Calcium hydroxide food grade, a seemingly simple compound, unlocks a world of culinary potential, a story whispered through time and across cultures. Imagine the crunch of a perfectly prepared tortilla, the subtle tang of a pickled vegetable, or the velvety texture of a traditional dessert – all owing, in part, to this humble ingredient. From ancient civilizations to modern kitchens, calcium hydroxide has played a silent, yet essential role, shaping the foods we love and the ways we experience them.

This journey delves into its fascinating history, its diverse applications, and the science that makes it so vital.

We’ll explore its journey from production to plate, uncovering the intricate processes that ensure its purity and safety for human consumption. The narrative will also shed light on how this versatile compound enhances flavors, textures, and even nutritional value, making it an indispensable element in the art of food preparation. From its origins to its present-day role, calcium hydroxide food grade’s story is one of enduring relevance and understated brilliance.

Introduction to Calcium Hydroxide Food Grade

Right, so, we’re talkin’ ’bout calcium hydroxide food grade, yeah? Sounds proper technical, innit? Basically, it’s a chemical, a compound, that’s been given the seal of approval for use in the grub we eat. Think of it as the food-safe version of slaked lime. It’s all about making sure the food we chow down on is safe and, well, edible.

Defining Calcium Hydroxide Food Grade

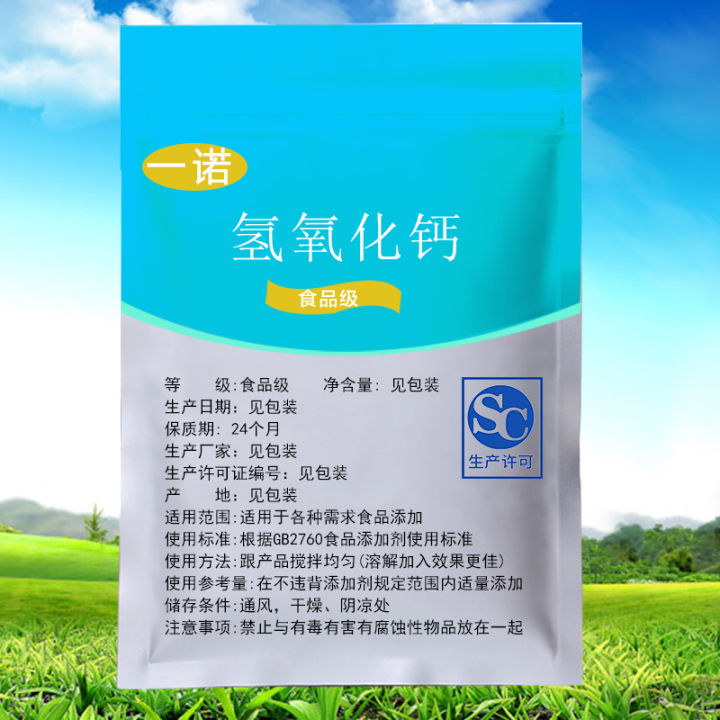

Calcium hydroxide food grade, also known as slaked lime or hydrated lime, is a white powder produced by reacting calcium oxide (quicklime) with water. Its primary characteristic is its alkaline nature, meaning it has a high pH, typically around 12.4. This property makes it useful for various applications in food processing. It needs to be pure, meeting specific standards set by regulatory bodies.

A Brief History of Use in Food Processing

This ain’t no new ting, fam. Calcium hydroxide has been around the block for centuries. Cultures worldwide have been using it for ages.

- Nixtamalization in Mesoamerica: The Mayans, Aztecs, and other Mesoamerican cultures used calcium hydroxide to nixtamalize maize (corn). This process involved soaking the corn kernels in an alkaline solution, usually a calcium hydroxide solution, which loosened the hulls, increased the nutritional value (by making niacin more available), and improved the flavor and texture of the corn. This is crucial for making tortillas, a staple food.

Picture it: massive vats of corn simmering away, all thanks to the magic of slaked lime.

- Preservation and Processing: Across different cultures, calcium hydroxide was employed for various purposes. It helped preserve food by raising the pH, inhibiting the growth of spoilage microorganisms.

- Pickling and Vegetable Processing: Calcium hydroxide has been used in the pickling process and the processing of certain vegetables. It helps maintain the crispness and texture of pickles and other pickled items.

Importance of Purity and Quality Standards

This ain’t just any old powder, yeah? It’s gotta be the real deal, pure and top-notch. The food industry relies heavily on consistent and reliable calcium hydroxide.

The purity of calcium hydroxide is crucial to avoid introducing unwanted contaminants into food products.

Quality control is key.

- Regulatory Bodies: Organisations like the Food and Drug Administration (FDA) in the US, and similar bodies in the UK and Europe, set strict standards. These standards dictate the permissible levels of impurities and the manufacturing processes to ensure safety.

- Testing and Analysis: Food-grade calcium hydroxide undergoes rigorous testing to ensure it meets the required specifications. This includes tests for heavy metals, contaminants, and the correct calcium hydroxide content.

- Impact of Impurities: Impurities can affect the taste, appearance, and safety of food products. For example, the presence of heavy metals can pose health risks.

Production and Manufacturing Processes

Right, so we’re gonna get into how they actuallymake* this stuff – the calcium hydroxide, yeah? It ain’t just magically appearing in the bags, you know. We’re talking proper industrial processes, with a focus on getting it pure enough for munching. Food grade, innit?

Production Methods for Food-Grade Calcium Hydroxide

Producing calcium hydroxide involves a few key methods, each with its own vibe, yeah? They all aim for that high purity needed for food applications, so the processes are carefully controlled.The main methods are:

- Slaking of Quicklime: This is the OG, the classic. Quicklime (calcium oxide, CaO) reacts with water. Think of it like a mad chemistry dance. The quicklime is “slaked” – basically mixed with water – and this kicks off a serious exothermic reaction, releasing a load of heat.

- The reaction is:

CaO + H2O → Ca(OH) 2 + Heat

- The resulting slurry is then filtered to remove any unreacted quicklime or impurities, ensuring the final product is pure.

- Carbonation of Calcium Hydroxide: A slightly different tack, but still gets the job done. This involves bubbling carbon dioxide (CO 2) through a calcium hydroxide suspension.

- This process forms calcium carbonate (CaCO 3) which then precipitates out, leaving behind a solution containing calcium hydroxide.

- It’s then filtered and purified, giving you that food-grade goodness.

- Electrolysis of Calcium Chloride: A more modern approach. Calcium chloride (CaCl 2) is dissolved in water, and then an electric current is passed through the solution.

- This breaks down the calcium chloride, producing calcium hydroxide, chlorine gas, and hydrogen gas.

- This method often requires extra steps to ensure purity, but it can yield a high-quality product.

Quality Control in Manufacturing, Calcium hydroxide food grade

Right, so, making sure this stuff is safe to eat is serious business. It ain’t like chucking a load of ingredients together and hoping for the best. There’s a whole raft of tests and certifications involved to guarantee quality.Here’s a rundown of what’s usually involved:

- Raw Material Testing: They start at the source. Before anything gets processed, the quicklime or calcium chloride gets tested for purity. This stops any dodgy starting materials from messing up the final product.

- In-Process Testing: During the manufacturing process, regular checks are carried out. This could involve measuring the pH, checking for particle size, and looking for any contaminants.

- Final Product Testing: After the calcium hydroxide is produced, it undergoes a final round of tests. This includes tests for:

- Purity: Ensuring the calcium hydroxide content is up to spec.

- Heavy Metals: Checking for lead, mercury, and other nasties. These gotta be kept well below the allowed limits.

- Microbial Content: Making sure there’s no unwanted bacteria or other microorganisms.

- Particle Size Distribution: Making sure the powder has the right texture and consistency.

- Certification: The finished product is then often certified by recognised bodies. This could be something like a food safety standard, confirming that the product meets the necessary requirements. These certifications are like a stamp of approval, saying it’s safe for consumption.

Comparison of Production Methods

Different methods have their own pros and cons, innit? Some are more efficient, some are cheaper, and some are just better at delivering that food-grade purity.Here’s a quick comparison:

| Method | Advantages | Disadvantages |

|---|---|---|

| Slaking of Quicklime | Relatively simple, readily available raw materials, can be cost-effective. | Can be difficult to control the reaction, potential for impurities if the quicklime isn’t pure, exothermic reaction requires careful handling. |

| Carbonation of Calcium Hydroxide | Can produce high-purity products, good for removing certain impurities. | Requires careful control of the carbon dioxide flow, less efficient than slaking, more complex equipment needed. |

| Electrolysis of Calcium Chloride | Potentially high-purity product, good for producing calcium hydroxide on a smaller scale. | More complex and expensive setup, requires a source of electricity, potential for generation of hazardous byproducts (chlorine and hydrogen). |

The choice of method really depends on the scale of production, the desired purity, and the available resources. Some manufacturers might even use a combination of methods to get the best results.

Applications in Food Processing

Right, let’s get this straight. Calcium hydroxide, yeah, that chalky stuff, ain’t just for builders. It’s a proper player in the food game, used in more ways than you might think. From your morning brekkie to your late-night snack, it’s often doing bits behind the scenes, making things taste better, last longer, and even helping your body absorb nutrients. It’s all about chemistry, innit?

And calcium hydroxide’s got a wicked role to play.

Diverse Applications of Calcium Hydroxide in Food Processing

Calcium hydroxide, often referred to as slaked lime, is a versatile food additive. Its use spans various stages of food production, from ingredient preparation to final product enhancement. It acts as a pH adjuster, a firming agent, and even a source of calcium enrichment. Its versatility contributes to its widespread use across numerous food categories.Here’s how it’s getting involved:* Tortilla Production: Calcium hydroxide is used in the nixtamalization process, where corn kernels are cooked in an alkaline solution.

This process softens the kernels, releases niacin, and improves the nutritional value and flavour of tortillas.

Find out about how raw lamb dog food can deliver the best answers for your issues.

Sugar Refining

It helps in the clarification of sugarcane juice by removing impurities, resulting in purer sugar crystals.

Pickling

Calcium hydroxide helps to firm up the texture of pickles and other pickled vegetables, giving them that satisfying crunch.

Beverage Production

It’s used in the production of certain beverages, acting as a processing aid.

Dairy Products

In some dairy processes, it helps adjust acidity.

Specific Food Products and Calcium Hydroxide

Right, let’s break down some specific grub where calcium hydroxide is a key player. It’s not always listed as a direct ingredient on the label, but trust me, it’s often in there, doing its thing.Examples include:* Tortillas: As mentioned before, essential for nixtamalization.

Pickles

The secret to that satisfying crunch.

Corn-based snacks

Similar to tortillas, it’s involved in the processing of corn used in these snacks.

Processed cheese

Sometimes used to adjust acidity or as a calcium source.

Some baked goods

Used to control acidity and improve texture.

Calcium Hydroxide in Food: Application, Function, and Benefits

Here’s a quick rundown, proper organised in a table, showing you the lowdown on calcium hydroxide in different food categories.

| Application | Function | Benefits | Examples |

|---|---|---|---|

| Nixtamalization (Corn Processing) | Alkaline treatment of corn kernels | Improves nutritional value (releases niacin), enhances flavour, softens kernels. | Tortillas, corn chips, masa |

| Sugar Refining | Clarification of sugarcane juice | Removes impurities, produces purer sugar. | Refined sugar, sugar syrups |

| Pickling | Firming agent | Enhances texture, provides crispness. | Pickles, pickled vegetables |

| Dairy Processing | Acidity regulator | Controls pH, aids in specific processing steps. | Some cheeses, processed dairy products |

Functional Properties and Benefits

Calcium hydroxide, or slaked lime, ain’t just some dusty powder; it’s a proper workhorse in the food game. It’s all about tweaking the grub to make it better, longer lasting, and sometimes, even more nutritious. From street food stalls to fancy restaurants, this stuff plays a vital role.

pH Adjustment

Calcium hydroxide’s main gig is as a pH regulator. It’s alkaline, innit? So, when you add it to something acidic, it neutralizes it, which affects how food tastes, how it behaves, and how long it lasts. Think of it like a culinary balancing act.

Texture Modification

Calcium hydroxide can also change the texture of food. This is down to how it interacts with proteins and other compounds. This is how it helps to create some proper tasty results.

Benefits of Calcium Hydroxide in Food Processing

Using calcium hydroxide ain’t just a trendy thing; it brings real benefits to the table. These benefits are why it’s a staple in so many different food applications.

- Shelf Life Extension: By controlling pH and preventing the growth of spoilage organisms, calcium hydroxide helps food last longer. This means less waste and more time for the food to reach the consumer.

- Improved Texture: In some foods, like pickles or tortillas, calcium hydroxide firms up the texture. This is because it reacts with the pectin and other compounds, creating a stronger structure.

- Enhanced Nutritional Value: Calcium hydroxide can boost the calcium content of food.

- Color Enhancement: In certain processes, it can help maintain or even enhance the color of food.

Contribution to Nutritional Profile

Calcium hydroxide’s contribution to nutrition is significant, mainly due to its calcium content. Here’s how it works in some specific examples.

- Tortillas: In the process of nixtamalization, where corn is soaked in a calcium hydroxide solution, the lime not only softens the corn but also significantly increases the bioavailability of niacin (Vitamin B3) and, of course, adds calcium to the final product.

- Pickles: Calcium hydroxide helps in creating the crisp texture of pickles, but it also contributes a small amount of calcium to the final product.

- Canned Vegetables: During the canning process, calcium hydroxide can be used to maintain the texture and firmness of vegetables, while also contributing a bit of calcium.

Regulatory Aspects and Safety

Right, so we’re gettin’ into the nitty gritty now, the rules and regs that keep food safe, innit? Calcium hydroxide, or slaked lime as some of you might know it, ain’t no exception. This section breaks down the laws and the dangers of handling this stuff, so you know what’s what.

Regulatory Guidelines and Standards

Calcium hydroxide, when used in food, is subject to strict rules. These guidelines ensure that it’s safe for consumption and doesn’t cause any nasty side effects. Different countries and regions have their own sets of rules, but they generally align with international standards.The primary organisations setting these standards include:

- The Food and Drug Administration (FDA): In the United States, the FDA regulates the use of calcium hydroxide in food. They set standards for its purity and how it can be used.

- The European Food Safety Authority (EFSA): The EFSA provides scientific advice on food safety within the European Union. They assess the safety of food additives, including calcium hydroxide.

- The Joint FAO/WHO Expert Committee on Food Additives (JECFA): JECFA is an international scientific expert committee that provides advice to the World Health Organization (WHO) and the Food and Agriculture Organization of the United Nations (FAO). They evaluate the safety of food additives and contaminants, and establish acceptable daily intakes (ADIs).

These regulatory bodies base their decisions on thorough scientific assessments, including toxicity studies and usage data. They look at how much calcium hydroxide is used, what it’s used for, and whether it poses any health risks. These assessments result in permitted uses, concentration limits, and purity specifications.

Safety Considerations and Potential Hazards

Now, handling calcium hydroxide ain’t like playin’ with flour. It’s a caustic substance, meaning it can cause burns if you ain’t careful. It’s important to know the risks and how to deal with ’em.Here’s what you need to keep in mind:

- Skin and Eye Irritation: Calcium hydroxide can irritate your skin and eyes. Contact can cause redness, pain, and even serious burns. That’s why wearing protective gear is crucial.

- Inhalation Hazards: Breathing in calcium hydroxide dust can irritate your respiratory system, causing coughing and difficulty breathing. Avoid creating dust clouds, and always work in a well-ventilated area.

- Ingestion Risks: Swallowing calcium hydroxide can be extremely dangerous, leading to burns in the mouth, throat, and stomach. Keep it out of reach of kids and animals.

- Protective Measures: Always wear gloves, eye protection (like goggles), and a dust mask when handling calcium hydroxide. If you get it on your skin or in your eyes, rinse thoroughly with water for at least 15 minutes and seek medical attention.

Calcium hydroxide is generally considered safe when used in food at the approved levels. The hazards mainly arise from improper handling or exposure to high concentrations. Proper handling and storage are crucial for preventing accidents.

Permissible Limits and Acceptable Daily Intake (ADI)

The ADI is a measure of how much of a substance you can safely consume daily over your lifetime without any significant health risk. Food safety agencies set these limits to protect public health.

The Joint FAO/WHO Expert Committee on Food Additives (JECFA) has not established a specific ADI for calcium hydroxide, but its use in food is generally regulated based on good manufacturing practices (GMP), which means it should be used in the minimum amount necessary to achieve the desired technical effect. This approach ensures that exposure is kept as low as reasonably achievable.

Forms and Grades of Calcium Hydroxide

Right, so we’ve talked about what Calcium Hydroxide is, what it does, and how it keeps things safe. Now let’s get into the different guises it rocks up in, and how you know which one’s the right fit for your grub. We’re gonna break down the different forms and grades, so you know your stuff when it comes to using it in food.

Classification Criteria for Calcium Hydroxide Grades

Calcium Hydroxide ain’t just a one-size-fits-all kinda deal. It comes in different grades, and these grades are based on a few key things. Purity is massive – how much actual Calcium Hydroxide is in there, and how much gunk (impurities) is lurking about. Particle size matters too – smaller particles often mean it dissolves and reacts quicker. Then there’s the amount of things like heavy metals that are present; gotta keep it safe for the munch.

Finally, the production process has a say too; it affects how the Calcium Hydroxide behaves.

Different Forms of Calcium Hydroxide and Their Applications

Calcium Hydroxide can be found in a few different forms, each with its own specific uses in the food game. Here’s the lowdown:

- Powder: This is the most common form. It’s a fine, white powder, like talc, and is super versatile.

- Slaked Lime: This is the result of adding water to quicklime (calcium oxide). It’s often used directly in food processing, especially in things like nixtamalization.

- Milk of Lime: A suspension of Calcium Hydroxide in water. It’s basically slaked lime mixed with water.

Here’s a breakdown of typical applications:

- Food Grade Calcium Hydroxide Powder: Used for acidity regulation, as a firming agent, and as a dough conditioner. Think pickles, canned veggies, and some baked goods.

- Nixtamalization (Slaked Lime): Used to process corn in the making of tortillas and masa. This process improves the nutritional value and flavour of the corn.

- Water Treatment: Calcium Hydroxide is used to soften water in food production, removing excess calcium and magnesium ions. This improves the taste and quality of water used in food.

- Preservation: Calcium Hydroxide can be used to preserve certain foods by controlling pH and preventing spoilage.

- Pickling: It is used in pickling to firm up the texture of pickles and other pickled vegetables. This helps to maintain their crispness.

Sourcing and Purchasing: Calcium Hydroxide Food Grade

Right, listen up. Getting your hands on proper food-grade calcium hydroxide ain’t like nicking a bag of crisps from the corner shop. You need to know where to look and what to look for, innit? This section’s all about how to get the good stuff, the stuff that won’t leave your customers with a dodgy belly.

Finding the Right Supplier

Choosing the right geezer, or company, to get your calcium hydroxide from is crucial. You need someone reliable, who’s got the proper gear and knows their onions. This is about quality, innit? And that means checking things out properly.

- Reputation is Key: Check out the supplier’s rep. Word on the street, or rather, the industry, is important. Look for reviews, testimonials, and case studies. See who else uses them. Are they known for quality and reliability?

Are they known for being straight up?

- Experience Matters: How long have they been in the game? A supplier with years of experience is likely to know the ropes, the regulations, and the best practices. They’ll know the common pitfalls and how to avoid them. They will know how to handle the product properly.

- Technical Support: Do they offer technical support? Can they answer your questions about the product, its applications, and its potential issues? Do they have a technical team that can advise you?

- Logistics and Supply Chain: Consider the supplier’s logistics. Can they deliver on time? Do they have a reliable supply chain? Can they handle the volumes you need? Do they have backup plans?

Certifications and Testing: The Proof is in the Pudding

You need to be certain that the calcium hydroxide is legit. That means checking for certifications and testing. Don’t just take their word for it; demand proof.

- Food-Grade Certifications: Make sure the supplier has the necessary certifications, like those from recognised food safety bodies. These certifications are a guarantee that the product meets the standards for food use. Look for certifications that show compliance with relevant regulations and standards.

- Third-Party Testing: Insist on third-party testing. This means an independent lab has verified the product’s purity and composition. Request certificates of analysis (COA) that detail the results of the testing. Make sure the COA is recent and covers the batch you are buying.

- Batch-Specific Information: Get batch-specific information. Each batch of calcium hydroxide should have its own COA, which provides details on its purity, particle size, and other relevant parameters.

- Quality Control Procedures: Ask the supplier about their quality control procedures. How do they ensure the quality of their product throughout the manufacturing process? What steps do they take to prevent contamination?

Packaging and Storage: Keeping it Fresh

Proper packaging and storage are essential to maintain the quality and safety of food-grade calcium hydroxide. You don’t want the stuff to go off, yeah? That’s a disaster waiting to happen.

- Packaging Materials: Food-grade calcium hydroxide is typically packaged in sealed bags or containers made from materials that are inert and won’t react with the chemical. Common options include polyethylene bags, lined paper bags, or sealed drums.

- Moisture Control: Calcium hydroxide is hygroscopic, meaning it absorbs moisture from the air. The packaging must be airtight to prevent moisture ingress. This prevents the calcium hydroxide from reacting and losing its quality.

- Storage Conditions: Store the calcium hydroxide in a cool, dry place, away from direct sunlight and sources of heat. This will help to maintain its quality and prevent degradation. Ideal storage temperature is usually between 20-25°C (68-77°F) with a relative humidity below 60%.

- Handling Precautions: Always handle calcium hydroxide with care. Avoid contact with skin and eyes. Use appropriate personal protective equipment (PPE), such as gloves, eye protection, and a dust mask.

- Shelf Life and Expiration: Check the shelf life of the product and follow the supplier’s recommendations for storage and use. Be aware of any expiration dates and use the product before it expires.

Alternative Ingredients and Considerations

Right, so we’ve been chatting about calcium hydroxide, yeah? Now, let’s switch gears and look at the other mandem in the food game – the alternative ingredients. We’re gonna break down what they bring to the table, what they cost, and if they’re worth the hype. It’s all about keeping it real and making informed choices, innit?

Comparison with Alternative Ingredients

Calcium hydroxide, often referred to as slaked lime, ain’t the only player in town. Other ingredients are used to achieve similar effects in food processing, from adjusting pH levels to acting as a firming agent. Understanding the alternatives helps in making informed decisions based on the specific application, desired properties, and budgetary constraints.

| Ingredient | Functionality | Advantages | Disadvantages | Cost (Relative) |

|---|---|---|---|---|

| Sodium Hydroxide (NaOH) | pH adjustment, peeling agent (e.g., in lye-peeled potatoes) | Strong pH control, efficient peeling | Highly corrosive, potential for food safety issues if not handled correctly. | Low |

| Sodium Carbonate (Na₂CO₃) | pH adjustment, leavening agent | Readily available, milder than NaOH. | Can impart a soapy taste if used in excess. | Low |

| Potassium Hydroxide (KOH) | pH adjustment, peeling agent (e.g., in pretzel making) | Similar to NaOH, but may be preferred in some applications due to its different solubility. | Corrosive, more expensive than NaOH. | Medium |

| Citric Acid (C₆H₈O₇) | pH adjustment, flavoring agent, preservative | Natural origin, adds tartness, acts as a preservative. | Can’t achieve as high a pH as alkaline alternatives. | Medium |

| Acetic Acid (CH₃COOH) | pH adjustment, flavoring agent, preservative (e.g., in pickling) | Readily available, adds a distinct flavor, effective preservative. | Strong smell and taste, can affect texture. | Low |

| Sodium Bicarbonate (NaHCO₃) | Leavening agent, pH adjustment | Reacts with acids to produce carbon dioxide (CO₂), creating air bubbles in baked goods. | Can leave a metallic taste if overused. | Low |

Detailed Illustration of Chemical Structures

Let’s visualise the chemical make-up of calcium hydroxide and its alternatives. This isn’t about drawing, but about describing the structures. Imagine this:The central figure is a model of

- Calcium Hydroxide*

- Ca(OH)₂. The illustration would depict the calcium atom (Ca) as a central sphere, large and solid, maybe coloured grey. Attached to it are two hydroxide (OH) groups. Each OH group is made up of an oxygen atom (O) and a hydrogen atom (H). The oxygen atom, depicted as a slightly smaller red sphere, is connected to the calcium atom by a single bond, and the hydrogen atom (a tiny white sphere) is connected to the oxygen by a single bond.

The angle between the O-H bond would be roughly 104.5 degrees, typical of water-like structures. The overall structure is symmetrical, reflecting the even distribution of the hydroxide groups.

Next to it, let’s have

- Sodium Hydroxide*

- NaOH. The sodium atom (Na) is represented as a medium-sized sphere, say blue, and the hydroxide (OH) group is identical to that in calcium hydroxide. The key difference is the single sodium atom attached to the OH group. This highlights the monovalent nature of sodium.

Now,

- Sodium Carbonate*

- Na₂CO₃. Here, we see two sodium atoms (Na) linked to a central carbonate ion (CO₃²⁻). The carbonate ion is a carbon atom (C), shown as a smaller black sphere, bonded to three oxygen atoms (O), which are red. The carbon atom has double bonds to two of the oxygen atoms and a single bond to the third, giving it a net negative charge.

The two sodium atoms balance this charge.

Moving on,

- Citric Acid*

- C₆H₈O₇. This structure is more complex, featuring a chain of carbon atoms (C, black), with hydrogen atoms (H, white) attached to the carbon backbone. Attached to the chain are carboxyl groups (-COOH) and a hydroxyl group (-OH). This illustrates the organic nature and acidity of the compound.

Finally,

- Acetic Acid*

- CH₃COOH. It shows a methyl group (CH₃, one carbon atom bonded to three hydrogen atoms) connected to a carboxyl group (-COOH). The carboxyl group contains a carbon atom, a double-bonded oxygen, and a hydroxyl group. This is a simple organic acid structure.

This mental image, a simplified visual of the molecular structures, highlights the differences in composition, bonding, and overall properties of these compounds.

Future Trends and Innovations

The food game is constantly evolving, innit? Always lookin’ for ways to get better, faster, and more sustainable. Calcium hydroxide, or “lime water” as some might know it, ain’t exempt from this. We’re talkin’ about the future of this stuff in the food world, and it’s lookin’ proper interesting. From the lab to the streets, here’s the lowdown on where it’s all headin’.

Advanced Applications in Food Preservation

Food preservation techniques are constantly being revamped to ensure food safety and extend shelf life. Calcium hydroxide is playing a role.

- Enhanced Antimicrobial Activity: Researchers are exploring ways to boost calcium hydroxide’s antimicrobial punch. This could involve modifying the particle size or using it in combination with other natural preservatives. Think about using calcium hydroxide in novel food packaging systems.

- Controlled Release Systems: Imagine calcium hydroxide being locked inside tiny capsules, slowly releasing its preservation powers. This is a real possibility, offering longer-lasting protection and reducing the need for frequent applications.

- Modified Atmosphere Packaging (MAP): MAP is where the air around food is tweaked to slow down spoilage. Calcium hydroxide could be used in conjunction with MAP to absorb carbon dioxide, further extending shelf life.

Sustainable Production Methods

Sustainability ain’t just a buzzword; it’s the future, yeah? And calcium hydroxide production is gettin’ a green makeover.

- Renewable Energy Sources: The shift to using solar, wind, and other renewable energy sources in calcium hydroxide production is gaining traction. This would significantly reduce the carbon footprint.

- Waste Material Utilization: Turning waste materials, like eggshells or industrial byproducts, into calcium hydroxide is a hot topic. This not only reduces waste but also makes production more resource-efficient.

- Closed-Loop Systems: Closed-loop systems aim to recycle and reuse water and other resources in the production process, minimizing waste and environmental impact.

Novel Delivery Systems and Formulations

How calcium hydroxide gets to the food matters. New delivery systems are being developed to maximize its effectiveness.

- Microencapsulation: Encapsulating calcium hydroxide in microscopic shells allows for controlled release, improved stability, and targeted delivery within food products.

- Nano-sized Calcium Hydroxide: The use of nanoparticles of calcium hydroxide is being investigated. These tiny particles could enhance the reactivity and effectiveness of calcium hydroxide in food applications.

- Combination with Other Ingredients: Scientists are experimenting with combining calcium hydroxide with other natural preservatives or functional ingredients to create synergistic effects, enhancing its overall performance.

Research Areas and Developments

The lab rats are busy, and their work will shape the future of calcium hydroxide.

- Understanding Reaction Mechanisms: Deepening the understanding of how calcium hydroxide interacts with food components is crucial. This will allow for more targeted and effective applications.

- Optimizing Particle Size and Morphology: Researchers are exploring how the size and shape of calcium hydroxide particles affect its performance. This could lead to the development of more efficient forms.

- Exploring New Food Matrices: The application of calcium hydroxide in novel food matrices, like plant-based proteins or alternative dairy products, is being actively researched.

Eco-Friendly Practices in Production and Use

Going green isn’t just a trend; it’s a must. Calcium hydroxide is part of this shift.

- Reducing Waste: Minimizing waste generation throughout the production process is a priority. This includes finding ways to recycle byproducts and reduce energy consumption.

- Water Conservation: Implementing water-saving technologies and reusing water in the production process are becoming increasingly important.

- Life Cycle Assessment (LCA): Conducting LCAs to evaluate the environmental impact of calcium hydroxide production and use helps identify areas for improvement.

Ultimate Conclusion

As our exploration concludes, we’re left with a newfound appreciation for the unsung hero of our culinary world: calcium hydroxide food grade. Its influence extends far beyond a simple ingredient, shaping traditions, enhancing experiences, and quietly contributing to the foods we savor. From the ancient wisdom of nixtamalization to the innovations of modern food science, this compound continues to surprise, adapt, and enrich our lives.

So, the next time you enjoy a favorite dish, remember the subtle magic of calcium hydroxide – a testament to the power of simple ingredients and the enduring artistry of food.