Alright, buckle up, because we’re diving headfirst into the world of the 2 lb food tray. Forget the fancy stuff, we’re talking about the unsung hero of takeout, the silent guardian of your leftovers, the trusty sidekick to your late-night cravings. This seemingly simple container has a surprisingly rich history and a complex relationship with everything from sustainability to food safety.

We’re going to peel back the layers, from the humble beginnings of food trays to the cutting-edge innovations shaping their future.

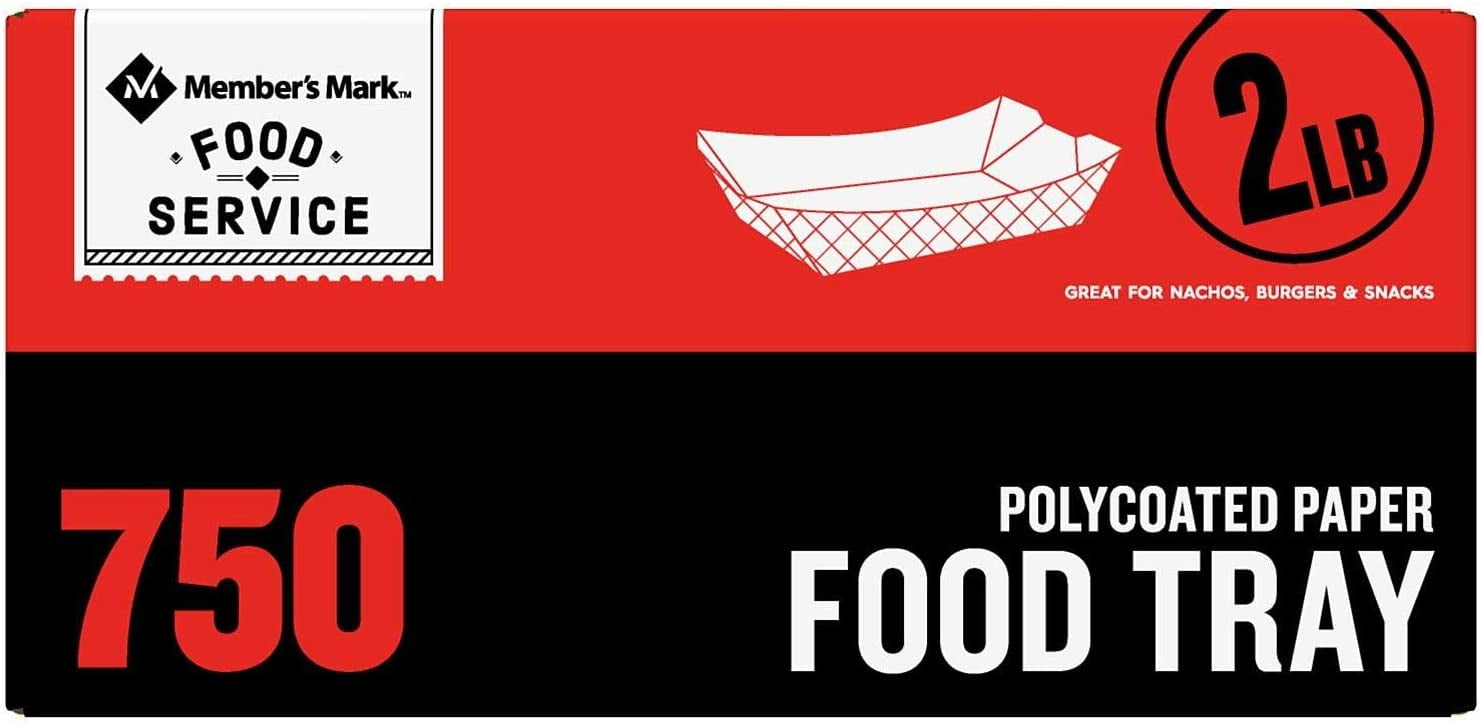

From greasy spoons to high-end restaurants, the 2 lb food tray is a workhorse. We’ll explore its many forms, from the classic rectangular to the sleek and modern designs, and dissect the materials that make them tick. We’ll uncover the secrets of their construction, the regulations that govern them, and the environmental impact they leave behind. Get ready to see this everyday object in a whole new light – it’s more than just a container; it’s a microcosm of the food industry itself.

Introduction to the ‘2 lb Food Tray’

The 2 lb food tray is a ubiquitous container in the food industry, serving a variety of purposes from food preparation to presentation. Its versatility makes it a staple in restaurants, catering services, and even home kitchens. This article delves into the world of the 2 lb food tray, exploring its uses, history, and the materials that bring it to life.

Typical Uses of a 2 lb Food Tray

The 2 lb food tray’s utility spans a broad spectrum of applications. Its size makes it ideal for portioning and serving a variety of foods, especially those that are heavier or denser.

- Restaurant Service: Commonly used for serving side dishes, appetizers, or smaller entrees. Think of a generous portion of fries, onion rings, or a hearty salad.

- Catering Events: Excellent for buffet-style presentations. Caterers often use these trays for showcasing a range of foods, allowing guests easy access and portion control.

- Takeout and Delivery: A practical choice for packaging meals that need to be kept separate and protected during transport. This is particularly relevant for items like fried chicken, pasta dishes, or even pre-made salads.

- Food Preparation: In commercial kitchens and home kitchens, these trays are useful for organizing ingredients, marinating meats, or holding prepped components ready for cooking.

- Food Displays: Used to present food attractively in display cases, such as at delis, bakeries, or supermarkets.

A Brief History of Food Tray Usage, 2 lb food tray

The concept of using trays to contain and serve food dates back centuries. The materials and designs have evolved significantly.The earliest forms of food trays were likely simple wooden or woven baskets. As civilizations developed, trays became more sophisticated. In ancient Rome, for example, trays were crafted from metal and used in banquets. The Industrial Revolution ushered in mass production and the use of new materials.

Paperboard and plastics became increasingly popular for their cost-effectiveness and disposability. The mid-20th century saw a surge in disposable food packaging, driven by the rise of fast food and the demand for convenience. Today, the evolution continues, with a focus on sustainable materials and designs that minimize environmental impact.

Common Materials Used in Manufacturing 2 lb Food Trays, and Their Pros and Cons

The materials used in manufacturing 2 lb food trays significantly impact their functionality, cost, and environmental footprint. The choice of material is a trade-off between these factors.

- Paperboard: Paperboard trays are made from paper pulp and are often coated with a food-grade wax or plastic for moisture resistance.

- Pros: Relatively inexpensive, biodegradable (depending on coating), recyclable (if uncoated).

- Cons: Can be less durable than plastic, may not be suitable for very wet or greasy foods, and coated versions can hinder recyclability.

- Expanded Polystyrene (EPS) – Commonly known as Styrofoam: EPS trays are lightweight and provide good insulation.

- Pros: Inexpensive, good insulation properties, can be molded into various shapes.

- Cons: Not biodegradable, difficult to recycle, and poses environmental concerns due to its long decomposition time and potential for pollution.

- Polypropylene (PP) Plastic: PP trays are durable, heat-resistant, and can be microwaved.

- Pros: Durable, heat-resistant, microwave-safe, recyclable (check local recycling guidelines).

- Cons: Derived from petroleum, requires energy to produce, and may not be readily recyclable in all areas.

- Aluminum: Aluminum trays are strong, conduct heat well, and can be recycled.

- Pros: Excellent heat conductivity, strong and durable, recyclable.

- Cons: More expensive than other materials, can dent easily, and may react with acidic foods if not properly coated.

- Biodegradable Alternatives: A growing trend involves trays made from sustainable materials like molded pulp (made from recycled paper or plant fibers) or compostable plastics (e.g., PLA – polylactic acid, made from renewable resources).

- Pros: Environmentally friendly, compostable or biodegradable.

- Cons: Often more expensive than traditional materials, may not be as durable, and composting facilities may not be widely available.

Types and Designs of 2 lb Food Trays

Alright, foodies! Now that we’ve covered the basics of the 2 lb food tray, let’s dive into the exciting world of shapes, materials, and lids. Because, let’s be honest, the tray is almost as important as the deliciousness it holds. We’ll explore the different designs available, considering both aesthetics and functionality. From rectangular classics to innovative shapes, the options are surprisingly diverse.

We’ll also tackle the crucial lid dilemma: to lid or not to lid, and what kind? Let’s get started!

Shapes and Materials of 2 lb Food Trays

The design of a 2 lb food tray isn’t just about looking pretty; it directly impacts how well it holds your food, how easy it is to transport, and even how it affects the food’s temperature. Different shapes and materials are best suited for various types of food and serving needs. Here’s a breakdown:

| Shape | Material | Common Use |

|---|---|---|

| Rectangular | Foam, Plastic, Aluminum, Cardboard | Sandwiches, salads, pasta dishes, general takeaway. |

| Square | Plastic, Cardboard | Side dishes, desserts, smaller portions. |

| Oval/Round | Aluminum, Plastic, Cardboard | Hot entrees, stews, soups (with appropriate lids). |

| Compartmentalized (Multiple Sections) | Plastic, Foam | Meal combos, bento boxes, dishes with separate components (e.g., rice, protein, vegetables). |

Lid Options: Advantages and Disadvantages

Lids are a crucial part of the 2 lb food tray experience. They protect the food, help maintain temperature, and prevent spills. However, the choice of lid can significantly impact the user experience. Let’s examine the pros and cons of different lid options:

- Attached Lids: These are often hinged and connected to the tray itself.

- Advantages: Convenient (one-piece design), less likely to get lost, good for stacking.

- Disadvantages: Can be bulky, may not seal as tightly as separate lids, potentially less recyclable depending on the material.

- Separate Lids: These are completely detached from the tray.

- Advantages: Often provide a tighter seal, can be made from different materials (e.g., clear plastic for visibility), more flexible in terms of stacking.

- Disadvantages: More prone to getting lost, can require more storage space.

- Vented Lids: These have small holes or vents to release steam.

- Advantages: Prevent condensation buildup, which can make food soggy.

- Disadvantages: Can slightly reduce heat retention, may not be suitable for all types of food.

Designing 2 lb Food Trays: Hot vs. Cold Food

The design of a 2 lb food tray must be tailored to the type of food it will hold. The requirements for hot food trays are very different from those for cold food trays. Here’s a comparison:

- Hot Food Tray:

- Material: Often made of aluminum, foam (expanded polystyrene – EPS), or heat-resistant plastic. Aluminum provides excellent heat retention and can be used for oven-ready dishes. EPS offers good insulation but may not be microwave-safe. Heat-resistant plastic is a versatile option.

- Design: Should be designed for heat resistance and potentially microwaving. The lid should provide a good seal to trap heat and prevent leaks. Vented lids can be beneficial to prevent sogginess. The tray should be sturdy enough to handle the weight of the food and the heat.

- Example: A rectangular aluminum tray with a tight-fitting, clear plastic lid, designed for a baked pasta dish. The lid might have a small vent to release steam.

- Cold Food Tray:

- Material: Often made of plastic, cardboard, or foam. Plastic provides good moisture resistance. Cardboard is a sustainable option. Foam offers good insulation to keep the food cold.

- Design: Focus on preventing leaks and maintaining the food’s temperature. The lid should provide a tight seal. Clear lids are often used to showcase the food’s appearance. The tray may have compartments to separate different food items.

- Example: A compartmentalized plastic tray with a clear, snap-on lid, designed for a salad with separate sections for greens, toppings, and dressing. The lid ensures the salad stays fresh and crisp.

Applications of 2 lb Food Trays

The versatility of 2 lb food trays makes them a staple across various sectors of the food service industry. From restaurants to delivery services, these trays provide a practical and efficient solution for packaging, transporting, and presenting food. Their size strikes a balance between portion control and sufficient capacity, making them suitable for a wide array of dishes.

Food Service Industries Utilizing 2 lb Food Trays

Numerous segments of the food service industry leverage the benefits of 2 lb food trays. Their adaptability caters to the specific needs of different business models.

- Restaurants: Restaurants, particularly those offering takeout or delivery options, frequently employ 2 lb trays. They are suitable for various dishes, including appetizers, entrees, and sides, providing a neat and convenient presentation for customers.

- Catering Services: Caterers rely on these trays for events of all sizes. The trays facilitate the organized transportation and serving of food, maintaining food integrity and presentation.

- Food Manufacturers and Processors: Companies that mass-produce prepared meals, such as frozen dinners or ready-to-eat options, often utilize 2 lb trays for portioning and packaging their products. This ensures consistent serving sizes and contributes to effective inventory management.

- Institutional Food Service: Schools, hospitals, and other institutions utilize 2 lb trays to serve meals in a controlled and efficient manner. This is particularly helpful in managing portion sizes and streamlining the serving process.

Specific Food Items Frequently Packaged in 2 lb Trays

The 2 lb tray’s size makes it appropriate for a wide variety of food items. These trays can hold a substantial amount of food without being overly large, making them suitable for single servings or smaller family portions.

- Entrees: Dishes like lasagna, baked ziti, casseroles, and roasted meats are commonly packaged in 2 lb trays. This allows for easy reheating and serving.

- Sides: Mashed potatoes, rice pilaf, vegetable medleys, and pasta salads often utilize 2 lb trays. They are ideal for providing a generous side portion alongside an entree.

- Appetizers: Chicken wings, mozzarella sticks, and other appetizers are frequently packaged in these trays, perfect for takeout orders or catered events.

- Desserts: Certain desserts, like brownies, cookies, or fruit crumbles, can be packaged in 2 lb trays for easy transportation and portioning.

- Prepared Meals: Pre-made meals like stir-fries, pre-cooked chicken, and other single-serving meals are commonly found in these trays.

Role of 2 lb Food Trays in Food Delivery and Takeout Services

The rise of food delivery and takeout services has significantly increased the demand for efficient and practical packaging solutions. 2 lb food trays play a crucial role in this industry.

These trays contribute to the preservation of food quality during transport. Their design helps to maintain the temperature of the food, whether hot or cold, and they protect the food from being crushed or damaged during transit. Furthermore, they provide a neat and presentable package for the customer, enhancing the overall dining experience.

The 2 lb tray’s standardized size makes it easy for restaurants and delivery services to manage their inventory. It simplifies portioning and helps to streamline the order fulfillment process. In a fast-paced environment, such as food delivery, efficiency is paramount, and the 2 lb tray is an important tool for maintaining operational efficiency.

The trend toward sustainable packaging has also impacted the use of 2 lb trays. Many companies are now opting for trays made from recyclable or compostable materials. This helps to reduce the environmental impact of food delivery and takeout services, appealing to environmentally conscious consumers.

Material Considerations for 2 lb Food Trays

Choosing the right material for a 2 lb food tray is a crucial decision that impacts not only the food’s safety and quality but also the environment. The material dictates everything from how well the food is preserved to its overall sustainability. Careful consideration of these factors ensures both customer satisfaction and responsible business practices.

Sustainability of Food Tray Materials

The environmental impact of food trays is a growing concern. Consumers are increasingly aware of the importance of sustainable packaging, and businesses must adapt to meet these expectations. Several materials are commonly used, each with varying degrees of sustainability.

- Plastic: Traditionally, plastic, particularly polyethylene terephthalate (PET) and polypropylene (PP), has been a popular choice due to its low cost, durability, and versatility. However, plastic’s sustainability is questionable. While some plastics are recyclable, recycling rates are often low, and a significant portion ends up in landfills or pollutes the environment. Furthermore, the production of plastic relies on fossil fuels, contributing to greenhouse gas emissions.

For example, a 2021 report by the Environmental Protection Agency (EPA) showed that only about 8.5% of plastic waste in the United States was recycled.

- Paper and Cardboard: Paper-based trays offer a more sustainable alternative, especially if sourced from responsibly managed forests and are certified by organizations like the Forest Stewardship Council (FSC). Paper trays are often biodegradable and compostable. However, their suitability for all food types depends on the application of coatings or liners. These coatings, such as polyethylene (PE) or wax, can improve moisture resistance but may hinder biodegradability.

Consider a scenario where a fast-food restaurant switches from plastic trays to paper trays with a compostable coating. This reduces plastic waste and aligns with consumer preferences for eco-friendly options.

- Biodegradable Options: Materials like polylactic acid (PLA), derived from renewable resources such as cornstarch or sugarcane, offer a biodegradable and compostable solution. PLA trays can break down in industrial composting facilities. However, they may not be suitable for all food types, particularly those that are very hot or greasy. Moreover, the availability of industrial composting facilities can be a limiting factor in some regions.

An example is the use of PLA trays for pre-packaged salads. After consumption, the trays can be composted along with food scraps, minimizing waste sent to landfills.

Food Safety Regulations Related to Tray Materials

Food safety is paramount, and the materials used for food trays must comply with stringent regulations to prevent contamination and protect consumer health. Regulations vary by region, but generally, they focus on the following aspects.

- Migration Limits: Food contact materials must not leach harmful chemicals into the food. Regulations specify migration limits, which are the maximum amounts of substances that can transfer from the tray to the food. Testing is often required to ensure compliance.

For instance, the U.S. Food and Drug Administration (FDA) sets specific regulations for materials used in food packaging, including limits on the migration of substances like phthalates and bisphenol A (BPA).

- Material Composition: The materials used must be of food-grade quality and free from contaminants that could pose a health risk. This includes ensuring that inks, adhesives, and coatings are also safe for food contact.

In the European Union, regulations (e.g., Regulation (EC) No 1935/2004) mandate that food contact materials must not transfer their constituents to food in quantities that could endanger human health or change the composition, taste, or smell of the food.

- Traceability: Regulations often require traceability systems to track the origin and composition of materials used in food trays. This enables quick identification and removal of contaminated products in case of a safety issue.

A recall of food products due to contaminated packaging illustrates the importance of traceability. Traceability systems allow manufacturers to pinpoint the source of the contamination and remove affected products from the market promptly.

Impact of Material Choice on Food Temperature and Preservation

The material of a 2 lb food tray directly influences the food’s temperature and preservation capabilities. This impacts the food’s shelf life, taste, and safety.

- Temperature Resistance: Different materials have varying temperature resistance levels. Some materials, like plastic, can withstand a wide range of temperatures, from freezing to microwave heating. Others, such as paper, may be less suitable for high-temperature applications.

Consider the example of a frozen meal. The tray must withstand freezing temperatures during storage and heating in a microwave.

A plastic tray designed for this purpose is ideal.

- Moisture and Gas Barrier Properties: The material’s ability to act as a barrier to moisture and gases (like oxygen) is crucial for food preservation. Materials with poor barrier properties can lead to food spoilage.

For instance, a tray for a fresh salad needs to prevent moisture loss to maintain crispness and also act as a barrier to oxygen to slow down oxidation and maintain freshness.

- Heat Transfer: The rate at which heat is transferred through the tray affects the food’s cooking or cooling process. Materials with good heat transfer properties, like some metals, can facilitate faster heating. Insulating materials, on the other hand, help to keep food warm or cold for longer periods.

A takeout container for hot food should have some degree of insulation to keep the food warm for the customer.

Conversely, a tray for ice cream needs to have good insulation to prevent melting.

Purchasing and Sourcing 2 lb Food Trays

So, you’ve learned the ins and outs of 2 lb food trays, from their diverse types to the materials that make them. Now, it’s time to talk about the practical side: how to actuallyget* these trays. This section dives into the crucial steps of sourcing and purchasing, ensuring you get the right trays at the right price.

Factors to Consider When Choosing a Supplier

Selecting the right supplier is critical for your food service operation’s success. It’s not just about the lowest price; it’s about a long-term partnership that delivers quality, reliability, and value. Several factors should be carefully evaluated when choosing a supplier for 2 lb food trays.

- Product Quality: This is paramount. Inspect samples of the trays. Assess their structural integrity – will they hold the weight of a 2 lb portion without bending or breaking? Consider the material’s suitability for the food you’ll be serving. Does it maintain food temperature effectively?

Obtain a comprehensive document about the application of vollrath food warmer that is effective.

Does it resist leaks and spills? Look for certifications related to food safety and material compliance.

- Material Options and Customization: Does the supplier offer a range of materials, like foam, plastic, or biodegradable options? Can they customize the trays with your branding or specific design requirements? Flexibility is key, especially as your needs evolve.

- Pricing and Payment Terms: Obtain quotes from multiple suppliers. Compare not just the unit price, but also consider minimum order quantities, shipping costs, and payment terms. Negotiate favorable terms that fit your budget and cash flow.

- Lead Times and Delivery Reliability: Determine how quickly the supplier can fulfill your orders. Inquire about their inventory management practices. A reliable supplier ensures you never run out of trays, disrupting your service.

- Supplier Reputation and Customer Service: Research the supplier’s reputation. Read online reviews, and ask for references. Good customer service is essential for addressing any issues that may arise, such as damaged goods or delivery delays.

- Sustainability Practices: If sustainability is a priority, assess the supplier’s environmental impact. Do they offer eco-friendly tray options? Do they use sustainable sourcing practices? Consider their waste reduction and recycling programs.

- Compliance and Certifications: Ensure the supplier complies with all relevant food safety regulations and has the necessary certifications, such as FDA approval for food-grade materials.

Estimating Tray Quantity for Food Service Operations

Accurately estimating the number of 2 lb food trays you need is crucial for avoiding waste and ensuring you always have enough on hand. The process involves considering several factors, including your customer volume, menu items, and storage capacity.

Here’s a step-by-step guide:

- Determine Daily/Weekly Customer Volume: Analyze your sales data to understand your average daily or weekly customer count. If you’re a new business, estimate based on market research and projected growth.

- Analyze Menu and Portion Sizes: Identify which menu items are served in 2 lb portions. Calculate the percentage of customers who order these items. For example, if you sell 100 meals a day, and 30 of them are 2 lb portions, then 30% of your meals require 2 lb trays.

- Calculate Daily Tray Usage: Multiply your daily customer count by the percentage of customers ordering 2 lb portions. For instance, 100 customers

30% = 30 trays needed per day.

- Factor in Peak Hours and Fluctuations: Consider peak hours or days when customer volume is higher. Increase your estimated tray usage to accommodate these fluctuations.

- Account for Spoilage and Waste: Add a small percentage to your estimated tray usage to account for accidental damage or spoilage. A buffer of 2-5% is generally recommended.

- Calculate Weekly/Monthly Needs: Multiply your daily tray usage by the number of operating days per week or month.

- Consider Storage Capacity: Ensure you have enough storage space to accommodate your estimated tray inventory. This will prevent you from running out of trays during busy periods.

Example:

A restaurant anticipates serving 200 customers daily. 40% of the orders include a 2 lb portion. The restaurant also expects a 3% waste rate.

Daily Tray Usage = 200 customers

– 40% = 80 traysTray Buffer = 80 trays

– 3% = 2.4 trays (round up to 3)Total Daily Tray Need = 80 trays + 3 trays = 83 trays

If the restaurant is open 6 days a week, Weekly Tray Need = 83 trays/day

– 6 days/week = 498 trays

Cost Variations Based on Tray Materials and Designs

The price of 2 lb food trays can vary significantly based on the materials used and the complexity of the design. Understanding these cost variations allows you to make informed decisions that balance your budget with your functional and aesthetic requirements.

Here’s a breakdown:

| Material | Cost Considerations | Examples |

|---|---|---|

| Foam (Polystyrene) | Generally the most economical option. However, it may not be suitable for all food types, and its environmental impact is a concern. It may not be as sturdy. | Standard foam trays are often the cheapest. Prices may range from $0.05 to $0.15 per tray, depending on quantity and features. |

| Plastic (Polypropylene, PET) | Offers a good balance of cost, durability, and functionality. Recyclable options are available. | PP trays, commonly used for takeout, are mid-range in price. PET trays, often used for deli items, can be slightly more expensive. Prices typically range from $0.10 to $0.30 per tray. |

| Paperboard/Cardboard | More environmentally friendly than plastic, and can be customized with printing. They may require a food-safe coating to prevent leaks. | Paperboard trays are usually more expensive than plastic but can be a good choice for specific applications. Prices can range from $0.20 to $0.50 or more per tray, depending on the finish and customization. |

| Biodegradable/Compostable | Made from renewable resources like plant fibers. They are the most environmentally friendly but can be more expensive. | Trays made from sugarcane bagasse or molded pulp are often more expensive. The price can vary greatly, from $0.30 to $0.75 or more per tray. |

| Design Complexity | Trays with custom shapes, compartments, or printing will generally cost more than standard designs. | Custom-printed trays will add to the overall cost. Compartmentalized trays are usually more expensive than single-compartment trays. |

Innovation and Future Trends

The food tray industry is constantly evolving, driven by consumer demand for convenience, sustainability, and enhanced food presentation. Innovation is crucial to meet these needs and address the environmental impact of packaging. Emerging trends focus on eco-friendly materials, smart functionalities, and advanced manufacturing techniques.

Emerging Trends in Food Tray Design and Manufacturing

The future of food trays is being shaped by several key trends, aiming to create more efficient, sustainable, and consumer-friendly products. These trends are interconnected and often influence each other.

- Sustainable Materials: There’s a significant shift towards using biodegradable and compostable materials like plant-based plastics (PLA), molded pulp, and mushroom packaging. These materials reduce reliance on fossil fuels and minimize waste.

- Smart Packaging: Incorporating technology into food trays is becoming more common. This includes features like:

- Temperature Sensors: Monitoring food temperature to ensure safety and quality.

- RFID Tags: Tracking food products throughout the supply chain for inventory management and traceability.

- Modified Atmosphere Packaging (MAP): Extending shelf life by controlling the gas composition within the tray.

- Design for Recyclability: Food tray designs are being optimized to be easily recyclable, using single-material construction and minimizing the use of adhesives and coatings that can hinder recycling processes.

- 3D Printing: This technology enables the creation of customized food trays with complex geometries and features, offering flexibility in design and rapid prototyping.

- Automation and Robotics: Implementing automation in manufacturing processes to increase efficiency, reduce labor costs, and improve production consistency.

Hypothetical Innovative 2 lb Food Tray

Imagine a 2 lb food tray designed for a ready-to-eat meal, incorporating several innovative features to enhance the consumer experience and minimize environmental impact.The tray is made from a molded pulp material sourced from agricultural waste, making it fully compostable. It features a built-in heating element powered by a small, biodegradable battery. The heating element is activated by a simple button, providing even heating for the meal.

The tray also includes a small, transparent window made from a bio-based polymer, allowing consumers to see the food without opening the package. The lid is sealed with a compostable film that provides a modified atmosphere to extend the shelf life of the food. The tray’s design is optimized for easy stacking and storage, both for retailers and consumers. The tray also includes a QR code that provides access to information about the meal’s ingredients, nutritional information, and preparation instructions.

Potential Impact of New Technologies on Food Tray Production and Usage

New technologies are poised to revolutionize how food trays are produced, used, and disposed of, leading to significant changes across the industry.The illustration depicts a futuristic food packaging facility. The central image shows a large, automated production line. Robots are precisely placing food trays on a conveyor belt. On the left, a robotic arm is carefully placing food into the trays, ensuring portion control and consistent presentation.

On the right, another robotic arm is applying lids and sealing the packages. Above the production line, large screens display real-time data about the production process, including material usage, energy consumption, and product quality. In the background, a large warehouse is visible, showcasing automated storage and retrieval systems. The overall scene emphasizes efficiency, precision, and the integration of technology to minimize waste and maximize productivity.

The use of eco-friendly materials is highlighted by the bright green color of the food trays and the sustainable energy sources depicted in the facility.

Alternative Packaging Solutions

Choosing the right packaging is crucial for food businesses. While 2 lb food trays have their place, exploring alternatives can lead to better cost-effectiveness, sustainability, and customer experience. This section dives into the pros and cons of different packaging options, highlighting the advantages of reusable trays and showcasing innovative, eco-friendly alternatives.

Comparing Packaging Options

Different packaging types offer varying advantages depending on the food product and the needs of the business. Understanding these differences allows for informed decisions.Here’s a comparison table outlining common packaging alternatives to 2 lb food trays:

| Packaging Type | Material | Pros | Cons |

|---|---|---|---|

| Containers (e.g., plastic, paper) | Plastic (PET, PP), Paperboard, Aluminum |

|

|

| Boxes (e.g., cardboard, corrugated) | Cardboard, Corrugated Cardboard |

|

|

| Clamshells (e.g., plastic, molded fiber) | Plastic (PET, PP), Molded Fiber (e.g., sugarcane bagasse) |

|

|

| Flexible Packaging (e.g., pouches, films) | Plastic films (e.g., polyethylene, polypropylene), Laminates |

|

|

Advantages of Reusable Food Trays

Reusable food trays offer significant benefits in specific scenarios. Their durability and long lifespan can offset the initial investment, especially for businesses with high turnover.Here’s a look at the advantages:

- Reduced Waste: Reusable trays significantly minimize waste compared to single-use options. They are designed to be used multiple times, decreasing the volume of packaging ending up in landfills. This aligns with the growing consumer demand for sustainable practices.

- Cost Savings (Long Term): While the initial cost may be higher, the longevity of reusable trays translates to long-term cost savings. Businesses can reduce their ongoing packaging expenses by using trays repeatedly, eliminating the need for frequent purchases of disposable alternatives.

- Enhanced Brand Image: Utilizing reusable packaging demonstrates a commitment to sustainability, which can positively impact a brand’s image and appeal to environmentally conscious consumers. It can be a powerful marketing tool.

- Improved Product Presentation: Reusable trays can be designed for aesthetic appeal and durability, enhancing the overall presentation of the food product. This can improve customer perception and encourage repeat purchases.

- Suitable for Specific Applications: Reusable trays are especially well-suited for applications like in-house dining, catering, and food delivery services where the trays can be collected and reused. Consider the example of a university cafeteria switching from disposable trays to reusable ones. The university would reduce waste significantly.

Eco-Friendly Packaging Innovations

The packaging industry is constantly evolving, with numerous innovations focused on sustainability. These eco-friendly solutions can replace traditional 2 lb trays.Here are some examples:

- Molded Fiber Trays: These trays are made from renewable resources such as sugarcane bagasse, bamboo, or recycled paper pulp. They are biodegradable, compostable, and offer excellent strength and insulation.

- Plant-Based Plastics: These plastics, such as those made from cornstarch (PLA), are derived from renewable resources and can be composted under specific conditions. They provide a sustainable alternative to traditional petroleum-based plastics. However, their compostability can vary depending on the infrastructure available.

- Edible Packaging: This is an emerging technology that uses materials like seaweed or edible films to create packaging that can be consumed with the food. This eliminates packaging waste altogether. While still in early stages, it holds immense potential.

- Reusable Containers with Closed-Loop Systems: Companies are developing systems where customers can purchase food in reusable containers and return them to a designated collection point for cleaning and reuse. This creates a circular economy for packaging.

- Fungi-Based Packaging: Mycelium, the root structure of mushrooms, can be grown into custom shapes to create protective packaging. This material is biodegradable, compostable, and offers excellent cushioning properties.

Ending Remarks

So, there you have it – the 2 lb food tray, demystified. We’ve navigated the choppy waters of materials, regulations, and innovative designs, emerging with a newfound appreciation for this essential piece of packaging. From the humble beginnings to the future of sustainable solutions, the 2 lb food tray’s journey is far from over. Whether you’re a restaurant owner, a takeout enthusiast, or just someone curious about the world around them, hopefully, this deep dive has given you a fresh perspective.

Now, if you’ll excuse me, I’m suddenly craving some leftovers.