Zip pouch for food has become a ubiquitous packaging solution, quietly revolutionizing how we store, transport, and consume our meals. From the humble sandwich bag to sophisticated stand-up pouches, these versatile containers offer a blend of convenience, preservation, and branding opportunities that have made them indispensable in the modern food industry. This exploration will delve into the multifaceted world of zip pouches, examining their design, materials, applications, and the evolving trends shaping their future.

We will begin by defining the fundamental characteristics of zip pouches, exploring the food-grade materials that ensure safety, and highlighting the advantages they offer over traditional storage methods. This will then transition into a detailed analysis of various pouch types, their features, and the diverse food products they accommodate. Further discussion will encompass the critical aspects of food safety, printing and branding techniques, and the growing importance of environmental sustainability in the design and use of these essential food packaging solutions.

Zip Pouch for Food: An Introduction

A zip pouch for food is a flexible, resealable container designed specifically for storing and preserving food items. These pouches are a staple in both commercial food packaging and home food storage, offering a convenient and effective way to maintain freshness, prevent spoilage, and extend the shelf life of various food products. They come in various sizes, shapes, and materials, tailored to the specific needs of the food they contain.

Defining the Zip Pouch for Food

The core characteristic of a zip pouch is its resealable closure, typically a zipper mechanism that allows for repeated opening and closing. This feature is crucial for maintaining the integrity of the food inside and preventing contamination. Beyond the zipper, the pouch is constructed from layers of food-grade materials, which create a barrier against moisture, oxygen, light, and odors. The intended use is to protect food products from external factors, thereby preserving their quality, taste, and nutritional value.

Materials Used in Food-Grade Zip Pouch Construction

The selection of materials is paramount in ensuring the zip pouch is safe for food contact and provides the necessary barrier properties. Several materials are commonly employed, often in combination to achieve optimal performance. These materials must be food-grade, meaning they are approved by regulatory bodies like the FDA (in the United States) for direct contact with food. Here’s a look at the key players:

- Polyethylene (PE): A widely used thermoplastic polymer. It’s flexible, inexpensive, and provides good moisture resistance. PE is commonly used as an inner layer for direct food contact.

- Polypropylene (PP): Another thermoplastic polymer, PP offers higher temperature resistance than PE, making it suitable for hot-fill applications. It also provides good clarity and acts as a barrier against some gases.

- Polyethylene Terephthalate (PET): PET is a strong, clear, and recyclable plastic. It provides excellent barrier properties against oxygen and carbon dioxide, extending the shelf life of food products. PET is often used as an outer layer to provide strength and printability.

- Aluminum Foil: Aluminum foil is an excellent barrier against light, oxygen, and moisture. It is often laminated with other materials to create a multi-layer pouch, providing superior protection for sensitive foods. The use of aluminum foil pouches is very common for products like coffee and snacks.

- Metalized Films: These films are created by depositing a thin layer of metal, typically aluminum, onto a plastic film like PET. They offer a cost-effective alternative to aluminum foil, providing good barrier properties and a metallic appearance.

- Paper-Based Materials: In some cases, paper-based materials, often treated with coatings, are used to create a more sustainable pouch option. These may include kraft paper or other specialized papers designed for food contact.

Advantages of Using Zip Pouches for Food Storage

Zip pouches offer several significant advantages over alternative food storage methods, making them a popular choice for both consumers and businesses. These benefits contribute to their widespread adoption.

- Preservation of Freshness: The airtight seal provided by the zip closure, combined with the barrier properties of the pouch materials, helps to prevent air, moisture, and contaminants from reaching the food. This slows down spoilage, oxidation, and the growth of microorganisms, thus extending the shelf life of the food.

- Convenience and Portability: Zip pouches are lightweight, flexible, and easy to handle, making them ideal for on-the-go use. They take up minimal space in storage, and their resealable nature allows for portion control and easy access to the food.

- Cost-Effectiveness: Compared to rigid containers like glass jars or plastic containers, zip pouches are often more economical to produce and transport. This can translate to lower costs for both manufacturers and consumers.

- Enhanced Shelf Life: The barrier properties of the pouch materials, especially when combined with features like vacuum sealing or modified atmosphere packaging (MAP), can significantly extend the shelf life of perishable food products. This reduces food waste and increases the time available for consumption. For example, vacuum-sealed pouches are commonly used for storing meats, cheeses, and other products, extending their shelf life by weeks or even months compared to traditional storage methods.

- Printability and Branding: Zip pouches offer a large surface area for printing, allowing manufacturers to display branding, nutritional information, and other important details. This is a key advantage for marketing and product visibility.

- Sustainability (Emerging): While traditional plastic pouches have environmental concerns, there is a growing trend towards using more sustainable materials in zip pouch production, such as compostable films or recycled plastics. These innovations aim to reduce the environmental impact of food packaging.

Types and Variations of Food Zip Pouches

Food zip pouches come in a variety of designs, each offering unique advantages for packaging and preserving different food items. The choice of pouch style often depends on factors like product weight, shelf life requirements, and desired presentation. Understanding these variations allows for selecting the most appropriate pouch for a specific food product, optimizing both protection and consumer appeal.

Design Categories of Food Zip Pouches

Different designs cater to various needs in the food packaging industry. The table below provides a comprehensive overview of the common types of food zip pouches, outlining their key attributes.

| Pouch Type | Description | Key Features | Typical Food Applications |

|---|---|---|---|

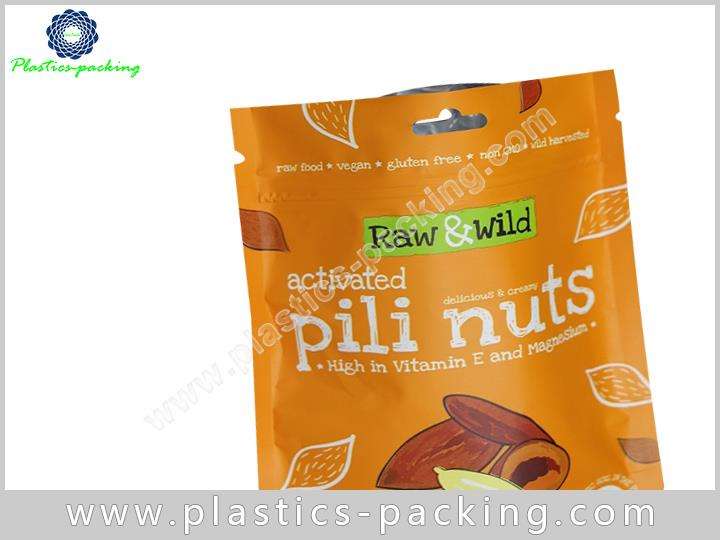

| Stand-Up Pouch | These pouches have a gusseted bottom that allows them to stand upright on a shelf. | Excellent shelf presence, reclosable zipper, often includes a tear notch for easy opening. | Snack foods (chips, nuts), pet food, coffee, granola. |

| Flat Pouch | Simple, two-dimensional pouches. | Cost-effective, can be easily customized with printing, suitable for single-serve portions. | Dried fruits, spices, seasonings, single-serve snacks. |

| Gusseted Pouch | Features folded side or bottom gussets that expand to accommodate product volume. | Increased capacity, can stand up (bottom gusset), provides flexibility for irregular shapes. | Coffee beans, tea leaves, bulk food items, pet food. |

| Spouted Pouch | Includes a spout for dispensing the product. | Convenient for liquids and semi-liquids, allows for controlled pouring, often includes a tamper-evident cap. | Juices, sauces, baby food, yogurt. |

Differentiating Features of Zip Pouch Styles

Each pouch style offers distinct advantages, making them suitable for different applications. Stand-up pouches, for example, maximize shelf space and brand visibility, while flat pouches offer a cost-effective solution for single-serve packaging. Gusseted pouches provide increased volume capacity, and spouted pouches offer convenient dispensing for liquids.

- Stand-Up Pouches: Their ability to stand upright is a significant advantage, making them highly visible on store shelves. They often incorporate reclosable zippers and tear notches for ease of use. The gusseted bottom provides stability, and they can be customized with various printing options.

- Flat Pouches: These are generally the most economical option, suitable for products where shelf presence is less critical. They are easy to manufacture and can be printed with high-quality graphics. Flat pouches are ideal for single-serve applications, like spice packets or small snacks.

- Gusseted Pouches: The gussets, or folded sections, expand to accommodate a larger volume of product. Bottom gusseted pouches offer stand-up capabilities. Side gusseted pouches are commonly used for products like coffee beans or pet food, where a larger capacity is needed.

- Spouted Pouches: The integrated spout and cap provide a convenient dispensing mechanism, making them ideal for liquid or semi-liquid products. They often include tamper-evident features for safety. These pouches are commonly used for baby food, juices, and sauces.

Common Sizes and Capacities of Zip Pouches

Zip pouch sizes vary significantly depending on the food product and its intended use. Pouches are available in a wide range of sizes, from small single-serve packets to large bulk packaging.

- Single-Serve Pouches: These are often flat pouches, designed to hold small quantities of food, such as 1-ounce snack bags or individual spice packets.

- Retail Pouches: Stand-up pouches are common for retail applications, with sizes ranging from 4 ounces to several pounds, depending on the product. For example, a 12-ounce stand-up pouch is a common size for coffee beans.

- Bulk Pouches: Gusseted pouches and larger stand-up pouches are used for bulk packaging, holding several pounds of product. Pet food, for instance, is frequently packaged in pouches ranging from 5 to 20 pounds.

The capacity of a zip pouch is typically measured in ounces or pounds, reflecting the weight of the food it can contain. However, the actual volume can vary based on the density of the food product. For example, a pouch that holds 12 ounces of coffee beans might hold a significantly larger volume of a lighter product, like puffed rice.

The selection of the appropriate size is crucial for both product protection and consumer convenience.

Materials and Food Safety Considerations

Ensuring the safety of food stored in zip pouches is paramount. The materials used directly impact the food’s integrity, preventing contamination and preserving its quality. Understanding the specific materials, their properties, and the relevant safety standards is crucial for both manufacturers and consumers. This section delves into the crucial aspects of food-grade materials, their comparisons, and the regulations that govern their use in zip pouch production.

Importance of Food-Grade Materials

The selection of food-grade materials is fundamental to prevent the transfer of harmful substances from the packaging to the food. Non-food-grade materials may contain chemicals that can leach into the food, leading to potential health risks. Food-grade materials are specifically designed and tested to meet stringent safety standards, guaranteeing that they do not contaminate the food they contain. This ensures that the food remains safe for consumption and retains its original flavor and nutritional value.

Using the wrong materials could lead to food spoilage, bacterial growth, and potential poisoning.

Common Food-Safe Materials

Several materials are commonly used in the manufacturing of food-safe zip pouches, each offering unique characteristics.

- Polyethylene (PE): PE is a widely used thermoplastic polymer, valued for its flexibility, low cost, and excellent moisture barrier properties. It’s available in various densities, with Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) being the most common. LDPE is often used for flexible pouches due to its softness and ability to seal easily, while HDPE offers greater strength and is often used for stand-up pouches.

- Polypropylene (PP): PP is another thermoplastic polymer known for its high melting point, chemical resistance, and clarity. It provides a good barrier against moisture and oxygen, making it suitable for preserving the freshness of food. PP is often used for pouches that require a higher level of protection, such as those used for microwaveable meals.

- Polyethylene Terephthalate (PET): PET is a strong, clear, and lightweight plastic that offers excellent barrier properties against gases and moisture. It is commonly used in combination with other materials to create multi-layer pouches, enhancing the overall protection of the food. PET is also known for its recyclability.

- Polyamide (PA, or Nylon): PA, commonly known as nylon, is a strong and flexible material with excellent resistance to punctures and tears. It’s often used in multi-layer pouches to provide structural integrity and improve barrier properties. Nylon is frequently used in pouches for products requiring high-temperature processing, such as retort pouches.

- Ethylene Vinyl Alcohol Copolymer (EVOH): EVOH is a high-barrier material that effectively prevents the passage of oxygen and other gases. It’s often used as a layer in multi-layer pouches to extend the shelf life of food products. EVOH is particularly useful for preserving the flavor and aroma of sensitive foods.

Safety Certifications and Regulations

Adherence to safety certifications and regulations is critical for ensuring the safety of food packaging materials.

- U.S. Food and Drug Administration (FDA): The FDA regulates the materials used in food packaging in the United States. Packaging materials must comply with FDA regulations, specifically those Artikeld in 21 CFR (Code of Federal Regulations). Compliance with these regulations ensures that the materials are safe for direct contact with food. Food contact materials must meet specific requirements to prevent the migration of harmful substances into food.

- European Food Safety Authority (EFSA): EFSA provides scientific advice on food safety within the European Union. Packaging materials intended for use in the EU must comply with EFSA regulations, including those related to the use of plastics and other materials. The EFSA sets limits on the migration of substances from packaging materials into food.

- Global Migration Limits: Packaging manufacturers must adhere to global migration limits, which specify the maximum amount of a substance that can migrate from the packaging material into the food. These limits are designed to protect consumer health.

- Good Manufacturing Practices (GMP): GMP guidelines are essential for ensuring the quality and safety of food packaging production. They cover all aspects of the manufacturing process, from raw materials to finished products. Adherence to GMP ensures that packaging materials are produced in a controlled environment, minimizing the risk of contamination.

- Specific Migration Limits (SML): SMLs are the maximum permitted amount of a specific substance that can migrate from the packaging material into the food. These limits are based on scientific assessments of the potential health risks associated with each substance.

- Overall Migration Limit (OML): OML refers to the maximum total amount of all substances that can migrate from the packaging material into the food. This limit helps ensure the overall safety of the packaging material, considering the combined effects of all the substances present.

Applications of Zip Pouches in the Food Industry

Zip pouches have revolutionized food packaging, offering versatility and practicality across various food product categories. Their adaptability allows them to cater to different needs, from preserving freshness to enhancing consumer convenience. They are widely used in the food industry because of their ability to protect food and prolong its shelf life.

Understand how the union of cost less food ad can improve efficiency and productivity.

Examples of Food Products Packaged in Zip Pouches

Zip pouches are employed for packaging a diverse array of food products, catering to both retail and foodservice sectors. This versatility stems from the pouches’ customizable nature, allowing for tailored solutions based on the specific product requirements. Here are some examples of food products that commonly utilize zip pouches:

- Snacks: Chips, pretzels, cookies, nuts, and dried fruits. These pouches often feature resealable zippers for portion control and freshness.

- Frozen Foods: Vegetables, fruits, ready-to-eat meals, and seafood. The pouches are designed to withstand freezing temperatures and prevent freezer burn.

- Prepared Meals: Soups, stews, sauces, and pre-cooked entrees. These pouches often include features for microwave heating.

- Dry Goods: Coffee, tea, spices, and grains. Zip pouches provide an airtight seal to maintain flavor and aroma.

- Pet Food: Dry and wet pet food. Larger pouches with sturdy zippers are used for convenient storage and dispensing.

- Confectionery: Candies, chocolates, and gummy snacks. The pouches help preserve product texture and prevent moisture absorption.

- Powdered Products: Protein powders, drink mixes, and baby formula. The pouches ensure product integrity and ease of dispensing.

Advantages of Using Zip Pouches for Specific Food Categories

The advantages of using zip pouches are numerous and vary depending on the food category. From enhancing consumer convenience to extending product shelf life, zip pouches offer a compelling packaging solution.

- Snacks: Resealable zippers provide portion control and maintain freshness, preventing snacks from becoming stale. Consumers can easily reseal the pouch to keep the remaining product fresh for later consumption.

- Frozen Foods: Zip pouches are designed to withstand freezing temperatures and provide a barrier against freezer burn. They also offer flexibility in storage and are easy to handle.

- Prepared Meals: Many zip pouches are microwave-safe, providing convenience for consumers who can heat the meal directly in the pouch. They also offer portion control and easy storage.

Contribution of Zip Pouches to Extending Shelf Life

Zip pouches significantly contribute to extending the shelf life of food products by creating a protective barrier against environmental factors that cause spoilage. This is achieved through several key features.

- Airtight Seal: The resealable zipper creates an airtight seal that prevents oxygen and moisture from entering the pouch. Oxygen exposure can lead to oxidation, causing food to spoil, while moisture can promote the growth of mold and bacteria.

- Barrier Properties: Zip pouches are often made from multi-layer films with barrier properties. These films block the passage of light, odors, and gases, further protecting the food from degradation.

- Protection from Contaminants: Zip pouches shield food from external contaminants, such as dust, dirt, and insects, which can compromise food safety and quality.

- Modified Atmosphere Packaging (MAP): Some zip pouches are designed for MAP, where the air inside the pouch is replaced with a modified gas mixture to slow down the spoilage process. This can significantly extend the shelf life of perishable foods.

For example, pre-packaged coffee beans stored in a zip pouch with a one-way valve can maintain their freshness and aroma for several weeks longer than coffee stored in a less effective packaging. Similarly, the use of zip pouches for frozen vegetables can prevent freezer burn and extend their storage life by several months.

Features and Functionality of Zip Pouches

Zip pouches are designed with various features to enhance their usability and provide convenience for both manufacturers and consumers. These features contribute significantly to the protection, preservation, and overall handling of food products. They offer significant improvements in user experience and overall functionality.

Different Types of Closures Available for Zip Pouches

The type of closure is a critical feature of a zip pouch, directly influencing its ability to seal and protect the contents. Several closure mechanisms are employed, each offering different levels of sealing performance and ease of use.

- Zipper Types: Zippers are the most common closure method. They come in various designs, including:

- Press-to-close zippers: These are simple, user-friendly zippers that create a secure seal when pressed together. They are suitable for a wide range of products.

- Slider zippers: A slider is used to open and close these zippers. They offer a more robust seal and are often preferred for products requiring a higher level of protection, such as liquids or powders. A slider also facilitates ease of opening and closing, particularly for larger pouches.

- Double-track zippers: These zippers feature two tracks, enhancing the seal’s integrity and providing extra protection against leaks and contamination.

- Extended zippers: Some zip pouches incorporate extended zippers, which provide a wider sealing area, making them easier to grip and close, especially for consumers with dexterity challenges.

- Sealing Mechanisms: Besides zippers, other sealing mechanisms are used, either independently or in combination with zippers:

- Heat sealing: Heat sealing creates a permanent seal along the pouch edges. This is typically done during the pouch manufacturing process to ensure airtightness.

- Pressure-sensitive adhesives: In some cases, pressure-sensitive adhesives are used for sealing, particularly for creating a tamper-evident seal or for temporary closures.

- Fold-over seals: Certain pouches utilize a fold-over design with a sealing strip, providing a simple and cost-effective closure method, often found in snack packaging.

Benefits of Incorporating Features

Incorporating specific features into zip pouches significantly enhances their functionality and user experience. These features contribute to ease of use, product protection, and consumer convenience.

- Tear Notches: Tear notches are small, pre-cut indentations along the edge of the pouch.

- Benefits: They make it easier for consumers to open the pouch without needing scissors or other tools. This feature is particularly useful for on-the-go consumption or for products where ease of access is critical.

- User Experience: A well-placed tear notch can significantly improve the consumer experience by eliminating frustration and saving time.

- Hang Holes: Hang holes are perforations at the top of the pouch.

- Benefits: They allow pouches to be displayed on hooks in retail environments, optimizing shelf space and improving product visibility. They also facilitate storage at home, allowing consumers to hang the pouch in a pantry or kitchen.

- Applications: Hang holes are commonly found in packaging for snacks, pet food, and other products.

- Resealable Zippers: Resealable zippers enable consumers to reclose the pouch after opening.

- Benefits: They help preserve the freshness and quality of the food by preventing exposure to air, moisture, and contaminants. This is crucial for maintaining the taste, texture, and shelf life of the product. They also prevent spills and messes.

- User Experience: Resealable zippers add convenience for consumers, allowing them to consume portions of the product at different times without compromising the remaining contents.

How These Features Improve User Experience and Enhance Functionality

The integration of features like tear notches, hang holes, and resealable zippers directly impacts how consumers interact with zip pouches. These enhancements significantly improve the overall functionality and user experience.

- Ease of Use: Tear notches and user-friendly zippers make pouches easier to open and close, reducing frustration and saving time.

- Product Protection: Resealable zippers, combined with robust sealing mechanisms, help preserve product freshness and prevent spoilage, ensuring that the contents remain safe and of high quality.

- Convenience: Hang holes improve shelf visibility, while resealable zippers allow for portion control and on-the-go consumption.

- Sustainability: By helping preserve product freshness, resealable zippers can potentially reduce food waste, contributing to sustainability efforts.

Printing and Branding on Zip Pouches

Creating visually appealing and informative zip pouches is crucial for attracting consumers and ensuring product success. The printing and branding aspects of these pouches play a significant role in communicating product value and differentiating a brand in a competitive market. This section delves into the common printing methods, the impact of branding, and the key elements of effective zip pouch design.

Printing Methods for Zip Pouches

Several printing methods are employed for zip pouches, each with its own advantages regarding cost, quality, and suitability for different applications. Understanding these methods is essential for selecting the optimal approach for a specific food product.

- Flexographic Printing: Flexography, or flexo, is a widely used printing technique for flexible packaging due to its versatility and cost-effectiveness, especially for large production runs. The process involves using flexible relief plates to transfer ink onto the pouch material. It’s known for its ability to print on various substrates, including those used for food packaging. The ink used is usually water-based, making it suitable for food contact.

Flexographic printing can handle a wide range of colors and offers good print quality, though it may not be ideal for highly detailed graphics or photographic images.

- Digital Printing: Digital printing is a more recent technology that is gaining popularity for its flexibility and ability to produce high-quality prints, even for short runs. This method uses digital files to directly transfer ink onto the pouch material, eliminating the need for printing plates. Digital printing is particularly advantageous for customized designs, variable data printing (e.g., batch codes, expiration dates), and complex graphics.

It allows for vibrant colors and high-resolution images. However, it can be more expensive than flexographic printing for large production volumes.

- Gravure Printing: Gravure printing uses a recessed cylinder to transfer ink onto the pouch material. This method is known for its exceptional print quality and is often used for high-volume production runs where premium aesthetics are required. Gravure printing can reproduce fine details and a wide color gamut. However, it is typically more expensive than flexographic printing, and the lead times are longer due to the creation of engraved cylinders.

Role of Branding and Graphics

Effective branding and graphics are essential for attracting consumers’ attention and conveying the product’s identity and value proposition. A well-designed zip pouch serves as a silent salesperson, communicating key messages and influencing purchasing decisions.

- Brand Recognition: Consistent branding, including logos, color schemes, and typography, helps consumers quickly recognize and remember the product. This familiarity builds trust and loyalty, encouraging repeat purchases.

- Product Information: Clear and concise information about the product, such as ingredients, nutritional facts, and usage instructions, is essential for consumer transparency and satisfaction.

- Visual Appeal: High-quality graphics, including attractive images and designs, enhance the pouch’s visual appeal and make the product more desirable. Appealing packaging can significantly impact sales, with studies showing that consumers are more likely to purchase products with attractive packaging. For example, a study by the Paperboard Packaging Council found that packaging design influences consumer perception of product quality by up to 70%.

- Differentiation: Unique branding and graphics help a product stand out from competitors on store shelves. This is particularly important in crowded markets where consumers are faced with numerous choices.

Key Elements of Zip Pouch Design, Zip pouch for food

A well-designed zip pouch incorporates several key elements to effectively communicate product information and attract consumers.

- Product Information: This includes the product name, net weight, ingredients list, nutritional information, and any relevant certifications or claims (e.g., organic, gluten-free).

- Branding Elements: The brand logo, color scheme, and typography are essential for establishing brand recognition and identity.

- Graphics and Imagery: High-quality images of the product, along with attractive design elements, enhance visual appeal and convey the product’s characteristics. Consider using lifestyle images that showcase the product in a relatable setting.

- Functionality Indicators: Clear instructions for opening and closing the zip pouch, as well as any other functional features (e.g., tear notches, resealable zippers), are important for user convenience.

- Regulatory Compliance: Adherence to all relevant labeling regulations, including those related to food safety and allergen information, is crucial for legal compliance.

- Sustainability Messaging: Highlighting eco-friendly aspects of the packaging, such as the use of recyclable materials or sustainable sourcing, can appeal to environmentally conscious consumers.

Environmental Impact and Sustainability

The environmental impact of food packaging, including zip pouches, is a growing concern. Understanding the lifecycle of these pouches, from material sourcing to disposal, is crucial for making informed choices. This section explores the environmental implications of different zip pouch materials and manufacturing processes, highlighting eco-friendly alternatives and industry initiatives.

Comparing Environmental Impacts of Materials and Manufacturing

The environmental footprint of zip pouches varies significantly depending on the materials used and the manufacturing processes involved. Analyzing these factors allows for a better understanding of the sustainability of different pouch types.

- Plastic Pouches (e.g., Polyethylene, Polypropylene): Conventional plastic pouches are typically derived from fossil fuels. Their production requires significant energy and water, contributing to greenhouse gas emissions. These pouches often end up in landfills, where they can take hundreds of years to decompose, releasing harmful microplastics and chemicals. The manufacturing process often involves extrusion and sealing, both of which consume energy.

- Multi-Layer Pouches: These pouches often combine multiple layers of different plastics and sometimes include aluminum foil for barrier properties. While offering excellent protection for food, they are difficult to recycle due to the complexity of separating the different materials. The manufacturing process is more complex, leading to higher energy consumption and waste generation.

- Paper-Based Pouches: Paper-based pouches, often with a plastic or bio-plastic lining, offer a more sustainable alternative. However, the sourcing of paper must be from sustainably managed forests to avoid deforestation. Manufacturing these pouches generally involves less energy than plastic pouch production, but the use of adhesives and coatings can impact recyclability.

- Manufacturing Processes: The energy consumption, water usage, and waste generation during pouch manufacturing also contribute to the environmental impact. Processes that minimize waste, utilize renewable energy sources, and optimize water usage are more sustainable. For example, some manufacturers are using closed-loop systems to recycle water used in printing and lamination.

Eco-Friendly Zip Pouch Options

Several eco-friendly zip pouch options are available, offering reduced environmental impact compared to conventional plastic pouches. These alternatives are increasingly popular as consumers and businesses prioritize sustainability.

- Recycled Material Pouches: These pouches are made from post-consumer recycled (PCR) plastics, reducing the demand for virgin plastics and diverting waste from landfills. The use of PCR materials can significantly lower the carbon footprint of the pouch. For example, a pouch made with 50% PCR content reduces greenhouse gas emissions by approximately 30% compared to a pouch made entirely from virgin materials.

- Biodegradable Plastic Pouches: These pouches are made from biodegradable plastics, such as polylactic acid (PLA) derived from renewable resources like cornstarch or sugarcane. They are designed to break down into natural substances under specific composting conditions. However, the biodegradability of these pouches often requires industrial composting facilities, which are not widely available.

- Compostable Pouches: These pouches are designed to break down into nutrient-rich compost in industrial composting facilities. They are often made from a combination of bio-based materials and compostable polymers. The compostability of these pouches is certified by organizations such as the Biodegradable Products Institute (BPI).

- Bio-Based Plastic Pouches: These pouches are made from plant-based materials. They reduce reliance on fossil fuels and can offer a lower carbon footprint. However, it’s important to note that the environmental impact of bio-based plastics can vary depending on the agricultural practices used to grow the source materials.

Industry Initiatives to Reduce Environmental Footprint

Companies are actively taking steps to reduce the environmental impact of zip pouch packaging through various initiatives. These efforts demonstrate a growing commitment to sustainability within the food industry.

- Sustainable Material Sourcing: Companies are sourcing materials from sustainable suppliers, such as those certified by the Forest Stewardship Council (FSC) for paper-based pouches. This ensures responsible forestry practices.

- Design for Recyclability: Companies are designing pouches to be easily recyclable. This includes using mono-material structures (pouches made from a single type of plastic) and avoiding complex laminates.

- Lightweighting: Reducing the amount of material used in pouch production minimizes waste and lowers transportation emissions. This involves optimizing pouch thickness and using thinner films.

- Closed-Loop Recycling Programs: Some companies are implementing closed-loop recycling programs where they collect used pouches and recycle them into new products. This helps to keep materials in use and reduces waste.

- Partnerships and Collaborations: Companies are partnering with environmental organizations, recycling facilities, and other stakeholders to develop sustainable packaging solutions and promote recycling initiatives. For example, collaborations to create infrastructure for recycling flexible packaging.

- Carbon Footprint Reduction: Companies are calculating the carbon footprint of their pouch production and implementing strategies to reduce emissions, such as using renewable energy, optimizing transportation routes, and investing in carbon offsetting programs.

Best Practices for Using Zip Pouches: Zip Pouch For Food

Using zip pouches effectively is crucial for preserving food quality and extending its shelf life. Proper handling minimizes waste and maximizes the benefits of this convenient storage solution. This section will explore the best practices for sealing, storing, cleaning, and reusing zip pouches.

Proper Sealing and Storage Techniques

Achieving an airtight seal and appropriate storage conditions are essential for maintaining food freshness. The following points Artikel the correct methods for sealing and storing food in zip pouches.

- Sealing the Pouch: Ensure the pouch is clean and dry before sealing. Fill the pouch, leaving some headspace (empty space at the top) to allow for expansion, especially with liquids or items that might release gases. For the best seal, press firmly along the entire zip closure, starting from one end and working to the other. You might also use a “pinch and slide” method, where you pinch the seal together with your fingers and then slide your fingers along the seal to ensure complete closure.

- Storage Environment: The storage environment is just as important as the seal.

- Refrigeration: Most food items benefit from refrigeration. Place sealed zip pouches in the refrigerator promptly after filling.

- Freezing: For longer-term storage, freezing is often the best option. Ensure the pouch is freezer-safe. Lay the pouch flat in the freezer to allow for even freezing and easier stacking later.

- Pantry Storage: For dry goods like snacks or grains, store sealed pouches in a cool, dark, and dry pantry. Avoid direct sunlight and heat sources.

- Labeling: Always label the pouch with the food item, date of preparation or storage, and any other relevant information, such as special ingredients or preparation instructions. Use a permanent marker on the designated area of the pouch.

Common Mistakes in Zip Pouch Usage

Avoiding common errors can significantly improve the effectiveness of zip pouches. Awareness of these mistakes can help users prevent food spoilage and ensure the best results.

- Improper Sealing: Failing to create a complete seal is a primary cause of food spoilage. Air and moisture can easily enter, leading to mold growth and deterioration.

- Overfilling: Overfilling a pouch can put stress on the seal, making it more likely to fail. It can also make it difficult to close the pouch properly.

- Incorrect Storage Temperature: Storing food at the wrong temperature accelerates spoilage. For example, leaving perishable items at room temperature instead of refrigerating them.

- Reusing Without Cleaning: Reusing a zip pouch without proper cleaning can lead to cross-contamination, especially if it previously contained raw meat or other potentially hazardous foods.

- Using Non-Food-Grade Pouches: Not all zip pouches are food-grade. Using pouches not designed for food storage can potentially leach harmful chemicals into the food.

Cleaning and Reusing Zip Pouches

Cleaning and reusing zip pouches, when done correctly, can be both environmentally friendly and cost-effective. However, it’s important to prioritize food safety during this process. Here are some guidelines.

- Cleaning Process:

- Rinsing: Rinse the pouch thoroughly with warm, soapy water immediately after emptying.

- Washing: Wash the pouch by hand with hot, soapy water. Use a soft sponge or cloth to scrub the inside and outside of the pouch.

- Drying: Allow the pouch to air dry completely before reusing. You can prop the pouch open using a bottle or a drying rack to ensure proper airflow.

- Food Safety Considerations:

- When to Discard: Discard pouches that have contained raw meat, fish, or poultry to prevent cross-contamination.

- Visual Inspection: Before reusing, inspect the pouch for any damage, such as tears or cracks. Also, check for lingering odors or stains that indicate contamination.

- Limited Reusability: Zip pouches, especially those made of thinner materials, have a limited lifespan. Repeated washing and use can degrade the seal and the material.

- Specific Cleaning Methods:

- Dishwasher: Some pouches are dishwasher-safe. Check the manufacturer’s instructions. Use the top rack of the dishwasher.

- Vinegar Solution: For stubborn odors, soak the pouch in a solution of warm water and white vinegar for about 30 minutes before washing.

Innovations and Future Trends

The zip pouch industry is constantly evolving, driven by consumer demands for convenience, sustainability, and enhanced food safety. Technological advancements and a growing awareness of environmental concerns are shaping the future of this versatile packaging solution. This section explores the latest innovations and forecasts the direction of zip pouches in the food industry.

Smart Packaging Features

Smart packaging is integrating technology to provide added value to consumers and enhance the functionality of zip pouches. These features go beyond simple sealing and reclosing.

- Active Packaging: This involves incorporating substances into the pouch material that actively interact with the food product to extend shelf life or improve quality. For example, oxygen scavengers can be included to reduce oxidation, preserving the freshness and color of food items like pre-cut fruits or deli meats.

- Intelligent Packaging: Intelligent packaging uses sensors and indicators to provide information about the food product’s condition.

- Time-Temperature Indicators (TTIs): These change color to reflect the cumulative time and temperature exposure of the product, alerting consumers to potential spoilage. For instance, a TTI on a frozen pizza pouch can indicate if the pizza has thawed and refrozen, affecting its quality.

- Freshness Indicators: These can detect changes in gas composition within the pouch, signaling spoilage or loss of freshness. This is especially useful for products like coffee or prepared meals.

- Near Field Communication (NFC) and QR Codes: These technologies allow consumers to access product information, track the product’s journey through the supply chain, or receive promotions by scanning the pouch with a smartphone. This enhances transparency and consumer engagement. For example, a QR code on a snack pouch could link to the product’s origin story or a recipe using the snack.

Enhanced Barrier Properties

Improving the barrier properties of zip pouches is crucial for extending shelf life, maintaining food quality, and reducing food waste. This involves using advanced materials and manufacturing techniques.

- High-Barrier Films: These films provide superior protection against oxygen, moisture, and light, preventing spoilage and preserving the flavor and nutritional value of the food. Examples include multi-layer films with layers of aluminum foil, metallized films, or advanced polymer blends. These are used for products like coffee, nuts, and dried fruits.

- Modified Atmosphere Packaging (MAP): This technique involves flushing the pouch with a gas mixture, typically nitrogen and carbon dioxide, to displace oxygen and slow down the growth of spoilage organisms. MAP is commonly used for fresh produce, ready-to-eat meals, and processed meats.

- Improved Seal Integrity: Enhancements in sealing technology, such as ultrasonic sealing or induction sealing, ensure a hermetic seal that prevents leaks and contamination. This is critical for maintaining product freshness and safety.

New Materials and Designs for Sustainability

Sustainability is a major driver of innovation in the zip pouch industry. The focus is on developing pouches that are more environmentally friendly without compromising performance.

- Bio-Based and Compostable Materials: Replacing traditional petroleum-based plastics with materials derived from renewable resources like corn starch, sugarcane, or cellulose is gaining traction. Compostable pouches can break down into natural elements in a composting environment.

- Polylactic Acid (PLA): PLA is a biodegradable plastic derived from corn starch, used in some zip pouches for products like snacks and coffee.

- Cellulose-based films: These are derived from wood pulp and offer good barrier properties and compostability.

- Recyclable Pouches: Designing pouches that are easier to recycle is another focus. This involves using mono-material structures, where the entire pouch is made from a single type of plastic, making it easier to recycle.

- Reduced Material Usage: Optimizing pouch designs to minimize the amount of material used while maintaining strength and functionality. This can involve thinner films or innovative pouch shapes.

- Innovative Designs: Exploring new pouch designs to reduce material usage and improve functionality. This can include stand-up pouches with gussets, pouches with reclosable zippers, and pouches with built-in spouts.

Vision for the Future of Zip Pouches

The future of zip pouches in the food industry will be shaped by consumer preferences, environmental concerns, and technological advancements.

- Personalization and Customization: Zip pouches will increasingly be tailored to specific consumer needs and preferences. This could involve portion-controlled packaging, customized recipes, or pouches designed for specific diets or lifestyles.

- Circular Economy: The industry will move towards a circular economy model, where zip pouches are designed for recyclability or compostability, and the materials are reused or returned to the environment. This will require collaboration between manufacturers, consumers, and waste management companies.

- Data-Driven Optimization: Data analytics will be used to optimize pouch design, material selection, and supply chain management. This will lead to more efficient and sustainable packaging solutions.

- Enhanced Consumer Experience: Zip pouches will offer an enhanced consumer experience through features like improved ease of use, intuitive reclosing mechanisms, and interactive elements that provide product information and engage consumers.

Final Conclusion

In conclusion, the journey through the realm of zip pouches for food reveals a dynamic landscape of innovation and adaptation. From the meticulous selection of food-grade materials to the strategic implementation of eco-friendly practices, these pouches continue to evolve, catering to both consumer demands and environmental concerns. As technology advances and consumer preferences shift, the zip pouch will likely remain a cornerstone of food packaging, ensuring freshness, extending shelf life, and playing a vital role in the sustainability of the food industry.

The future holds promise for even more advanced features, materials, and designs, solidifying the zip pouch’s position as a pivotal component of modern food preservation and presentation.