigating the use of rapid detection methods for food allergens in processed foods.

- Method Development and Validation: Creating and validating standardized methods for food analysis. This ensures consistency and accuracy in testing across different laboratories. A laboratory might develop a new method for detecting genetically modified organisms (GMOs) in food products and then validate it against established methods to ensure its reliability.

- Training and Capacity Building: Providing training to food industry professionals and laboratory personnel on food safety practices, analytical techniques, and regulatory requirements. This helps to build a skilled workforce capable of ensuring food safety. The laboratory might organize workshops for food handlers on proper hygiene practices.

- Surveillance and Monitoring: Monitoring the food supply for potential hazards and emerging risks. This often involves collecting and analyzing food samples from various points in the food chain. This includes setting up routine checks of food markets to collect and test samples of meat.

Regulatory Responsibilities of a National Food Laboratory

National Food Laboratories are often integral to a country’s food safety regulatory framework. They act as the scientific arm of regulatory bodies, providing crucial data and analysis to support enforcement activities. These responsibilities ensure that food products comply with national and international standards.

- Enforcement of Food Safety Regulations: Providing scientific data and analysis to support the enforcement of food safety regulations. This includes verifying that food products meet the required standards for safety and quality. The laboratory might analyze a shipment of imported seafood to ensure it meets the standards for mercury content.

- Development of Food Safety Standards: Contributing to the development and revision of food safety standards and regulations. This involves providing scientific expertise and data to inform the decision-making process. The laboratory might provide data on the levels of a specific food additive to help determine its safe use limits.

- Investigation of Foodborne Illness Outbreaks: Investigating foodborne illness outbreaks by identifying the source of contamination and the causative agents. This involves collecting and analyzing food samples, interviewing affected individuals, and tracing the outbreak back to its origin. The laboratory might analyze samples of a specific food product consumed by individuals who fell ill to identify the presence of a pathogen.

- Issuance of Certificates of Analysis: Issuing certificates of analysis for food products, which provide assurance that the product meets the required standards. This is often required for export and import purposes. The laboratory might issue a certificate of analysis for a batch of honey, confirming that it meets the standards for purity and composition.

- Collaboration with International Organizations: Collaborating with international organizations such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) on food safety issues. This involves sharing data, participating in research projects, and contributing to the development of international food safety standards.

Types of Food Products Commonly Tested and Analyzed

A wide variety of food products are routinely tested and analyzed by National Food Laboratories. This includes both processed and unprocessed foods, ensuring the safety of the entire food supply chain. The specific products tested can vary depending on the country’s food consumption patterns, import/export activities, and potential food safety concerns.

- Meat and Poultry Products: Testing for pathogens (e.g., Salmonella, E. coli), antibiotic residues, and contaminants. This is critical because meat and poultry are often associated with foodborne illnesses. For example, the laboratory may analyze ground beef samples to detect the presence of E. coli O157:H7.

- Dairy Products: Testing for pathogens (e.g., Listeria, Salmonella), adulteration, and composition. This includes testing milk, cheese, yogurt, and other dairy-based products. The laboratory might test a sample of cheese for the presence of Staphylococcus aureus, a bacterium that can produce toxins.

- Seafood Products: Testing for pathogens, heavy metals (e.g., mercury, lead), and toxins (e.g., ciguatoxin, produced by certain marine algae). This is important because seafood can accumulate contaminants from the marine environment. The laboratory may test tuna for mercury levels to ensure they meet safety standards.

- Fruits and Vegetables: Testing for pesticide residues, pathogens, and contaminants. This is crucial because fruits and vegetables are often consumed raw and can be easily contaminated. The laboratory might analyze a sample of imported strawberries for pesticide residues.

- Processed Foods: Testing for a wide range of parameters, including nutritional content, additives, contaminants, and allergens. This includes packaged foods, ready-to-eat meals, and other processed products. The laboratory might test a sample of a breakfast cereal to verify its nutritional labeling claims.

- Grains and Cereals: Testing for mycotoxins (e.g., aflatoxins), pesticide residues, and contaminants. This includes testing wheat, rice, corn, and other grains. The laboratory may analyze a sample of corn for the presence of aflatoxins, which are produced by molds and can be carcinogenic.

- Beverages: Testing for contaminants, adulteration, and composition. This includes testing water, juices, soft drinks, and alcoholic beverages. The laboratory might test a sample of juice for the presence of lead.

Laboratory Infrastructure and Equipment

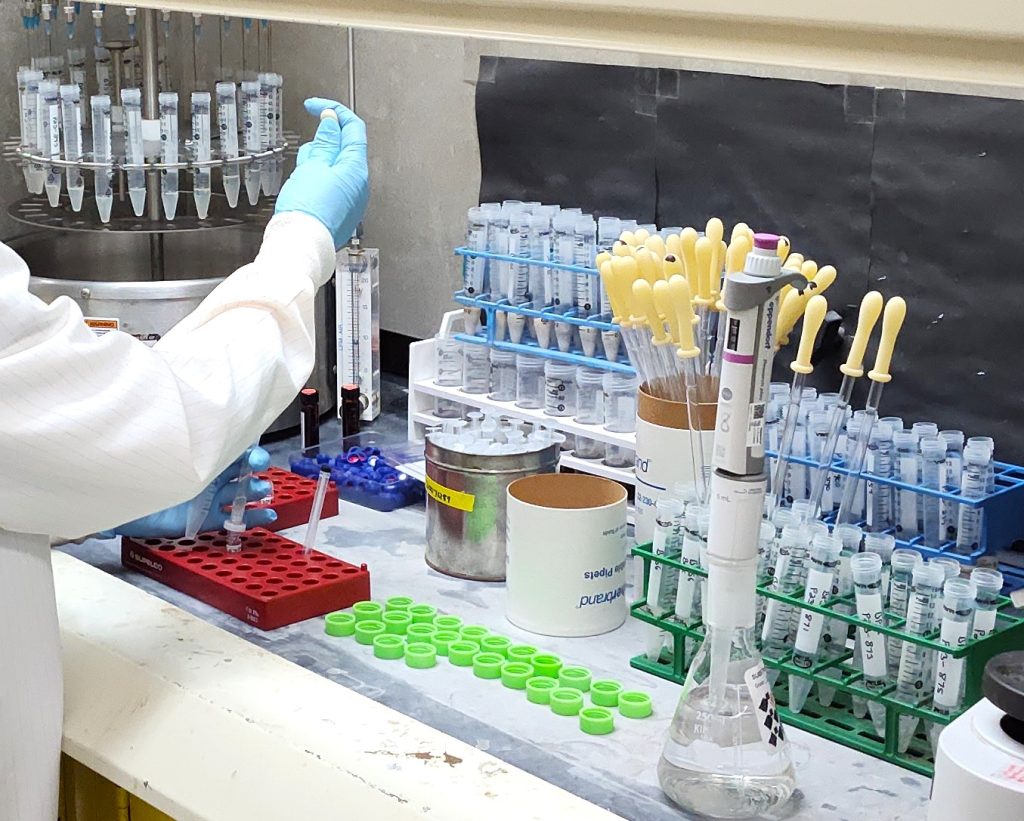

A National Food Laboratory’s infrastructure is the backbone of its ability to perform accurate and reliable food testing. This infrastructure encompasses the physical layout, specialized equipment, and rigorous quality control measures that ensure the integrity of the analysis and the safety of the food supply. The design and organization of these laboratories are crucial for efficiency, preventing cross-contamination, and maintaining the precision required for scientific investigation.

Physical Layout and Design

The physical layout of a National Food Laboratory is meticulously planned to accommodate the diverse range of analytical procedures performed. The design prioritizes workflow efficiency, safety, and the prevention of sample contamination. The laboratory is typically divided into several specialized areas, each dedicated to specific functions.

- Reception and Sample Management Area: This area is the first point of contact for incoming samples. It includes a reception desk, sample registration systems, and storage facilities for incoming and outgoing samples. This space is crucial for tracking samples, ensuring proper identification, and maintaining a chain of custody.

- Sample Preparation Area: This area is designed for the initial processing of food samples. It includes equipment such as homogenizers, blenders, and filtration systems. This area is equipped with safety features like fume hoods and ventilation systems to protect personnel from potential hazards.

- Analytical Chemistry Laboratories: These laboratories are dedicated to the quantitative and qualitative analysis of food components. They house sophisticated instruments such as gas chromatographs (GCs), high-performance liquid chromatographs (HPLC), mass spectrometers (MS), and atomic absorption spectrometers (AAS). The environment is carefully controlled to maintain stable conditions for instrument operation.

- Microbiology Laboratories: These laboratories are designed for the detection and identification of microorganisms in food. They contain incubators, autoclaves, and microscopes, and are equipped with biosafety cabinets to prevent contamination and protect laboratory personnel from biological hazards. Strict aseptic techniques are followed in these areas.

- Molecular Biology Laboratories: These labs are used for advanced techniques like PCR (Polymerase Chain Reaction) for detecting pathogens and genetically modified organisms (GMOs). They require specialized equipment and environmental controls to prevent contamination and ensure accurate results.

- Quality Control and Standards Laboratory: This area is dedicated to maintaining the accuracy and reliability of laboratory results. It houses reference standards, control samples, and equipment for calibration and validation.

- Storage Areas: Separate storage areas are allocated for chemicals, reagents, solvents, and samples. These areas are climate-controlled to ensure the stability and integrity of the stored materials. Refrigerators and freezers are essential for preserving samples and reagents.

Specialized Equipment for Food Testing and Analysis

National Food Laboratories utilize a wide array of specialized equipment to perform comprehensive food testing and analysis. These instruments are essential for identifying foodborne pathogens, detecting contaminants, and assessing the nutritional composition of food products. The selection of equipment depends on the laboratory’s specific functions and the scope of its testing capabilities.

| Equipment | Function | Application |

|---|---|---|

| Gas Chromatograph (GC) | Separates and quantifies volatile compounds based on their boiling points. | Detecting pesticide residues, analyzing flavor compounds, and determining the presence of adulterants. |

| High-Performance Liquid Chromatograph (HPLC) | Separates and quantifies non-volatile compounds based on their chemical properties. | Analyzing vitamins, preservatives, artificial colors, and mycotoxins. |

| Mass Spectrometer (MS) | Identifies and quantifies compounds based on their mass-to-charge ratio. | Detecting trace contaminants, identifying unknown substances, and confirming the identity of food components. Used in conjunction with GC and HPLC (GC-MS, LC-MS). |

| Atomic Absorption Spectrometer (AAS) | Measures the concentration of elements by absorbing light at specific wavelengths. | Determining the levels of heavy metals (lead, mercury, cadmium) and essential minerals in food. |

| Microscopes | Visualizes microscopic structures, including bacteria, molds, and food components. | Identifying microorganisms, assessing food quality, and detecting foreign materials. |

| Polymerase Chain Reaction (PCR) System | Amplifies specific DNA sequences for detection and identification. | Detecting foodborne pathogens (Salmonella, E. coli), identifying genetically modified organisms (GMOs), and verifying food authenticity. |

| Incubators | Maintains a controlled temperature environment for microbial growth. | Cultivating and isolating microorganisms for identification and enumeration. |

| Autoclaves | Sterilizes equipment and media using high-pressure steam. | Sterilizing laboratory equipment, preparing microbiological media, and decontaminating waste. |

Equipment Calibration and Quality Control

Maintaining the accuracy and reliability of analytical results is paramount in a National Food Laboratory. This is achieved through rigorous equipment calibration and comprehensive quality control procedures. These measures ensure that all instruments are functioning correctly and that the data generated is accurate, precise, and reliable.

- Calibration: Calibration involves comparing the instrument’s measurements to known standards or reference materials. This process ensures that the instrument provides accurate readings. Calibration is performed regularly, following a predetermined schedule and using certified reference materials. The calibration frequency varies depending on the instrument and the type of analysis.

- Quality Control Samples: Quality control (QC) samples are analyzed alongside the food samples to monitor the performance of the analytical methods. QC samples include control samples (e.g., matrix-matched reference materials), blanks, and spiked samples.

- Standard Operating Procedures (SOPs): SOPs are detailed, written instructions that specify how to perform each analytical procedure. SOPs ensure that all analyses are performed consistently, regardless of the analyst. They include steps for sample preparation, instrument operation, data analysis, and reporting.

- Proficiency Testing: Participation in proficiency testing programs involves analyzing unknown samples provided by an external organization. The laboratory’s results are compared to those of other laboratories to assess its performance and identify any potential issues.

- Preventive Maintenance: Regular maintenance of laboratory equipment is essential to ensure its optimal performance and longevity. This includes routine servicing, cleaning, and replacement of parts.

The implementation of these quality control measures ensures that the results generated by the National Food Laboratory are reliable and defensible, providing confidence in the safety and quality of the food supply.

Testing Procedures and Methods

The National Food Laboratory plays a crucial role in ensuring the safety and quality of the food supply through rigorous testing procedures. These procedures encompass sample collection and preparation, the application of various analytical methods, and stringent quality control measures to guarantee accurate and reliable results. The laboratory’s commitment to precision and scientific integrity is paramount in protecting public health and maintaining consumer confidence.

Sample Collection and Preparation

Sample collection and preparation are the initial and most critical steps in food analysis, directly impacting the accuracy and reliability of the results. The process must be meticulously controlled to avoid contamination and ensure the sample accurately represents the entire batch or lot of food being tested.The standard procedures involve several key steps:

- Sample Planning: This stage involves defining the testing objectives, identifying the specific analytes to be measured (e.g., contaminants, nutrients), and determining the appropriate sampling plan. A sampling plan specifies the number of samples to be collected, the sampling locations, and the methods used to collect the samples. For instance, when testing a batch of canned peaches for pesticide residues, the plan might dictate taking multiple cans from different parts of the production line and from various shipping pallets to ensure representative sampling.

- Sample Collection: This is the physical act of obtaining the sample. The method of collection varies depending on the food type and the analytes of interest. For solid foods, such as grains, a core sampler might be used to extract samples from different depths. For liquids, such as milk, a sterile container is used to collect a representative portion. The samples are immediately labeled with crucial information, including the date, time, source, and any relevant details about the sample, such as the batch number.

- Sample Transportation and Storage: Collected samples must be transported to the laboratory under conditions that maintain their integrity. This often involves using insulated containers and maintaining specific temperature ranges (e.g., refrigeration or freezing). Samples are then stored in a controlled environment (e.g., a freezer at -20°C for long-term storage of food samples). The storage conditions are meticulously documented to ensure traceability and prevent sample degradation.

Explore the different advantages of fremont baby food festival 2024 that can change the way you view this issue.

- Sample Preparation: Before analysis, the sample undergoes preparation steps to make it suitable for the chosen analytical method. This often involves:

- Homogenization: This process reduces the sample to a uniform consistency. For example, a food processor might be used to blend a sample of fruit into a homogenous pulp, or a mortar and pestle to grind solid foods into a fine powder.

- Extraction: This step isolates the analyte of interest from the food matrix. For example, in pesticide residue analysis, the pesticides are extracted from the food using solvents.

- Filtration: To remove solid particles from liquid samples, filtration might be used to clarify the extract, preventing interference in the analytical equipment.

- Dilution: The sample may be diluted to bring the analyte concentration within the measurable range of the analytical instrument.

Common Analytical Methods

Food laboratories utilize a diverse array of analytical methods to identify and quantify various components and contaminants in food products. These methods are chosen based on the specific analytes being investigated and the desired level of accuracy and sensitivity.

- Chromatography: This is a separation technique used to separate the components of a mixture based on their physical and chemical properties.

- Gas Chromatography (GC): Used to separate and quantify volatile compounds, such as pesticides, flavors, and volatile organic compounds (VOCs). The sample is vaporized and passed through a column, where the components are separated based on their boiling points and interactions with the column packing material.

The separated compounds are then detected and quantified by a detector, such as a flame ionization detector (FID) or a mass spectrometer (MS). For example, GC is used to detect and measure the levels of specific pesticides in fruits and vegetables.

- High-Performance Liquid Chromatography (HPLC): This is used to separate and quantify non-volatile compounds, such as vitamins, amino acids, and food additives. The sample is dissolved in a liquid solvent and pumped through a column packed with a stationary phase. The components are separated based on their affinity for the stationary phase and the mobile phase. The separated compounds are then detected and quantified by a detector, such as a UV-Vis detector or a fluorescence detector.

For instance, HPLC is used to measure the concentration of vitamins in fortified foods.

- Gas Chromatography (GC): Used to separate and quantify volatile compounds, such as pesticides, flavors, and volatile organic compounds (VOCs). The sample is vaporized and passed through a column, where the components are separated based on their boiling points and interactions with the column packing material.

- Spectroscopy: This involves the interaction of electromagnetic radiation with matter to analyze the composition and structure of a substance.

- Atomic Absorption Spectroscopy (AAS): Used to determine the concentration of specific elements, such as heavy metals (e.g., lead, cadmium) in food. The sample is atomized, and the absorption of light by the atoms of the element is measured. For example, AAS is used to check for the presence of lead in canned food, adhering to strict regulatory limits.

- Mass Spectrometry (MS): This technique measures the mass-to-charge ratio of ions to identify and quantify the components of a sample. MS is often coupled with chromatography techniques (GC-MS or LC-MS) to provide a powerful analytical tool. MS is used to identify and quantify a wide range of compounds, including pesticides, toxins, and food additives. For example, LC-MS is used to detect mycotoxins (e.g., aflatoxins) in grains and nuts.

- Infrared Spectroscopy (IR): Used to identify and quantify organic compounds by analyzing their absorption of infrared radiation. This is used to analyze the composition of fats and oils in food.

- Microbiology: This branch focuses on the detection and quantification of microorganisms in food to assess food safety and spoilage.

- Culture-Based Methods: Involve growing microorganisms on specific media to identify and quantify them. This can be used to identify pathogens like

-Salmonella* and

-E. coli* in food products. - Polymerase Chain Reaction (PCR): A molecular technique used to amplify specific DNA sequences from microorganisms. This allows for the rapid and sensitive detection of pathogens, even at low concentrations. PCR is used to detect

-Listeria monocytogenes* in ready-to-eat foods. - Enzyme-Linked Immunosorbent Assay (ELISA): An immunological technique used to detect and quantify specific antigens (e.g., toxins) or antibodies in a sample. ELISA is used to detect toxins such as staphylococcal enterotoxins in food.

- Culture-Based Methods: Involve growing microorganisms on specific media to identify and quantify them. This can be used to identify pathogens like

Ensuring Accuracy and Reliability of Test Results

Food laboratories implement a comprehensive quality assurance system to ensure the accuracy and reliability of test results. This system encompasses several key components:

- Method Validation: Before a new analytical method is implemented, it must be validated to ensure it is fit for its intended purpose. This involves demonstrating that the method is accurate, precise, sensitive, and specific for the target analyte. Method validation includes the following elements:

- Accuracy: The closeness of agreement between a test result and the accepted reference value. This is often assessed by analyzing certified reference materials (CRMs).

- Precision: The closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous material. This is often expressed as the relative standard deviation (RSD).

- Sensitivity: The ability of a method to detect small amounts of the analyte of interest.

- Specificity: The ability of a method to measure the analyte of interest without interference from other substances in the sample.

- Quality Control (QC) Samples: QC samples are used to monitor the performance of analytical methods and identify any potential problems. These samples include:

- Blanks: Used to check for contamination in the analytical process.

- Spiked Samples: Prepared by adding a known amount of the analyte of interest to a sample matrix. These samples are used to assess the accuracy of the method.

- Duplicates: Two or more samples of the same material analyzed in parallel to assess the precision of the method.

- Certified Reference Materials (CRMs): These are materials with certified values for specific analytes. CRMs are used to verify the accuracy of the analytical method. For example, if testing a sample for vitamin C content, a CRM containing a known amount of vitamin C is analyzed alongside the samples. The laboratory compares its results to the certified value.

- Proficiency Testing: Laboratories participate in proficiency testing programs to assess their performance and compare their results with those of other laboratories. This involves analyzing samples provided by an external organization and comparing the results to a consensus value.

- Internal Audits: Regular internal audits are conducted to ensure that the laboratory is adhering to its quality system and that all procedures are being followed correctly.

- Calibration and Maintenance of Equipment: Analytical instruments are calibrated regularly using standards of known concentration. Instruments undergo routine maintenance and are serviced by qualified technicians to ensure optimal performance.

- Staff Training and Competency: Laboratory staff receive comprehensive training on all analytical methods and quality control procedures. Their competency is regularly assessed through performance evaluations and proficiency testing.

Food Safety and Quality Assurance: National Food Laboratory

The National Food Laboratory plays a pivotal role in safeguarding public health and ensuring the integrity of the food supply. Through rigorous testing, analysis, and monitoring, these laboratories are at the forefront of preventing foodborne illnesses and maintaining high standards of food quality. This commitment involves a multi-faceted approach, encompassing the detection of contaminants, the assessment of product attributes, and the implementation of robust quality control measures.

Role in Ensuring Food Safety

The primary function of a National Food Laboratory is to provide scientific evidence that food products are safe for consumption. This is achieved through comprehensive testing and analysis, ensuring that food meets established safety standards and regulations. The laboratories act as a crucial line of defense, protecting consumers from potential hazards.The key activities include:

- Hazard Identification: Identifying potential biological, chemical, and physical hazards that may be present in food. This includes pathogens like Salmonella and E. coli, chemical contaminants such as pesticides and heavy metals, and physical hazards like glass or plastic fragments.

- Risk Assessment: Evaluating the likelihood of hazards occurring and the severity of their potential effects on public health. This involves analyzing data on food consumption patterns, prevalence of contaminants, and the susceptibility of different populations.

- Risk Management: Developing and implementing strategies to control identified hazards. This includes setting safety standards, establishing maximum residue limits (MRLs) for contaminants, and monitoring food production processes.

- Communication: Disseminating information about food safety risks and measures to consumers, food producers, and regulatory agencies. This ensures that all stakeholders are informed and can take appropriate action.

Contribution to the Detection and Control of Foodborne Illnesses

National Food Laboratories are critical in detecting and controlling outbreaks of foodborne illnesses. Their rapid response capabilities and advanced analytical techniques allow for swift identification of the source of contamination and the pathogens involved. This information is vital for containing outbreaks and preventing further spread of illness.The laboratories contribute to outbreak management through:

- Pathogen Identification: Employing advanced techniques like PCR (Polymerase Chain Reaction) and whole-genome sequencing to identify the specific pathogens responsible for outbreaks. These methods provide highly accurate and detailed information about the pathogens, including their genetic makeup.

- Source Tracing: Investigating the origin of contamination by analyzing food samples, environmental samples, and patient samples. This involves tracing the food product back through the supply chain to identify the point of contamination.

- Surveillance and Monitoring: Conducting ongoing surveillance of food products to detect the presence of pathogens and monitor the effectiveness of control measures. This includes routine testing of food samples and monitoring for emerging food safety threats.

- Outbreak Response: Collaborating with public health agencies to coordinate outbreak investigations and implement control measures. This includes issuing food recalls, advising on safe food handling practices, and providing guidance to healthcare professionals.

Methods Used to Assess Food Quality

Assessing food quality involves evaluating a range of attributes that contribute to the overall acceptability and desirability of a food product. National Food Laboratories employ a variety of methods to assess these attributes, ensuring that food products meet established quality standards and consumer expectations. These methods encompass both objective and subjective assessments.The key methods include:

- Physicochemical Analysis: Measuring the physical and chemical properties of food, such as moisture content, pH, acidity, fat content, and protein content. These analyses provide objective data about the composition and characteristics of the food.

- Microbiological Analysis: Assessing the presence and levels of microorganisms, including bacteria, yeasts, and molds. This ensures that food is free from spoilage organisms and pathogens that can cause illness.

- Sensory Evaluation: Evaluating the sensory attributes of food, such as appearance, flavor, aroma, and texture, through the use of trained panelists. This provides a subjective assessment of the food’s quality and consumer appeal.

- Instrumental Analysis: Using specialized instruments to measure specific food properties, such as color, texture, and flavor compounds. This provides objective data that can be used to monitor food quality and ensure consistency.

Sensory evaluation is a critical component of food quality assessment. Trained sensory panels are used to evaluate various aspects of food products, providing valuable insights into consumer acceptance and product characteristics.

- Panelist Training: Panelists undergo rigorous training to develop their sensory acuity and ability to accurately describe and differentiate between different food attributes. This ensures that the sensory evaluations are reliable and consistent.

- Descriptive Analysis: Panelists use descriptive terms to characterize the sensory attributes of food, such as sweetness, sourness, crunchiness, and aroma intensity. This provides a detailed profile of the food’s sensory properties.

- Preference Testing: Panelists are asked to rate their preference for different food products or variations of a product. This provides insights into consumer preferences and helps to guide product development.

- Consumer Testing: Representative consumers are involved in sensory evaluations to assess the overall acceptability of food products. This provides valuable feedback on the product’s appeal to the target market.

For example, consider the assessment of olive oil quality. A trained sensory panel would evaluate the olive oil for its fruity, bitter, and pungent characteristics, as well as any defects like rancidity. The results of these evaluations, combined with physicochemical analysis (e.g., free fatty acid content), determine the olive oil’s grade and compliance with quality standards. The International Olive Council (IOC) sets standards for olive oil grades, and national food laboratories would test the oil against these.

The presence of defects, or the absence of key desirable traits, can lead to downgrading of the oil and prevent it from being sold as extra virgin olive oil.

Research and Development Activities

National food laboratories are not merely testing facilities; they are dynamic hubs of innovation, constantly striving to improve food safety, quality, and the efficiency of food production. Their research and development (R&D) activities are critical to staying ahead of emerging challenges and consumer demands. These activities span a wide range of disciplines, from microbiology and chemistry to food engineering and sensory science.

Types of R&D Projects

The types of R&D projects undertaken by national food laboratories are diverse, reflecting the multifaceted nature of the food industry. They often focus on addressing pressing issues, exploring new technologies, and improving existing processes.

- Development of New Analytical Methods: These projects involve creating and validating novel techniques for detecting contaminants, identifying food fraud, and assessing the nutritional content of foods. For example, a laboratory might develop a new high-performance liquid chromatography (HPLC) method to detect trace amounts of pesticide residues in fruits and vegetables. This method would be more sensitive and accurate than existing methods, leading to improved food safety.

- Food Processing and Preservation Research: This area focuses on improving food processing techniques to enhance shelf life, maintain nutritional value, and ensure food safety. Research might explore innovative packaging solutions or the use of pulsed electric fields for food preservation. An example would be researching the use of modified atmosphere packaging (MAP) to extend the shelf life of fresh-cut produce, allowing for wider distribution and reduced food waste.

- Food Product Development and Formulation: This involves creating new food products or improving existing ones. This could include developing healthier versions of popular foods, creating products for specific dietary needs (e.g., gluten-free, vegan), or exploring the use of novel ingredients. For example, a laboratory might work on developing a low-sodium processed meat product that maintains the same taste and texture as the original, addressing consumer health concerns.

- Food Microbiology and Pathogen Control: Research in this area focuses on understanding and controlling foodborne pathogens. This includes developing rapid detection methods for bacteria like Salmonella and E. coli, as well as investigating effective methods for sanitizing food processing environments. This research might involve the development of bacteriophage-based technologies to control Listeria monocytogenes in ready-to-eat foods, significantly reducing the risk of foodborne illnesses.

- Sensory Evaluation and Consumer Research: This involves evaluating the sensory characteristics of food products (taste, smell, texture, appearance) and understanding consumer preferences. This information is crucial for product development and marketing. This research might involve conducting consumer taste tests to determine the optimal formulation of a new snack food, ensuring its market success.

Contribution to Innovation

National food laboratories are pivotal in driving innovation within the food industry, often acting as catalysts for technological advancements and the development of new products and processes. Their work directly contributes to a more efficient, safer, and sustainable food supply.

- Development of Advanced Analytical Techniques: Laboratories are at the forefront of developing advanced analytical techniques. For instance, the development of rapid PCR-based methods for detecting foodborne pathogens has significantly reduced the time required to identify and respond to outbreaks, leading to improved public health outcomes.

- Application of Novel Processing Technologies: Research into innovative processing technologies, such as high-pressure processing (HPP) for food preservation, allows for the production of safer and higher-quality food products with extended shelf lives. This innovation reduces the need for preservatives and enhances the nutritional value of foods.

- Ingredient Innovation and Functional Foods: Laboratories often explore the use of novel ingredients and the development of functional foods that offer specific health benefits. The research into incorporating probiotics into yogurt products, for example, has created a market for foods that promote gut health.

- Sustainable Food Production: Research efforts frequently focus on promoting sustainable food production practices. For example, the development of biodegradable food packaging materials helps reduce environmental impact.

- Automation and Robotics in Food Processing: Research and development in automation and robotics enhance efficiency and minimize human error in food processing, improving food safety and consistency. This is particularly crucial in large-scale food production facilities.

Collaborative Research Efforts

Collaborative research efforts are integral to the success of national food laboratories. Partnering with universities, industry partners, and other research institutions allows for the sharing of expertise, resources, and perspectives, leading to more comprehensive and impactful research outcomes.

- Universities: Collaborations with universities provide access to cutting-edge research, specialized equipment, and a pool of talented researchers and students. These partnerships often involve joint research projects, student internships, and the exchange of knowledge and expertise. For instance, a laboratory might collaborate with a university’s food science department to study the effects of different processing methods on the nutritional content of foods.

- Industry Partners: Working with food manufacturers and other industry partners provides laboratories with real-world insights into the challenges and needs of the food industry. These collaborations can lead to the development of practical solutions and the commercialization of research findings. A laboratory might partner with a food manufacturer to develop a new food product, testing its feasibility and market potential.

- Government Agencies: Collaboration with government agencies, such as health departments and regulatory bodies, ensures that research aligns with public health priorities and regulatory requirements. These collaborations can involve joint research projects, data sharing, and the development of new food safety standards.

- International Organizations: Partnerships with international organizations, such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO), enable laboratories to participate in global research initiatives and share their expertise with other countries.

Regulatory Compliance and Standards

The National Food Laboratory operates within a complex framework of regulations and standards designed to ensure the safety and quality of the food supply. Adherence to these guidelines is paramount, impacting every aspect of the laboratory’s operations, from testing methodologies to data reporting. Compliance demonstrates a commitment to consumer protection and facilitates international trade.

International and National Regulations and Standards

Food laboratories must navigate a dual landscape of international and national regulations. These regulations dictate the acceptable levels of contaminants, labeling requirements, and testing procedures. Compliance is demonstrated through meticulous documentation and adherence to established protocols.

- International Standards: These standards provide a baseline for food safety practices worldwide. They facilitate international trade and harmonize food safety regulations across borders.

- Codex Alimentarius: The Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), develops harmonized international food standards, guidelines, and codes of practice. These standards cover a wide range of food products and establish maximum residue limits (MRLs) for pesticides and veterinary drugs.

- ISO Standards: The International Organization for Standardization (ISO) develops and publishes a vast array of standards relevant to food laboratories. ISO 17025, for example, is a critical standard specifying the general requirements for the competence of testing and calibration laboratories.

- National Regulations: National regulations implement and often expand upon international standards, tailored to the specific needs and conditions of a country. These regulations are enforced by national food safety agencies.

- Food Safety Modernization Act (FSMA) (US): This landmark US legislation, signed into law in 2011, gives the Food and Drug Administration (FDA) more authority to regulate the food industry. It focuses on preventing food safety problems rather than reacting to them.

- European Union Food Law: The EU has a comprehensive legal framework for food safety, including regulations on hygiene, contaminants, and labeling. The European Food Safety Authority (EFSA) provides scientific advice to support the development of these regulations.

Role in Enforcing Food Safety Regulations

National Food Laboratories play a critical role in enforcing food safety regulations by providing scientific data and analysis to support regulatory decisions. They serve as an independent body to assess compliance and ensure consumer protection.

- Testing and Analysis: Laboratories conduct a wide range of tests to detect contaminants, verify nutritional content, and assess the presence of pathogens. This data is used to determine if food products meet regulatory requirements. For instance, a laboratory might analyze samples of imported seafood for mercury levels to ensure they are below the maximum allowed by the relevant national regulations.

- Surveillance and Monitoring: Laboratories participate in food surveillance programs, collecting and analyzing food samples from across the supply chain. This helps to identify potential food safety hazards and track the effectiveness of regulatory measures. This could involve the regular sampling of processed meats to check for the presence of

-Listeria monocytogenes*. - Investigation of Foodborne Illness Outbreaks: During foodborne illness outbreaks, laboratories play a crucial role in identifying the source of the contamination. This involves isolating and characterizing pathogens from food samples and patient specimens. They collaborate with public health officials to implement measures to control the outbreak and prevent further illnesses.

- Providing Expert Advice: Laboratories provide scientific expertise to regulatory agencies and other stakeholders. This can include advising on the development of regulations, interpreting test results, and providing training on food safety practices.

Certifications and Accreditations

Accreditations and certifications demonstrate a laboratory’s commitment to quality and competence. These credentials provide assurance to stakeholders, including consumers, regulators, and the food industry.

- ISO 17025 Accreditation: This is the most widely recognized international standard for testing and calibration laboratories. Accreditation to ISO 17025 demonstrates that a laboratory operates a quality management system and is technically competent to perform specific tests. A laboratory’s accreditation certificate, typically displayed prominently, lists the specific tests for which the laboratory has been accredited.

- ISO 9001 Certification: ISO 9001 is a standard for quality management systems. Certification to this standard demonstrates that a laboratory has a robust quality management system in place to ensure consistency and continuous improvement.

- Good Laboratory Practice (GLP) Compliance: GLP is a quality system concerned with the organizational process and the conditions under which non-clinical health and environmental safety studies are planned, performed, monitored, recorded, archived and reported. Compliance ensures the reliability, reproducibility, and integrity of data generated in the laboratory.

- Specific Industry Certifications: Depending on the scope of their work, laboratories may also hold certifications specific to particular food sectors or testing methodologies. For example, a laboratory testing for organic certification might be certified by an accredited organic certifier.

Staff and Expertise

The National Food Laboratory’s effectiveness hinges on the expertise and dedication of its staff. A diverse team of professionals, each bringing specialized knowledge and skills, ensures the laboratory’s ability to perform its critical functions. Their collective expertise underpins the reliability of test results, the development of new methodologies, and the overall advancement of food safety and quality standards.

Types of Professionals Employed

The National Food Laboratory employs a multidisciplinary team, each member contributing unique skills and perspectives to the overall mission. This diverse composition is crucial for addressing the multifaceted challenges of food safety and quality.

- Food Scientists and Technologists: These professionals are the core of the laboratory’s operations. They apply scientific principles to analyze food composition, processing, and preservation. They may specialize in areas such as food chemistry, microbiology, or sensory evaluation.

- Chemists: Chemists perform detailed analyses of food samples to identify and quantify various components, including nutrients, contaminants, and additives. Their expertise is essential for ensuring food meets regulatory standards and consumer safety.

- Microbiologists: Microbiologists are responsible for detecting and identifying microorganisms in food samples. They assess the presence of pathogens, spoilage organisms, and other microbial indicators of food safety.

- Biochemists: Biochemists investigate the chemical processes and substances occurring within food. They study the impact of processing on food components and develop methods to improve food quality and stability.

- Toxicologists: Toxicologists assess the potential health risks associated with contaminants in food. They evaluate the toxicity of substances and provide data to inform risk assessments and regulatory decisions.

- Quality Assurance Specialists: These professionals ensure that all laboratory procedures and processes meet established quality standards. They are responsible for implementing and maintaining quality control systems, including Good Laboratory Practice (GLP) and ISO standards.

- Laboratory Technicians: Laboratory technicians perform a wide range of routine tasks, including sample preparation, instrument maintenance, and data entry. They support the work of scientists and analysts, ensuring the smooth operation of the laboratory.

- Regulatory Affairs Specialists: These specialists are experts in food regulations and standards. They ensure that the laboratory’s activities comply with all relevant laws and guidelines. They also monitor changes in regulations and provide guidance to laboratory staff.

- Data Analysts and Statisticians: These professionals analyze laboratory data to identify trends, assess risks, and improve the accuracy and reliability of test results. They use statistical methods to interpret data and provide insights to support decision-making.

- Research Scientists: Research scientists conduct investigations to develop new testing methods, improve food safety practices, and address emerging food safety challenges. They may work on projects related to foodborne illness, food fraud, or the development of novel food products.

Qualifications and Expertise Required for Various Roles

Each role within the National Food Laboratory demands specific qualifications and a deep understanding of the principles and practices of food science and related fields. The following details the qualifications and expertise necessary for various positions.

- Food Scientists and Technologists: Typically, a minimum of a Bachelor’s degree in Food Science, Food Technology, or a related field is required. Advanced degrees (Master’s or Ph.D.) are often preferred for research and leadership positions. Expertise in areas such as food chemistry, food microbiology, food processing, or sensory evaluation is essential. They should possess strong analytical skills and a thorough understanding of food regulations and safety standards.

- Chemists: A Bachelor’s or Master’s degree in Chemistry, Biochemistry, or a related field is usually required. Experience with analytical techniques such as chromatography (HPLC, GC), mass spectrometry (MS), and spectroscopy is critical. Knowledge of laboratory safety protocols and data analysis is also essential.

- Microbiologists: A Bachelor’s or Master’s degree in Microbiology, Biology, or a related field is generally required. Expertise in culturing, identifying, and characterizing microorganisms is essential. Experience with molecular biology techniques (PCR, sequencing) is often preferred. A strong understanding of foodborne pathogens and food safety regulations is also needed.

- Biochemists: A Bachelor’s or Master’s degree in Biochemistry, Chemistry, or a related field is typically required. A strong understanding of biochemical pathways, enzyme kinetics, and analytical techniques is crucial. Experience with food analysis and processing is beneficial.

- Toxicologists: A Master’s or Ph.D. in Toxicology, Pharmacology, or a related field is generally required. Expertise in assessing the toxicity of substances and understanding the mechanisms of toxicity is essential. Experience with risk assessment and regulatory toxicology is often preferred.

- Quality Assurance Specialists: A Bachelor’s degree in Food Science, Chemistry, or a related field is typically required. Certification in quality management systems (e.g., ISO 9000) is often preferred. Knowledge of Good Laboratory Practice (GLP) and experience in implementing and maintaining quality control systems are essential.

- Laboratory Technicians: A Bachelor’s degree in Food Science, Biology, Chemistry, or a related field is often required. Experience with laboratory techniques, sample preparation, and instrument operation is essential. A strong attention to detail and the ability to follow standard operating procedures are also crucial.

- Regulatory Affairs Specialists: A Bachelor’s or Master’s degree in Food Science, Law, or a related field is typically required. In-depth knowledge of food regulations and standards, including those of relevant government agencies (e.g., FDA, USDA), is essential. Experience in regulatory compliance and communication is also beneficial.

- Data Analysts and Statisticians: A Bachelor’s or Master’s degree in Statistics, Mathematics, or a related field is generally required. Proficiency in statistical software and data analysis techniques is essential. Experience in interpreting data and communicating findings is also beneficial.

- Research Scientists: A Ph.D. in Food Science, Chemistry, Microbiology, or a related field is typically required. A strong research background and experience in designing and conducting scientific studies are essential. Expertise in a specific area of food science (e.g., food safety, food processing) is also needed.

Training and Professional Development Opportunities

Continuous learning and professional development are essential for maintaining the expertise of the National Food Laboratory’s staff. Various training programs and opportunities are provided to enhance their skills and knowledge.

- On-the-Job Training: New employees receive comprehensive training on laboratory procedures, equipment operation, and safety protocols. Experienced staff members provide mentorship and guidance.

- Internal Training Programs: The laboratory offers regular training sessions on specific topics, such as new testing methods, instrument operation, and quality control procedures. These programs are often led by senior scientists or external experts.

- External Training Courses and Workshops: Staff members are encouraged to attend external training courses and workshops to stay current with the latest advancements in food science and technology. These opportunities provide specialized training on specific topics, such as food safety, food analysis, and regulatory compliance.

- Conferences and Seminars: Participation in scientific conferences and seminars allows staff members to present their research, network with other professionals, and learn about the latest developments in the field.

- Professional Certifications: The laboratory supports staff members in obtaining professional certifications, such as those offered by the American Society for Microbiology (ASM) or the Institute of Food Technologists (IFT). These certifications demonstrate a commitment to professional excellence and enhance career prospects.

- Higher Education Support: The laboratory may provide financial support or time off for staff members pursuing advanced degrees or other educational opportunities. This demonstrates a commitment to fostering professional growth and development.

Challenges and Future Trends

National Food Laboratories operate within a dynamic landscape, facing a complex interplay of challenges and opportunities. Navigating these requires continuous adaptation and strategic foresight. Understanding the current hurdles and anticipating future trends is crucial for ensuring the laboratory’s continued effectiveness in safeguarding food safety and quality.

Current Challenges Facing National Food Laboratories

The efficient operation of a National Food Laboratory is often hindered by various difficulties. Addressing these challenges is vital for maintaining the integrity and reliability of food testing processes.

- Maintaining Accuracy and Precision: Ensuring the consistent accuracy and precision of analytical results is paramount. This involves meticulous quality control procedures, regular instrument calibration, and the use of certified reference materials. Errors can arise from sample preparation, instrument malfunction, or operator variability. The ISO 17025 standard provides a framework for maintaining the quality of laboratory testing.

- Keeping Pace with Evolving Regulations: Food safety regulations are constantly evolving to address new hazards and scientific advancements. Laboratories must stay updated with these changes and adapt their testing methods accordingly. This requires ongoing training, investment in new equipment, and a proactive approach to regulatory compliance.

- Managing Data and Information: The volume of data generated by food testing is substantial. Effective data management systems are essential for storage, retrieval, and analysis of results. Laboratories need robust IT infrastructure, including Laboratory Information Management Systems (LIMS), to manage data efficiently and ensure data integrity.

- Addressing Resource Constraints: National Food Laboratories often face resource limitations, including budget constraints, staffing shortages, and limitations in infrastructure. These limitations can impact the laboratory’s ability to perform comprehensive testing and respond quickly to food safety incidents. Prioritization of testing activities and efficient resource allocation are critical.

- Combating Emerging Foodborne Hazards: New foodborne pathogens and contaminants are continuously emerging, posing a threat to food safety. Laboratories must develop and validate new testing methods to detect these hazards promptly. This requires research and development efforts, collaboration with other laboratories, and access to the latest scientific knowledge. For example, the emergence of Cyclospora cayetanensis in fresh produce has required rapid development of new testing protocols.

Emerging Trends in Food Testing and Analysis

The field of food testing is undergoing a rapid transformation driven by technological advancements and evolving consumer demands. Laboratories must embrace these trends to remain at the forefront of food safety and quality assurance.

- Advancements in Analytical Techniques: Technologies like liquid chromatography-mass spectrometry (LC-MS) and next-generation sequencing (NGS) are becoming increasingly prevalent. These techniques offer enhanced sensitivity, specificity, and throughput, enabling the detection of a wider range of contaminants and pathogens. For instance, LC-MS/MS is used to detect pesticide residues in food with greater accuracy than older methods.

- Increased Use of Automation and Robotics: Automation and robotics are being integrated into laboratory workflows to increase efficiency, reduce human error, and improve throughput. Automated sample preparation systems, robotic liquid handlers, and automated plate readers are becoming standard equipment in many laboratories.

- Development of Rapid Testing Methods: Rapid testing methods, such as PCR-based assays and lateral flow devices, are gaining popularity for their speed and ease of use. These methods enable quick detection of pathogens and contaminants, facilitating rapid response to food safety incidents. PCR testing can detect Salmonella in food samples within hours, whereas traditional methods take days.

- Focus on Food Authenticity: With increasing concerns about food fraud, there is a growing demand for methods to verify the authenticity of food products. Isotope ratio mass spectrometry (IRMS) and DNA barcoding are used to determine the origin and composition of food. These techniques can detect the addition of undeclared ingredients or the mislabeling of products.

- Application of Big Data and Artificial Intelligence: The large amounts of data generated by food testing can be analyzed using big data analytics and artificial intelligence (AI) to identify patterns, predict risks, and improve decision-making. AI algorithms can be used to analyze food safety data, predict outbreaks, and optimize testing procedures.

Potential Impact of Technological Advancements on Laboratory Operations

Technological advancements are poised to reshape the way National Food Laboratories operate. The adoption of these technologies will bring significant benefits, but also presents challenges that must be addressed proactively.

- Enhanced Efficiency and Productivity: Automation and robotics will streamline laboratory workflows, reducing manual labor and increasing throughput. This will allow laboratories to process more samples with greater speed and efficiency.

- Improved Accuracy and Reliability: Advanced analytical techniques will provide more accurate and reliable results. Automated systems will minimize human error and ensure consistent performance.

- Faster Turnaround Times: Rapid testing methods will reduce the time required to obtain results, enabling quicker responses to food safety incidents. This will help to prevent the spread of contaminated products and protect public health.

- Reduced Costs: While the initial investment in new technologies can be significant, automation and improved efficiency can lead to long-term cost savings. Reduced labor costs, lower reagent consumption, and decreased waste disposal can contribute to cost optimization.

- Increased Data Accessibility and Analysis: LIMS and big data analytics will facilitate data storage, retrieval, and analysis. This will enable laboratories to identify trends, predict risks, and improve decision-making. Data sharing and collaboration will become easier, fostering innovation and knowledge exchange. For example, integrating a LIMS with an online portal for results can improve communication with stakeholders.

Impact on Public Health

National Food Laboratories play a critical role in safeguarding public health by ensuring the safety and quality of the food supply. Their work directly translates to fewer illnesses, reduced healthcare costs, and a higher quality of life for the population. Through rigorous testing, research, and regulatory oversight, these laboratories act as a first line of defense against foodborne hazards.

Protecting Public Health

The primary function of National Food Laboratories in protecting public health revolves around identifying and mitigating risks associated with food consumption. This is achieved through comprehensive analysis and surveillance programs.

- Hazard Identification: Laboratories employ advanced techniques to detect a wide range of foodborne hazards, including bacteria (e.g., Salmonella, E. coli), viruses, parasites, and chemical contaminants (e.g., pesticides, heavy metals). A scanning electron microscope reveals the intricate surface details of a

-Salmonella* bacterium, highlighting the structures involved in its ability to attach to host cells and cause infection. - Risk Assessment: Once hazards are identified, laboratories conduct risk assessments to evaluate the likelihood and severity of potential health impacts. This involves analyzing data on food consumption patterns, the prevalence of contaminants, and the susceptibility of different population groups. This information informs the setting of safe levels for contaminants and the development of effective control measures.

- Surveillance and Monitoring: Continuous monitoring of the food supply is crucial for identifying emerging risks and tracking the effectiveness of food safety interventions. Laboratories collect and analyze samples from various points in the food chain, from farms and processing plants to retail outlets and restaurants. This data is used to identify trends, pinpoint sources of contamination, and trigger investigations when necessary.

- Outbreak Investigation: When foodborne illnesses occur, laboratories play a vital role in outbreak investigations. They analyze food samples and patient specimens to identify the causative agent and trace the source of the outbreak. This information is critical for preventing further illnesses and implementing corrective actions. A team of scientists in a laboratory, wearing protective gear, is shown meticulously extracting DNA from food samples to identify the specific strain of a pathogen responsible for an outbreak.

- Regulatory Enforcement: National Food Laboratories often work in collaboration with regulatory agencies to enforce food safety standards. They provide scientific evidence to support enforcement actions, such as product recalls and penalties for non-compliance.

Preventing Food Safety Crises

Laboratory work has demonstrably prevented numerous food safety crises by detecting and addressing potential hazards before they could cause widespread harm. These examples showcase the impact of laboratory efforts.

- Salmonella Outbreak in Peanut Products: In the early 2000s, National Food Laboratories detected

-Salmonella* contamination in peanut products, leading to a massive recall and preventing numerous illnesses. Laboratory analysis confirmed the presence of

-Salmonella* in peanut butter samples. The image depicts a scientist examining petri dishes containing bacterial cultures. - E. coli Outbreak in Fresh Produce: Laboratories identified

-E. coli* contamination in fresh produce, prompting recalls and enhanced safety measures. A detailed laboratory report shows the identification of

-E. coli* O157:H7 in a batch of spinach, traced back to a specific farm. - Melamine Contamination in Infant Formula: In a global crisis, laboratories detected melamine contamination in infant formula, protecting vulnerable infants from severe health consequences. A series of mass spectrometers and chromatography equipment, essential for detecting chemical contaminants, are seen operating in a laboratory.

- Listeria Contamination in Ready-to-Eat Foods: Laboratories routinely monitor ready-to-eat foods for

-Listeria monocytogenes*, a bacterium that can cause serious illness. The detection of

-Listeria* in a batch of deli meat led to a product recall, preventing potential illnesses.

Importance of Public Awareness and Education, National food laboratory

Public awareness and education are essential components of a comprehensive food safety strategy. When the public understands food safety risks and best practices, they can make informed choices and take proactive measures to protect themselves and their families.

- Promoting Safe Food Handling Practices: National Food Laboratories often participate in public awareness campaigns to educate consumers about safe food handling practices, such as proper cooking temperatures, handwashing, and preventing cross-contamination. An infographic, distributed by a National Food Laboratory, illustrates safe food handling practices in a kitchen setting, including proper handwashing techniques, separating raw and cooked foods, and cooking food to the correct internal temperature.

- Providing Information on Foodborne Illnesses: Laboratories provide information on the symptoms of foodborne illnesses, how to prevent them, and what to do if someone suspects they have a foodborne illness. This includes educating the public about common foodborne pathogens and the foods most frequently associated with outbreaks.

- Supporting Food Safety Regulations: Public awareness helps build support for food safety regulations and enforcement efforts. When the public understands the importance of food safety, they are more likely to support government initiatives aimed at protecting the food supply.

- Empowering Consumers: By educating consumers, laboratories empower them to make informed choices about the food they eat and to hold food producers and retailers accountable for food safety. A digital resource, available on a National Food Laboratory’s website, provides information on how to read food labels, understand expiration dates, and identify potentially unsafe food products.

Ending Remarks

In conclusion, the national food laboratory stands as a cornerstone of food safety and quality assurance. From its foundational mission to its complex operations, this laboratory is critical in maintaining public health and consumer confidence. The ongoing commitment to scientific rigor, regulatory compliance, and technological advancement ensures that these laboratories will continue to play a vital role in protecting our food supply and safeguarding the health of communities.

The evolution of these laboratories continues, embracing new challenges and opportunities, shaping the future of food safety and the protection of public health.